Tube pile structure

A pipe pile and pile head technology, which is applied in the field of pipe pile structure improvement, can solve the problems of poor prestress, single direction of force, and poor firmness, and achieve the effect of good firmness and strong prestress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

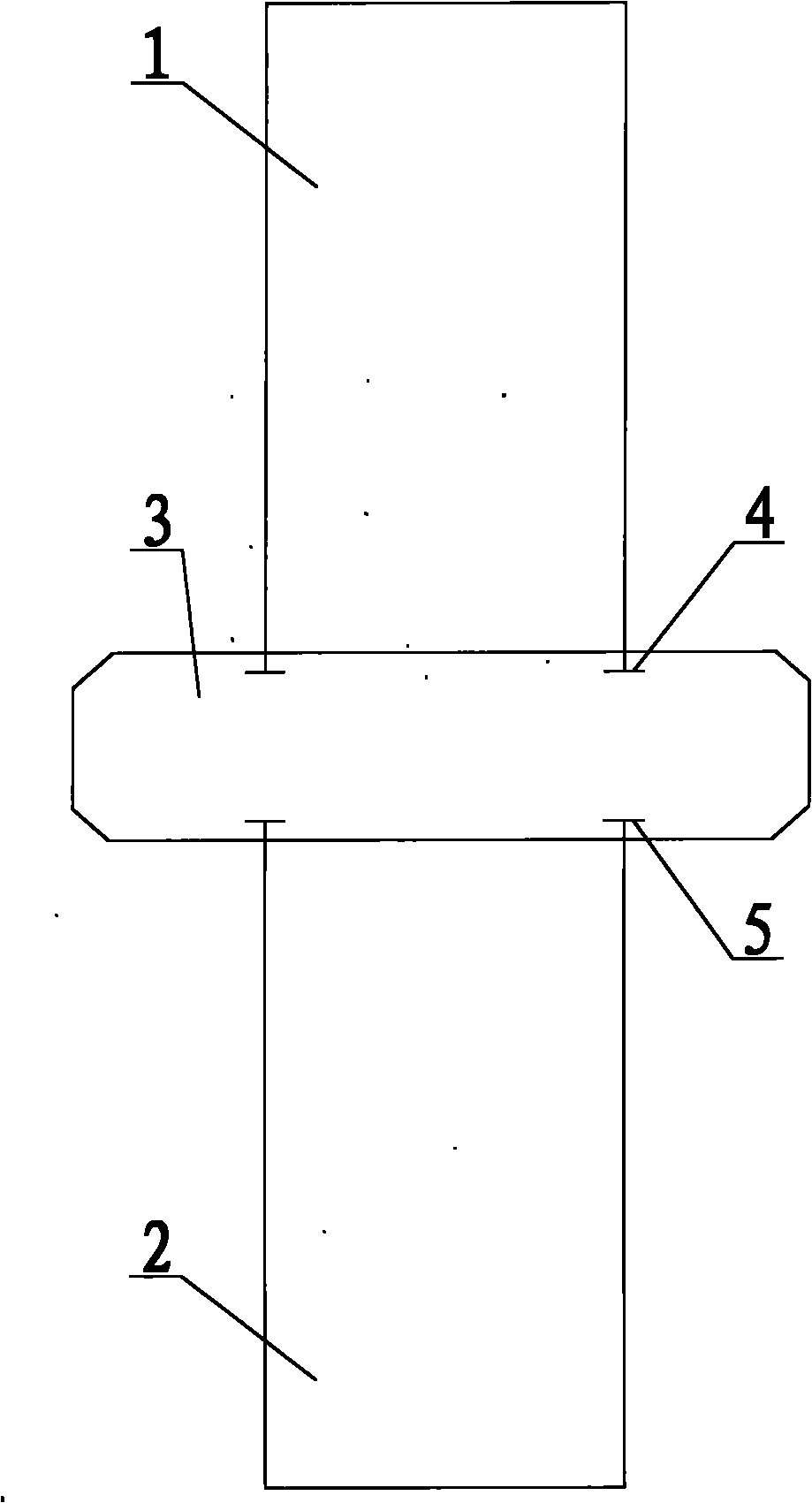

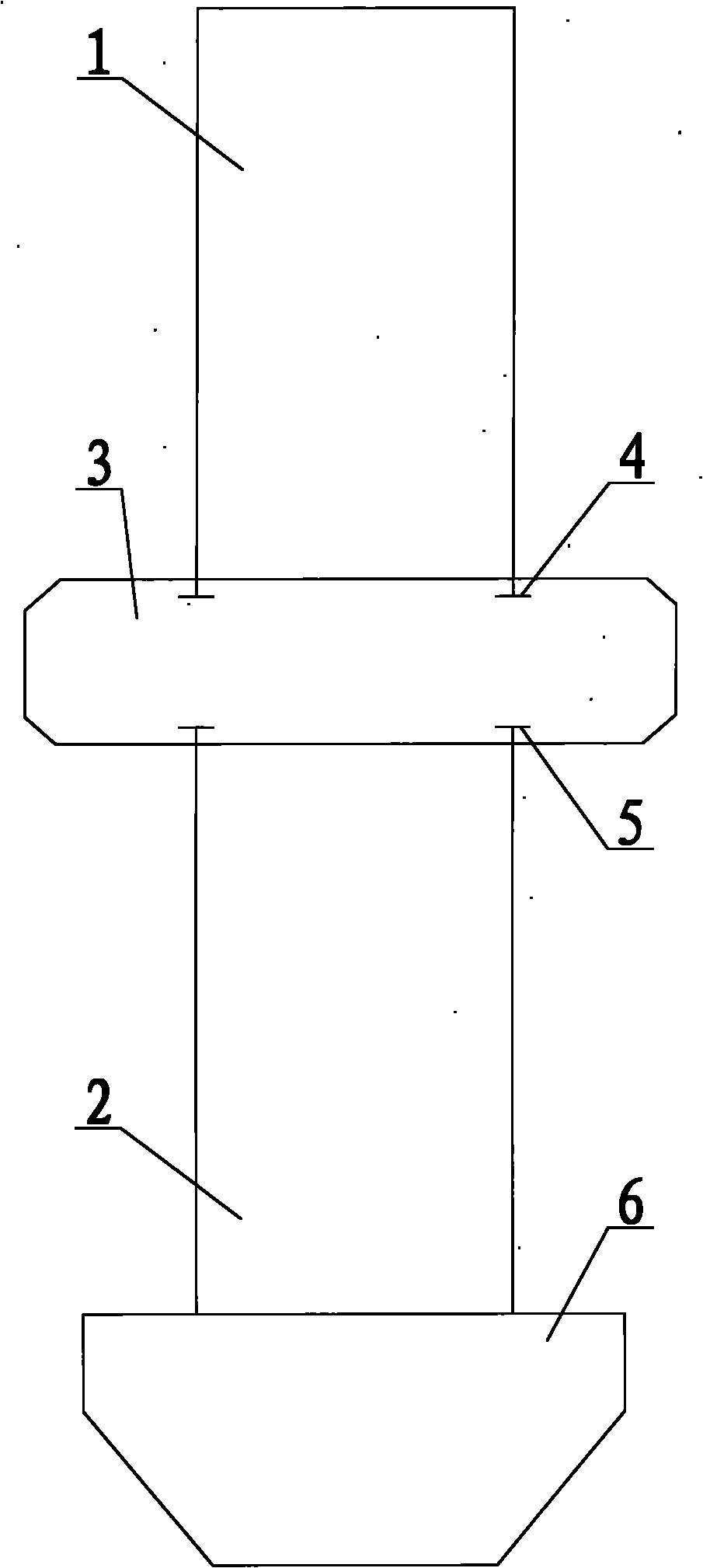

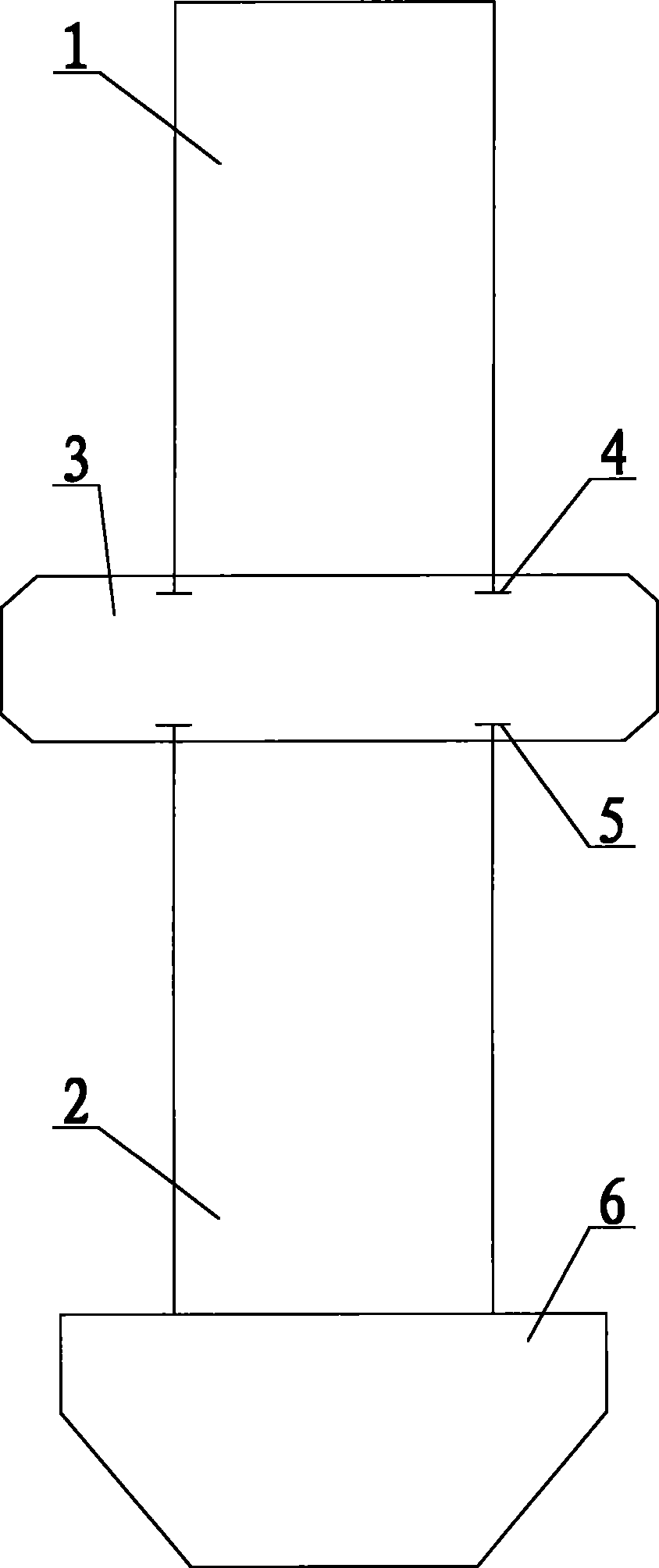

[0018] refer to figure 1 , a pipe pile structure, comprising an upper pile 1 and a lower pile 2, a support plate 3 is also provided between the upper pile 1 and the lower pile 2, and the cross-sectional areas of the upper pile 1 and the lower pile 2 are smaller than the support The cross-sectional area of disk 3. The bottom of the upper pile 1 is provided with an upper connection block 4 , and the top of the lower pile 2 is provided with a lower connection block 5 , and both the upper connection block 4 and the lower connection block 5 are buried in the support plate 3 . The upper pile 1 and the lower pile 2 are rectangular parallelepiped, the four vertices at the bottom of the upper pile 1 are respectively provided with upper connecting blocks 4, and the four vertices at the top of the lower pile 2 are respectively provided with lower connecting blocks 5. The upper pile 1 is a concrete upper pile 1, the lower pile 2 is a concrete lower pile 2, the support plate 3 is a conc...

Embodiment 2

[0020] refer to figure 2 In this embodiment, on the basis of Embodiment 1, a pile head 6 is added at the bottom of the lower pile 2, and the cross-sectional area of the pile head 6 is greater than that of the lower pile 2. The pile head 6 is in the shape of an inverted cone or an inverted table as a whole. The prestress of the pipe pile is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com