Piezoelectric conduit, prestressed tendon pre-tensioning bending device, and prestressed tendon pre-tensioning bending construction method

A technology of prestressed tendons and bending devices, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Plate thickness restrictions, high processing costs, etc., to achieve the effect of simplifying the dismantling method, reducing the risk factor, and simplifying the bending method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand and implement the present invention, but the examples cited are not intended to limit the present invention.

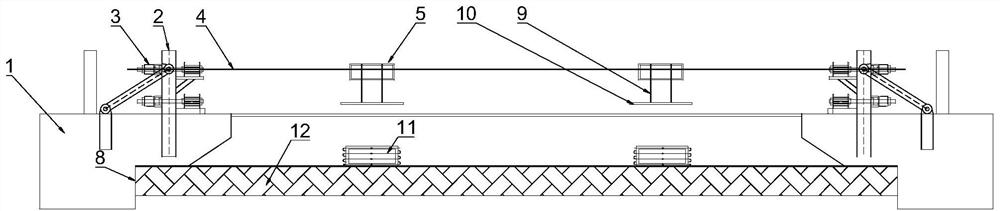

[0048]Such asfigure 1 Shown is a schematic diagram of an embodiment of a pre-tensioning and bending device for pre-stressed tendons of the present invention, including a worktable 1, and two ends of the worktable 1 are provided with tensioning mechanisms 2 for tensioning the pre-stressed tendons 4, each tensioning mechanism 2 is provided with an anchoring mechanism 3 for fixing the prestressing tendons;

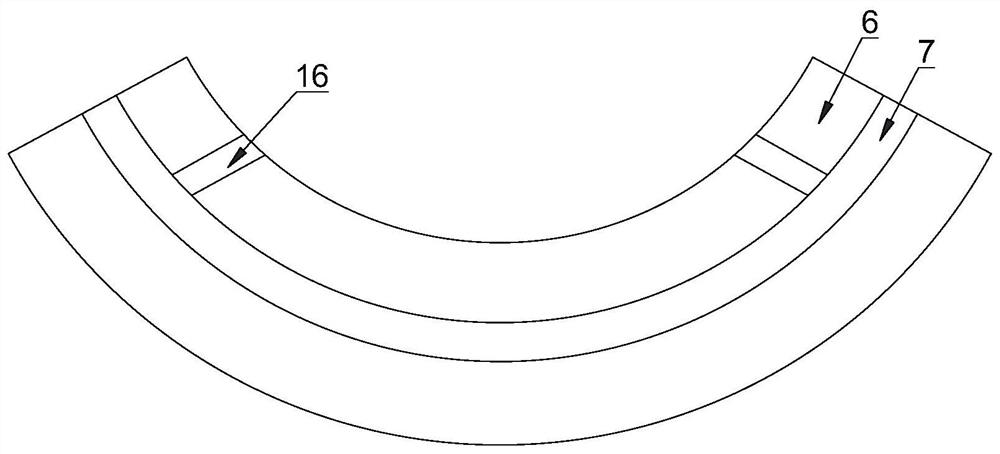

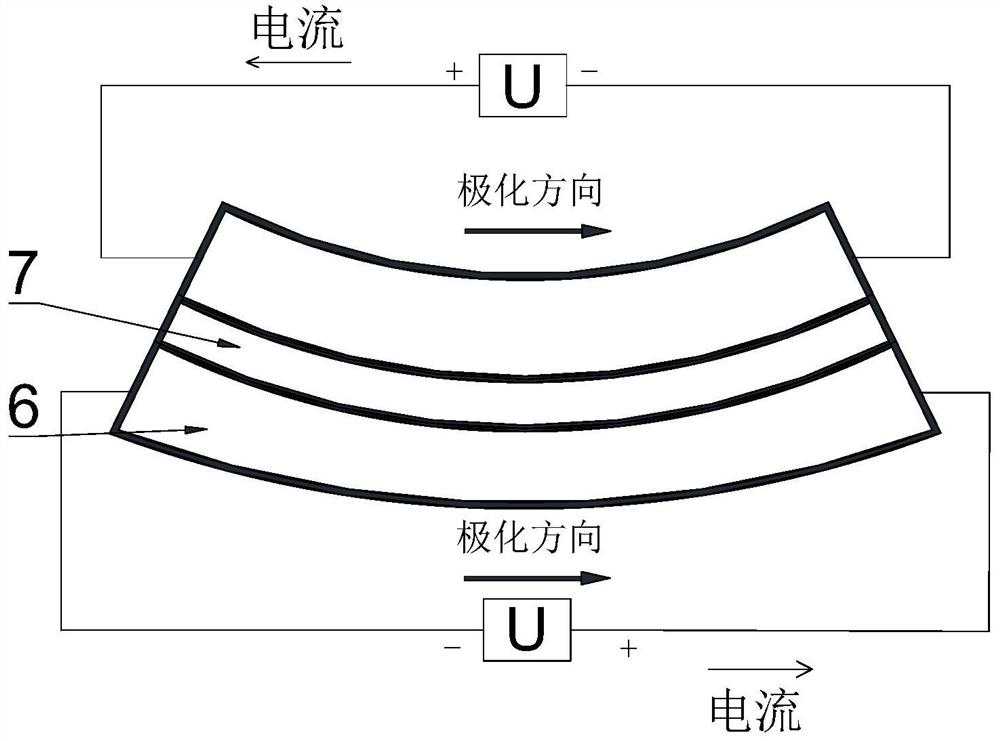

[0049]A pre-stressed tendon bending and tensioning mechanism is arranged between the two anchoring mechanisms 3, and the pre-stressed tendon bending and tensioning mechanism includes a piezoelectric conduit 5 that can undergo reverse bending deformation under the action of direct current and a pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com