Wall brick installation structure and wall brick installation method

A technology for installing structure and wall tiles, applied in building construction, covering/lining, building, etc., can solve the hidden danger of structural safety, the source of adjustment space and adjustment resistance cannot be observed, and the fastness and stability of new openings are uncertain. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0152] The present invention will be further described below in conjunction with specific examples.

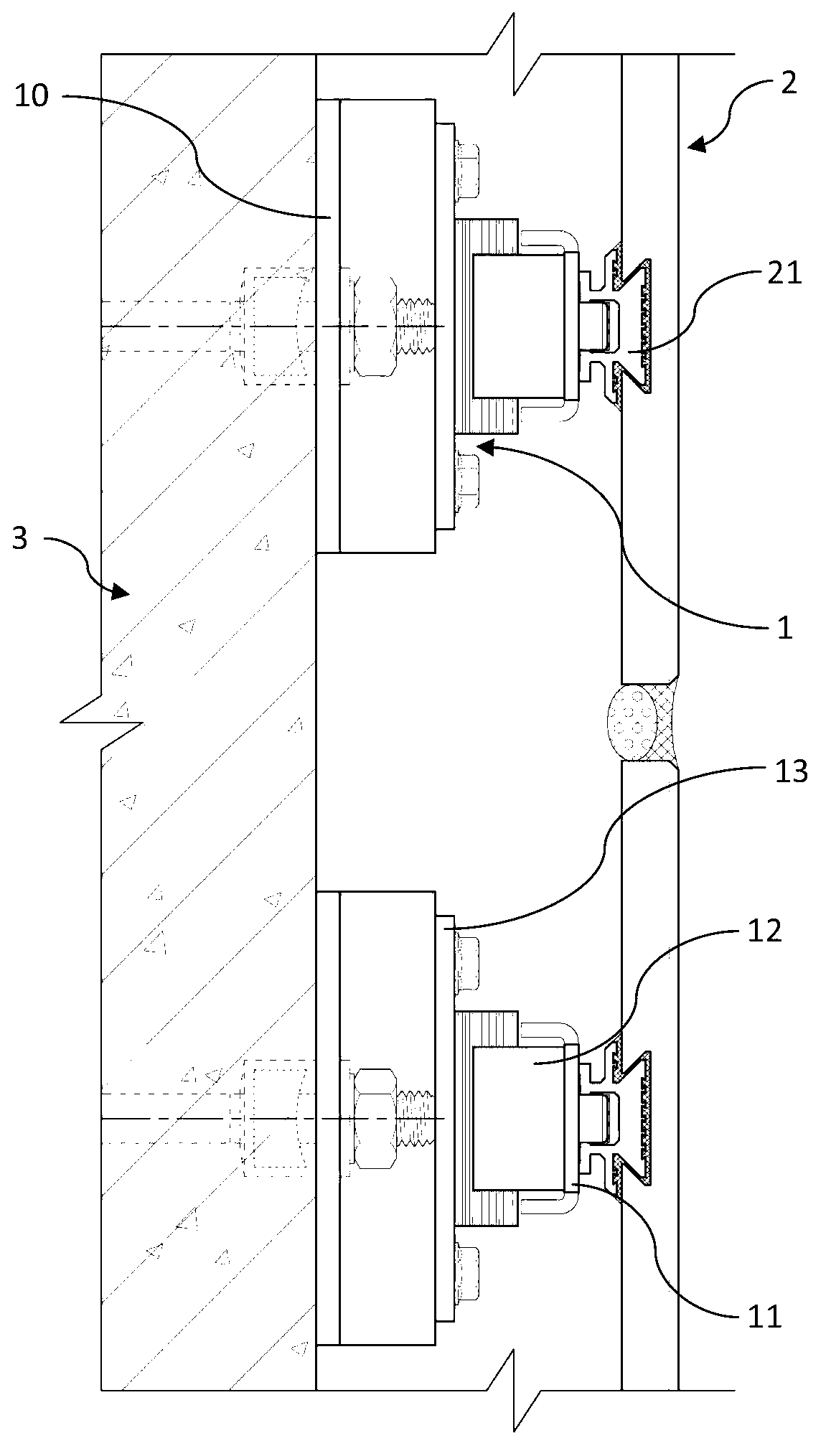

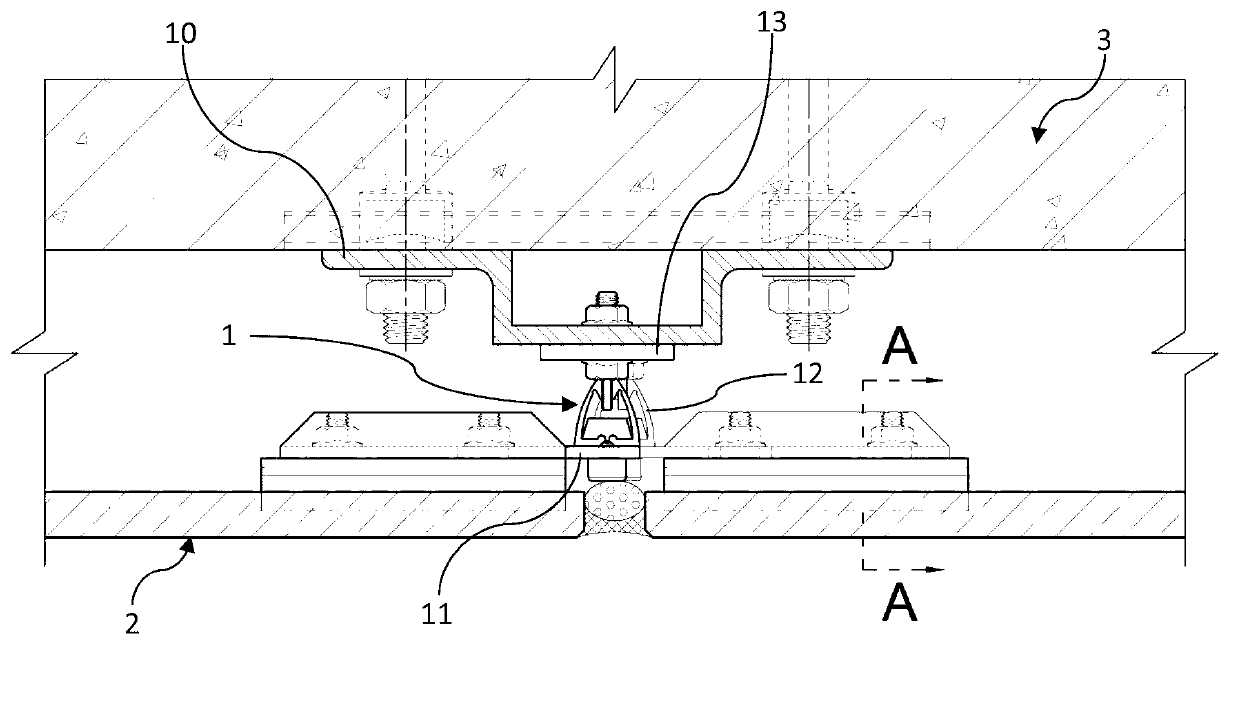

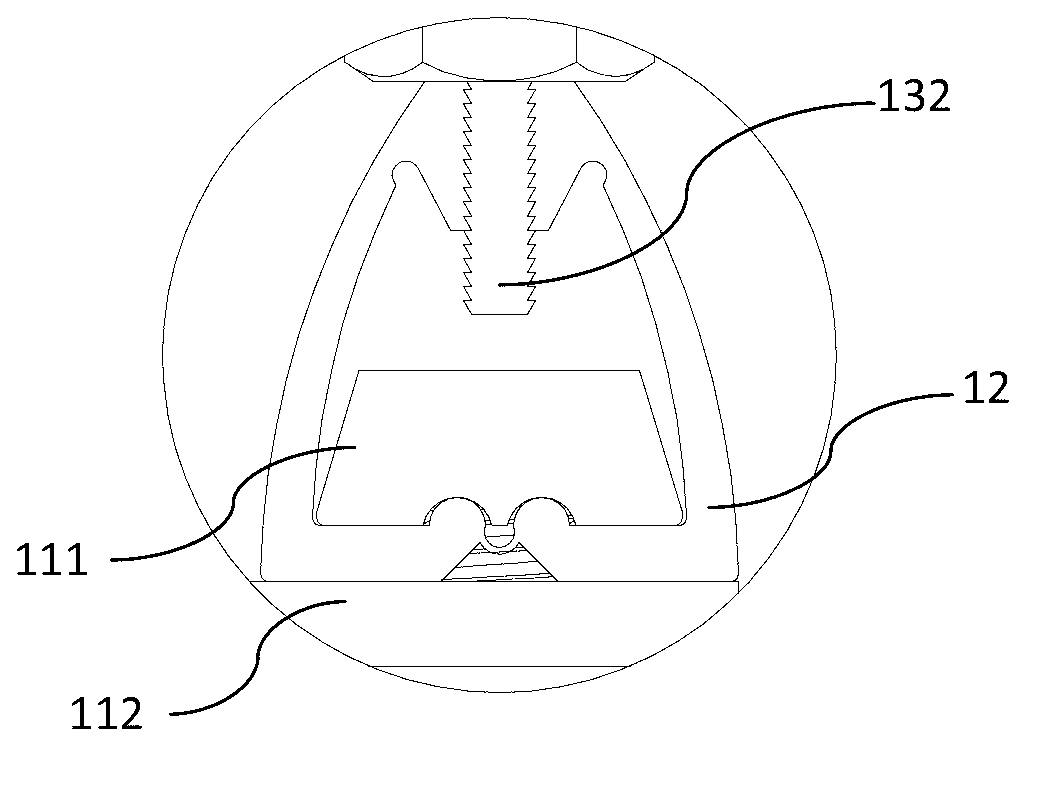

[0153] refer to Figure 1-Figure 3 , Figure 6-Figure 7 As shown, in the first preferred embodiment of the present invention, the dry-hanging wall tile installation structure of the present invention includes a building main body 3 and a wall brick 2 installed on the building main body 3, and the installation structure also includes a plurality of mutually independent installation Unit 1, the installation unit 1 includes a pressing component 11, a fastening component 12 and a fastened component 13;

[0154] The fastened component 13 includes a bottom plate 131 and a wing plate 132 formed on the bottom plate 131. The bottom plate 131 is connected to the building body 3 through the building body connector 10, and the bottom plate 131 is provided with a slot hole, and the fastened component 13 can pass through The slot-shaped hole on the bottom plate 131 is adjusted along a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com