Mounting structure for car door glass tightening and method for mounting car door glass

A technology of door glass and installation structure, applied in windshield, manual mechanism, vehicle parts, etc., can solve problems affecting industrial upgrading, unresolved, and restricting modernization development, so as to avoid rework and material scrapping, safety and Enhanced convenience and improved physical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with specific examples.

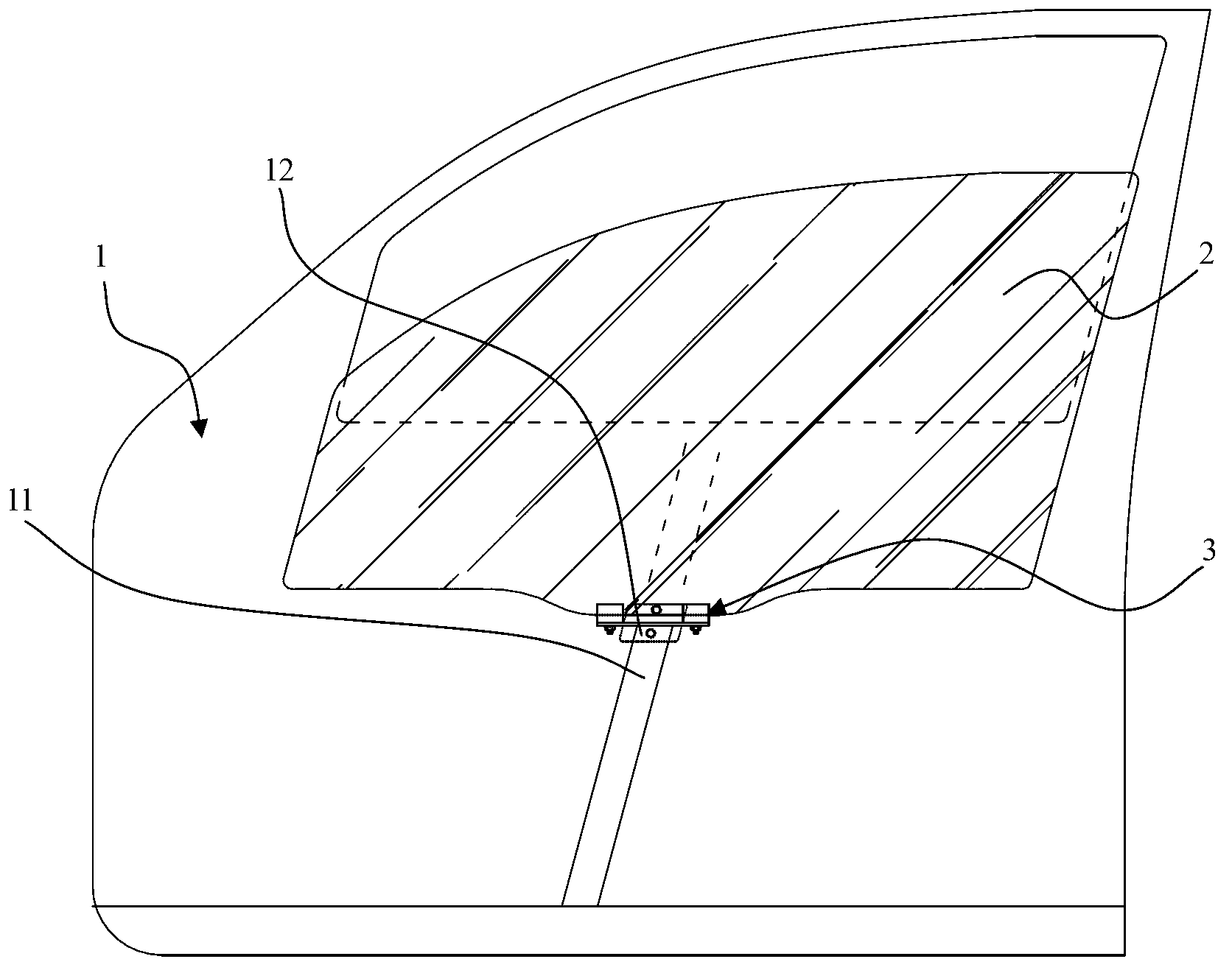

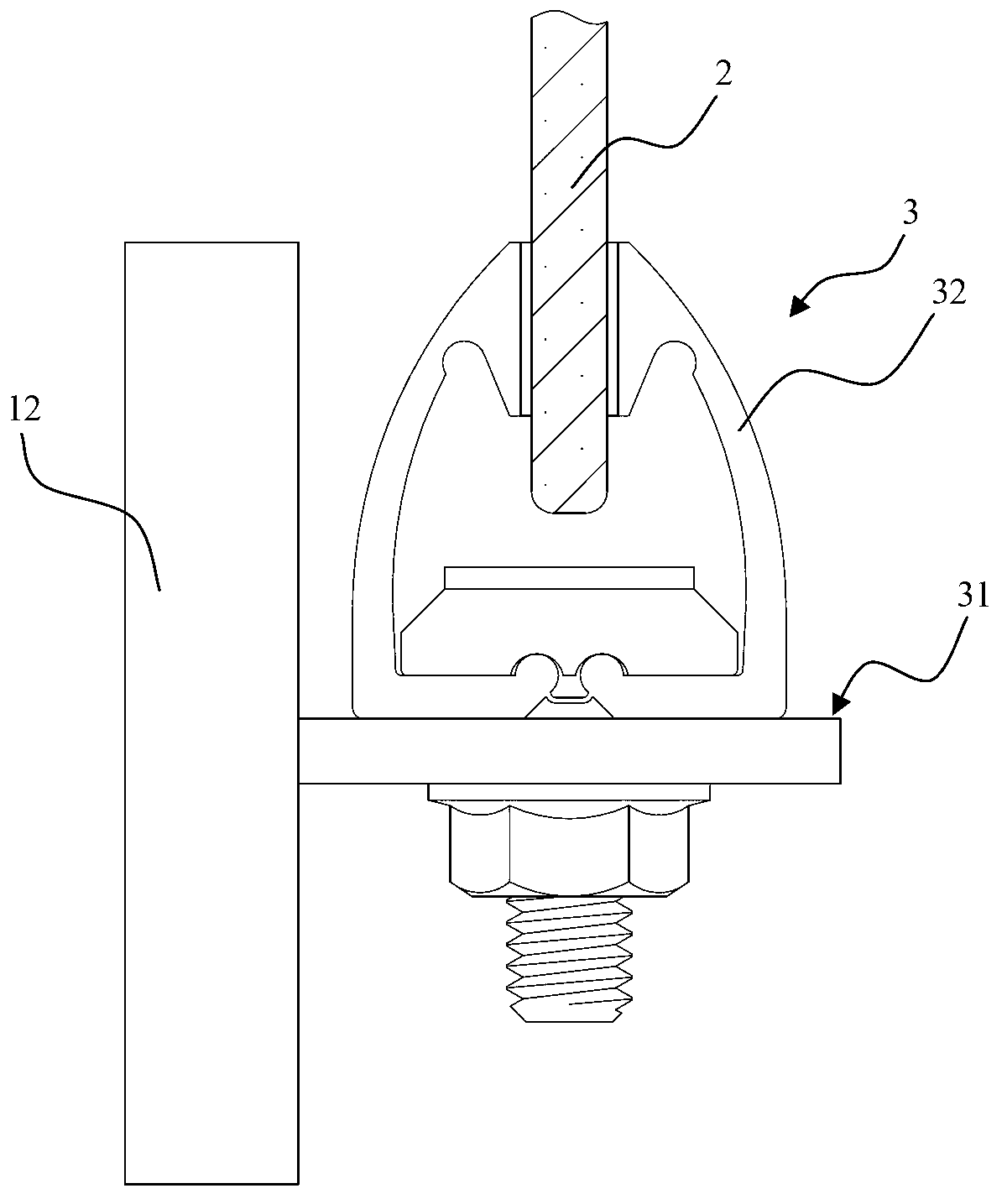

[0050] see figure 1 , 2 , a car door glass fastening installation structure of the present invention comprises a car door glass body 2, and the car door glass body 2 is movably arranged on the car door 1 through a moving device 12 on a car window track 11; the car door glass body 2 is fastened by a The system 3 is fixed on the mobile device 12 . The fastening system 3 includes a pressing assembly 31 and two fastening assemblies 32 . The pressing assembly 31 cooperates with the door glass body 2 to press the fastening assembly 32 to generate prestress and then fasten the door glass body 2 .

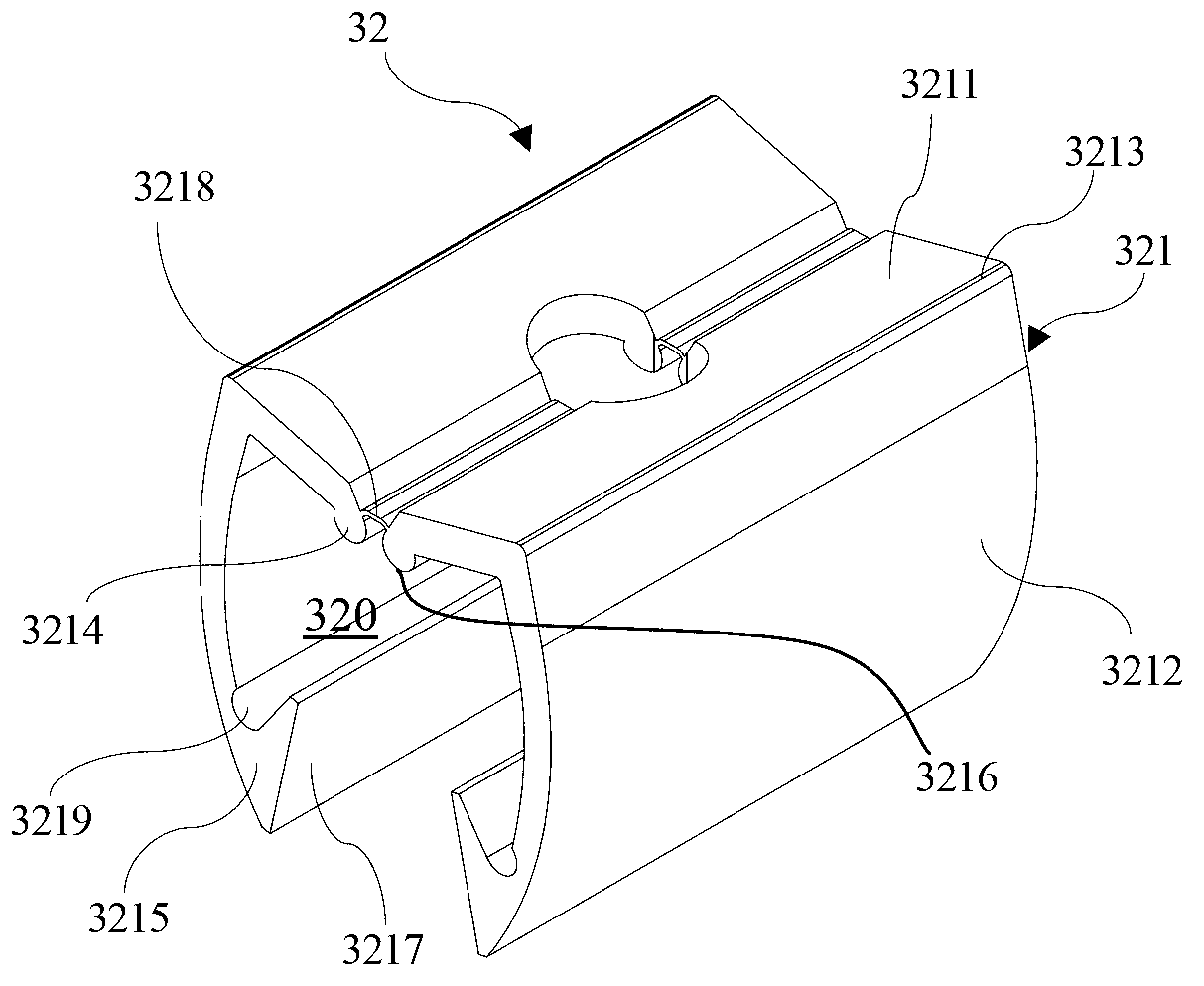

[0051] see image 3 , the fastening assembly 32 includes two bow-shaped arms 321 symmetrically clamped on both sides of the door glass body 2, and its material should be selected from a material with considerable strength and a certain degree of elasticity and toughness, such as metal, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com