Patents

Literature

60results about How to "Strong prestress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

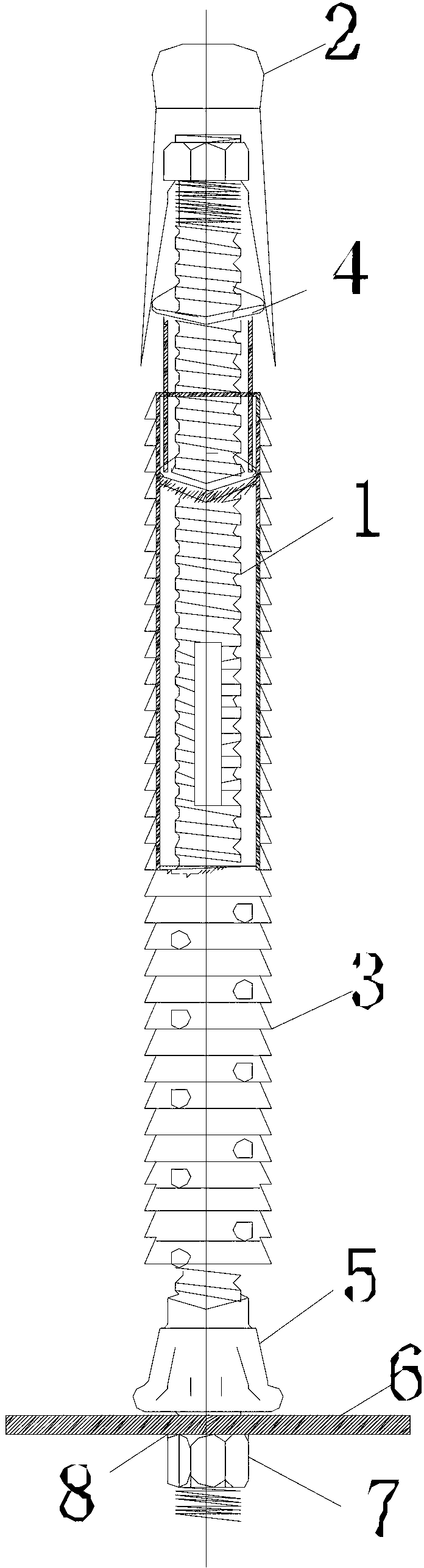

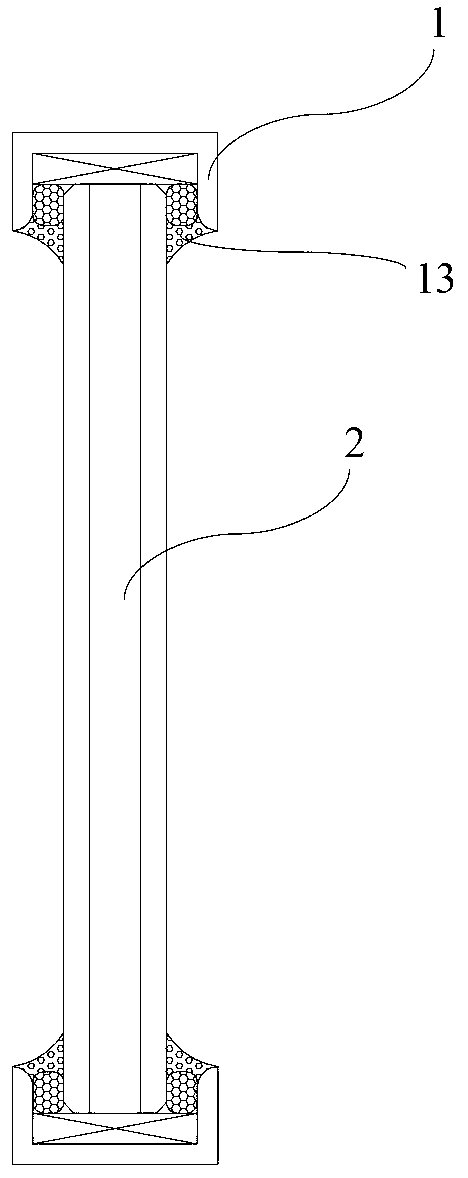

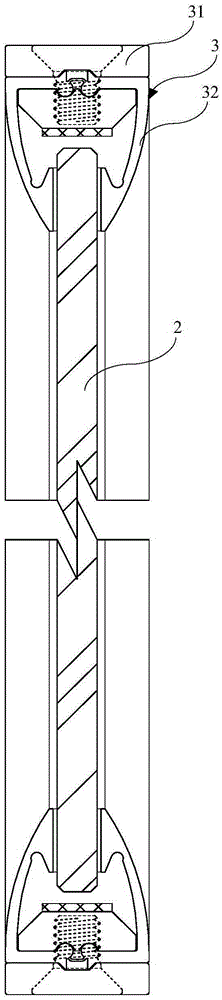

Novel expansion shell inverted wedge type grouting anchor rod

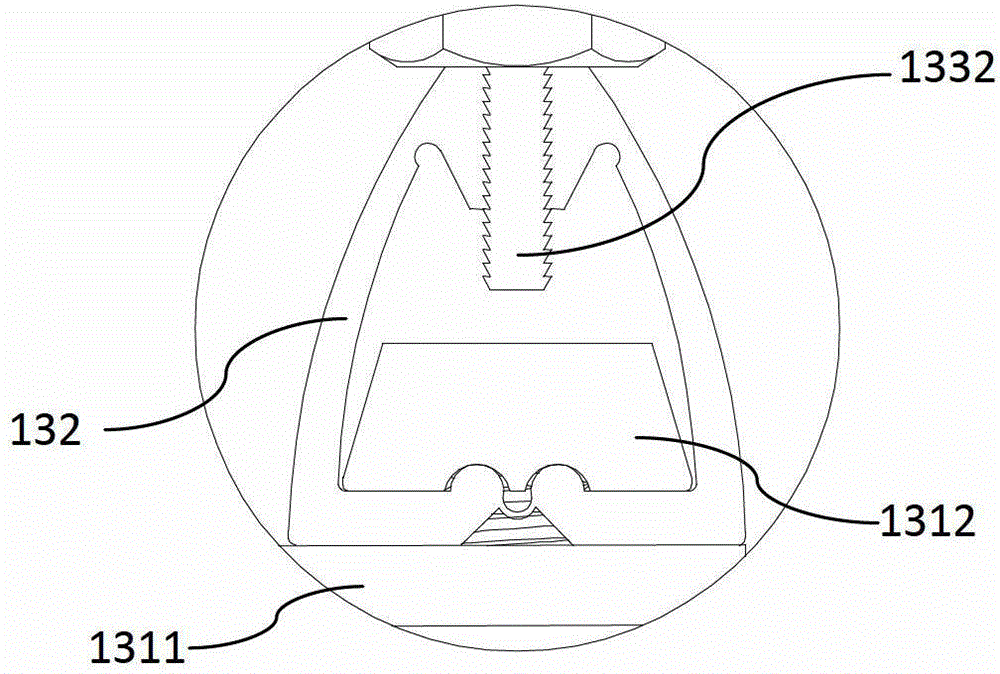

InactiveCN103133026ATo achieve unityControl deformationAnchoring boltsScrew threadMechanical construction

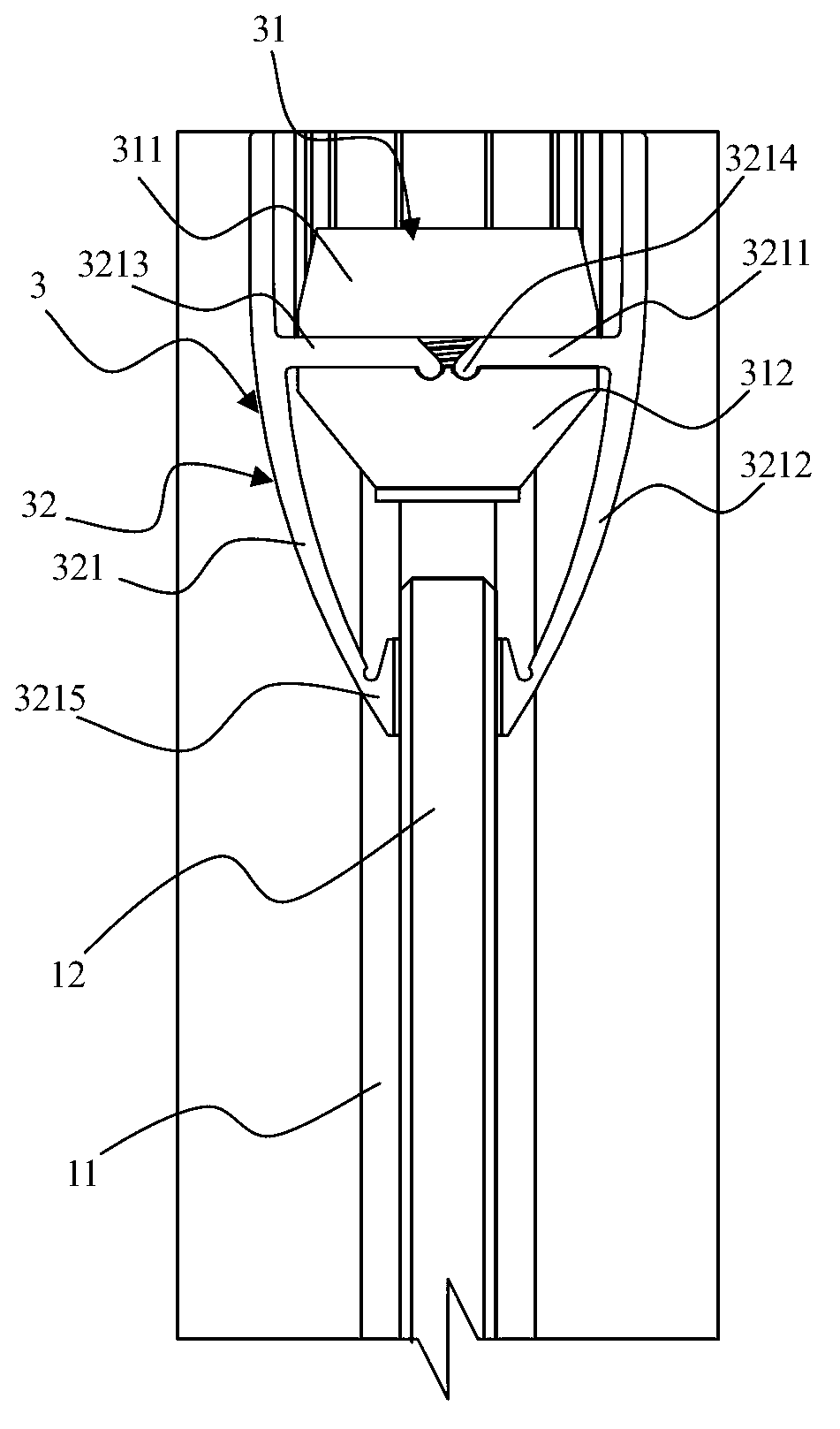

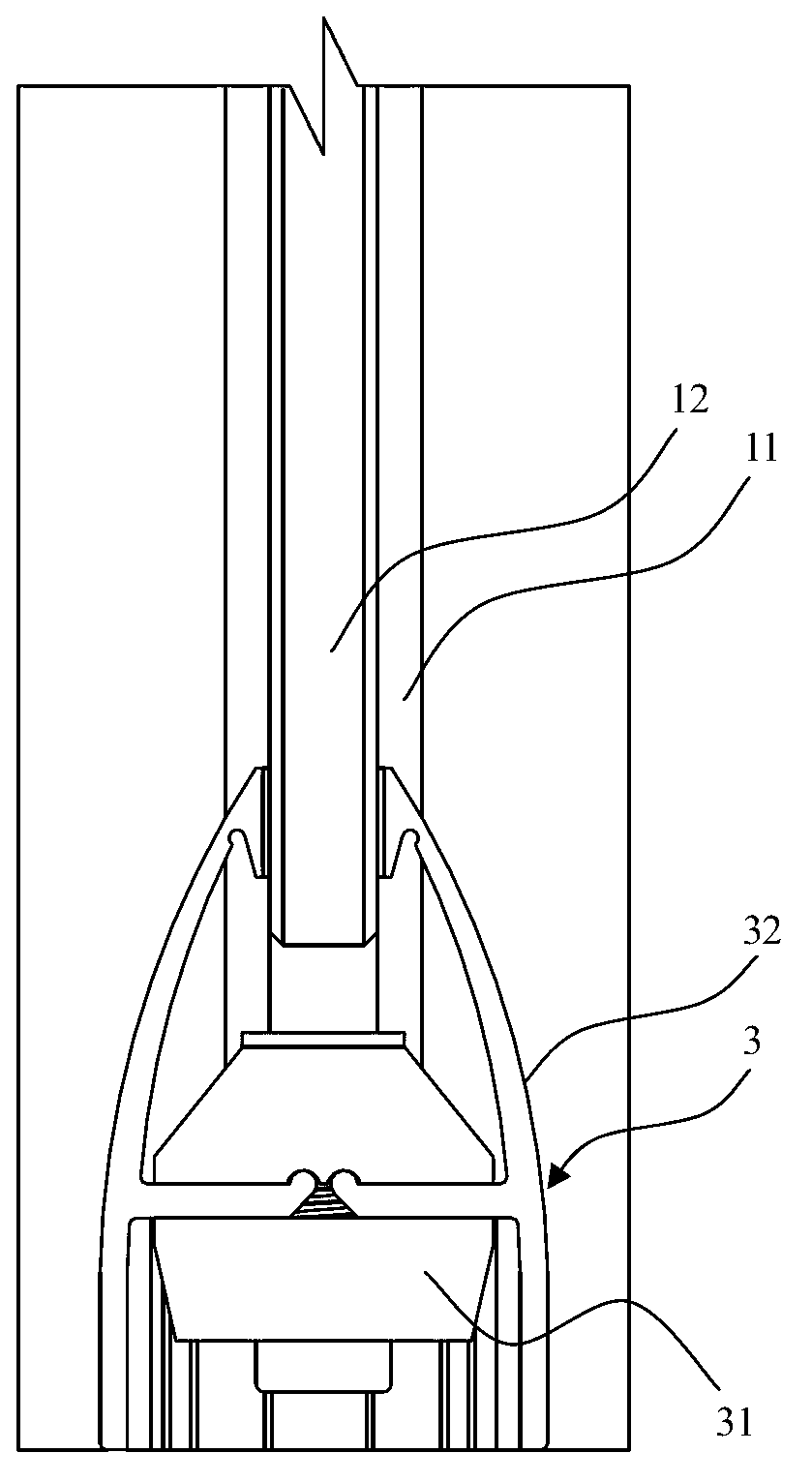

The invention provides a novel expansion shell inverted wedge type grouting anchor rod comprising an anchor rod body, an expansion shell type anchoring head, an inverted wedge type outer sleeve, a transmission ring, a grouting blocking plug, an anchoring base plate and nuts. The anchor rod is characterized in that the expansion shell type anchoring head and the anchoring base plate are located at two ends of the anchor rod body and are fixed through the nuts, the inverted wedge type outer sleeve is sleeved outside of the anchor rod body, the bottom of the transmission ring is arranged in the inverted wedge type outer sleeve, and the top end of the transmission ring contacts the expansion shell type anchoring head. The anchor rod body is a hollow metal rod element provided with left-hand threads. The expansion shell type anchoring head is small-end-up and provided with a flap-shaped structure which can open at a certain angle in an expansion mode, and can form barbs invertedly piercing in a rock body when stressed and expanded. The surface of the inverted wedge type outer sleeve is provided with inverted wedge type grooves in the annular direction. The novel expansion shell inverted wedge type grouting anchor rod has the advantages of being fast in anchoring, easy to install, capable of grouting and the like, facilitates mechanical construction, and has good anchoring effects on soft, expanded and cracked surrounding rock.

Owner:ANHUI UNIV OF SCI & TECH

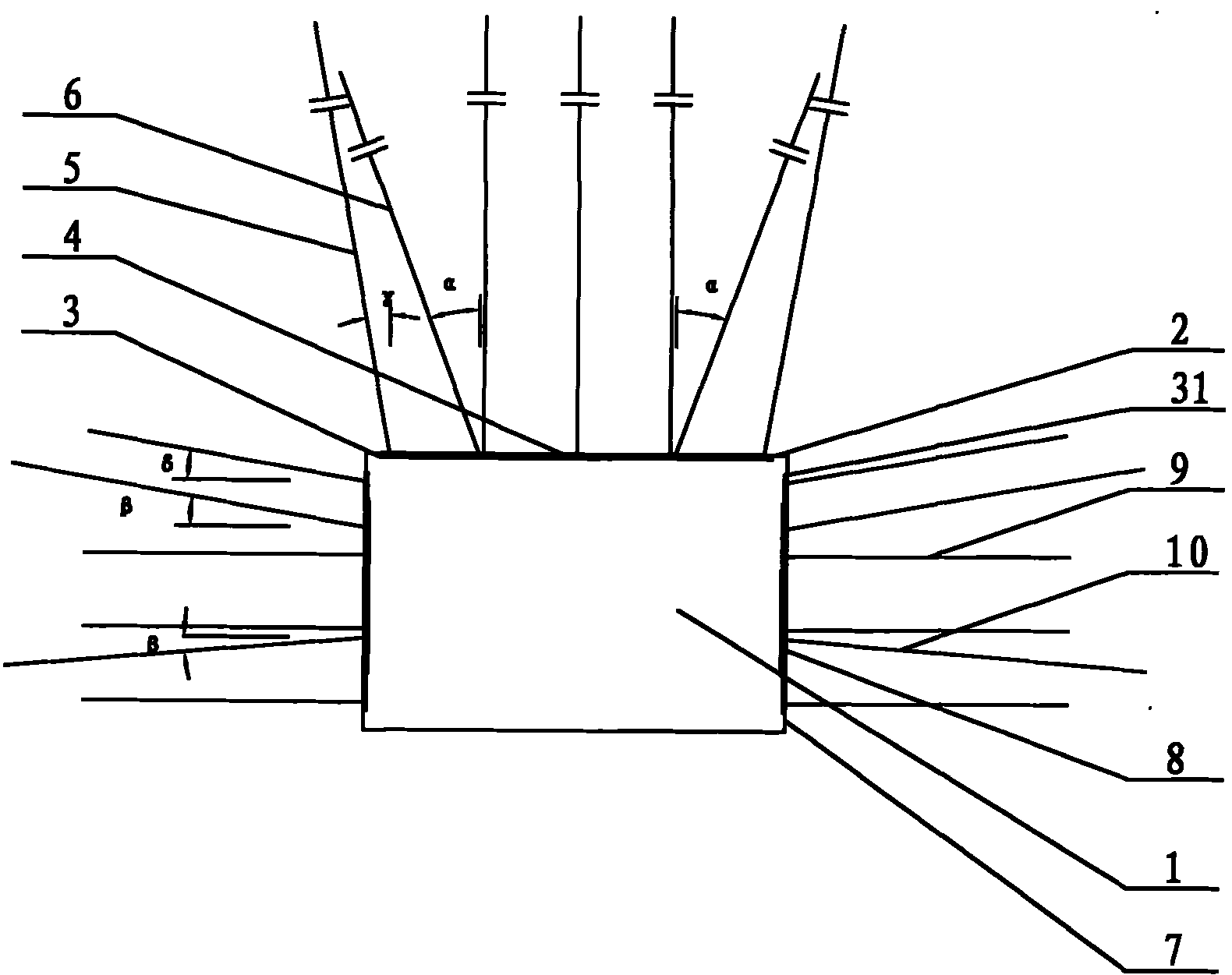

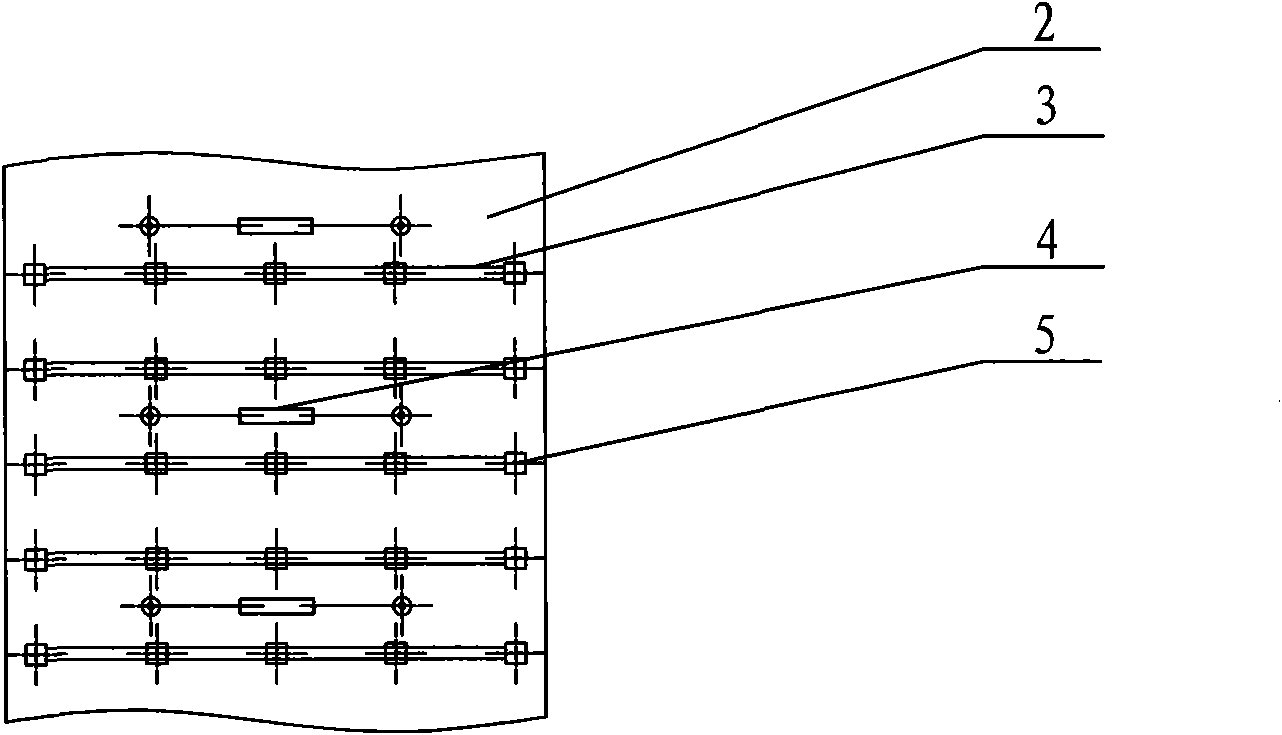

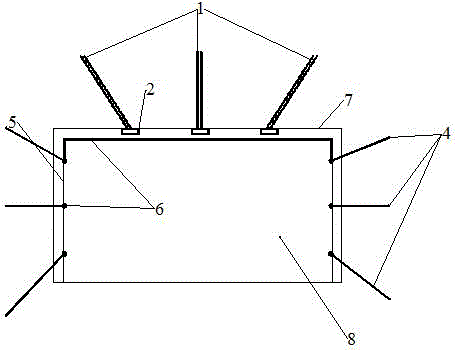

Method for preventing and treating roof falling and side collapsing of coal roadway surrounding rock by anchor rope truss

InactiveCN102121389AFlexible constructionImprove the support effectAnchoring boltsShear stressPre stress

The invention provides a method for preventing and treating roof falling and side collapsing of coal roadway surrounding rock by an anchor rope truss, which belongs to the field of mineral engineering or civil engineering, and mainly solves the problem of roof falling and side collapsing accidents of the coal roadway surrounding rock. In the method, a plurality of groups of top late monomer anchor ropes and top plate truss anchor ropes are arranged on the top plate of the coal roadway at intervals so as to support and protect the top plate of the coal roadway; and a plurality of groups of side monomer anchor ropes and side truss anchor ropes are arranged on the roadway side so as to support and protect the roadway side; the whole design takes full advantage of being flexible construction, occupying less sections, costing short construction time, having excellent safety and reliability, saving money, applying strong pre-stress and the like of the anchor ropes, the top plate truss anchor ropes can penetrate into a maximum shear stress region at the top of the coal roadway to form very strong pre-stress, and the side truss anchor ropes can penetrate into the deep part of the roadway side and can be fixed by a channel steel to form very strong pre-stress, so that the method is more advantageous, particularly, in strengthening the damaged coal roadway in comparison with other methods.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

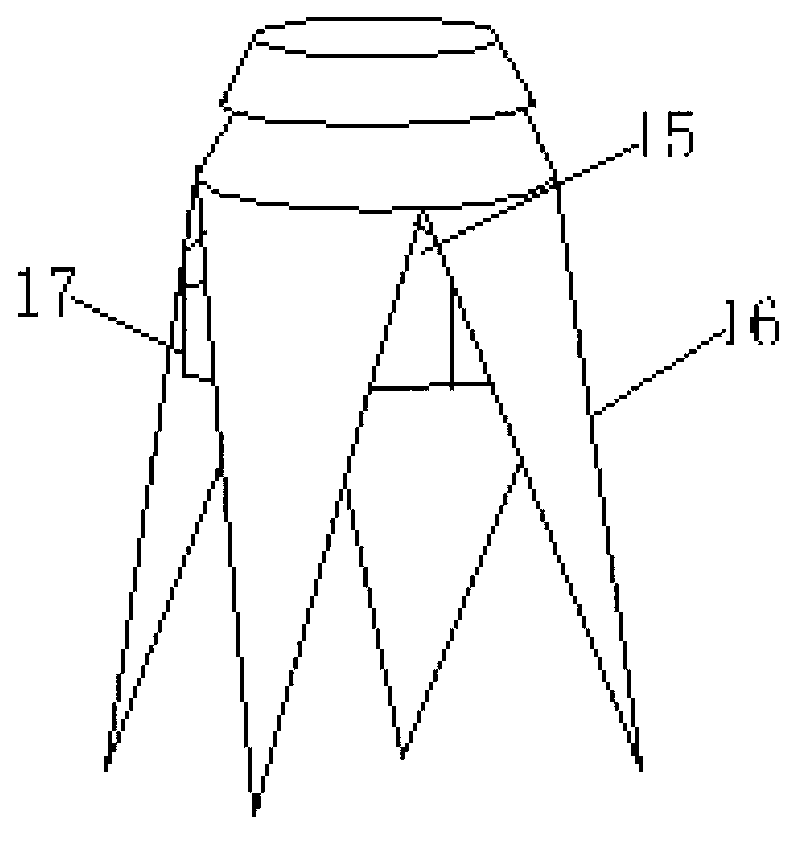

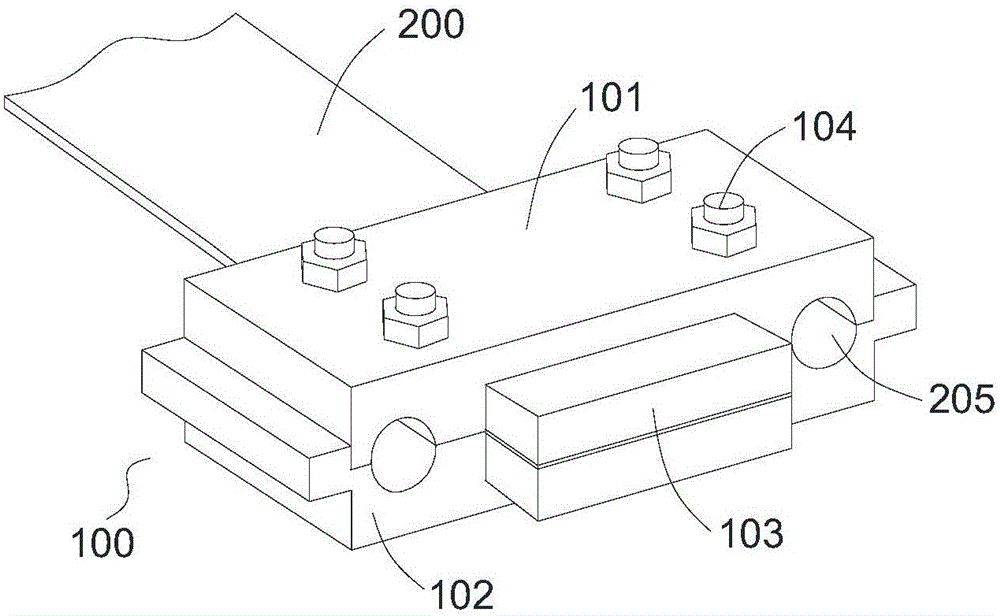

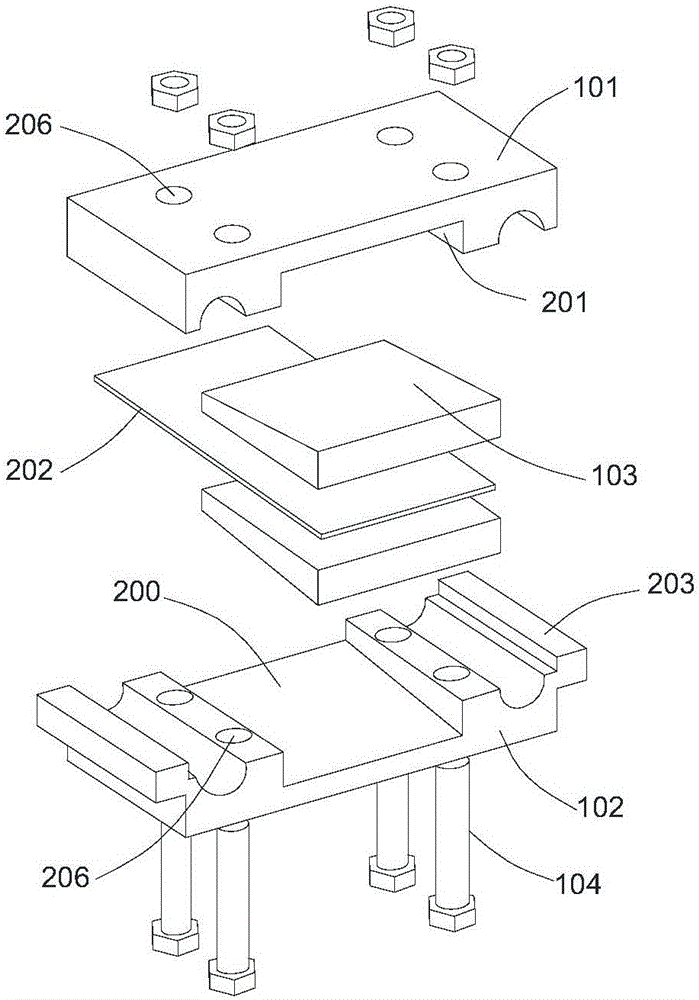

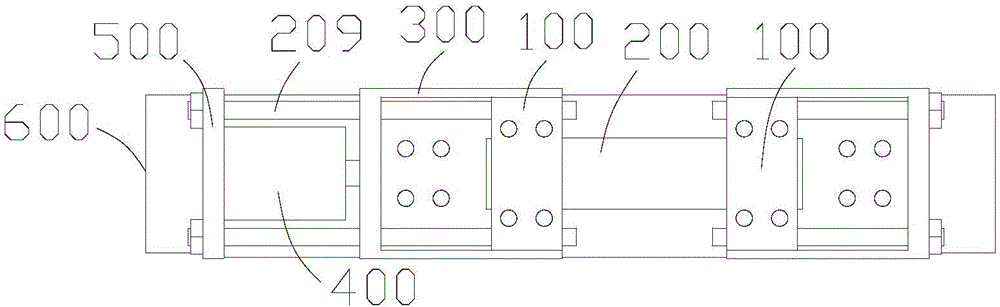

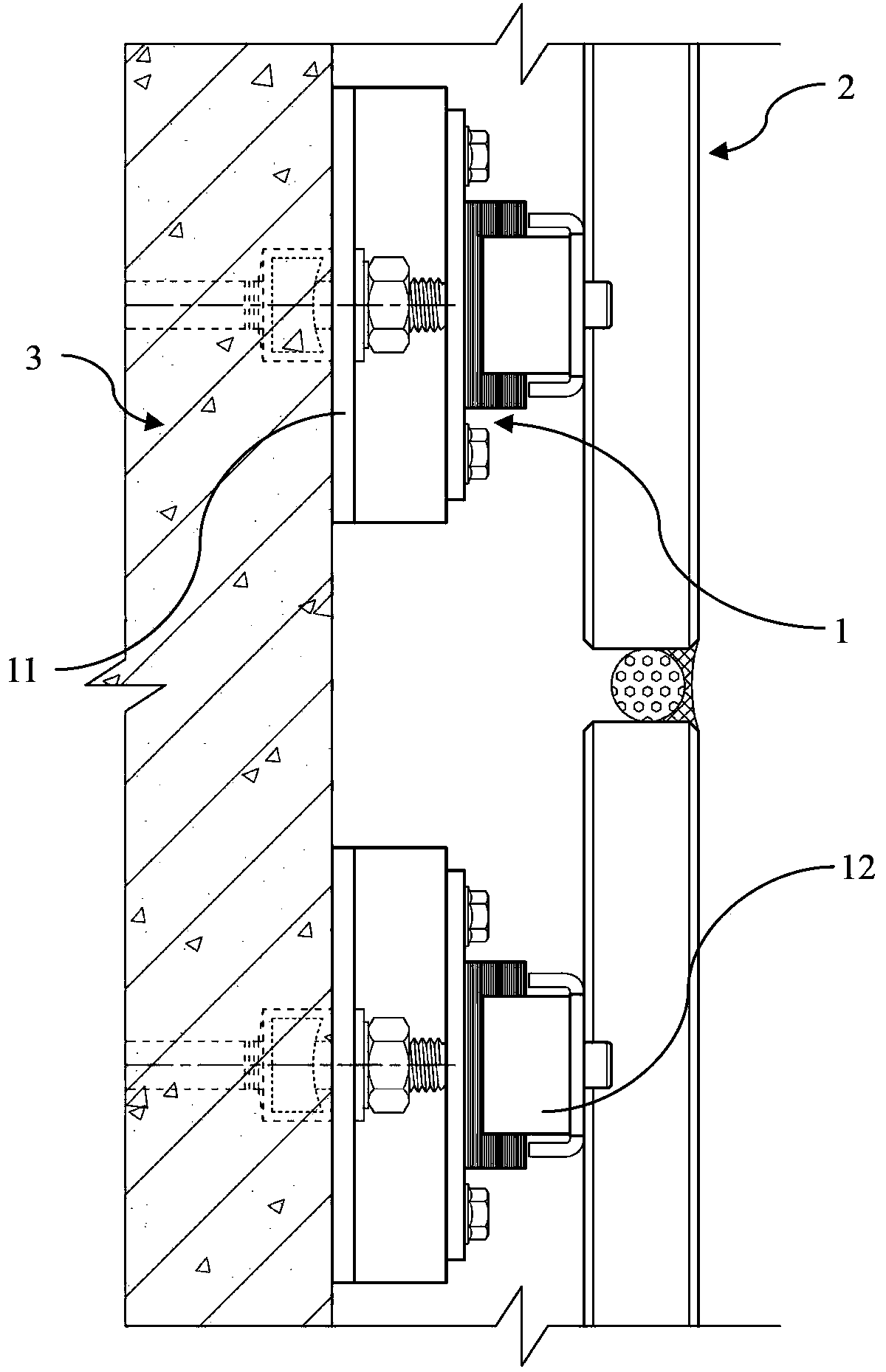

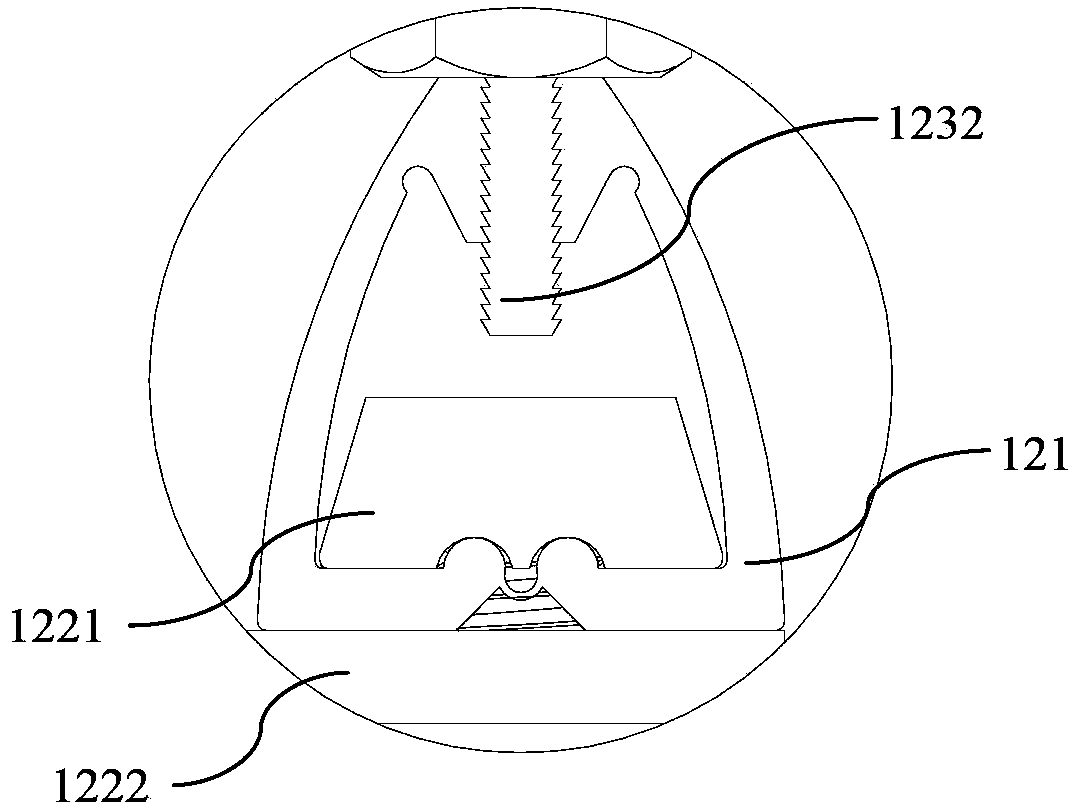

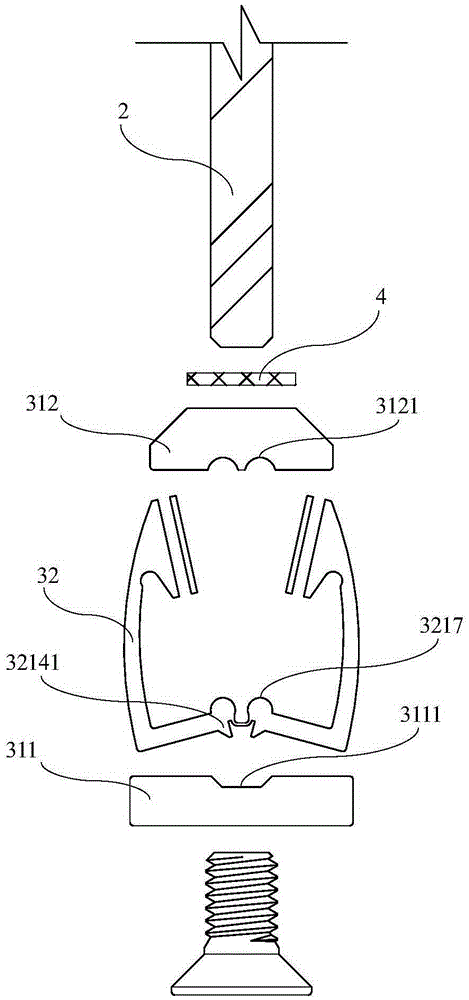

Mechanical gripping anchor for carbon fiber plate and reinforcing device

InactiveCN105781123ASimple structureEasy to processBuilding reinforcementsBuilding material handlingFiberEngineering

The invention provides a mechanical gripping anchor for a carbon fiber plate and a reinforcing device. The anchor comprises two anchor units, which are arranged in pairs, wherein each anchor unit comprises an upper anchor block, a lower anchor block and two clamping pieces; the two clamping pieces are oppositely arranged and are located between the upper anchor block and the lower anchor block; the upper anchor block is fixedly connected with the lower anchor block through a high-strength bolt; and the reinforcing device comprises the anchor and the carbon fiber plate. The installation method of the anchor is convenient to construct and good in anchoring effect; the construction period is shortened; the construction efficiency is improved; and the carbon fiber plate is uniform in stress after being anchored by the anchor.

Owner:SOUTHWEST JIAOTONG UNIV

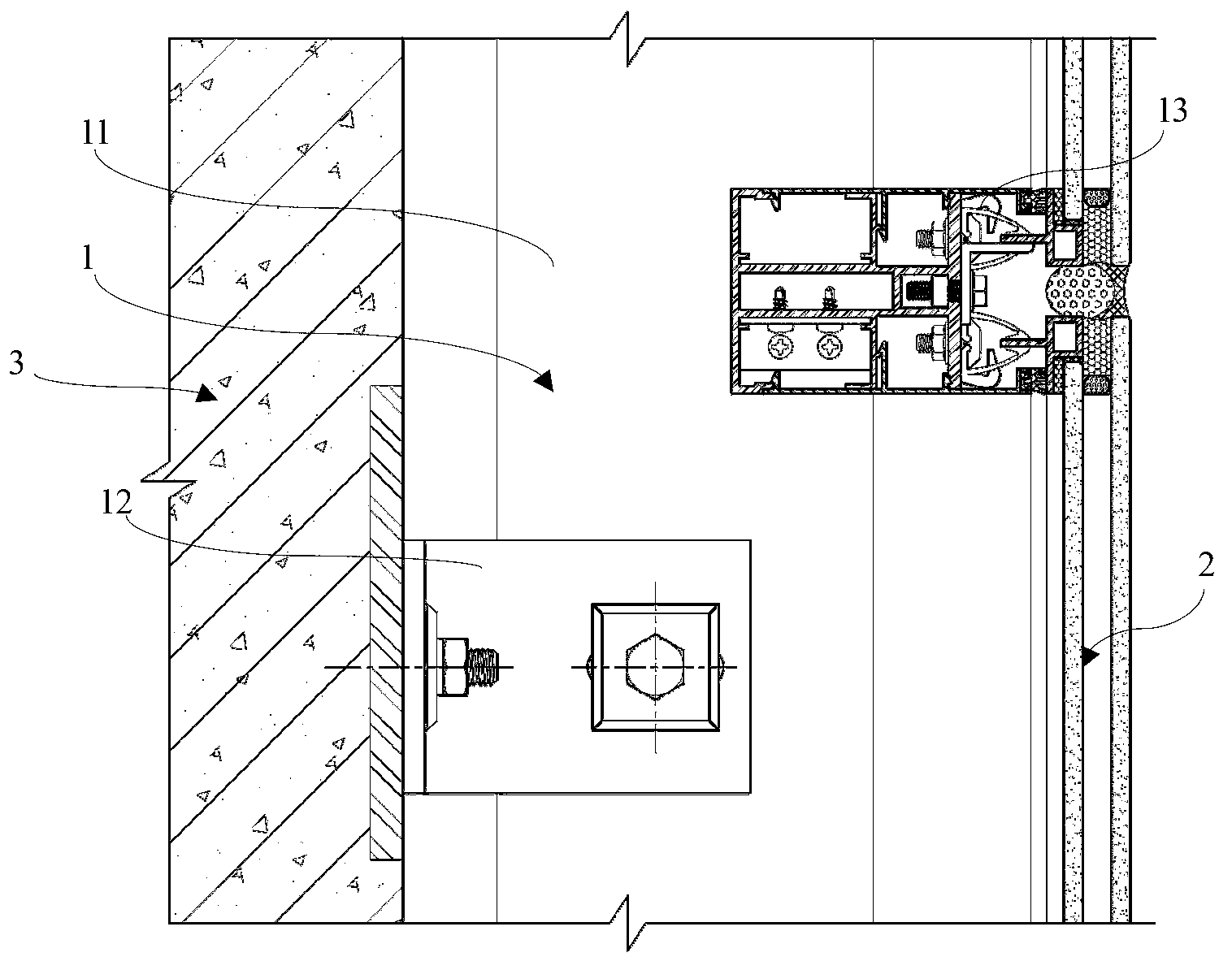

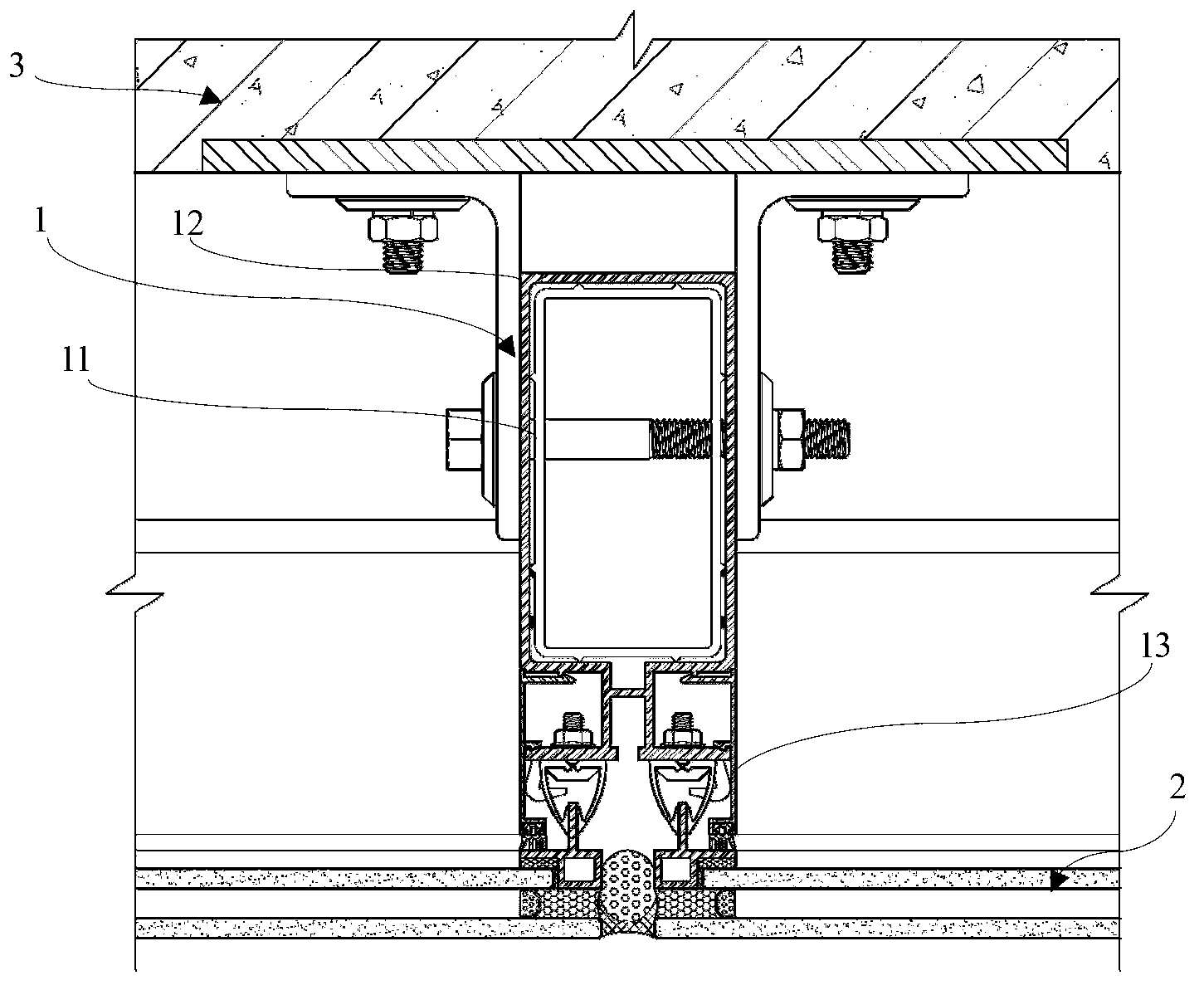

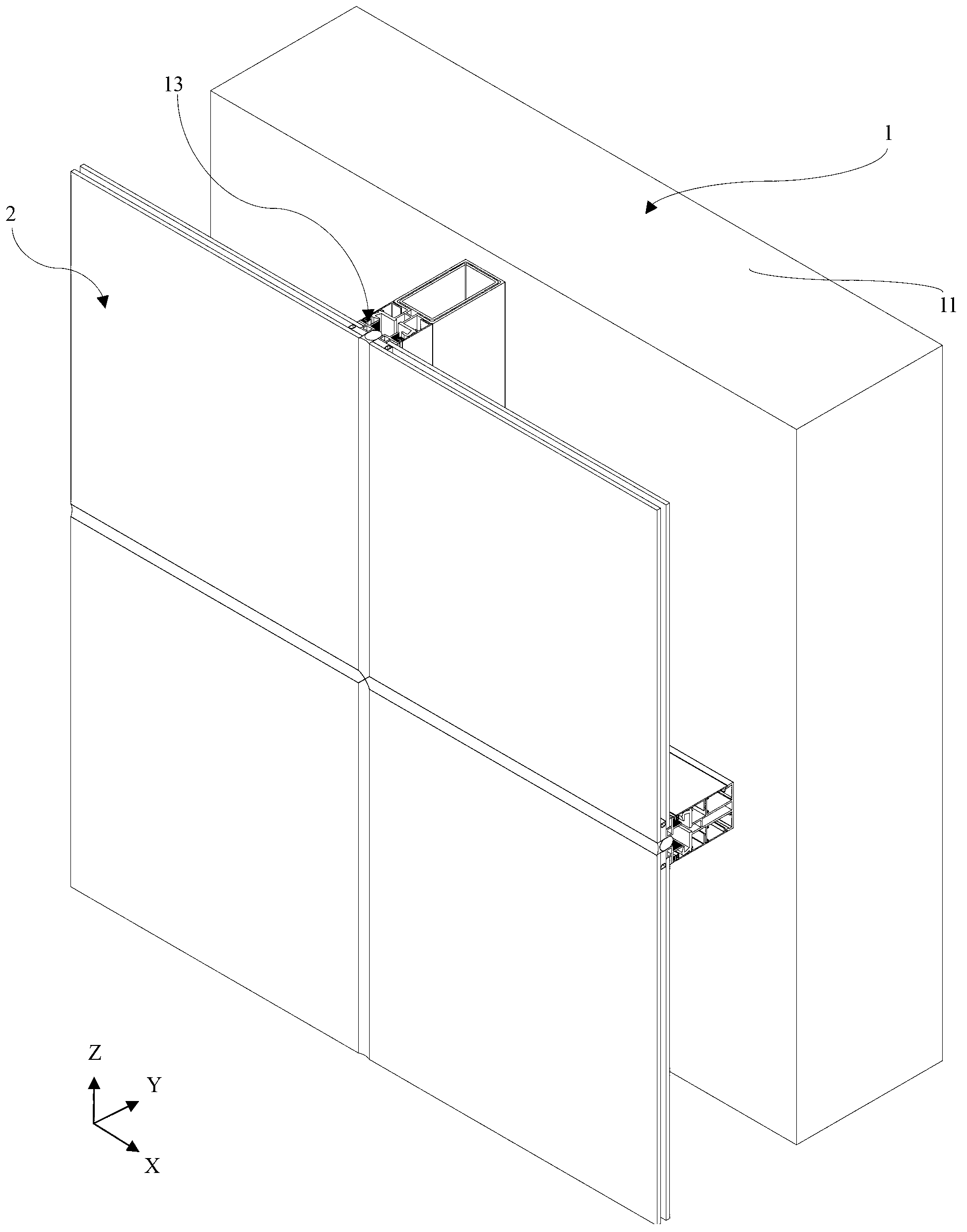

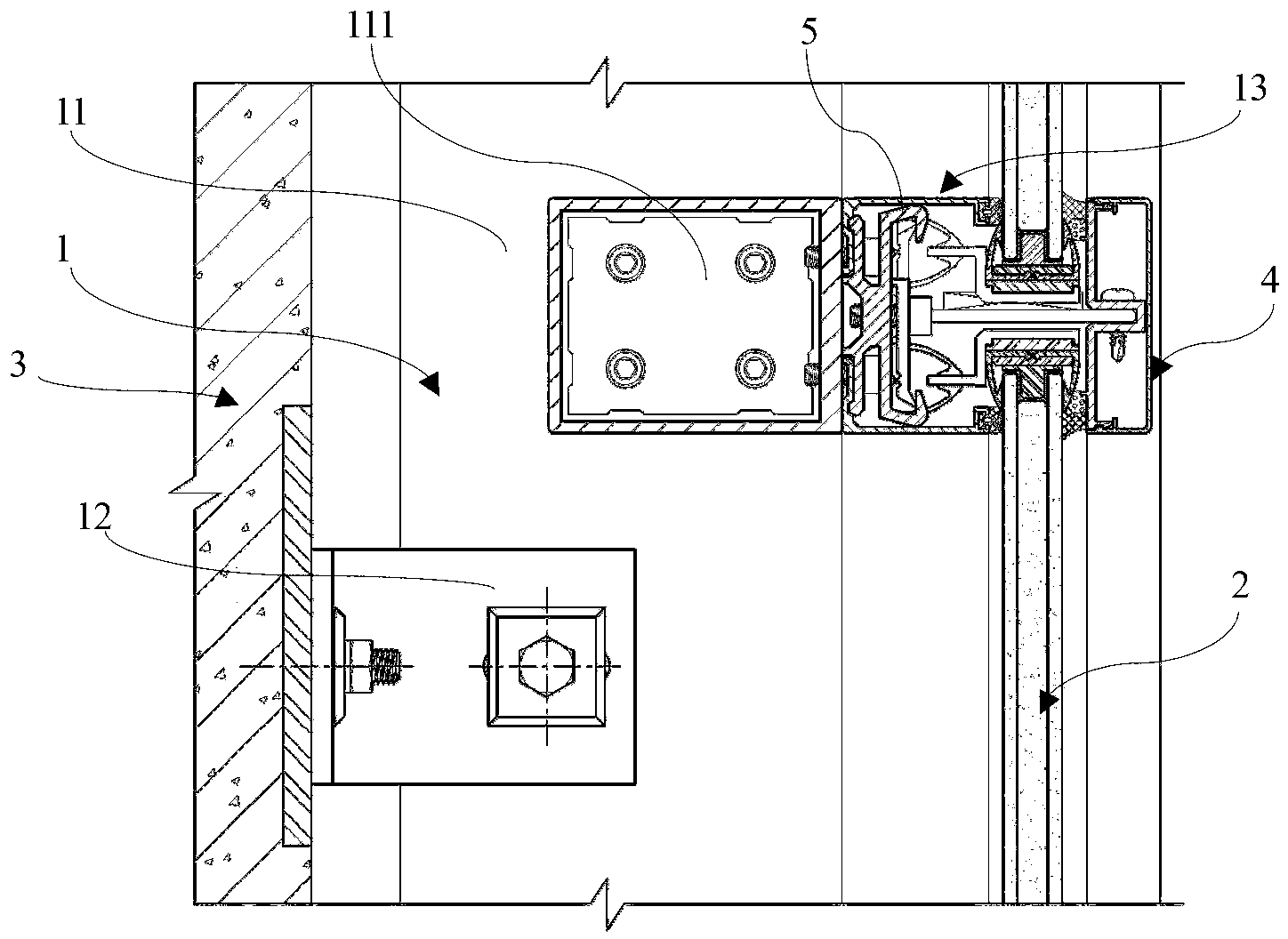

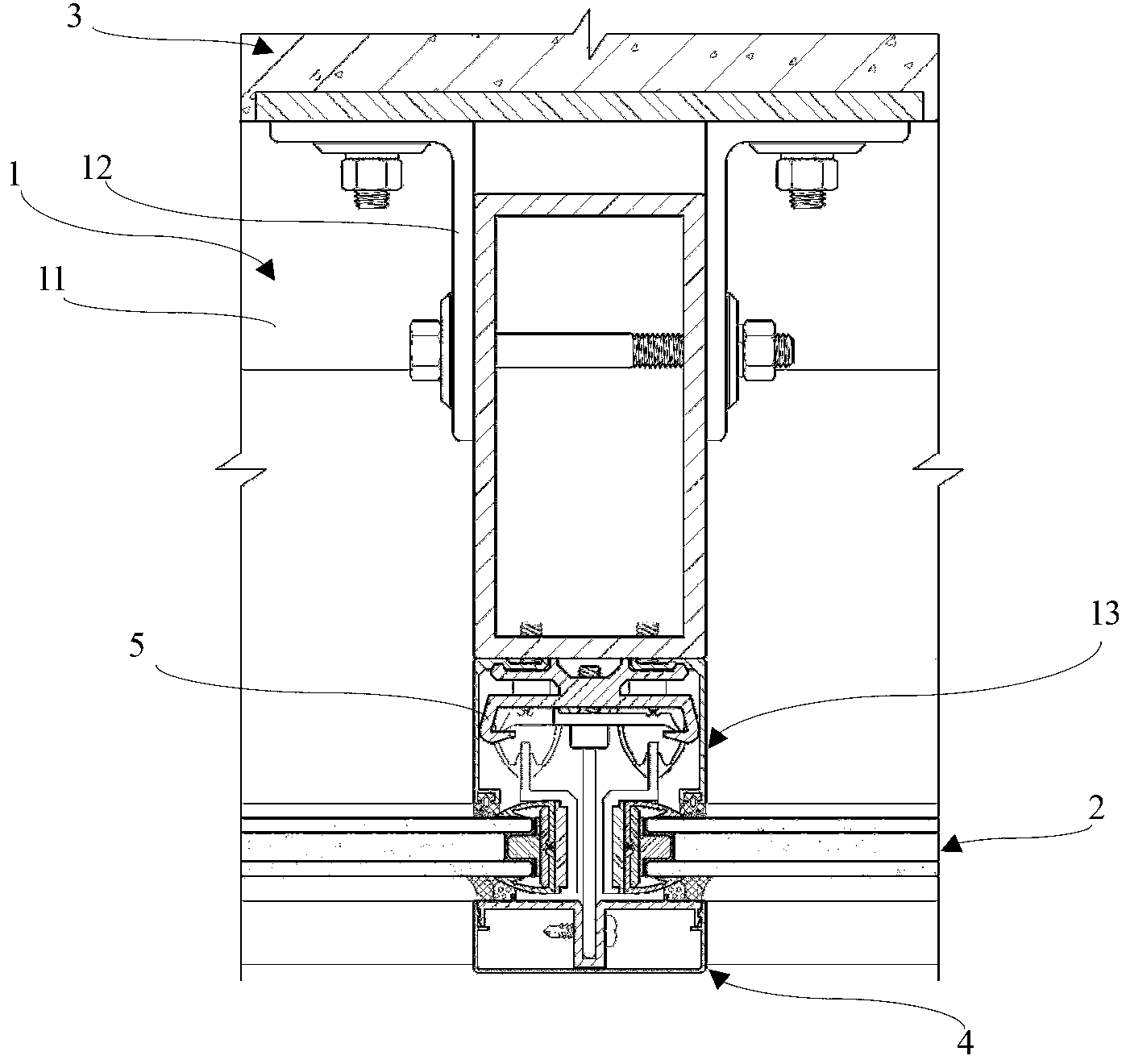

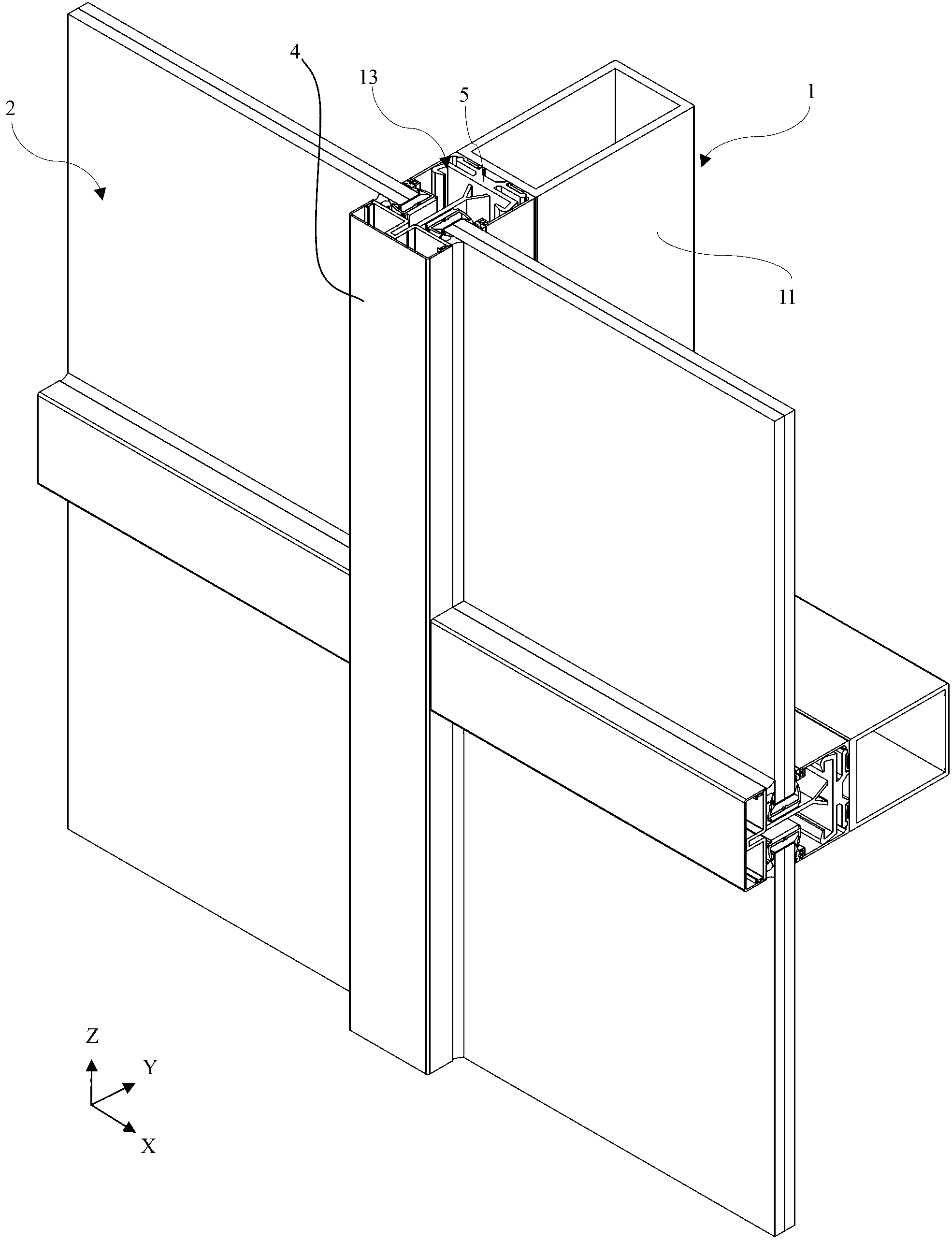

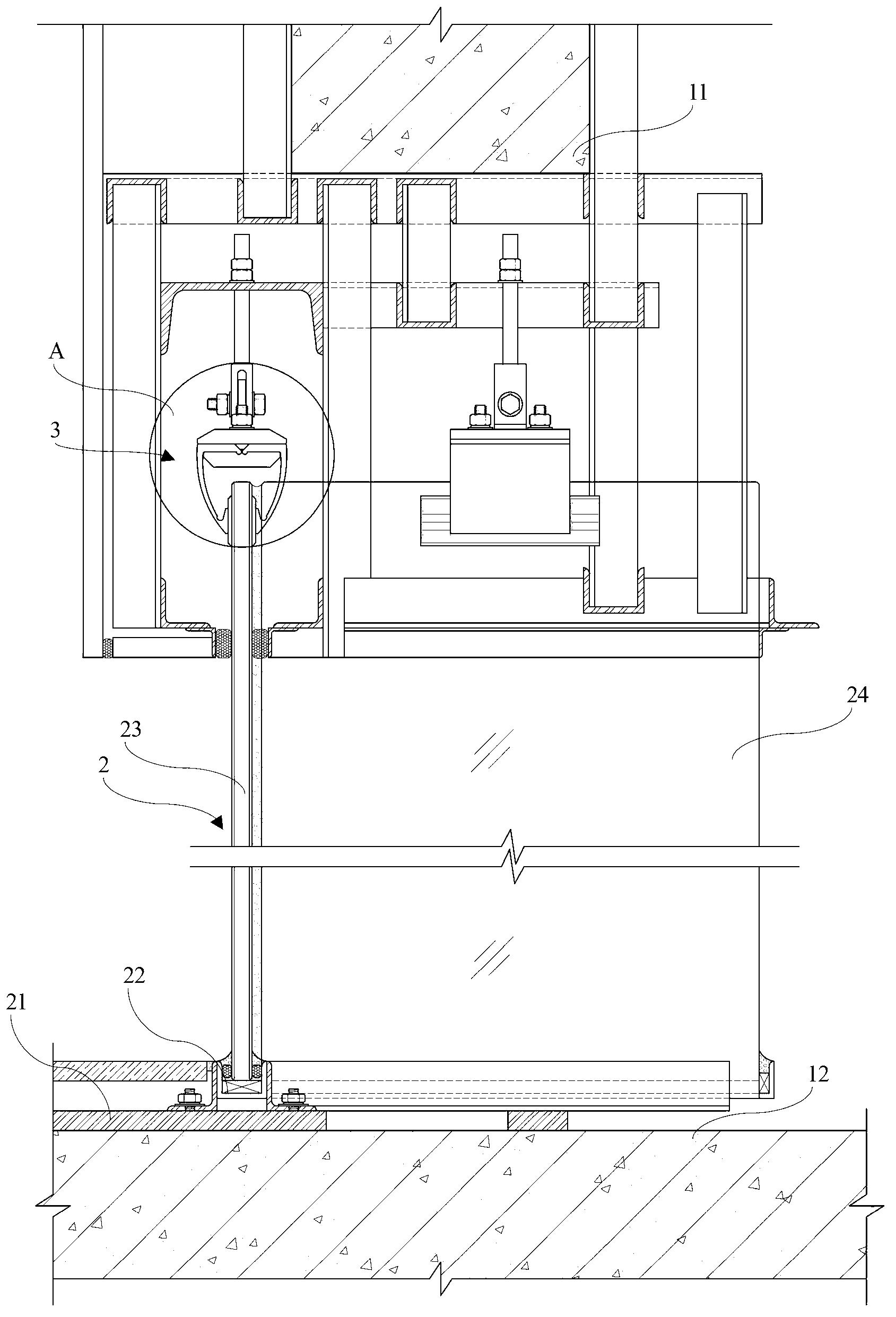

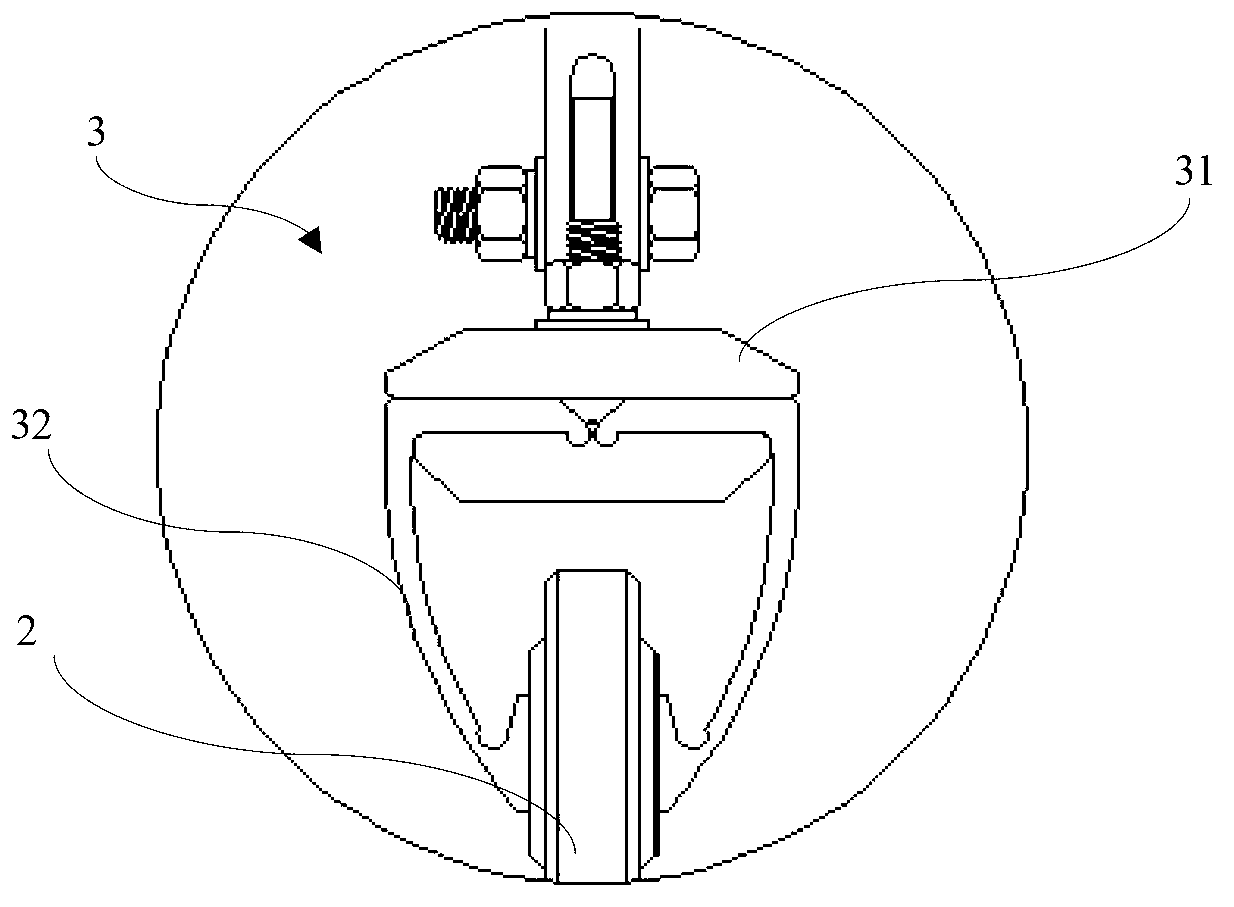

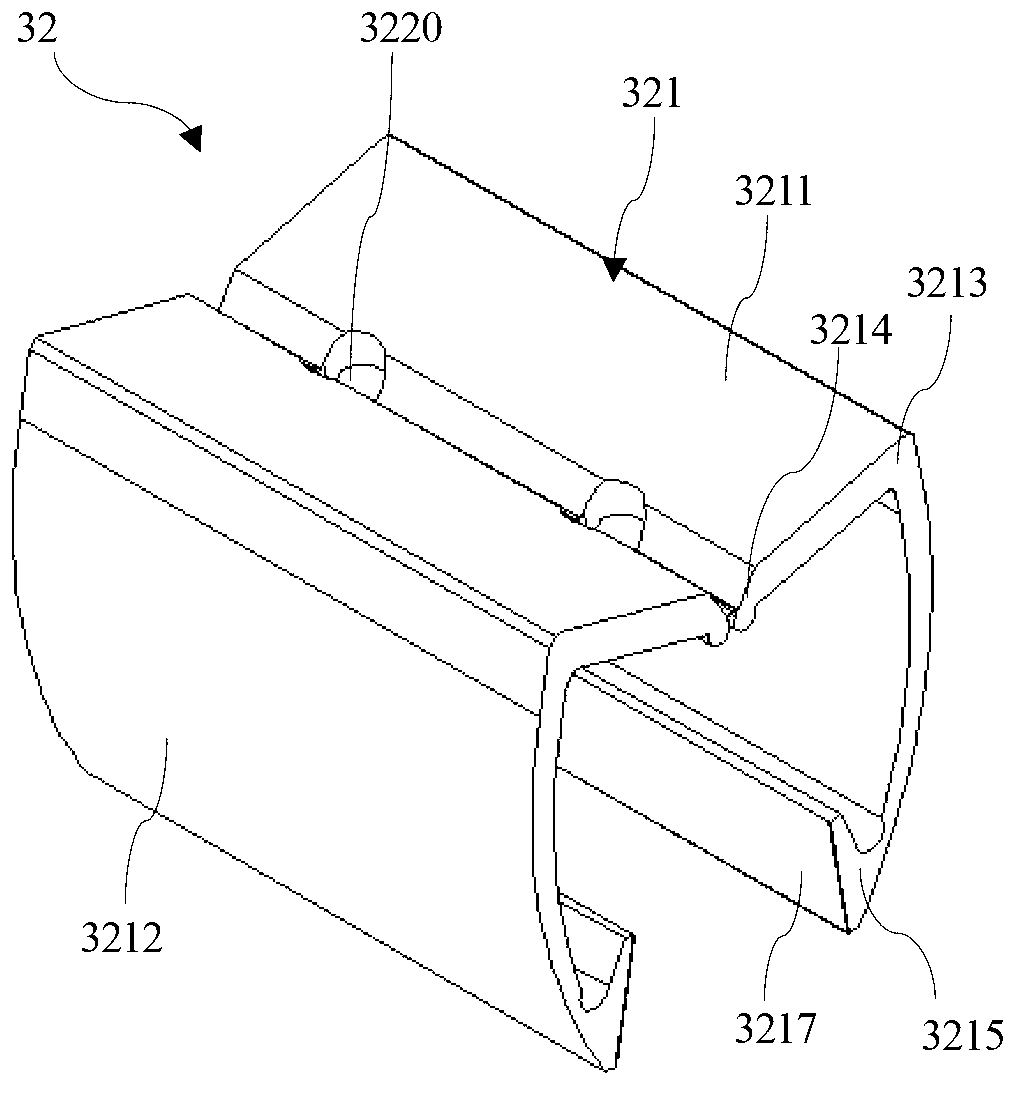

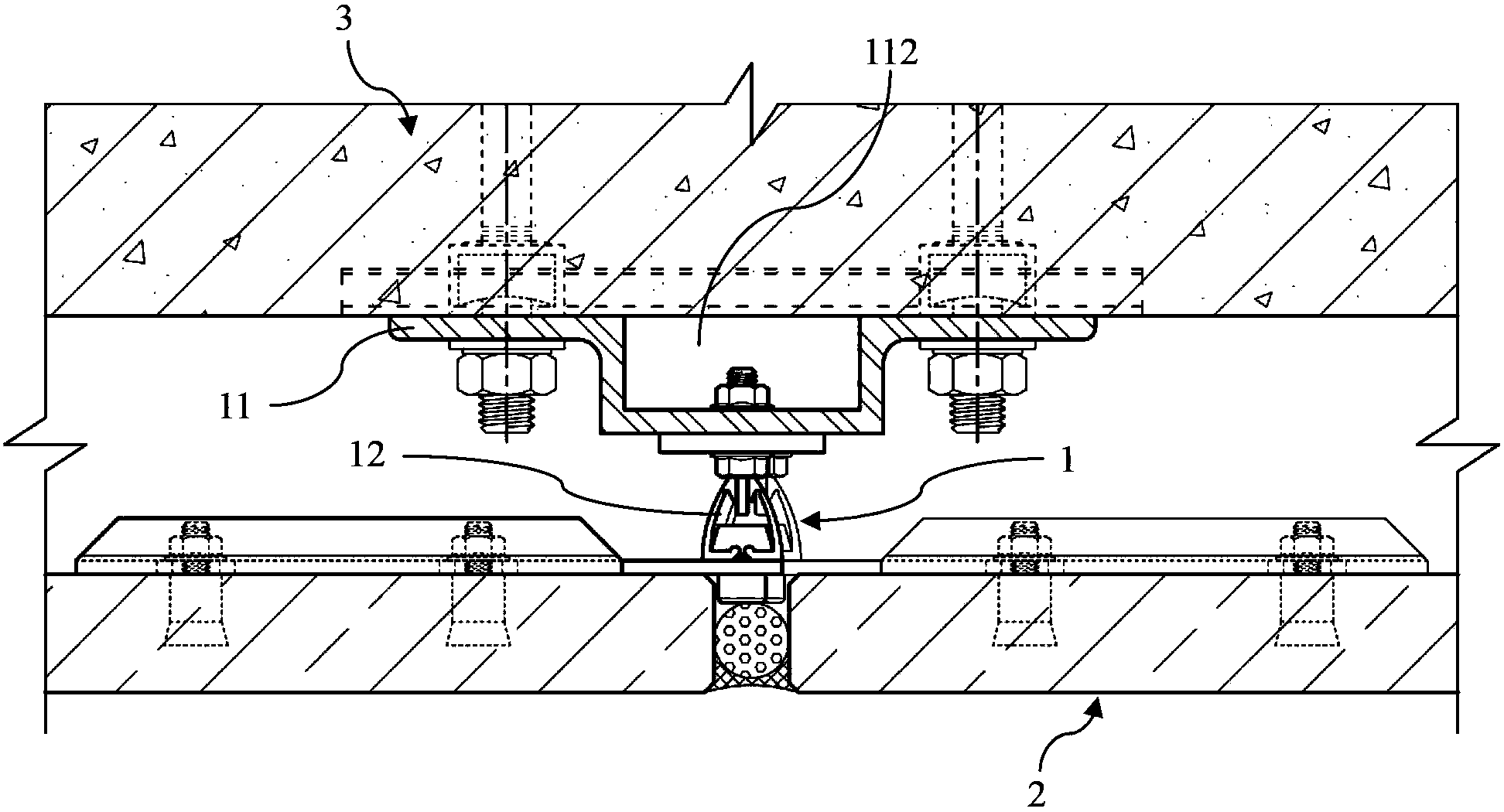

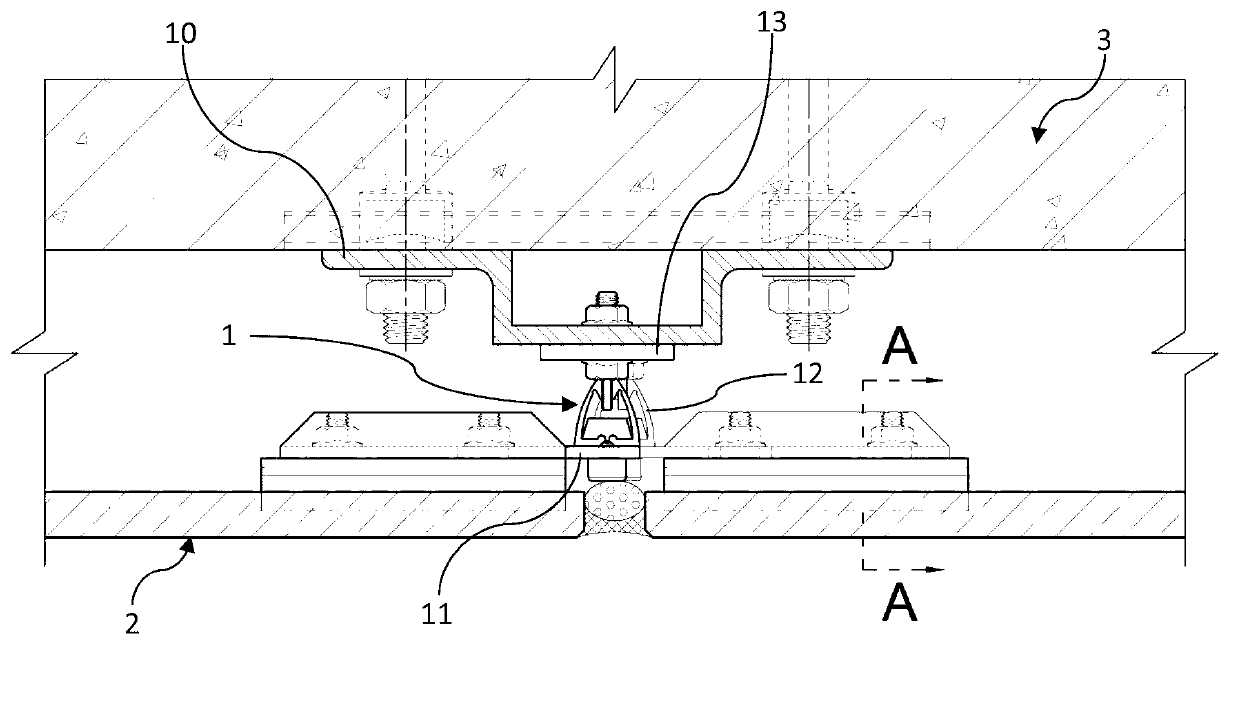

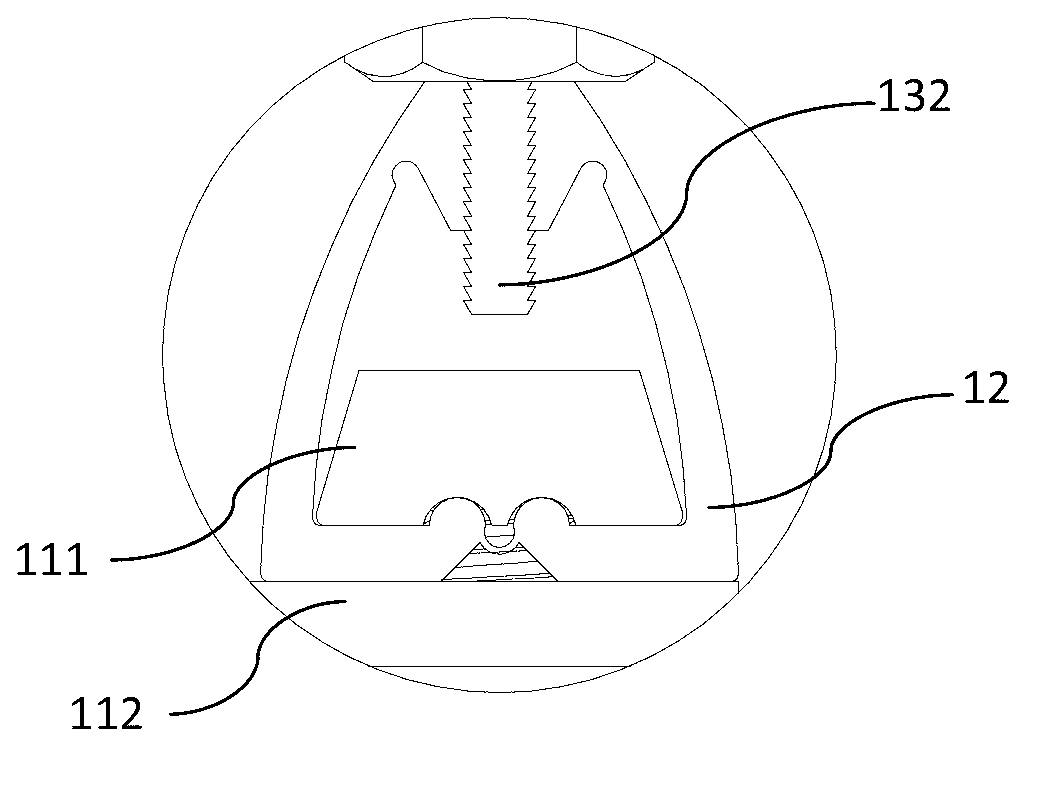

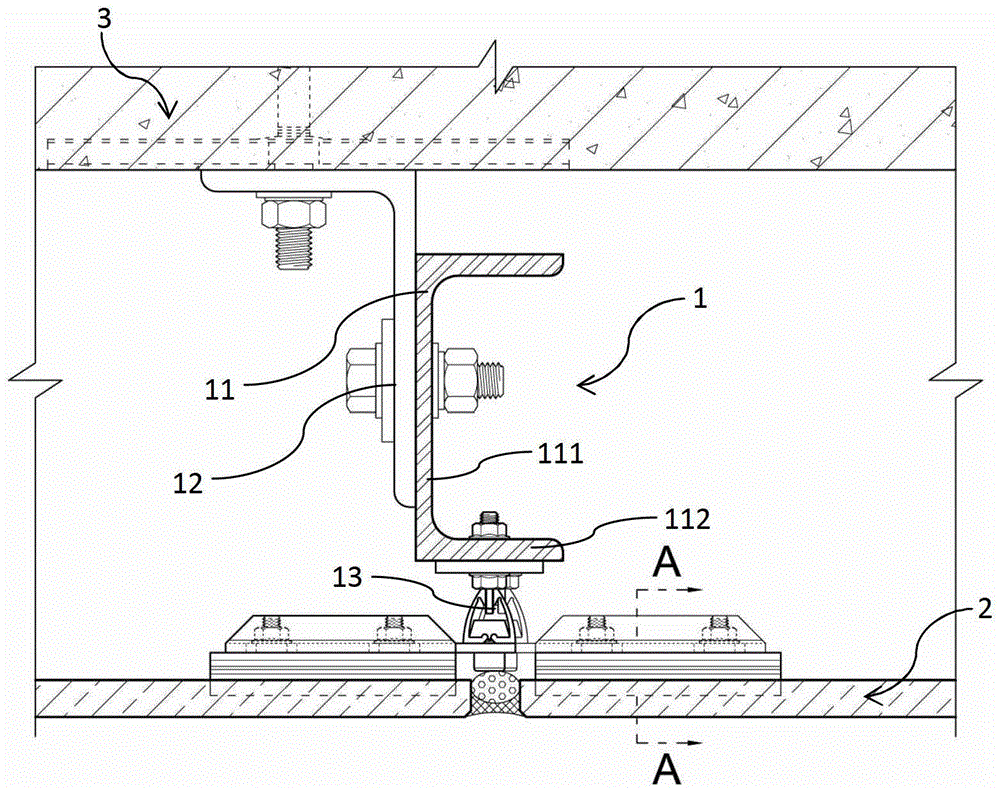

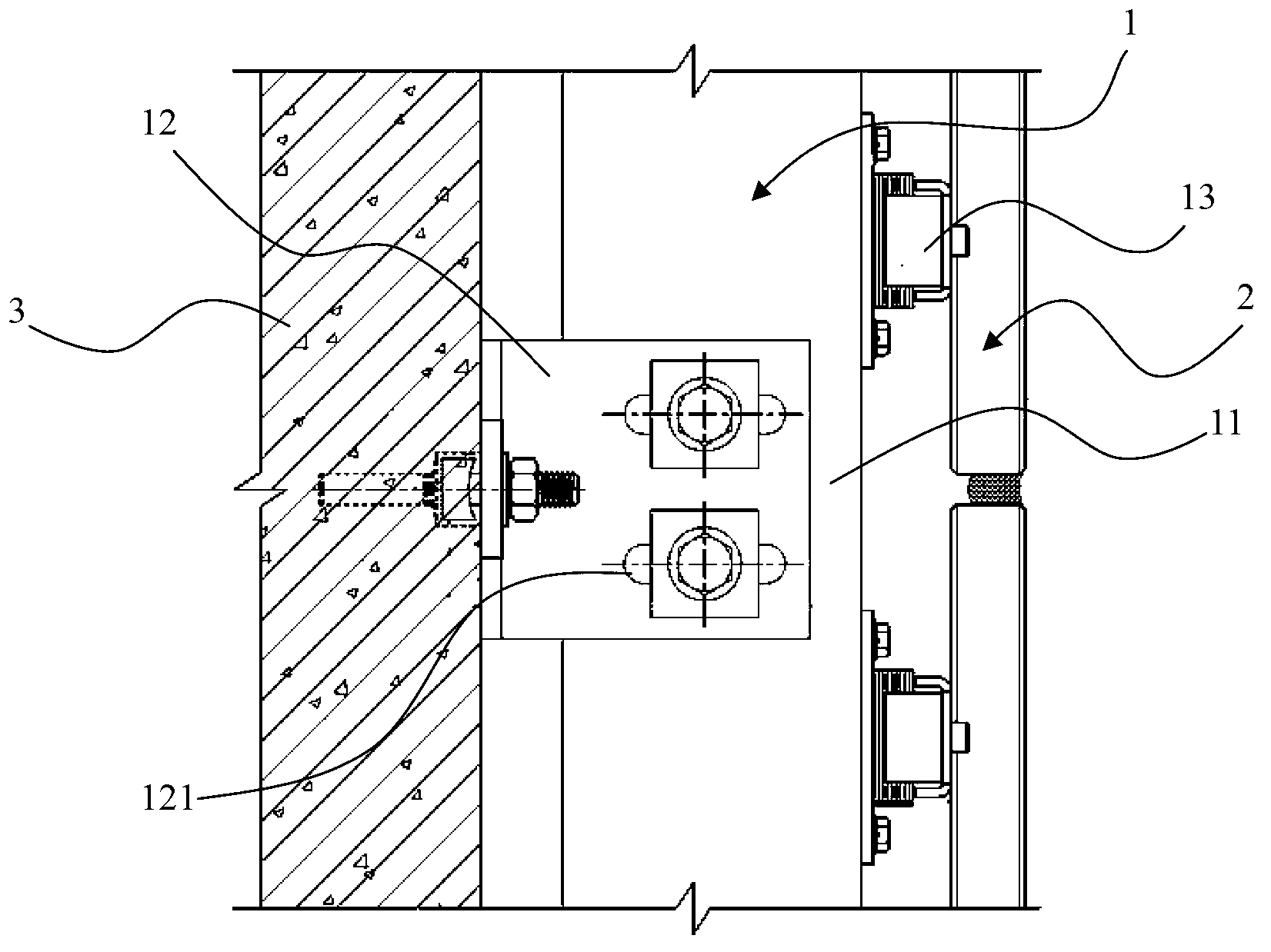

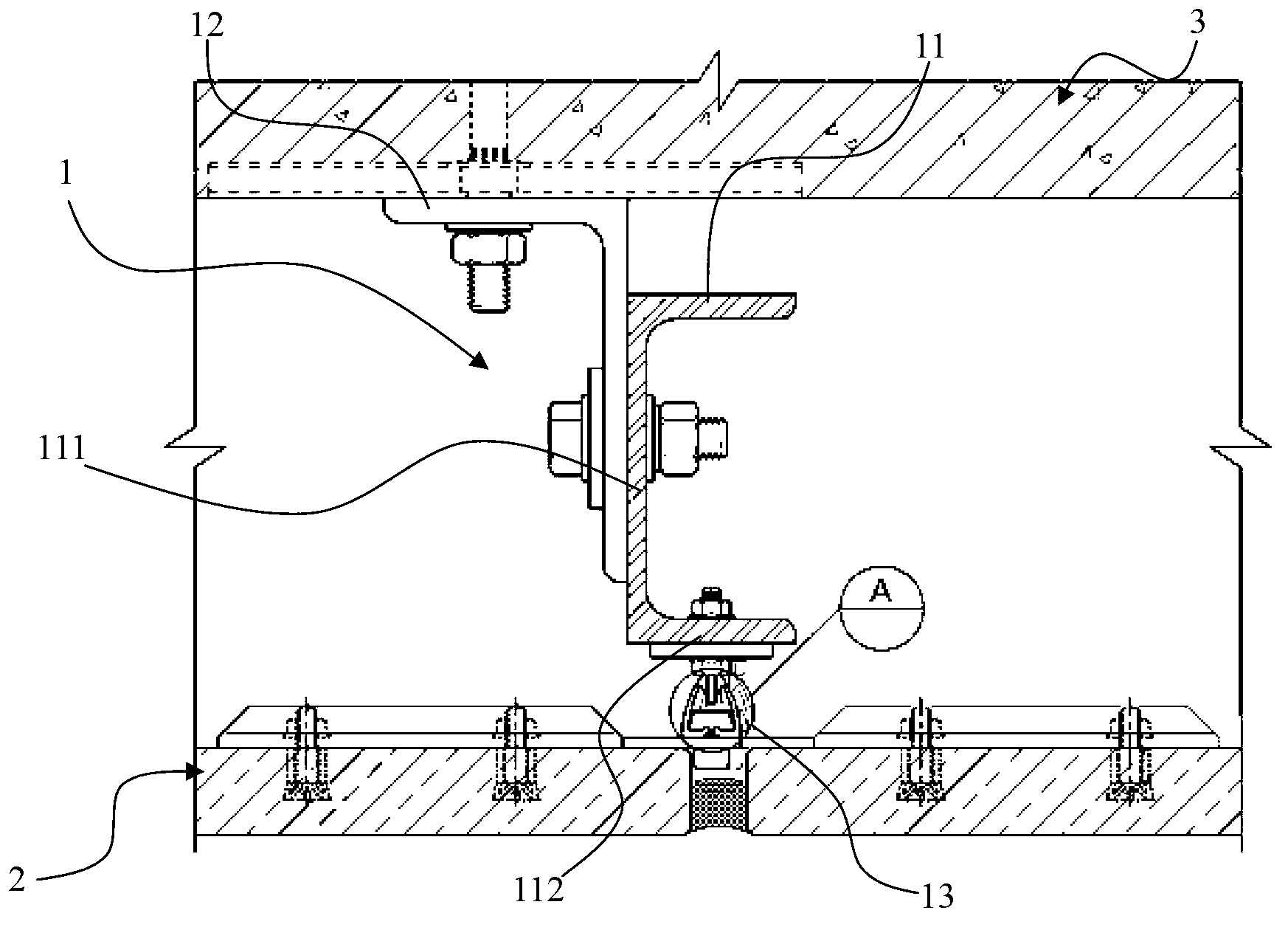

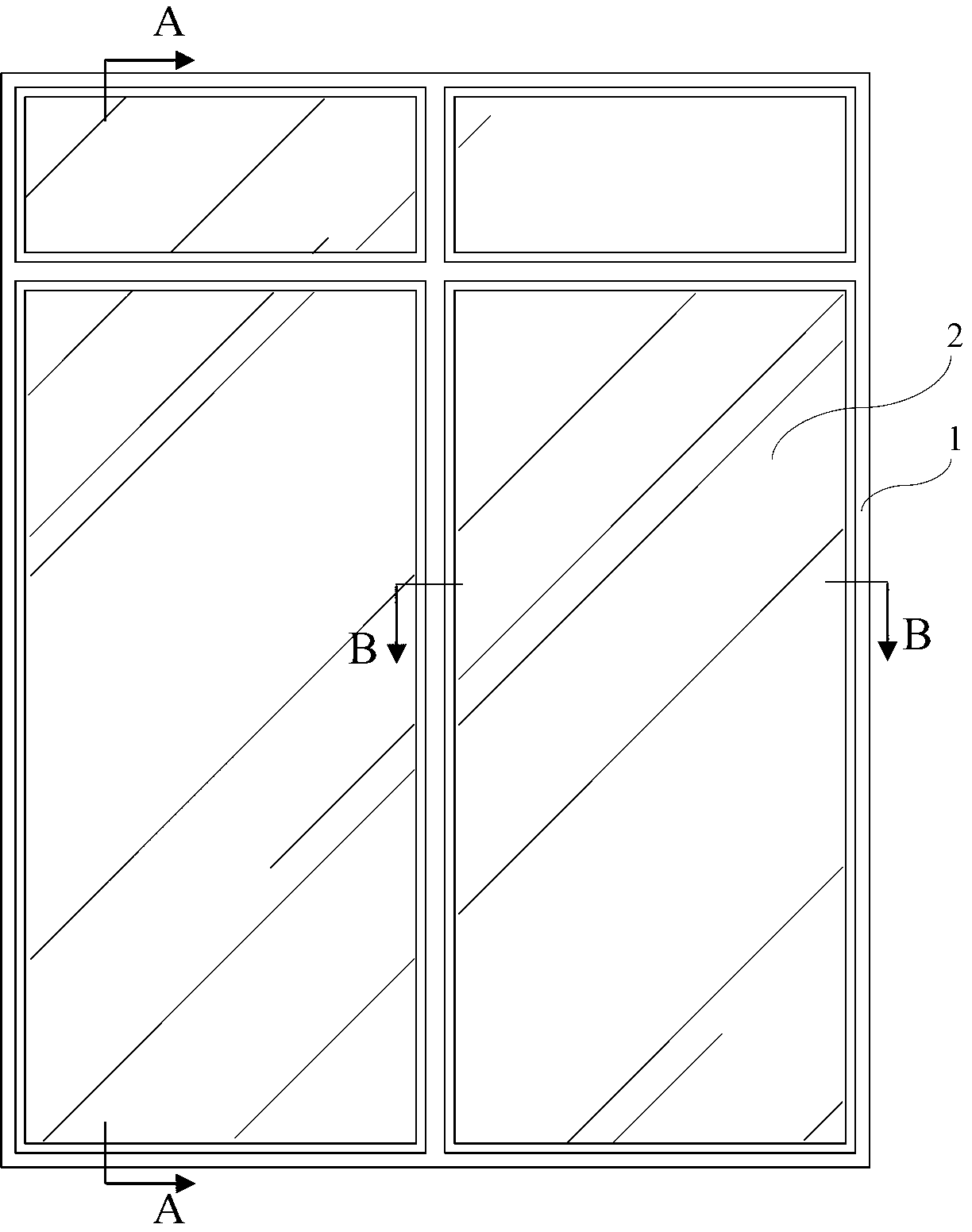

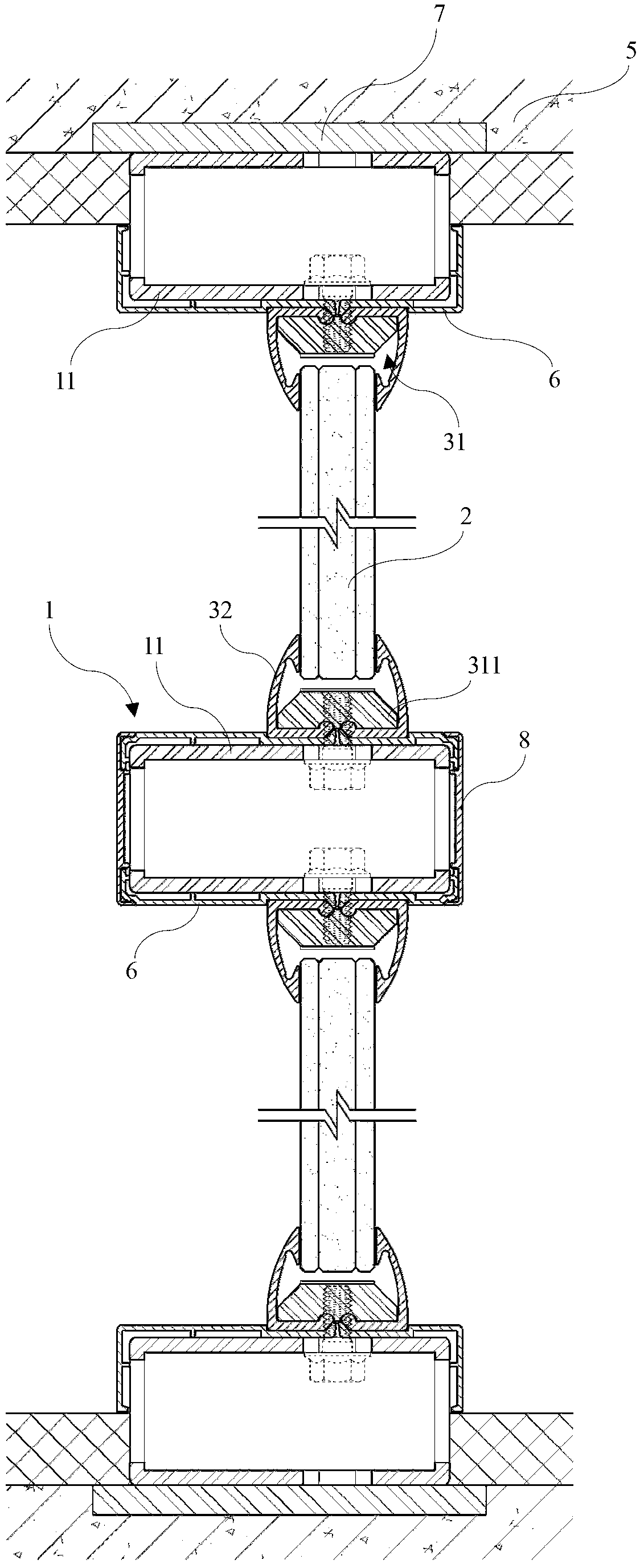

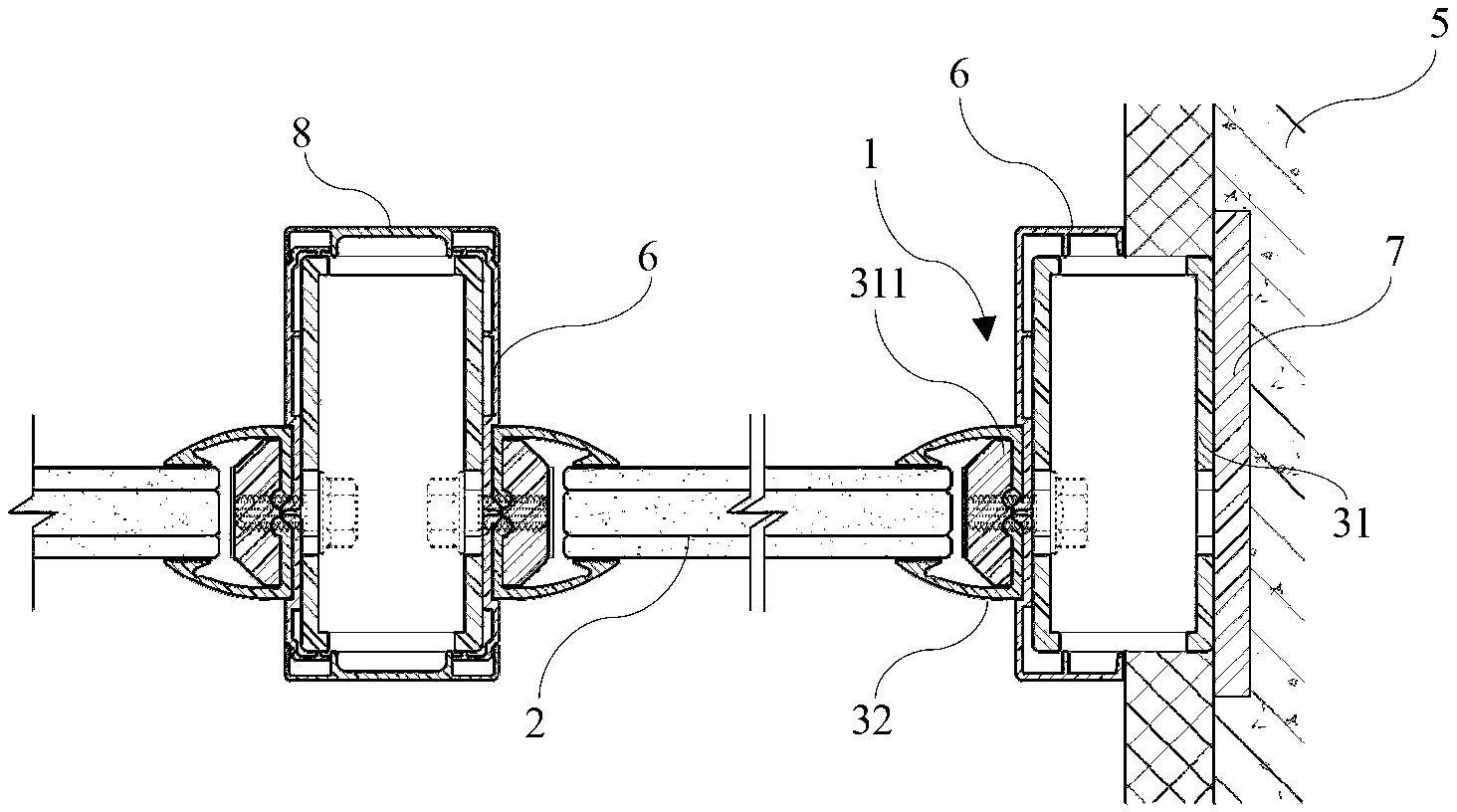

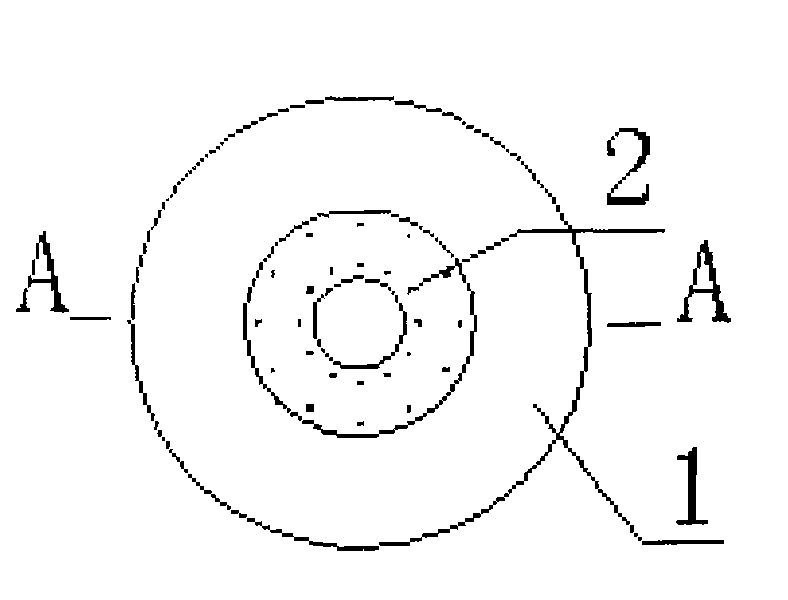

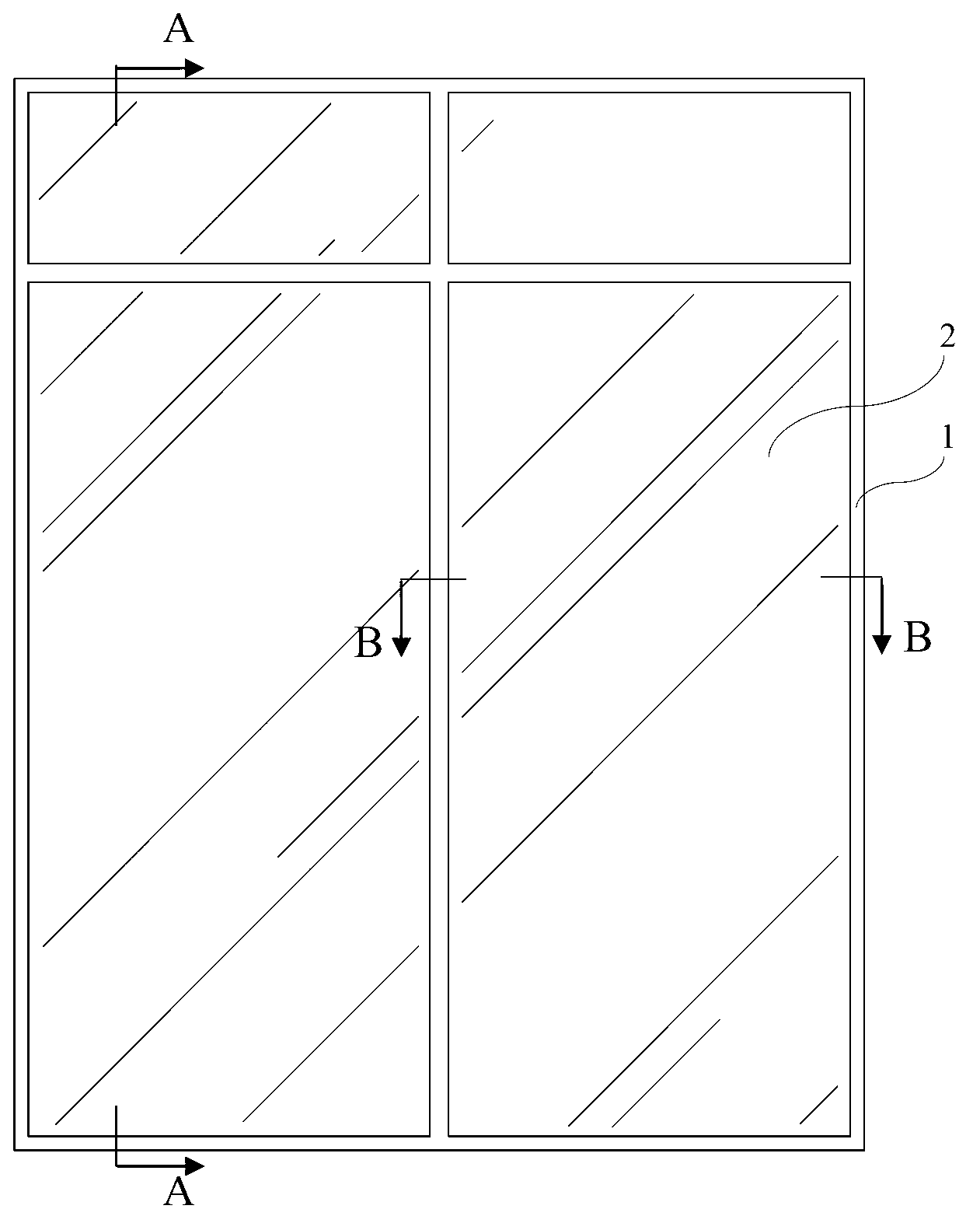

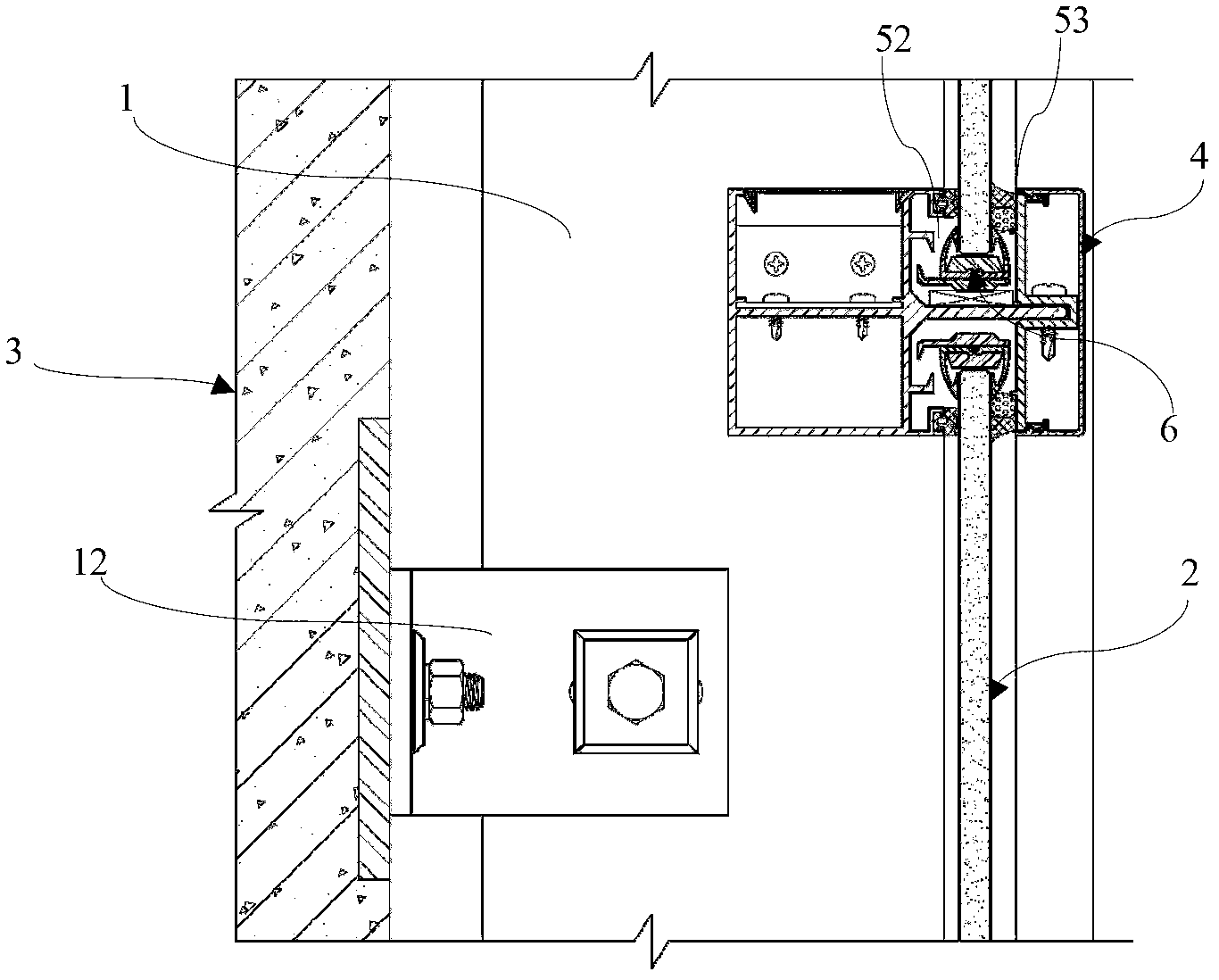

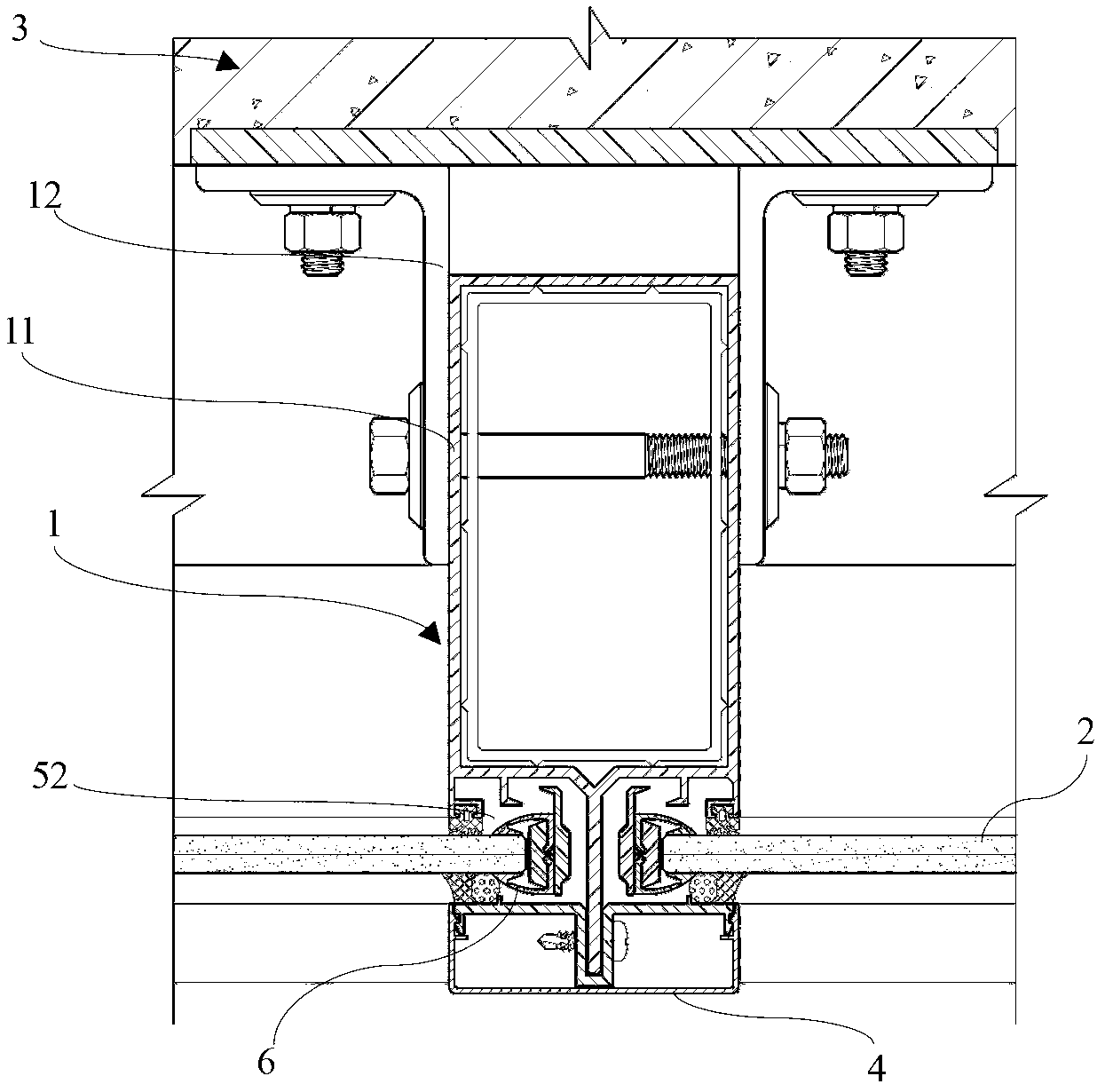

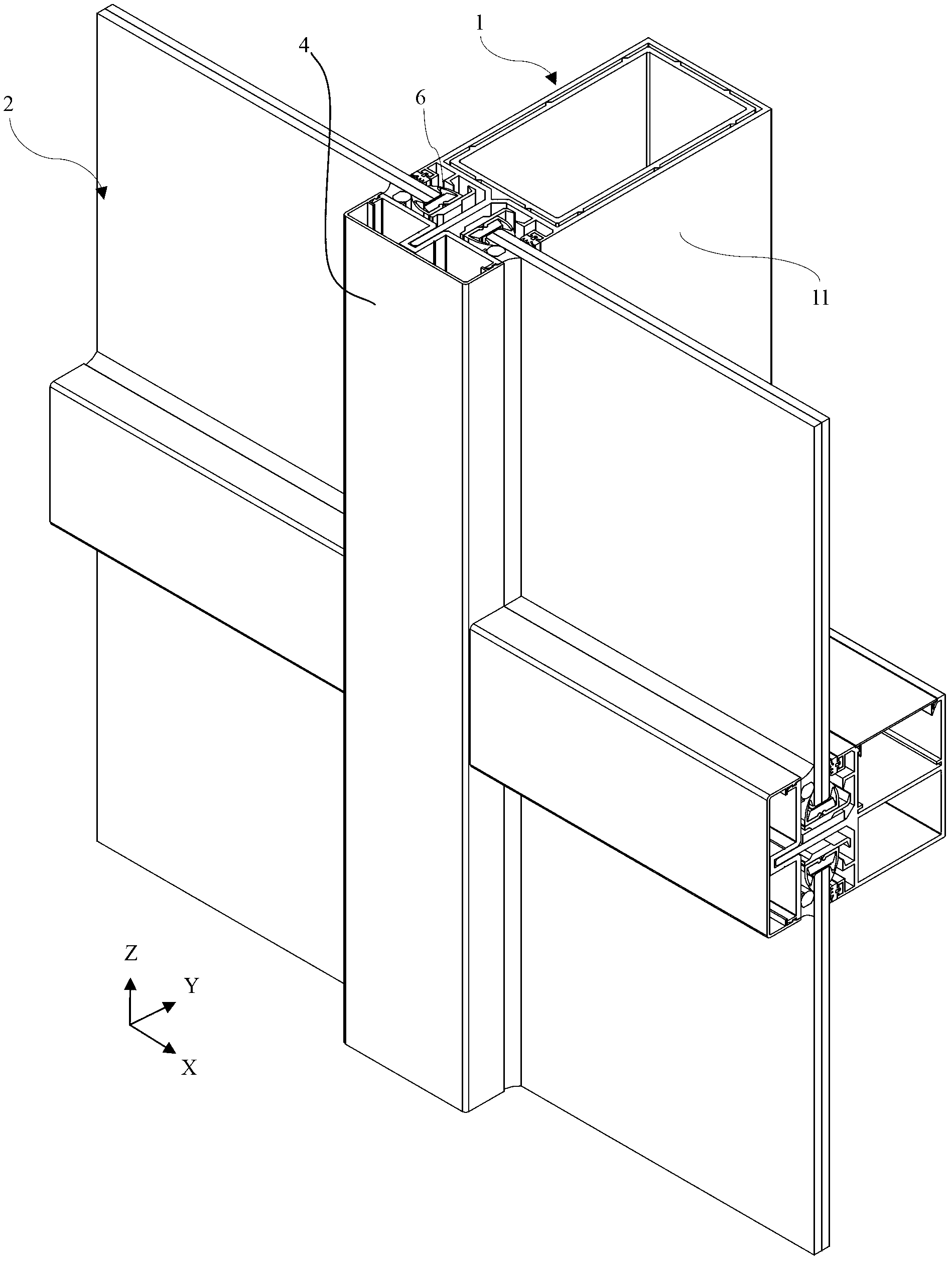

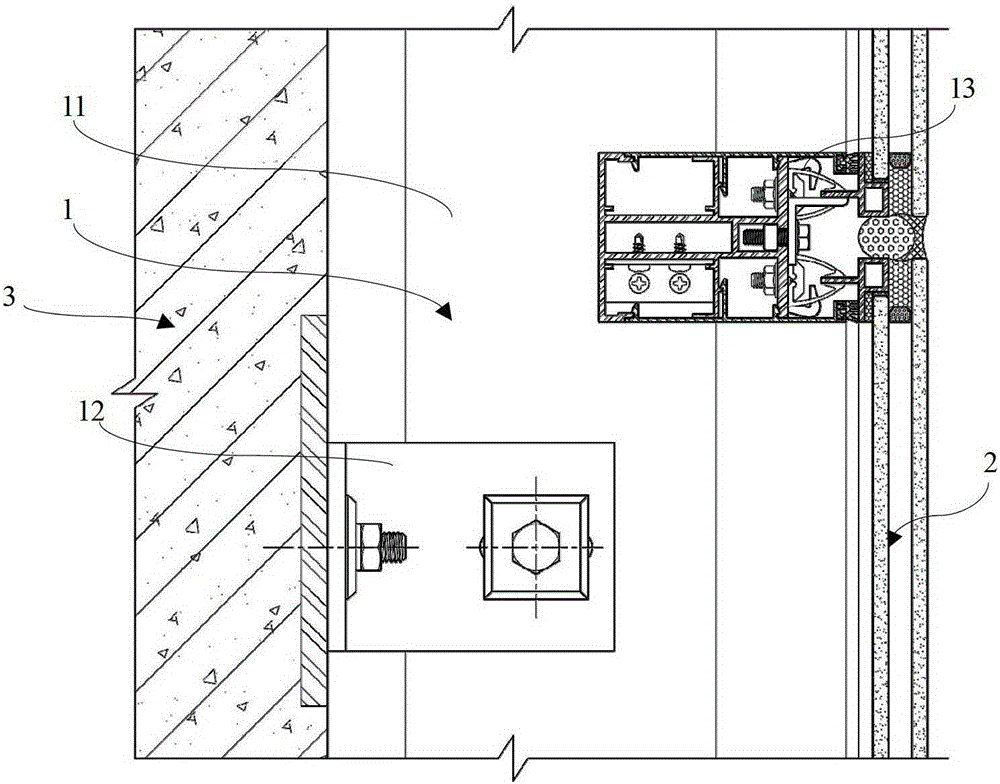

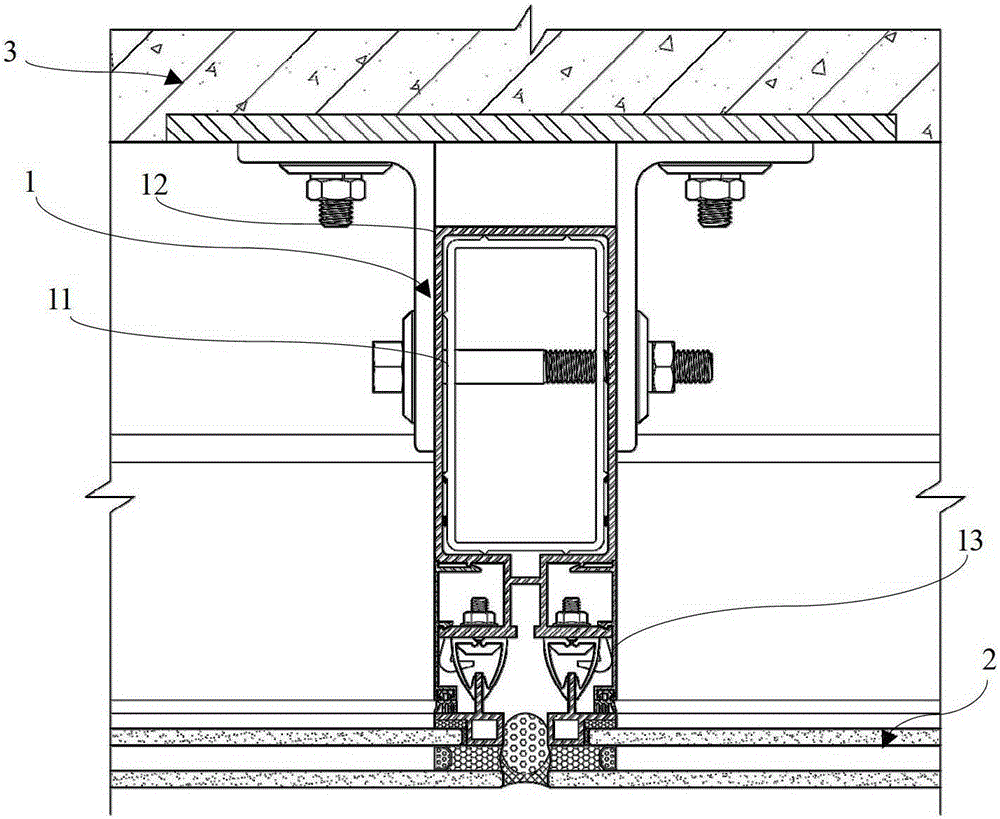

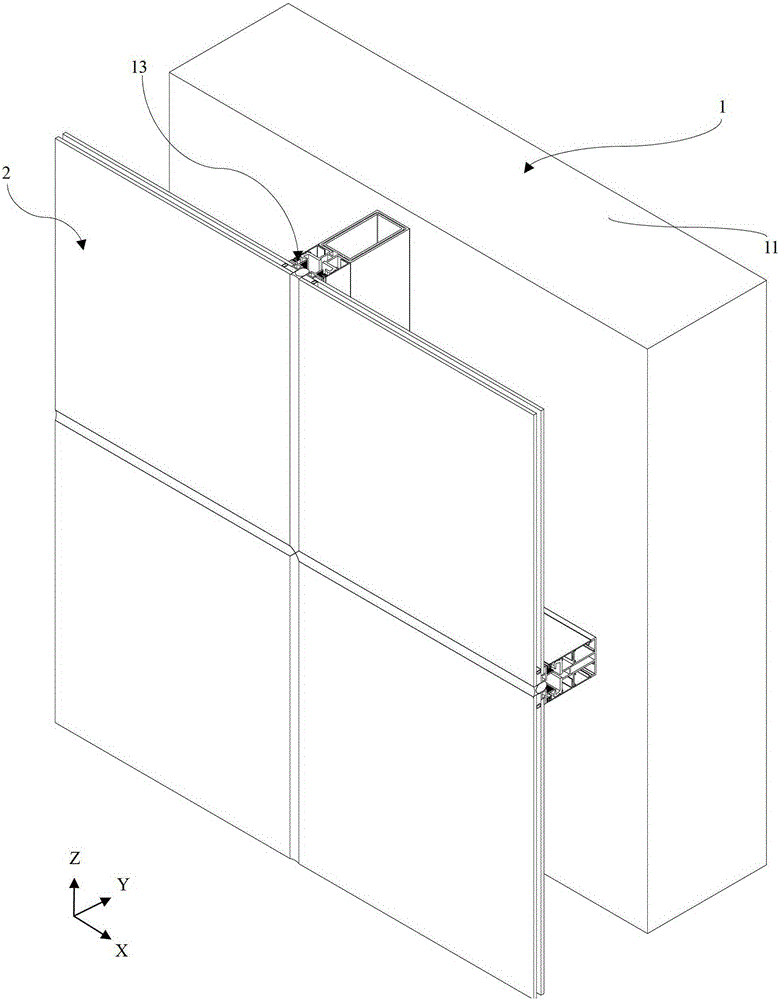

Hidden frame glass curtain wall installation structure and hidden frame glass curtain wall installation method

ActiveCN103306409AEffective prestressed fasteningMeet the requirements of installation accuracyCovering/liningsWallsChassisPrestressed structure

The invention discloses a hidden frame glass curtain wall installation structure which comprises a building main body and a glass curtain wall installed on the building main body, wherein the installation structure further comprises an installation chassis, the glass curtain wall is regulated through the installation chassis to a set position and is fastened, and the position of the glass curtain wall is unchanged in the fastening process. Due to the adoption of the hidden frame glass curtain wall installation structure, the hidden frame glass curtain wall installation structure exciting and controlling the dynamic production process of prestress of an elastic material to form a stable prestress structure and conducting three-dimensional regulation in the installation process to substantially improve the installation accuracy is provided, and the hidden frame glass curtain wall installation structure has the characteristics of excellent firmness, accuracy, safety, convenience and replacement.

Owner:明威科技集团股份有限公司

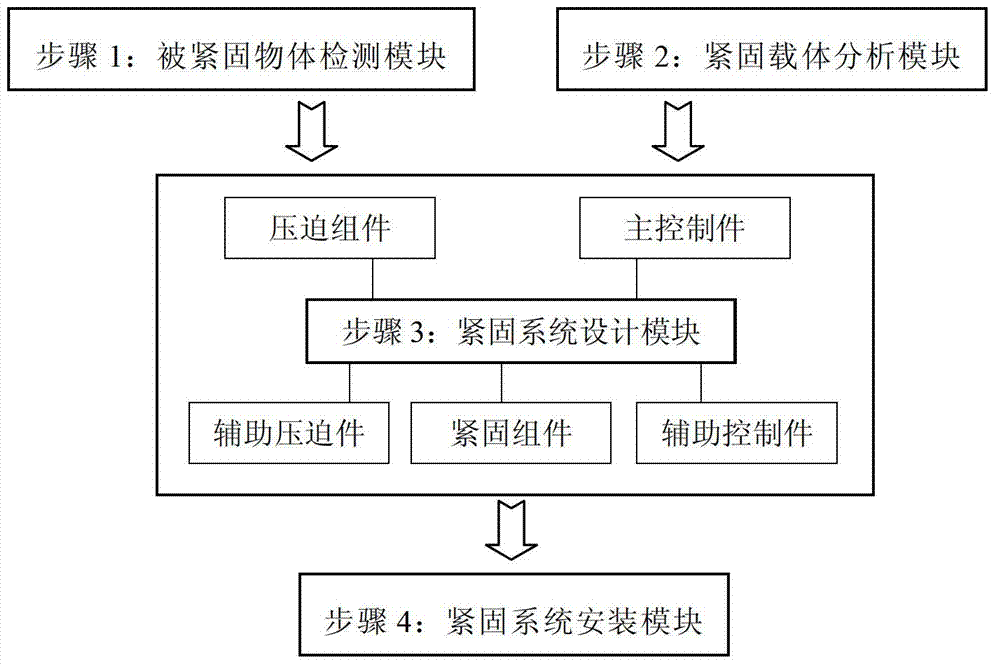

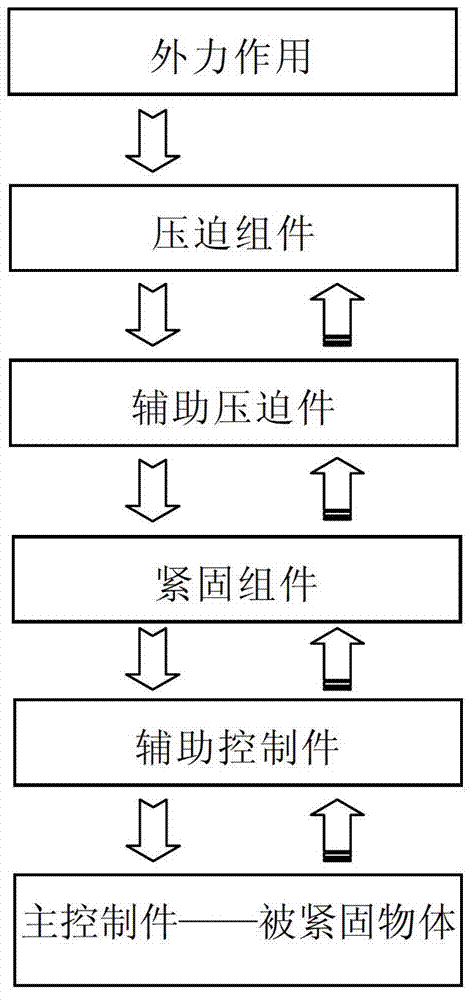

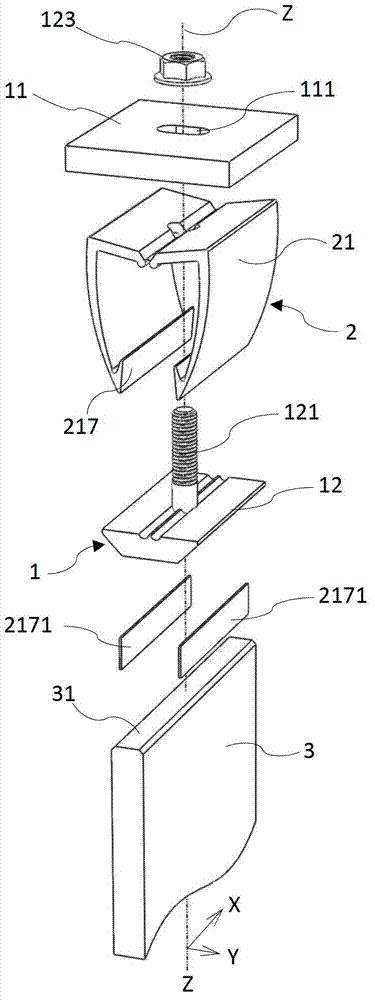

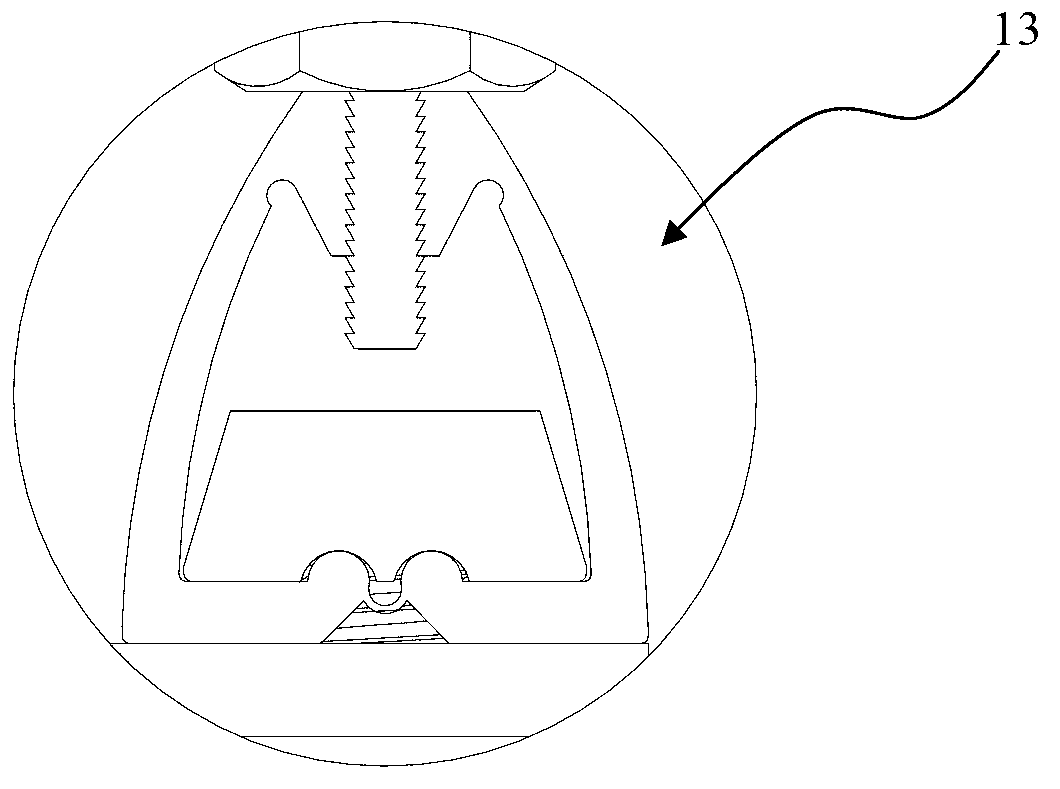

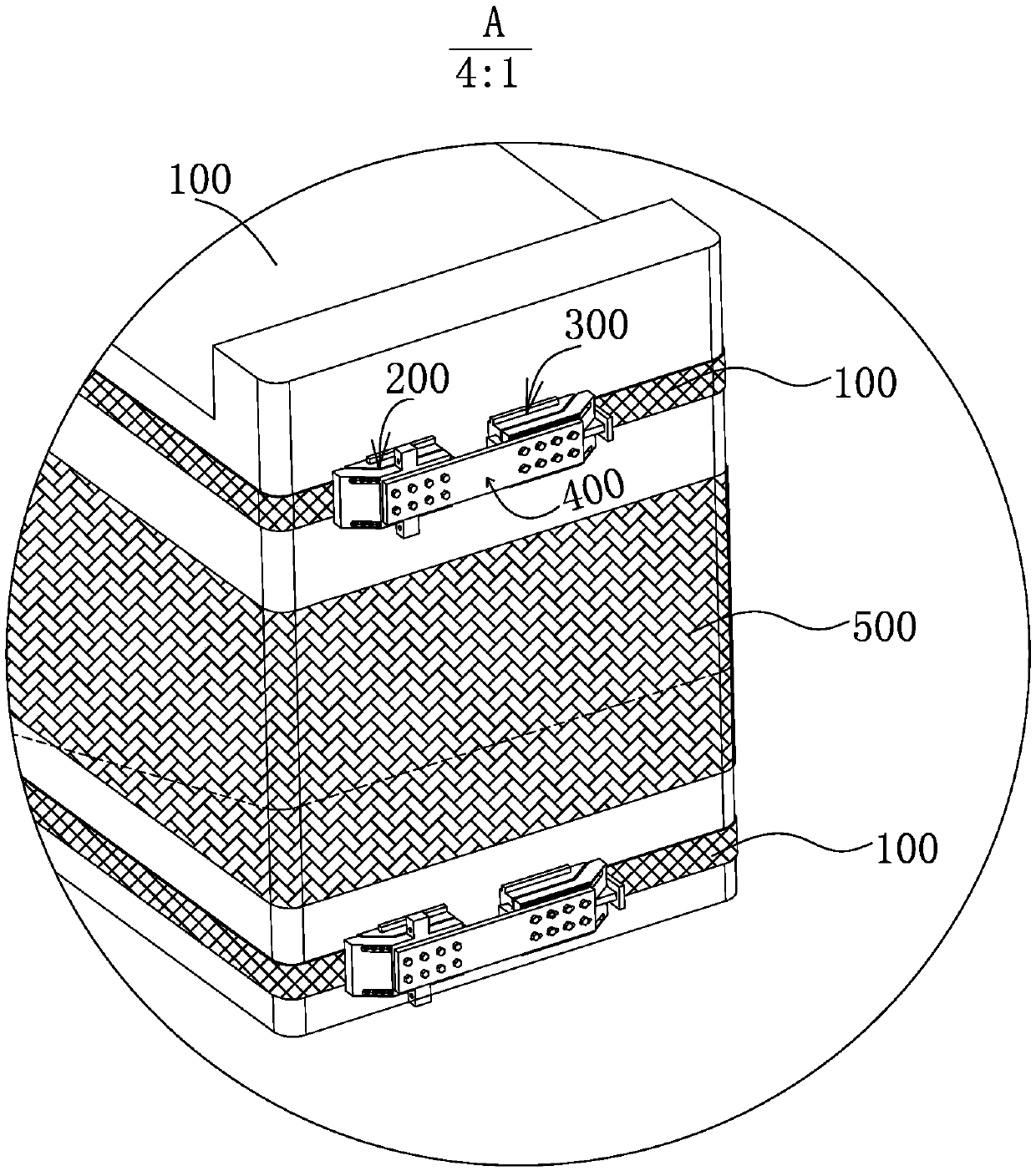

Fastening system

ActiveCN103243813ATo achieve fastening effectImprove smoothnessWallsBuilding material handlingPre stressEngineering

The invention discloses a fastening system which comprises a compression assembly, a fastening assembly and a fastened object. The compression assembly and the fastened object are matched with each other to compress the fastening assembly to generate prestressing force, so that the fastened object can be fastened. The fastening system has the advantages that the compression assembly and the fastened object are matched with each other to jointly compress the fastening assembly to generate the prestressing force, the fastened object becomes a main control part for generating the prestressing force, the fastening assembly is made of elastic materials, the stable prestressing force is formed inside the materials under the action of external force and is stored, and the fastening assembly, the fastened object and the compression assembly form a stable prestressing force system.

Owner:兴化市永正不锈钢制品有限公司

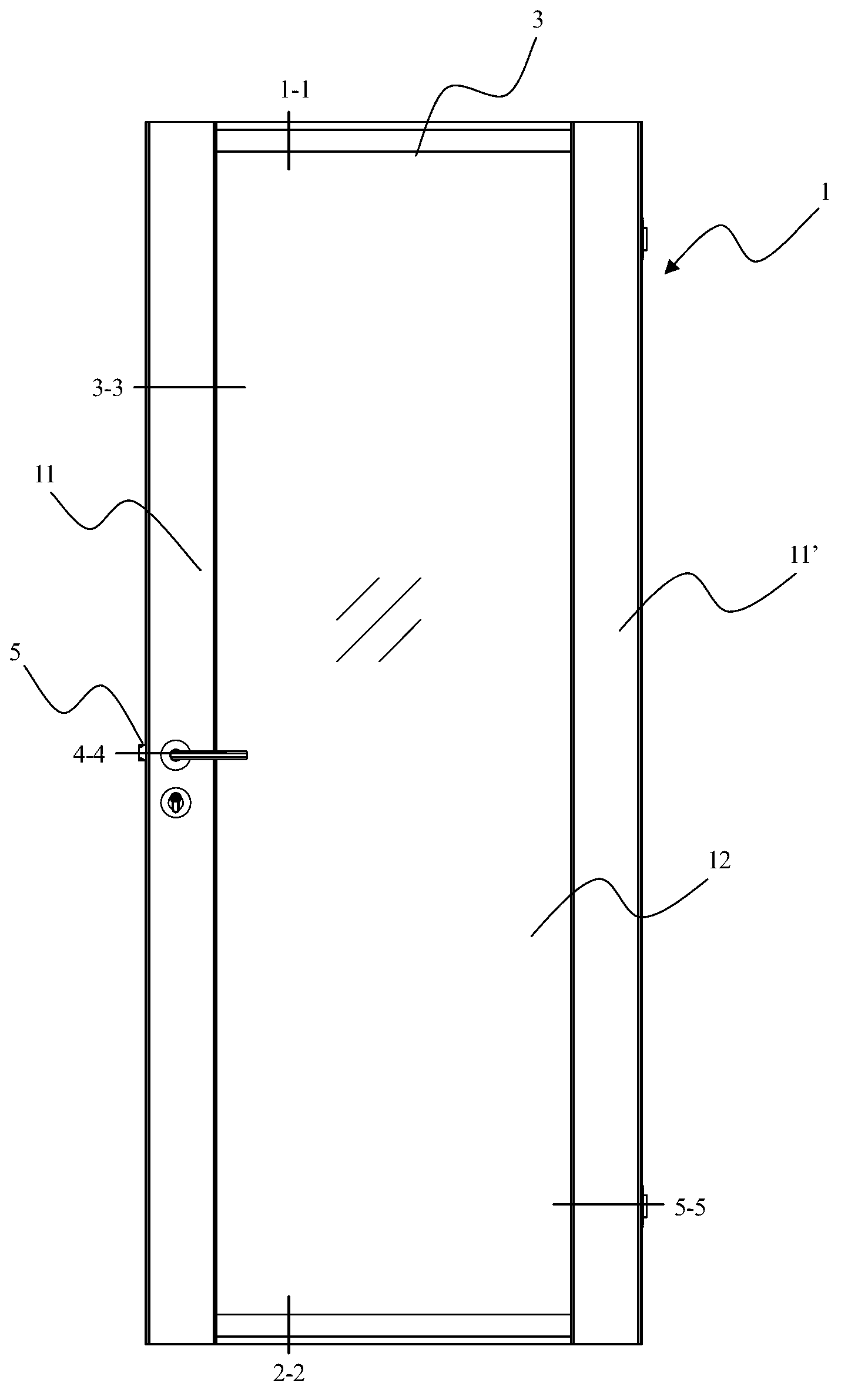

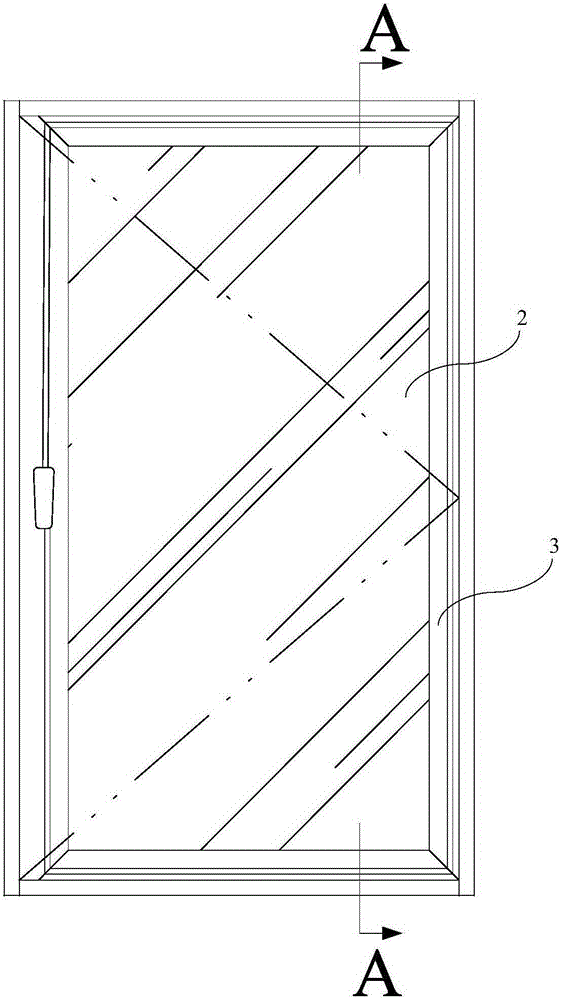

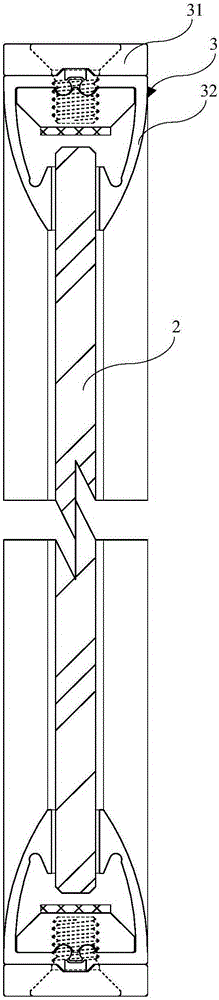

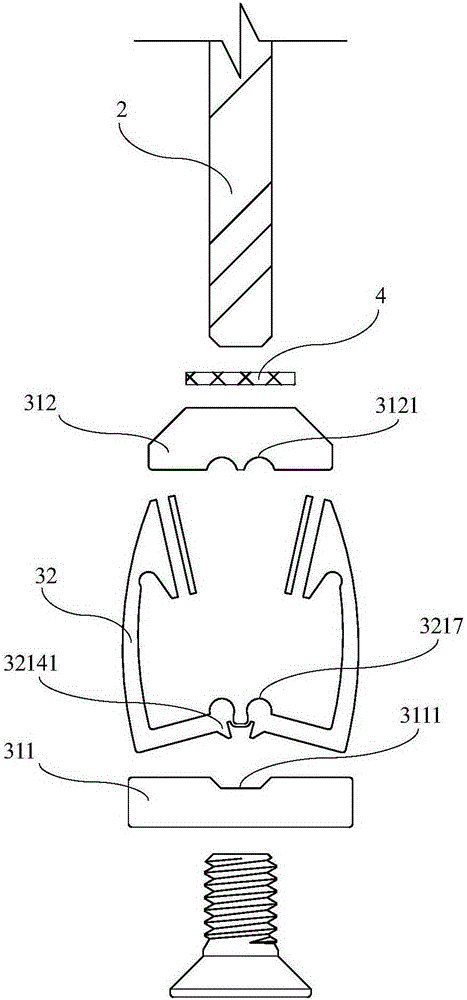

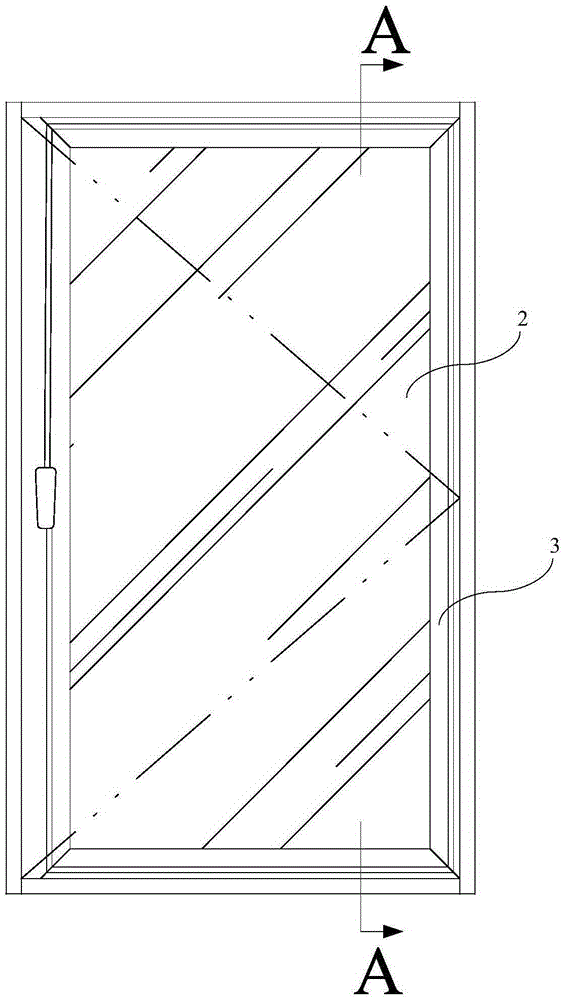

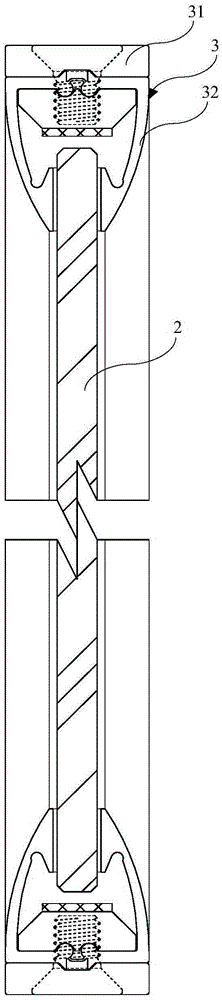

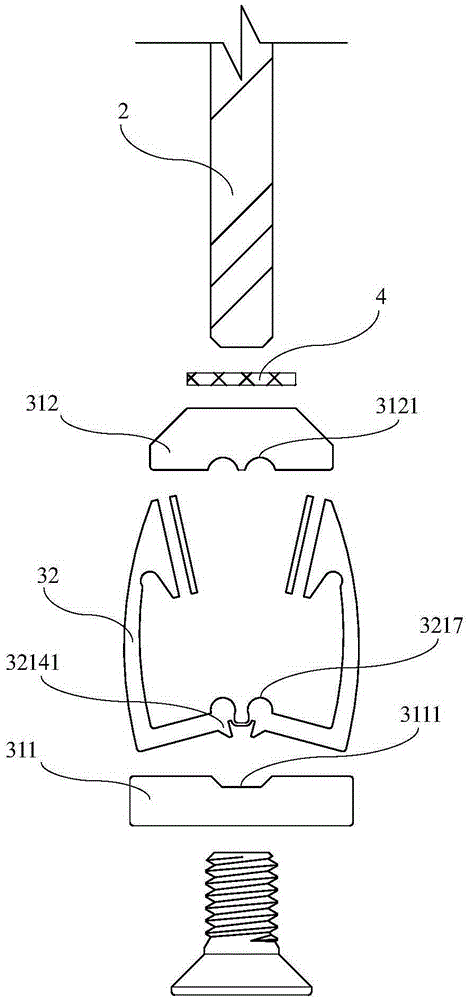

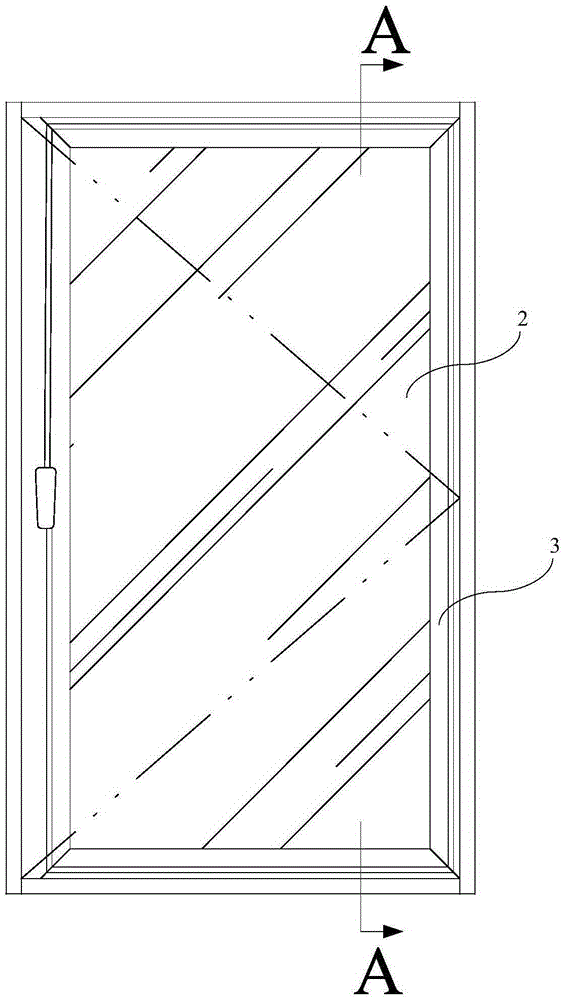

Glazed door window sash and assembly method thereof

ActiveCN103291195ATo achieve fastening effectImprove smoothnessGlass pane fixingDoor leavesEngineeringStructural stability

The invention discloses a glazed door window sash. The glazed door window sash comprises two side frames and a glazed door window sash body, a mounting component is combined at each of the top and the bottom of the glazed door window sash body, the glazed door window sash body is fixed between the two side frames through the mounting components, each mounting component comprises a pressing component and a fastening component, and the pressing components and the glazed door window sash body are matched to press the fastening components to generate prestress and further fasten the glazed door window sash body. The glazed door window sash has the advantages that the glazed door window sash body is fixed with the side frames through the prestress mounting components, and glass and a glazed door window sash frame form a rigid integral rather than an existing rectangular splicing structure, so that structural stability among the glazed door window sash body and the side frames is guaranteed, the problem of deformation of a door window sash connecting structure caused by self weight of the glazed door window sash body can be avoided, the problem of falling resulting from one-sided stress does not exist, and the glazed door window sash is safer in structure and more reasonable in stress.

Owner:山东东成玻璃科技有限公司

Mounting structure of anti-explosion glass curtain wall and curtain wall glass mounting method

ActiveCN103290960AReduce technical difficultyReduce operation links and contentWallsWar-like protectionPrestressed structureUltimate tensile strength

The invention discloses a mounting structure of an anti-explosion glass curtain wall. The mounting structure comprises a building body, curtain wall glass mounted on the building body and a mounting base plate, a decorating frame is covered on the outer wall surface of the curtain wall glass, the curtain wall glass is adjusted to a preset position via the mounting base plate and then fastened, the position of the curtain wall glass is not changed during fastening, and the decorating frame is fixed on the mounting base plate via a mounting piece. The curtain wall glass with edges covered by a prestressed structure is firmly fastened via a stand column and crossbeam frame, and in case of glass crushing or deformation caused by impact, and the glass cannot be integrally separated from the stand column and crossbeam frame, so that anti-explosion and separation functions are effectively realized, and indoor persons are protected to the greatest extend; since profile steel serving as the stand column and crossbeam frame is adopted to replace an existing aluminum profile frame, strength and rigidity of a whole curtain wall bearing system are greatly enhanced, and the anti-explosion glass curtain wall structure is stronger in capability for bearing impact loads from explosion and the like and good in safety performance.

Owner:珠海博曼建筑科技有限公司

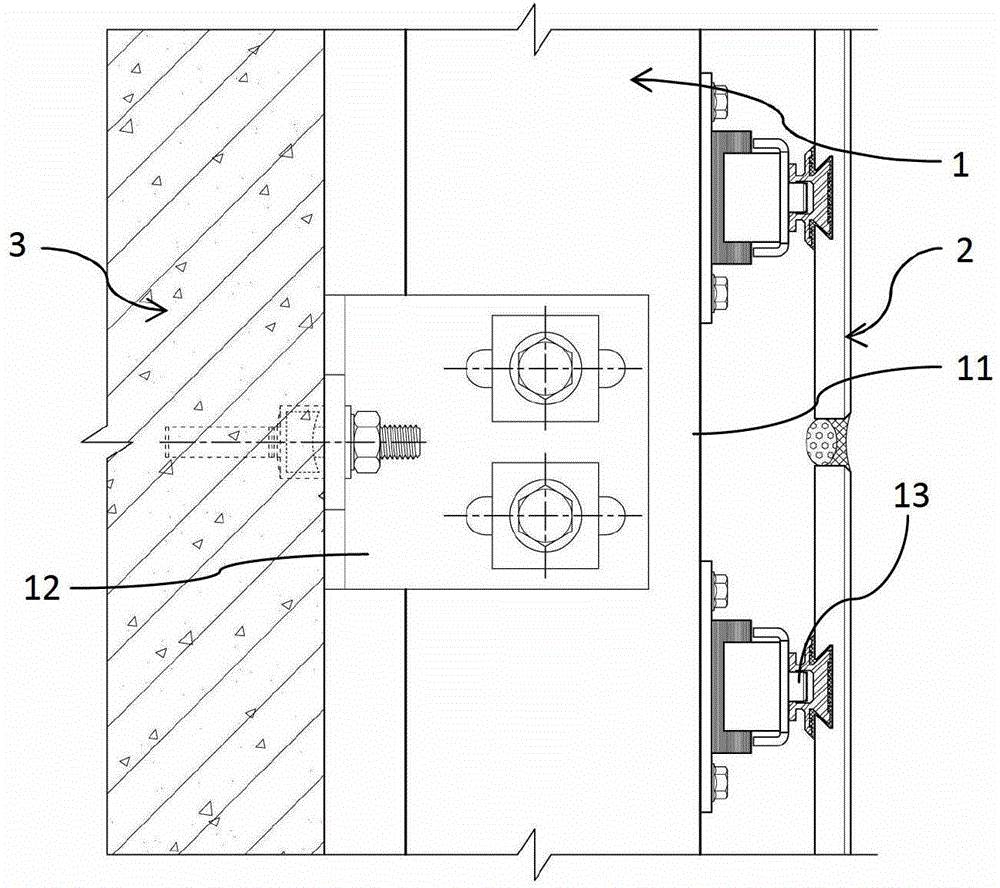

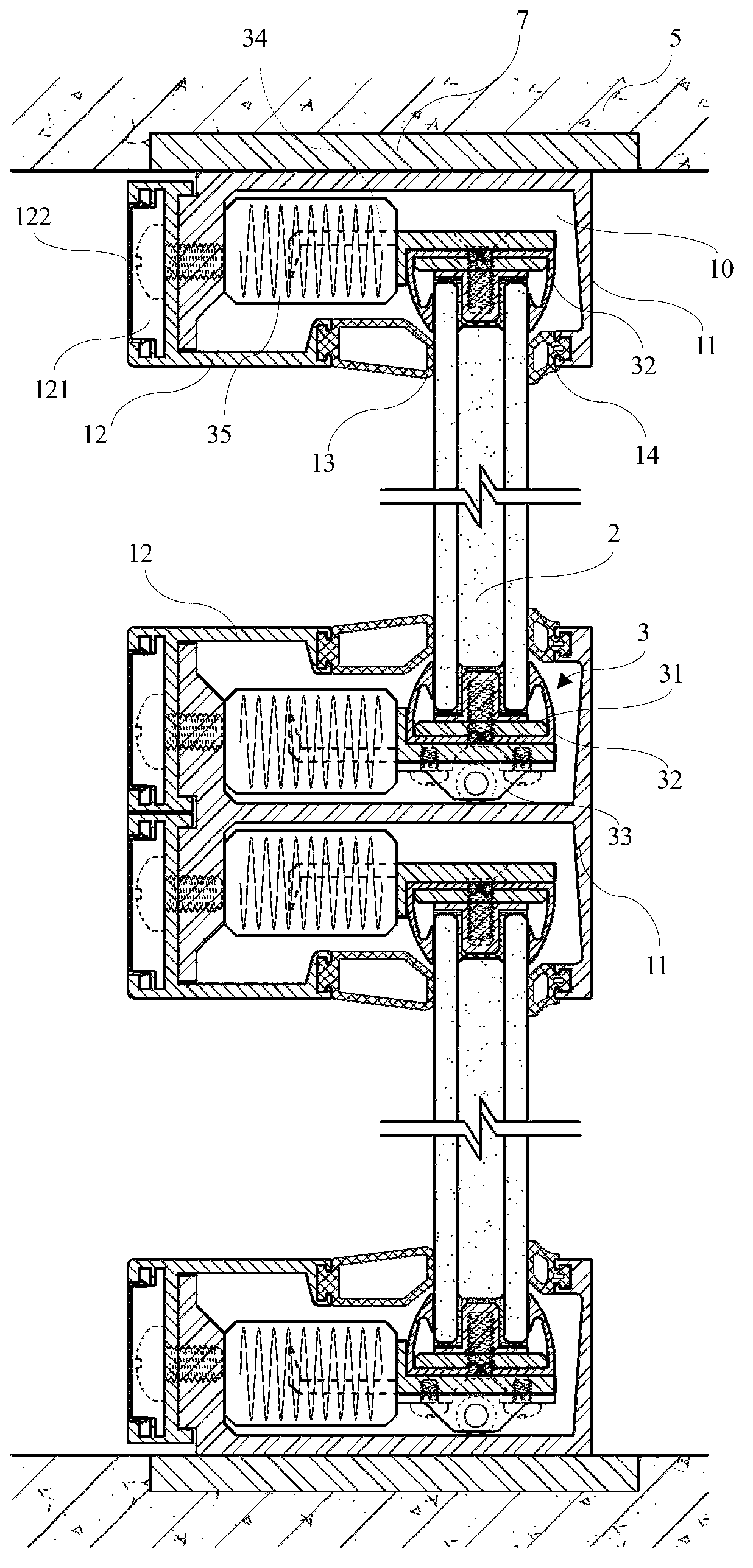

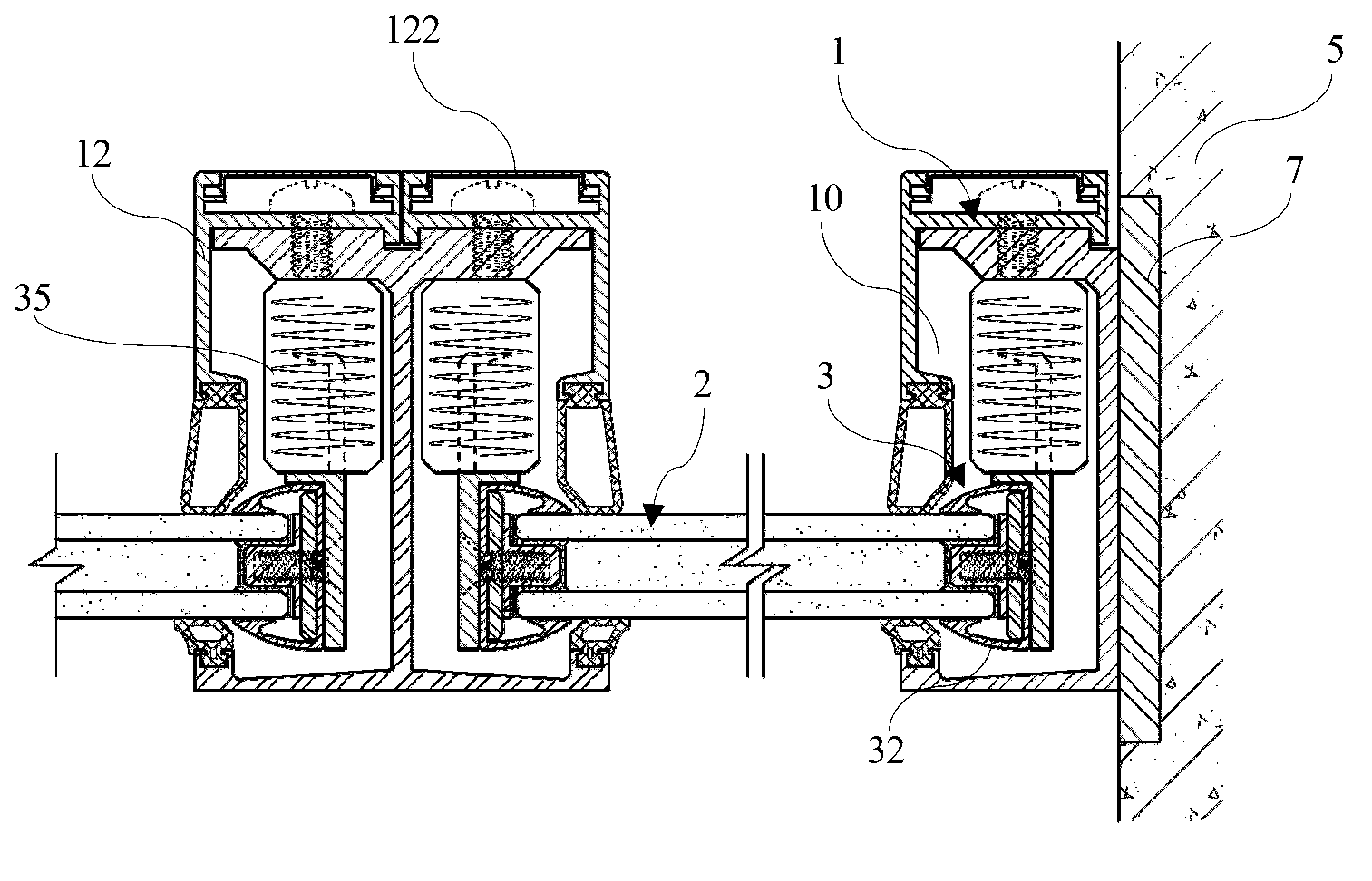

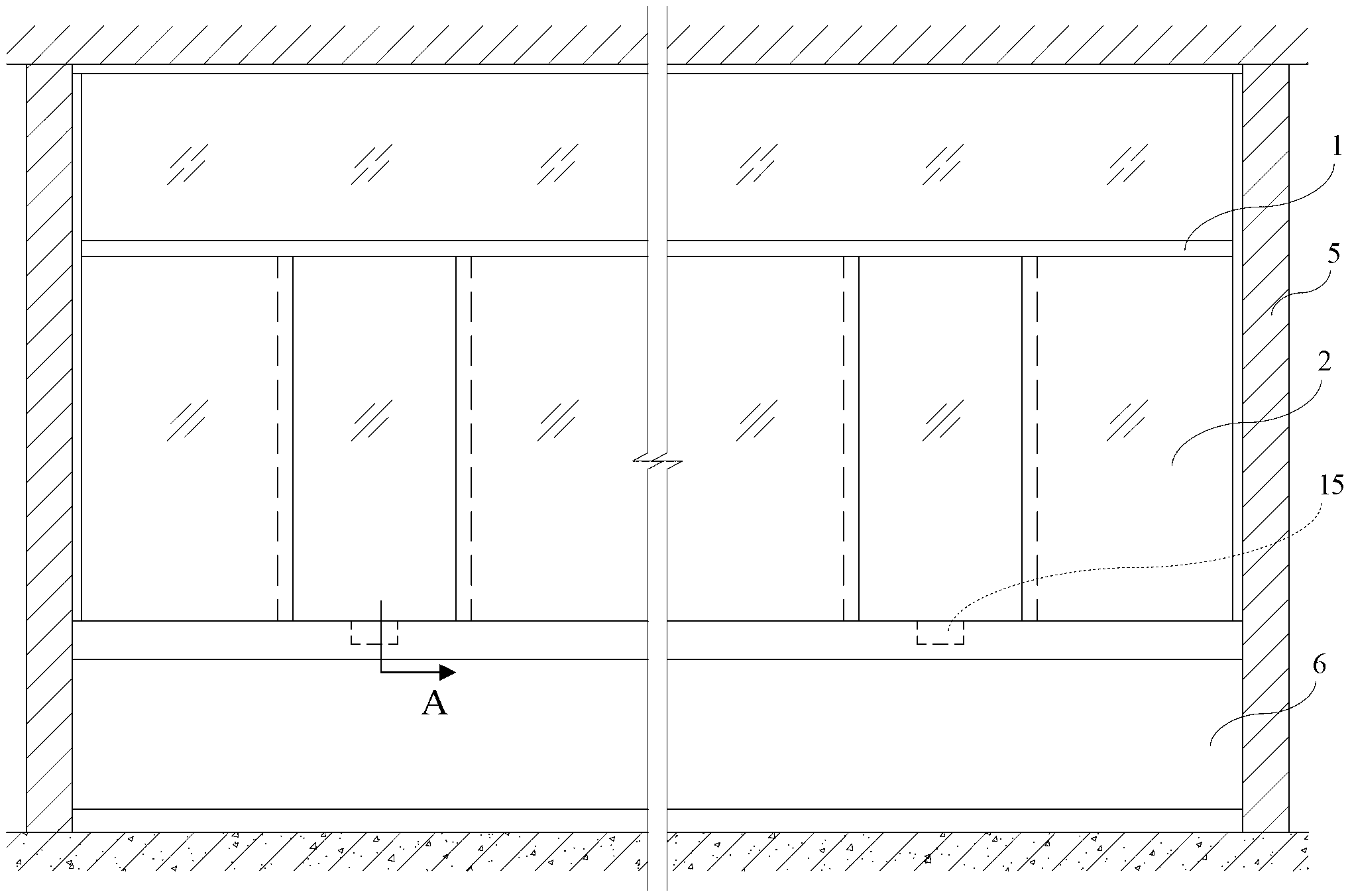

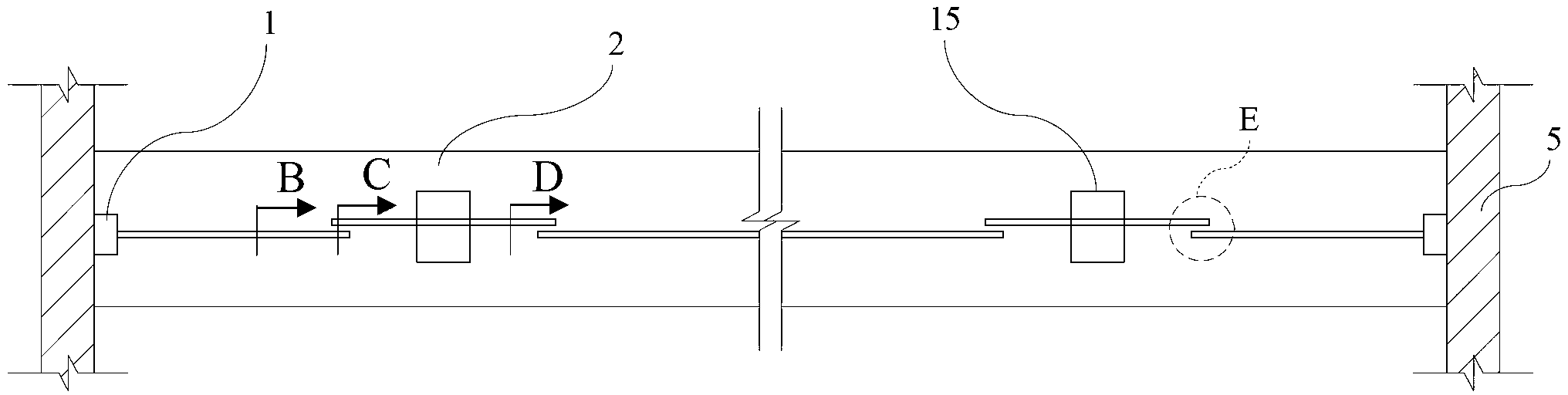

Hanging structure of glass curtain walls and method for installing glass curtain walls

InactiveCN103290961AStrong prestressStable characteristicsWallsBuilding material handlingPre stressEngineering

The invention discloses a hanging structure of glass curtain walls. The hanging structure comprises a plurality of glass curtain walls, the tops of the glass curtain walls are hung on an upper building body, and the bottoms of the glass curtain walls are fixed on a lower building body. Each glass curtain wall is hung on the upper building body through one fastening system comprising one oppression component and one fastening component, and the oppression component is matched with the glass curtain walls to oppress the fastening component to generate prestressing force to have the glass curtain walls fastened. According to the arrangement, the oppression component is matched with the glass curtain walls to oppress the fastening component together to generate the prestressing force, so that the glass curtain walls turn out to be master parts of the generated prestressing force; the fastening component is made of elastic materials, so that under the action of external force, the stable prestressing force are formed inside the elastic materials and stored, and constitutes a stable prestressing force system together with the glass curtain walls and the compression component.

Owner:湘西自治州兄弟玻璃有限公司

Stone installation structure and method for installing stone

InactiveCN103362283AEnhanced security and convenienceStrong prestressCovering/liningsPrestressed structureGeneration process

The invention discloses a stone installation structure, which comprises a building main body and stone installed on the building main body. The stone installation structure is characterized in that the installation structure also comprises a plurality of installation units mutually independent; the stone is adjusted to a setting position by the installation units and is fastened, and moreover, the position of the stone is not changed during a fastening process. As the stone installation structure disclosed by the invention is adopted, stimulation and control are provided for the dynamic generation process of the prestress of an elastic material to form a stable prestressed structure, and three-dimensional adjustment can be performed during an installation process, and therefore, the installation accuracy of the stone is greatly improved. The stone installation structure has the characteristics that the firmness, the accuracy and the safety degree are high and the convenience and the changeability are good.

Owner:YIHE TECH DEV SHANGHAI

Anti-riot transparent door and window structure and method for mounting glass by adopting same

ActiveCN103306587AImprove physical performanceImprove securitySafety transaction partitionSealing arrangementsElectrical and Electronics engineering

The invention discloses an anti-riot transparent door and window structure. The anti-riot transparent door and window structure comprises a mounting frame and a glass fixed inside the mounting frame, wherein the glass can be bullet-proof glass or anti-riot glass as needed; a lap of anti-escape frame is arranged on the periphery of the glass; and the glass is fixed onto the mounting frame through the anti-escape frame, so that the whole glass is prevented from being separated from the mounting frame under the impact of external forces, and the safety of the anti-riot transparent door and window structure is greatly increased. According to the anti-riot transparent door and window structure provided by the invention, an oppressing component and the glass are matched with each other to oppress the fastening component to generate prestress; the glass becomes a main control piece to generate the prestress; the fastening component is made of elastic material; under the action of external forces, stable prestress is formed inside the material and is stored; and the fastening component, the glass and the oppressing component together form a stable prestress system.

Owner:镇升玻璃制品(中山)有限公司

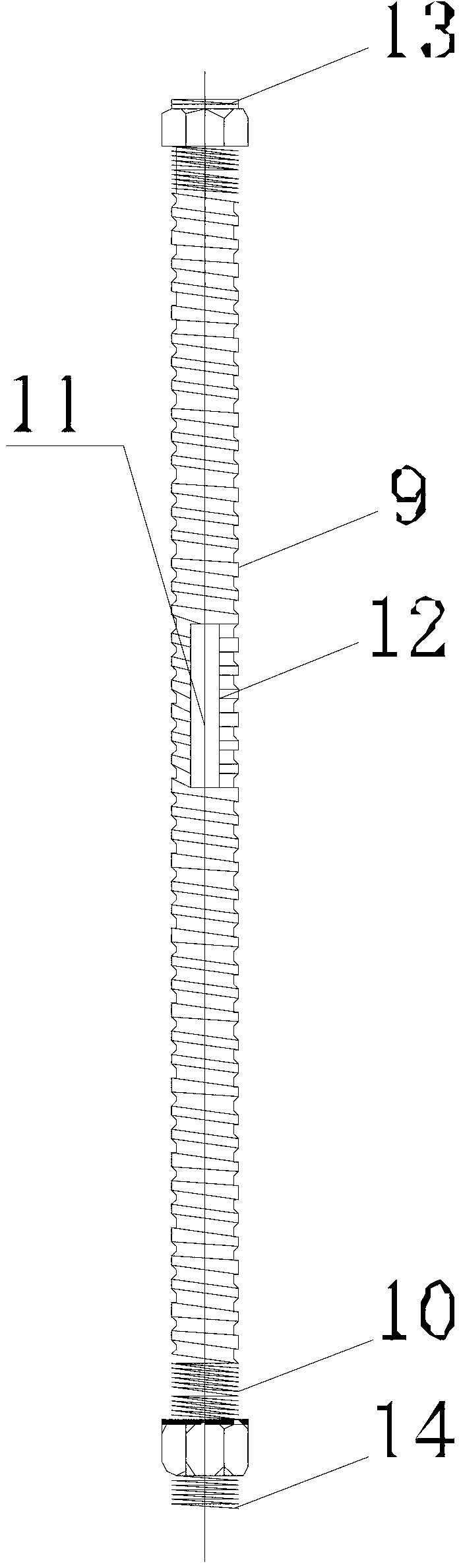

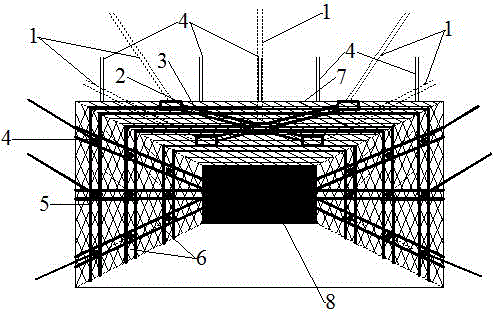

Roadway total-space prestress truss, anchor cable and anchor rod coordinated supporting method

InactiveCN104533483AControl deformation damageImprove stabilityAnchoring boltsSupporting systemPre stress

The invention belongs to the field of mine disaster prevention and control safety, and particularly relates to a roadway total-space prestress truss, anchor cable and anchor rod coordinated supporting method. Top plate truss anchor cables in a roadway total-space prestress truss, anchor cable and anchor rod support can penetrate into a coal roadway top deep stable rock stratum, high prestress is formed, side anchor rods can stretch into a deep roadside position and fixed through rebars, high prestress is formed, top plate anchor cable trusses and roadside anchor rod trusses which have different sections are connected through rebar belts, a space supporting system is formed, the synergistic effect can be achieved through the space structure, the anchor rods, the anchor cables and the rebar belts bear continuous load transmission, deformation and breakage of surrounding rock of a roadway are effectively controlled, the self-supporting capacity and the stability of the whole surrounding rock are improved, and therefore reinforcement and stabilization of the roadway are superior to those of other methods. The construction process of the total-space prestress trusses, anchor cables and anchor rods is easier and more convenient compared with that of U-shaped steel and concrete filled steel tube supporting and the like, erection labor intensity is greatly relived, the safety operation degree is increased, rolled steel is saved, and cost is reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

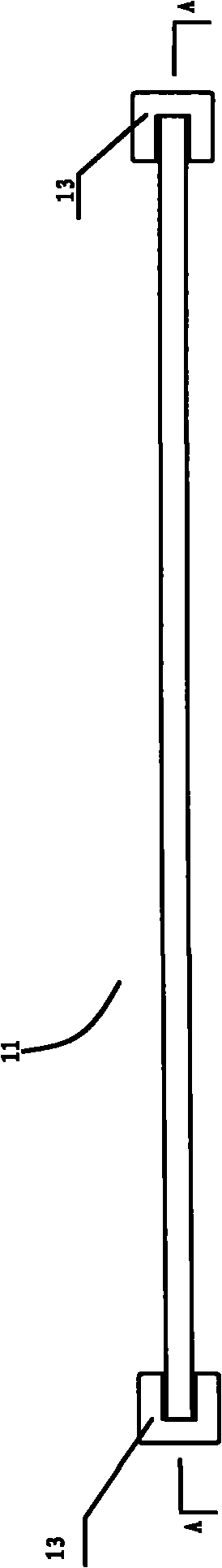

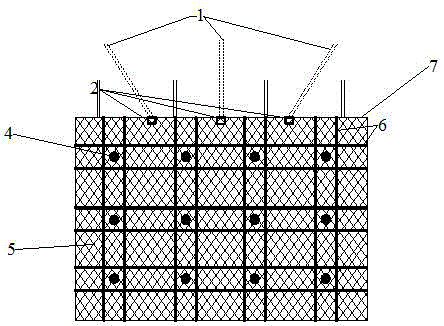

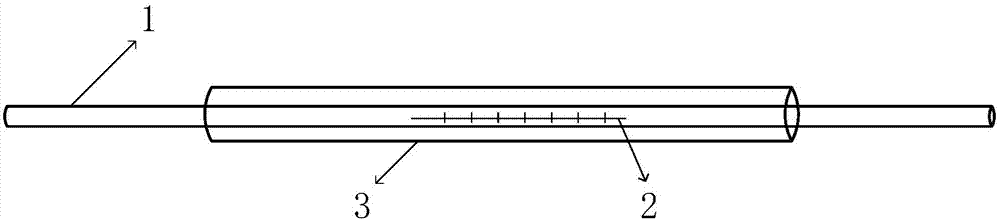

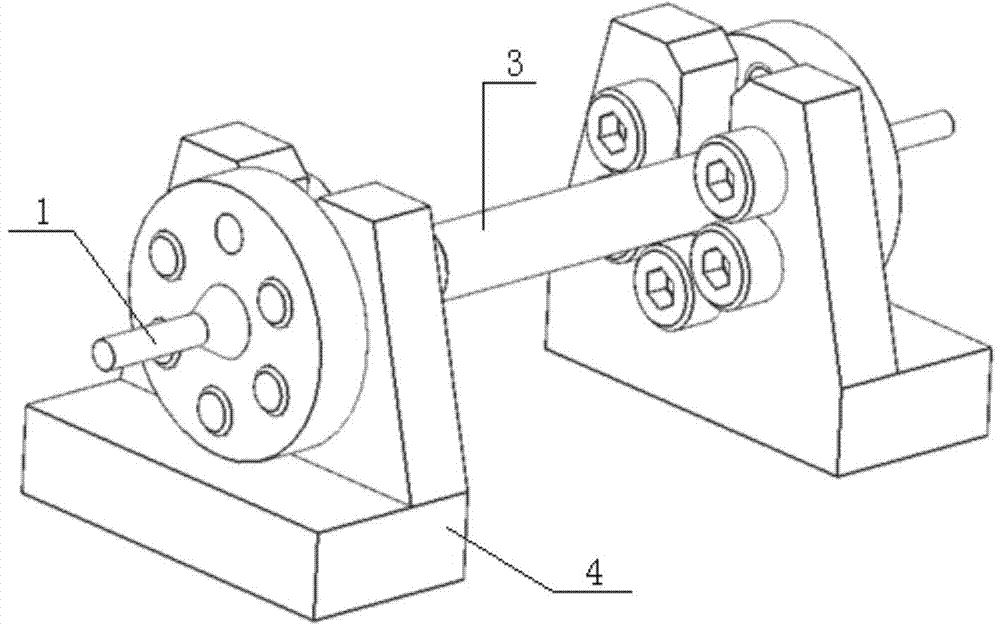

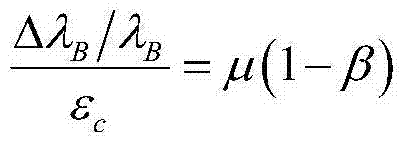

Split type optic fiber strain sensor assembly

InactiveCN104279974AEasy installation and layoutEasy to reuseUsing optical meansGratingUltrasonic welding

The invention provides a split type optic fiber strain sensor assembly. Under the premise that fiber bragg grating prestressed encapsulation is not influenced, an encapsulation mode and an assembling mode are decoupled, and the problem that a sensor cannot be used again after being mounted once is solved through separation of a metal encapsulation protection piece and an assembling base. The split type optic fiber strain sensor assembly comprises a sensing element, the encapsulation protection piece and the assembling base. The sensing element is a fiber bragg grating, and the encapsulation protection piece is a metal tube. After the fiber bragg grating penetrates through the mental tube, the clearance between the fiber bragg grating and the metal tube is welded and fastened in an ultrasonic welding mode. Optical fibers are led out from the two ends of the metal tube. The two ends of the metal tube are banded tightly through flange plates. The metal tube with the encapsulated sensing element is supported by the assembling base, and the flange plates at the two ends of the metal tube are connected with the assembling base.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

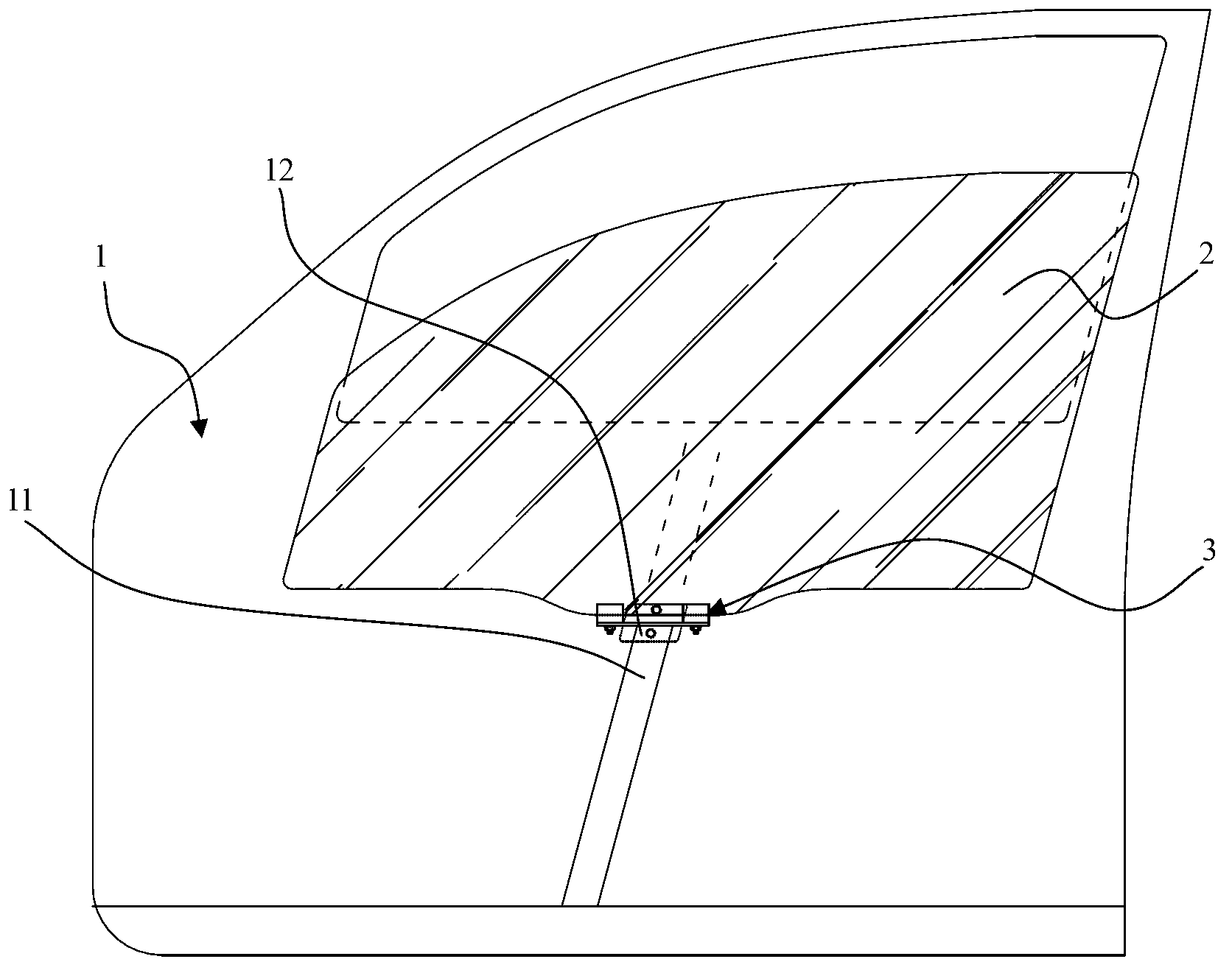

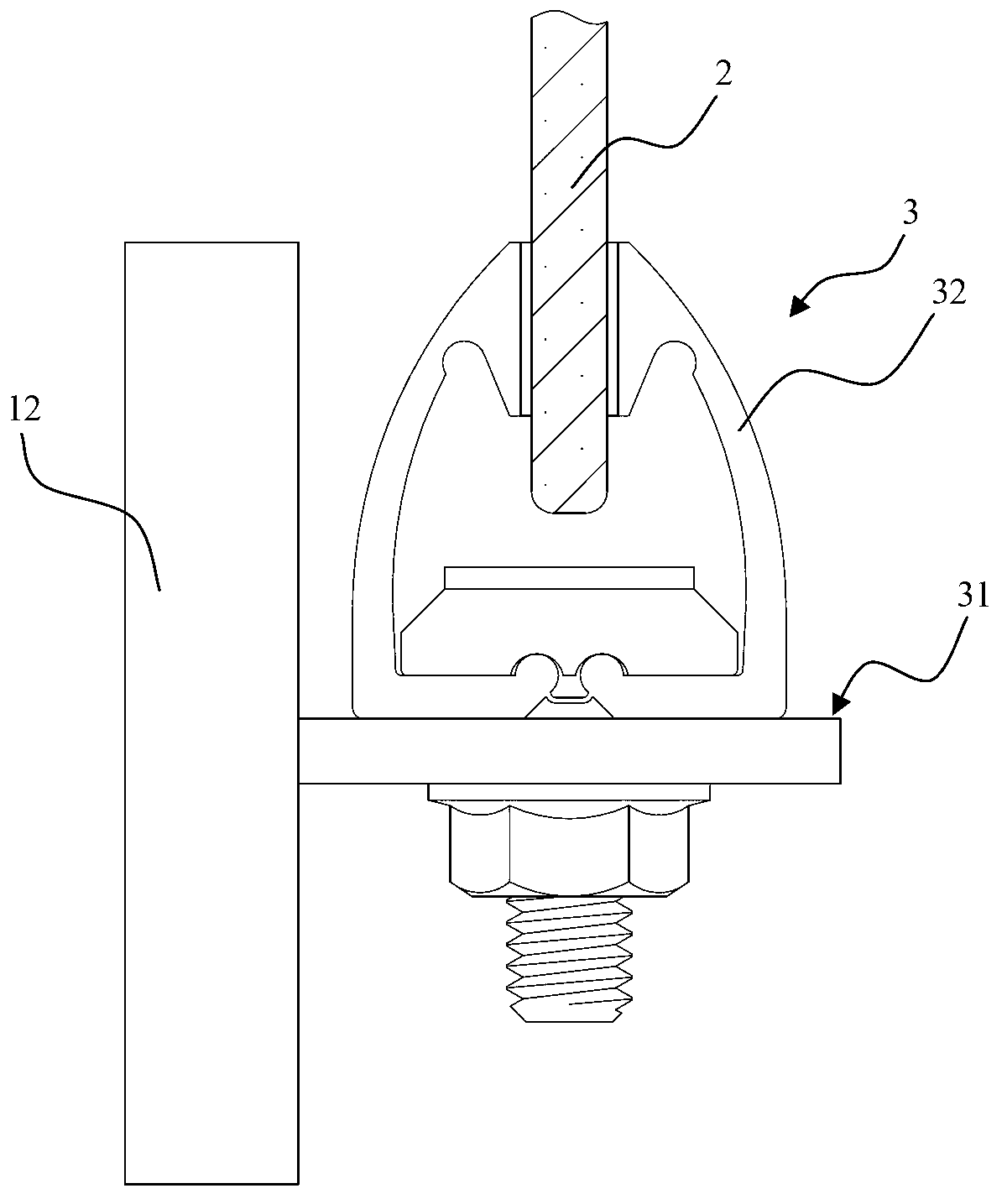

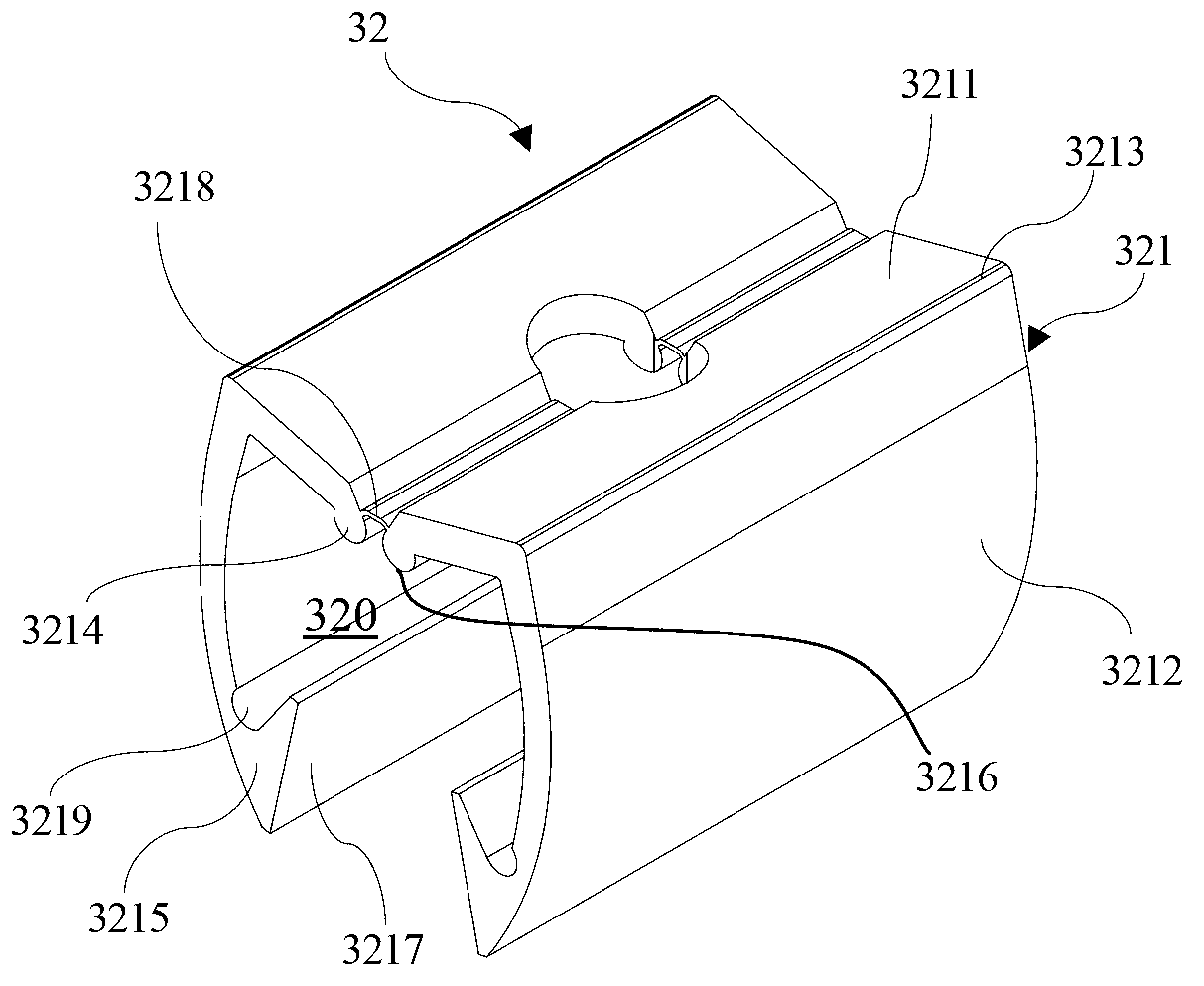

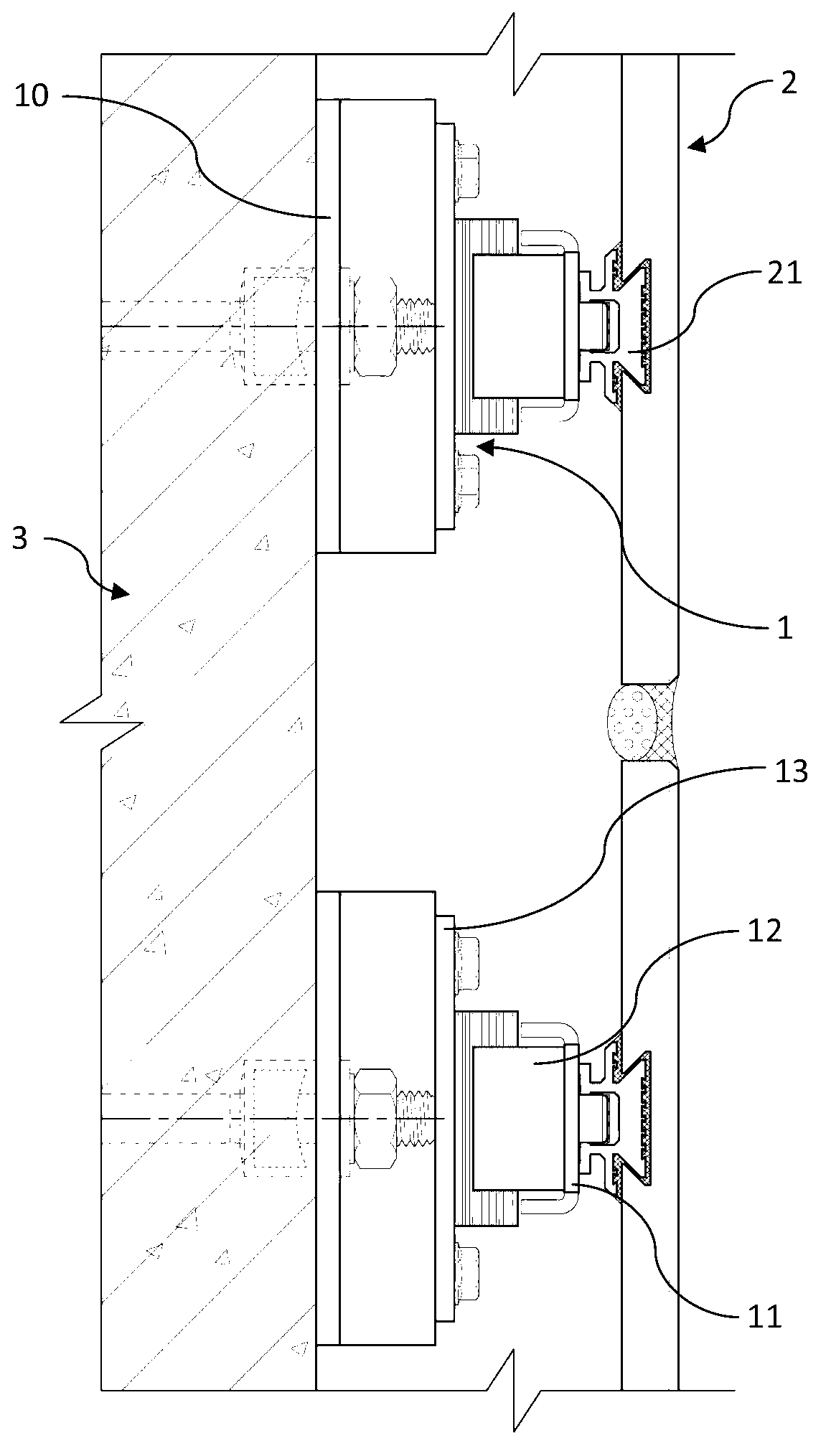

Mounting structure for car door glass tightening and method for mounting car door glass

ActiveCN103303105ATo achieve fastening effectImprove smoothnessWindowsWindscreensPre stressPre stressing

The invention discloses a mounting structure for car door glass tightening, which comprises a car door glass body, wherein the car door glass is movably arranged on a car door through a moving device on a car window track; the car door glass body is fixed on the moving device through a tightening system; the tightening system comprises an oppressing component and a plurality of tightening components; and the tightening components are oppressed through the match of the oppressing component with the car door glass body to generate a pre-stressing force to tighten the car door glass body. In the mounting structure for the car door glass tightening provided by the invention, the tightening components are oppressed through the match of the oppressing component with the car door glass body together to generate the pre-stressing force; the car door glass body becomes a main control element to generate the pre-stressing force; the tightening components are made of elastic materials; and under the action of external forces, a stable pre-stressing force is formed at the inner part of the materials and stored to form a stable pre-stressing force system with the car door glass body and the oppressing component together.

Owner:WM MOTOR TECH GRP CO LTD

Wall brick installation structure and wall brick installation method

ActiveCN103343604AStrong prestressStable characteristicsCovering/liningsPrestressed structureInternal stress

The invention discloses a wall brick installation structure which comprises a building body and wall bricks installed on the building body. The wall brick installation structure is characterized by further comprising multiple installation units which are independent from one another. The wall bricks are adjusted to be at set positions and fastened through the installation units, and the positions of the wall bricks do not change in the fastening process. By means of the wall brick installation structure, stimulation and control of the dynamic generation process of the prestress of elastic materials are provided, a stable prestress structure is formed, and three-dimensional adjustment can be conducted in the installation process so that the installation accuracy of the wall bricks is improved substantially. The wall brick installation structure has the advantages of good firmness, safety, convenience and easy replacement. In the fastening process, the wall brick installation structure cannot cause irregular compression on the wall bricks, therefore, damage to existing flatness and self-balanced internal stress of the wall bricks is avoided, wherein the damage is caused by component errors, installation carrier errors, the errors of the wall bricks, workpiece displacement and other factors, and the safety and the capability for resisting external force of a whole wall brick structure are enhanced.

Owner:贵州建工安顺建筑工程有限公司

Wall brick installing structure and method for installing wall bricks

InactiveCN103334564AStrong prestressed fasteningStable prestressed fasteningCovering/liningsBrickStructural engineering

The invention disclose a wall brick installing structure, which comprises a building main body and wall bricks installed on the building main body, and is characterized by further comprising an installing base plate, wherein the installing base plate comprises a framework, a first installing module and a second installing module; the framework comprises a building main body connecting end and a wall brick connecting end; the building main body connecting end is arranged on the building main body through the first installing module; the wall bricks are adjusted to set positions through the second installing module, and are fastened; and in a fastening process, the positions of the wall bricks are not changed. In a process of fastening by using the prestress of the second installing module, the wall bricks are prevented from being pressed and deformed irregularly by fastening, damages to the existing flatness of the wall bricks and inner stress of self-balance caused by the factors of error of each member, error of an installing carrier, errors of the wall bricks, and displacement of workpieces are avoided, and the safety and the capability of the external force resistance of an entire wall brick fastening system are enhanced greatly.

Owner:盖南南

Structure for mounting stone and method for mounting stone

ActiveCN103306453AStable prestressed fasteningEffective prestressed fasteningCovering/liningsGeneration processForce structure

The method discloses a structure for mounting a stone, which comprises a building main body, the stone mounted on the building main body, and as well as a mounting baseplate, wherein the stone is adjusted to a designed position to be fastened through the mounting baseplate; and the position of the stone is not changed in the process of fastening. Through the adoption of the structure, the motivation and the controlling for a dynamic generating process of prestressing force of elastic material are provided, a stable prestressing force structure is formed, a three-dimensional adjustment is conducted in the process of mounting to greatly improve the mounting accuracy of the stone, and the characteristics of excellent firmness, accuracy, safety, convenience, and changeable are adopted.

Owner:深圳市湛艺建设集团有限公司

Anti-explosion transparent partition mounting structure and mounting method thereof

ActiveCN103290954ATo achieve fastening effectImprove smoothnessWallsEngineeringUltimate tensile strength

The invention discloses an anti-explosion transparent partition mounting structure. The anti-explosion transparent partition mounting structure comprises a partition body fixed on a building body, a circle of mounting frame is bonded around the partition body which is fixed on the main building body or an adjacent partition body via the mounting frame, the mounting frame comprises a pressing assembly and a fastening assembly, and the pressing assembly is matched with the fastening assembly to press the same to generate prestressing force so as to fasten the partition body. By the aid of the mounting frame, the partition body cannot be separated after being impacted by explosion and the like, so that anti-explosion and separation functions are effectively realized, and indoor persons are protected to the greatest extent. Since a rigid bearing frame is firmly connected with the main building body structure, strength and rigidity of a whole partition bearing system are greatly improved, and the anti-explosion transparent partition structure is stronger in capability for bearing impact loads from explosion and the like and better in safety performance.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

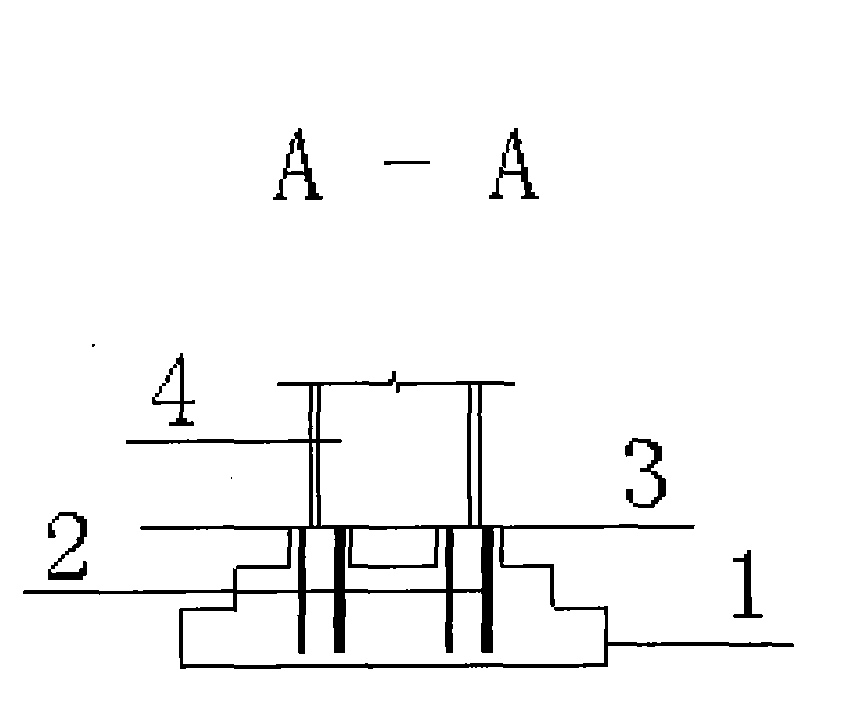

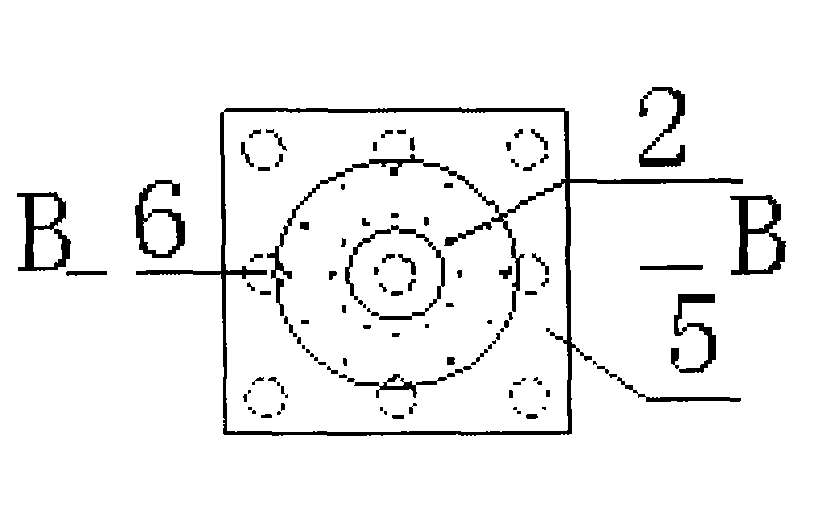

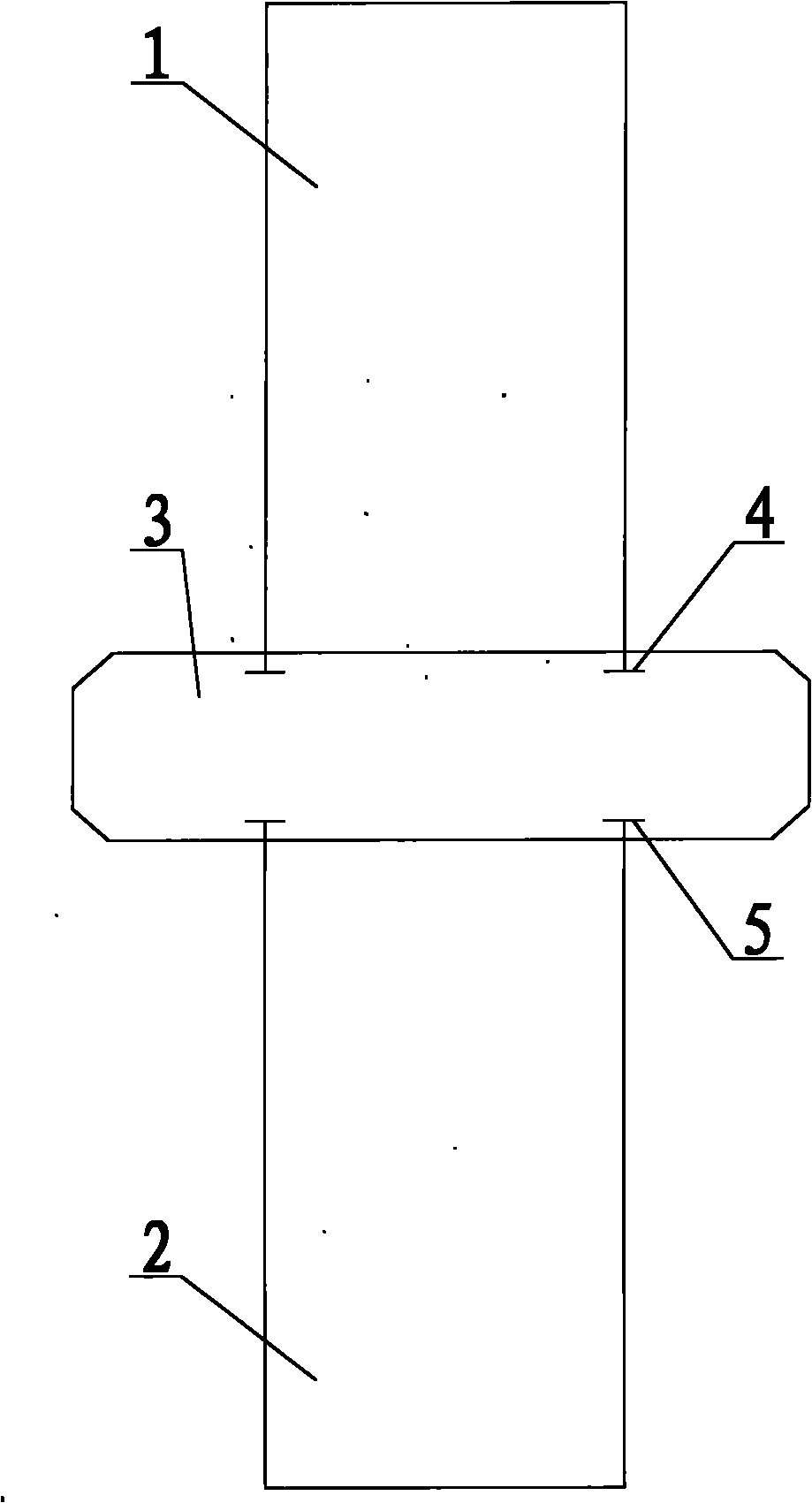

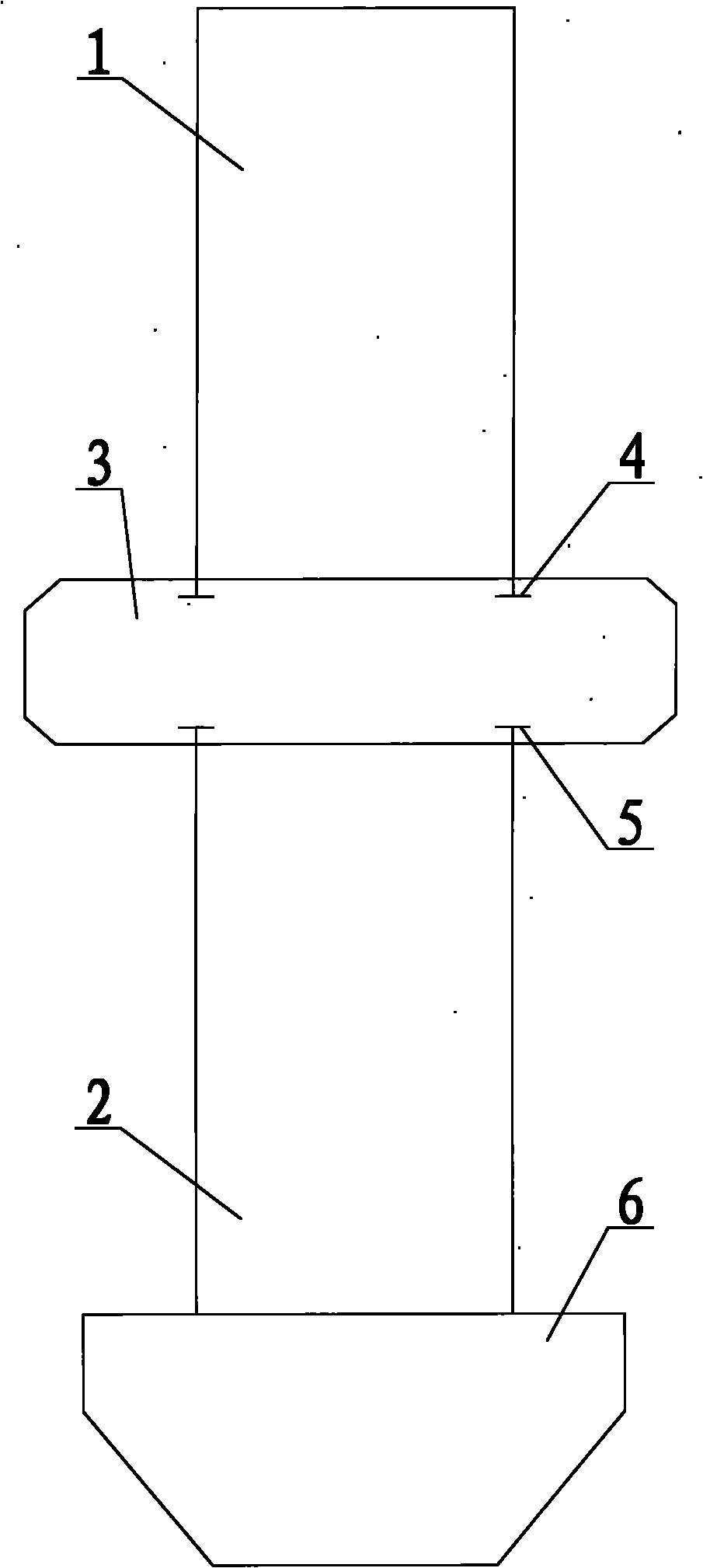

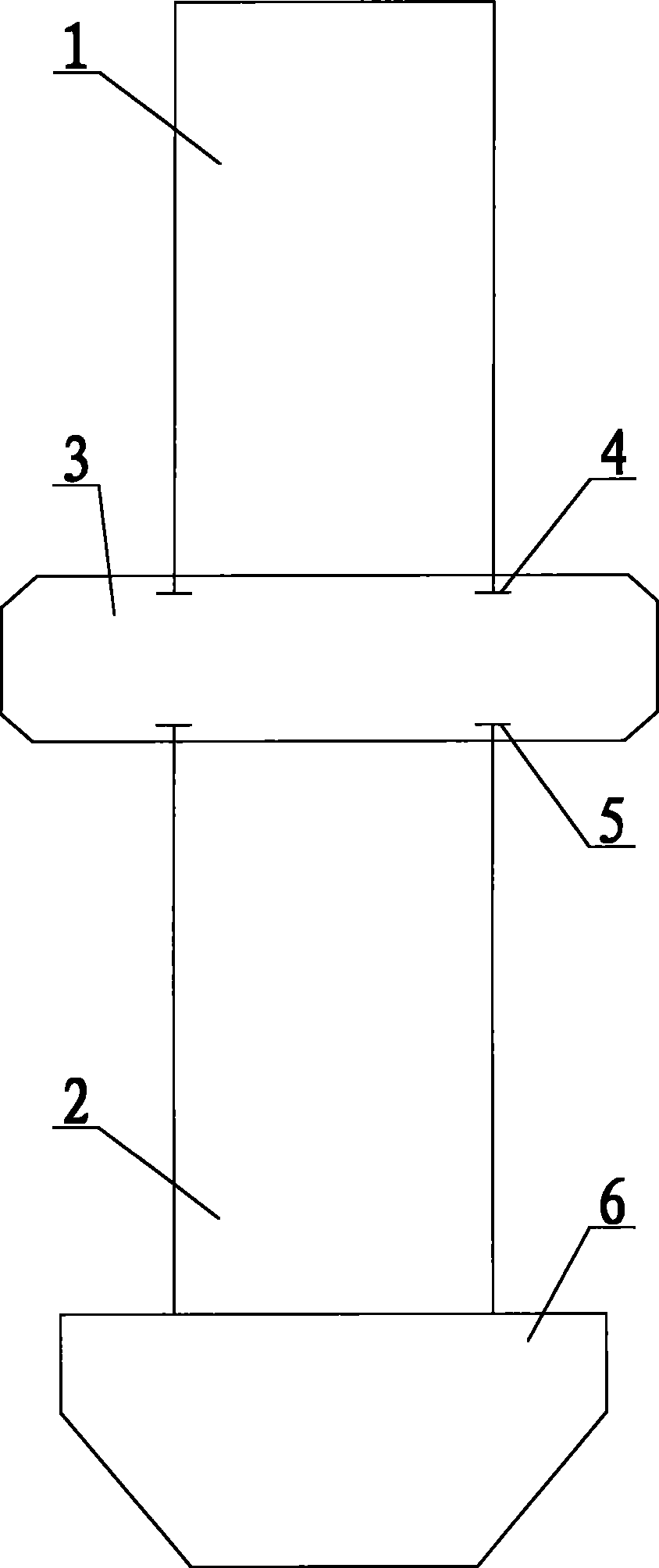

Method for designing reinforced concrete foundation or pile cap

ActiveCN101550703AReduce or offset tensile stressImprove crack resistanceFoundation engineeringCrack resistanceReinforced concrete

The invention relates to the field of towering buildings, in particular to a method for designing a reinforced concrete foundation or a pile cap. The device adopted in the method comprises an upper structure and a natural foundation or a pile foundation, and is characterized in that the reinforced concrete foundation (1) or the reinforced concrete pile cap (5) that is connected under the upper structure (4) is internally embedded with pre-stressed reinforcement (2). The method ensures that the reinforced concrete foundation or the pile cap adopts the pre-stressed structure in vertical direction, the force of the foundation or the pile cap is more reasonable, and the foundation or the pile cap has better crack resistance and stability.

Owner:POWERCHINA XIBEI ENG

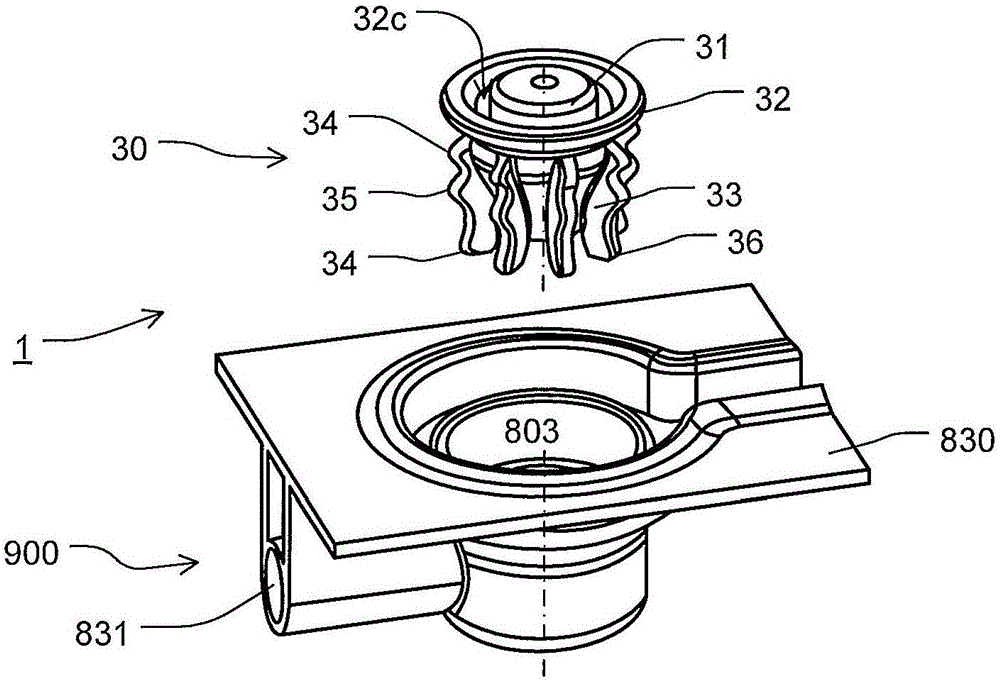

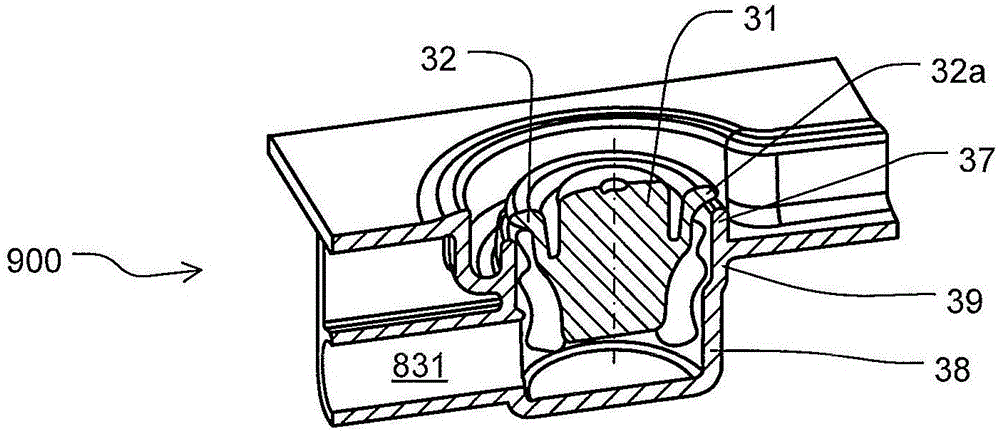

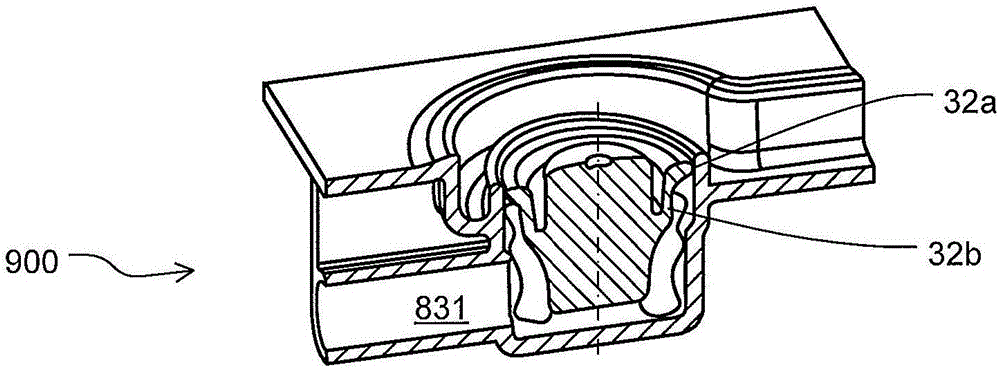

Functional medical device with a valve seat for a remanent non-return valve

ActiveCN106102822AReduced tightnessImprove sealingOther blood circulation devicesValvesReturn functionEngineering

The invention relates to a functional medical device (900) with a valve seat (803) for a non-return valve (1). In addition to a first position which is suitable for sterilizing gas, the non-return valve (1) is designed to assume a second functional position, in which the non-return valve (1) exerts a non-return function, by applying a force onto a portion of the non-return valve (1) and / or by moving the non-return valve. The non-return valve (1) is designed to remain in the second position after being successfully converted into the second position after the force and / or the moving element has been removed.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Explosion-proof and anti-riot transparent partition mounting structure with buffer function and mounting method of mounting structure

Owner:平邑经济开发区投资发展有限公司

Pre-stress arm structure of aluminum alloy door window

The invention discloses a pre-stress arm structure of an aluminum alloy door window, which comprises the glass door window body fixed in a fame, wherein the frame comprises a compression assembly and a fastening assembly, the fastening assembly is compressed by coordination between the compression assembly and the glass door window body to generate pre-stress and thus fasten the glass door window body, the glass door window body becomes a main control part which generates the pre-stress, the fastening assembly is made of an elastic material, the stable pre-stress is formed and stored in the material as driven by external force, and a stable pre-stress system is consisted by the material, the glass door window body and the compression assembly. The pre-stress arm structure of the aluminum alloy door window disclosed by the invention can enhance strength, torsional behaviors and external force resistance of a whole aluminum alloy door window structure in order to avoid problems such as door window falling and deformation; and due to application of the pre-stress structure frame around glass, corresponding fastening points and fastening manners can be disposed according to fastening installation requirements of hardware fittings at any position of a frame pressing block, so that utilization functions and firmness requirements of the hardware fittings can be satisfied, and limitations from a sectional material thickness are avoided.

Owner:YIHE TECH DEV SHANGHAI

Anti-separation glass curtain wall mounting structure and anti-separation glass curtain wall mounting method

InactiveCN103290959AStrong prestressStable characteristicsWallsBuilding material handlingArchitectural engineeringToughened glass

The invention discloses an anti-separation glass curtain wall mounting structure. The anti-separation glass curtain wall mounting structure comprises a main building body, a frame and curtain wall glass, the curtain wall glass is mounted on the main building body via a frame, a first mounting groove is formed in the frame, and side edges of the curtain wall glass are inserted into the first mounting groove and are combined with an anti-separation frame. A pressing assembly is adopted to match with the curtain wall glass so as to press a fastening assembly to generate prestressing force, the fastening assembly is made of an elastic material, the prestressing force is formed inside the elastic material under the action of external force, and a stable prestressing system is formed by the fastening assembly, the curtain wall glass and the pressing assembly. The anti-separation frame around the curtain wall glass can prevent the curtain wall glass from separating from the mounting frame after being deformed caused by external impact, so that the mounting structure is applicable to high-rise buildings. Laminated glass better in safety performance can be used for preventing crushed toughened glass from dropping in granules, and accidents of high-altitude falling of the integral laminated glass after being crushed are avoided.

Owner:广东美科建工集团有限公司

Transparent shield mounting structure and method for reception window

ActiveCN103291193AStrong prestressStable characteristicsSafety transaction partitionSealing arrangementsEngineeringProtective barrier

Owner:淮安市淮安区综合检验检测中心

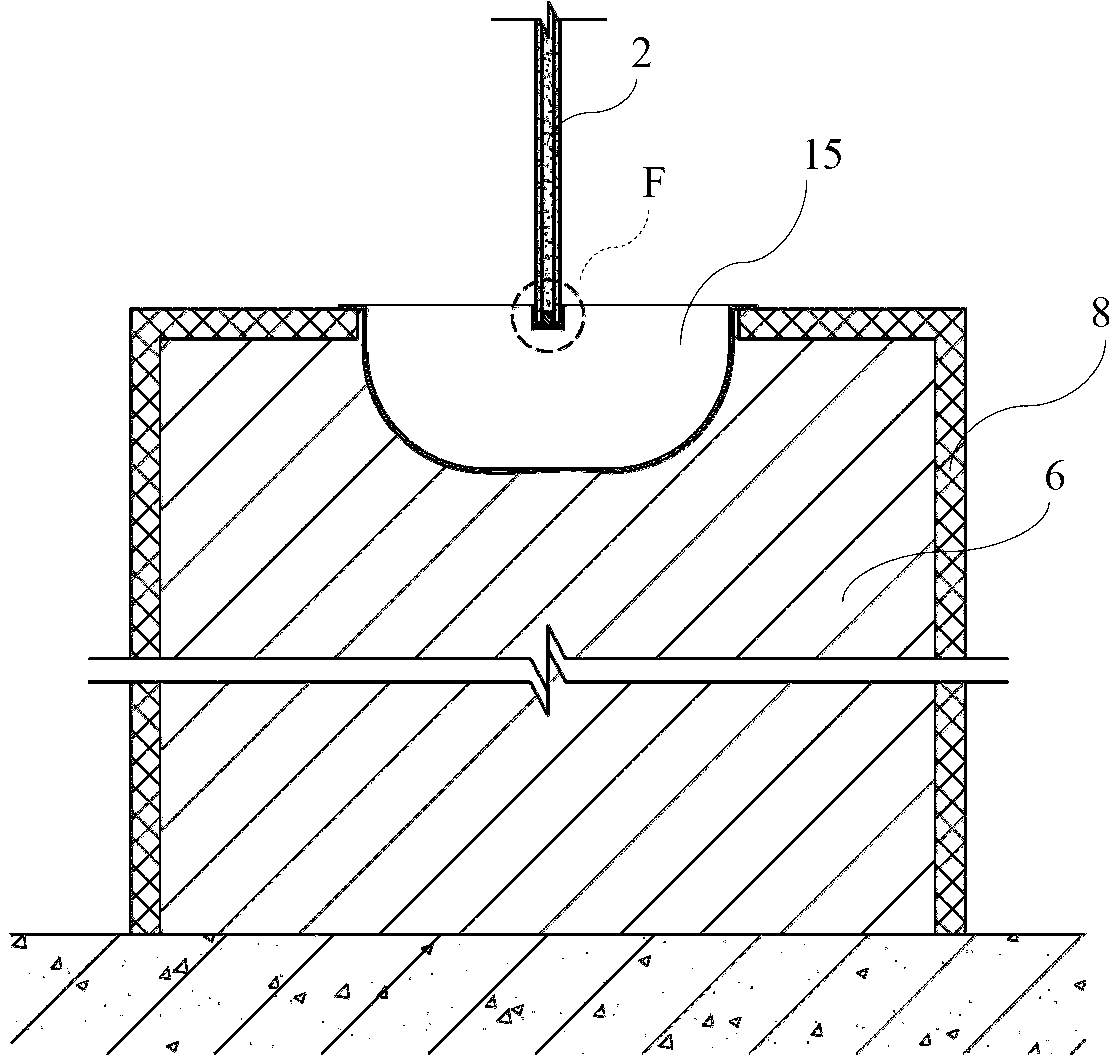

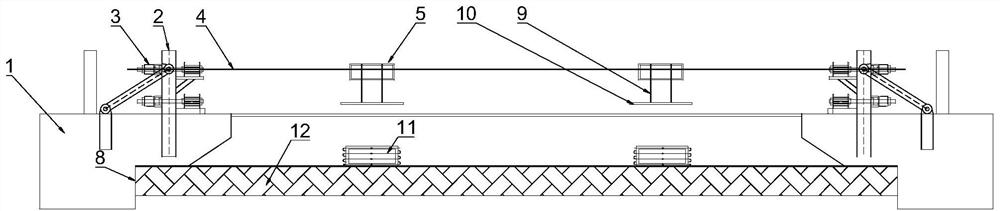

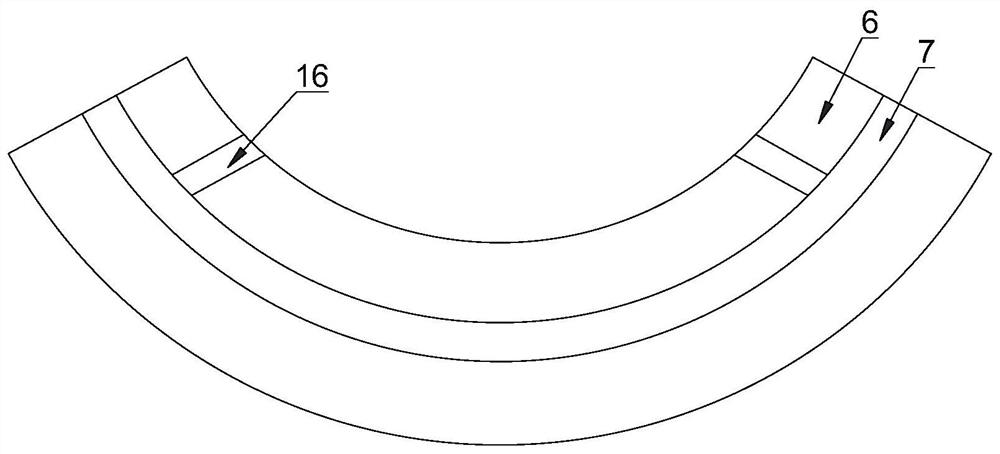

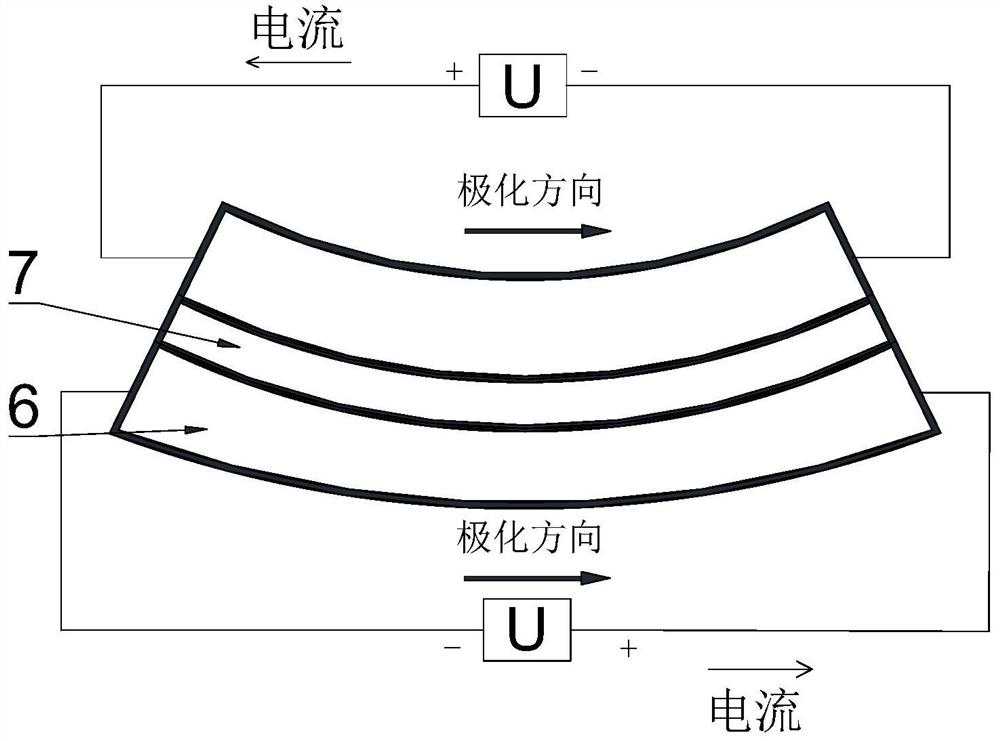

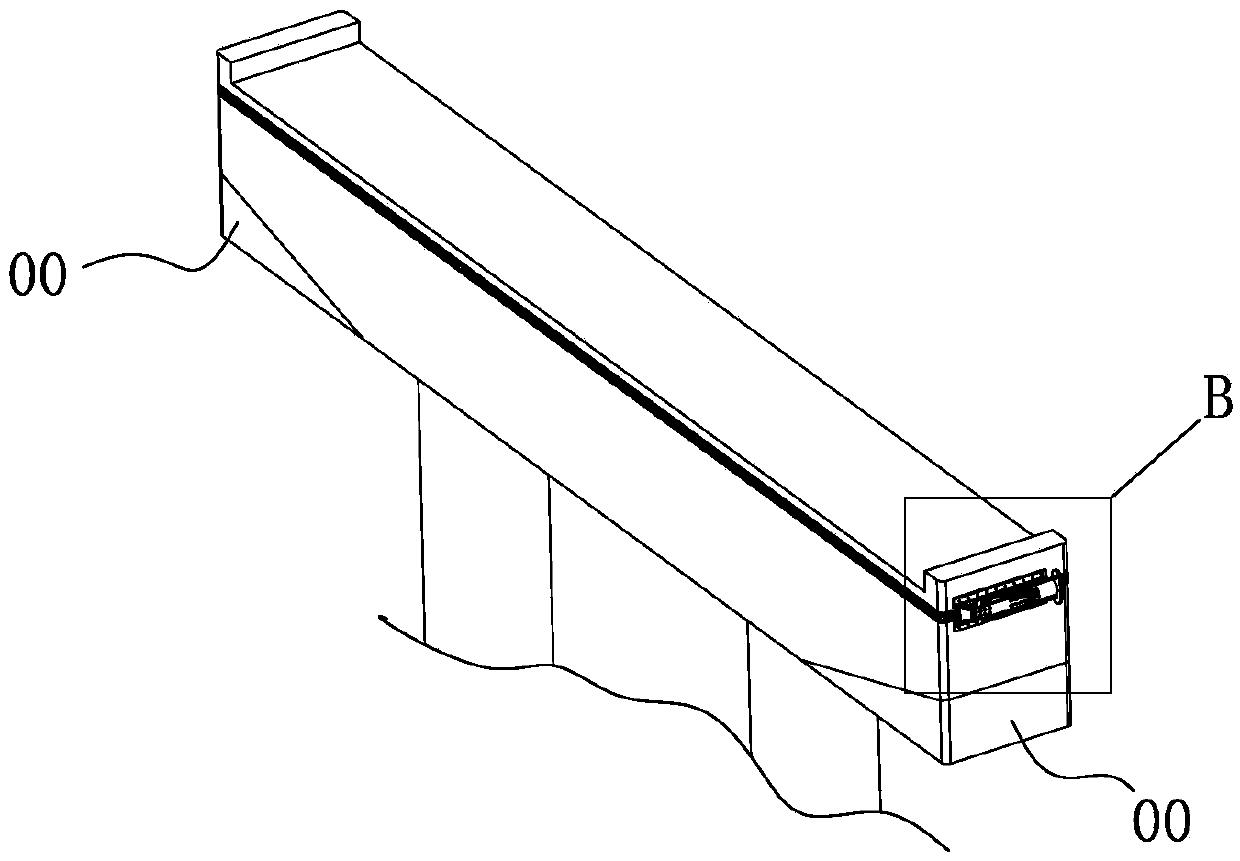

Piezoelectric conduit, prestressed tendon pre-tensioning bending device, and prestressed tendon pre-tensioning bending construction method

ActiveCN112343349AEasy to useSimplified bending methodPiezoelectric/electrostriction/magnetostriction machinesBuilding material handlingEngineeringStructural engineering

The invention discloses a piezoelectric conduit, a prestressed tendon pre-tensioning bending device, and a prestressed tendon pre-tensioning bending construction method. The piezoelectric conduit is connected into a pipe shape by adopting a piezoelectric plate and an insulating material which are oppositely arranged; a prestressed tendon bending and tensioning mechanism is arranged in the prestressed tendon pre-tensioning bending device; the prestressed tendon bending and tensioning mechanism comprises the piezoelectric conduits used for bending prestressed tendons and force application mechanisms used for applying tension to the piezoelectric conduits to enable the prestressed tendons to be bent and deformed and enable the tension of the prestressed tendons to reach a set range; and the force application mechanisms and the piezoelectric conduits are arranged in a one-to-one correspondence mode. The principle that the piezoelectric conduits generate bending deformation after being electrified with direct current is utilized, and the piezoelectric conduits can be used for tensioning the prestressed tendons, so that damage to the prestressed tendons can be avoided; and bending parameters and tensioning stress of the prestressed tendons can be indirectly controlled by accurately controlling the bending parameters of the piezoelectric conduits, so that the requirements on the bending parameters and the tensile stress of the prestressed tendons under different working conditions can be met.

Owner:CHONGQING JIAOTONG UNIVERSITY

Decorative frame sealing structure of aluminum alloy door window

Owner:YIHE TECH DEV SHANGHAI

Construction method of municipal comprehensive pipeline passage

InactiveCN111254945ASolve the problem of chaosLow costPipe laying and repairExcavationsArchitectural engineeringStructural engineering

The invention discloses a construction method of a municipal comprehensive pipeline passage. The construction method is characterized by comprising the following steps: 1, according to the requirementof a pipeline design construction drawing, positioning the coordinates and trend of the pipeline, and piling and paying off to determine the position, width and depth of a groove; 2, adopting mechanical channeling at the piling and paying-off parts, and if the pipeline exists underground, adopting manual channel near the pipeline; 3, tamping, levelling and treating the groove, and paving a waterproof cement mortar bonding layer; 4, on the basis of protecting a pipe body anticorrosive layer and not destroying concrete, adopting a high-strength nylon tape to hoist a prepared fabricated U shapedprefabricated pipeline to mechanically lower the pipeline; and 5, properly putting sand bags on the two sides of the lowered fabricated U shaped prefabricated pipeline to fix so as to stabilize the fabricated U shaped prefabricated pipeline. The construction method adopts centralized large-scale arrangement to effectively solve the problem about disordered pipelines in a town.

Owner:海鑫建工发展集团有限公司

Pressing component for installing an aluminum alloy door and window

InactiveCN105275330AStrong prestressStable characteristicsUnits with parallel planesGlass pane fixingPre stressPre stressing

The invention discloses a pressing component for installing an aluminum alloy door and window, comprising a glass door and window body fixed in a frame. The frame comprises a pressing component and a tightening component. Through matching of the pressing component and the glass door and window body, the tightening component is pressed to generate pre-stressing force to tighten the glass door and window body. The glass door and window body serves as a main control part for generating the pre-stressing force. The tightening component is made of an elastic material, a stable pre-stressing force is formed inside the material under the action of external force and is stored, and the pre-stressing force forms a stable pre-stressing force system together with the glass door and window body and the pressing component. The strength, torsion property and external force resistance of the whole aluminum alloy door and window structure can be increased, and door and window drop, deformation and the like can be avoided. Because of the adoption of a pre-stressing force structure frame around the glass, corresponding tightening points and tightening modes can be set in any position of a frame pressing block according to the hardware fitting tightening and mounting requirement, so that the using functions and fastness requirements of hardware fittings are satisfied, without being limited by the thickness of profiles.

Owner:YIHE TECH DEV SHANGHAI

Method for reinforcing capping beam by using carbon fiber and reinforcing structure

ActiveCN109537475AStrong prestressEasy to wrapBridge erection/assemblyBridge strengtheningFiberCarbon fibers

The invention discloses a method for reinforcing a capping beam by using carbon fiber and a reinforcing structure, which are used for solving the problem that the reinforcement is not firm. The methodcomprises the following steps: step 1, carrying out construction lofting and measurement on the capping beam to be reinforced, accurately determining the size of a repaired steel piece, preparing therepaired steel piece, and fixing the repaired steel piece at a chamfer of the capping beam; step 2, at least arranging one carbon fiber board, a set of fixed end support components, a tension end support component and a closed reinforcing ring consisting of connecting steel plates at the positions of the upper edge or / and the lower edge of the capping beam; step 3, treating the area between the two carbon fiber boards by using carbon fiber cloth. The method for reinforcing the capping beam by using carbon fiber and the reinforcing structure have sufficient self-locking property and floating property, ensures that a closed ring is formed between the carbon fiber board, the support component and the connecting steel piece through the connecting steel plate, and a pre-stress is formed between the closed rings to reinforce the capping beam, thereby having better reinforcing effect than the traditional reinforcing effect.

Owner:SHANDONG JIAOTONG UNIV

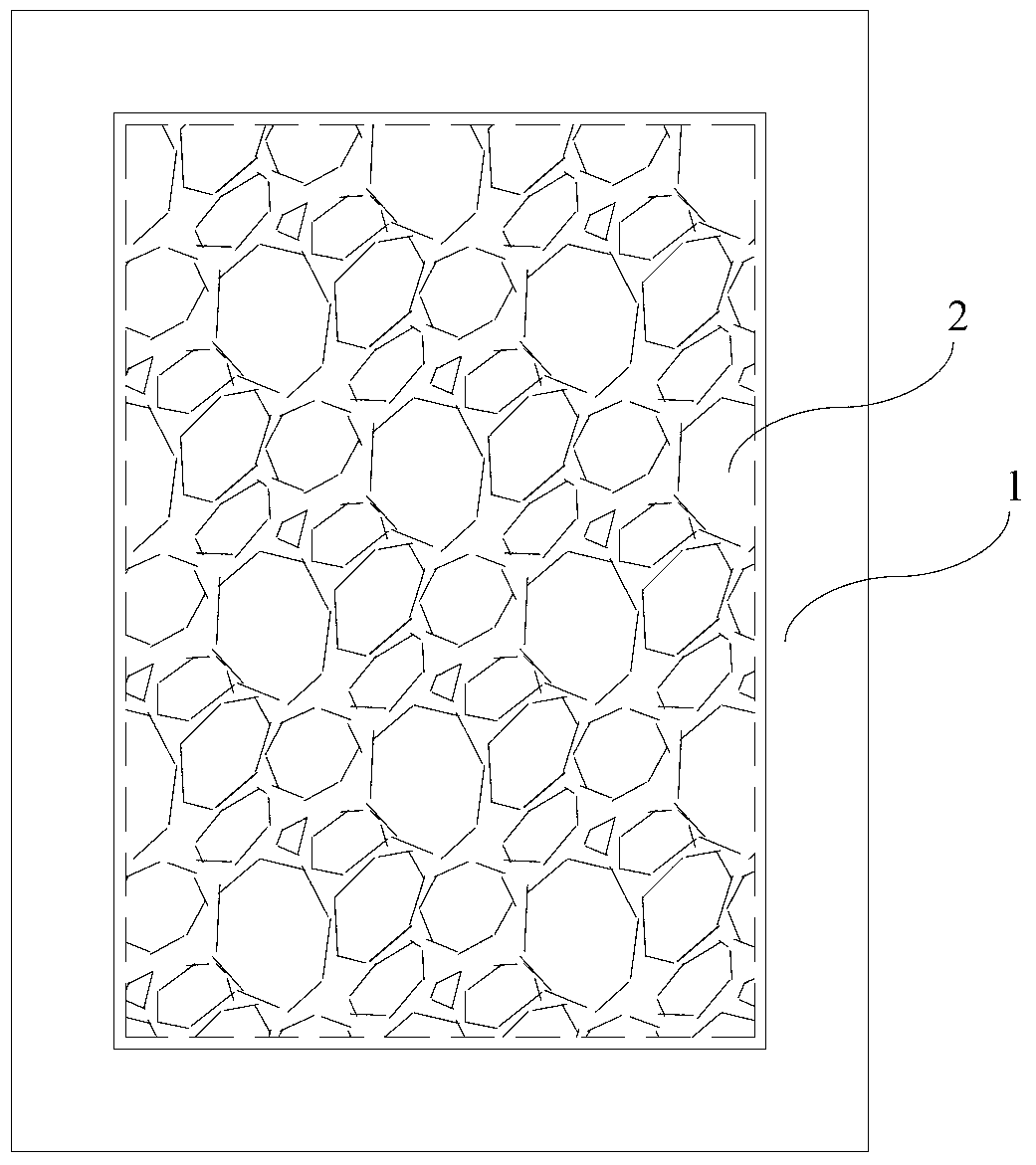

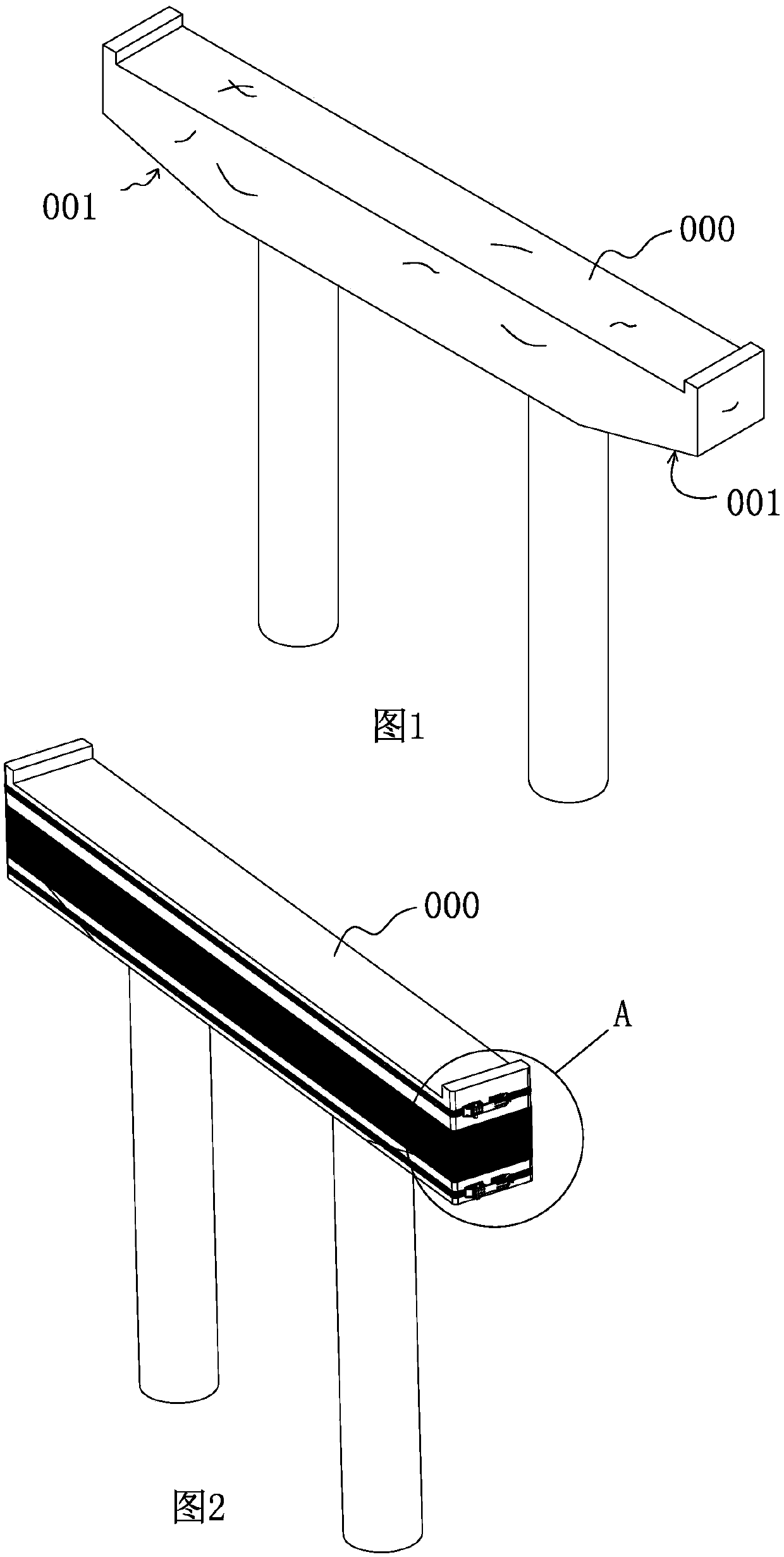

Tube pile structure

The invention discloses a tube pile structure, which comprises an upper pile and a lower pile, wherein a supporting disc is also arranged between the upper and the lower piles, and the cross section area of both the upper and the lower piles is smaller than that of the supporting disc. The supporting disc with larger cross section area is arranged at the joint between the upper and the lower piles, so the prestress of the entire tube pile structure is stronger, and the firmness is better.

Owner:浙江大东吴集团建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com