Method for designing reinforced concrete foundation or pile cap

A reinforced concrete and design method technology, applied in the field of reinforced concrete foundation or pile cap design, can solve the problems of large calculation cracks and multiple ordinary steel bars, and achieve the effects of improving fatigue resistance, saving materials, and being easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

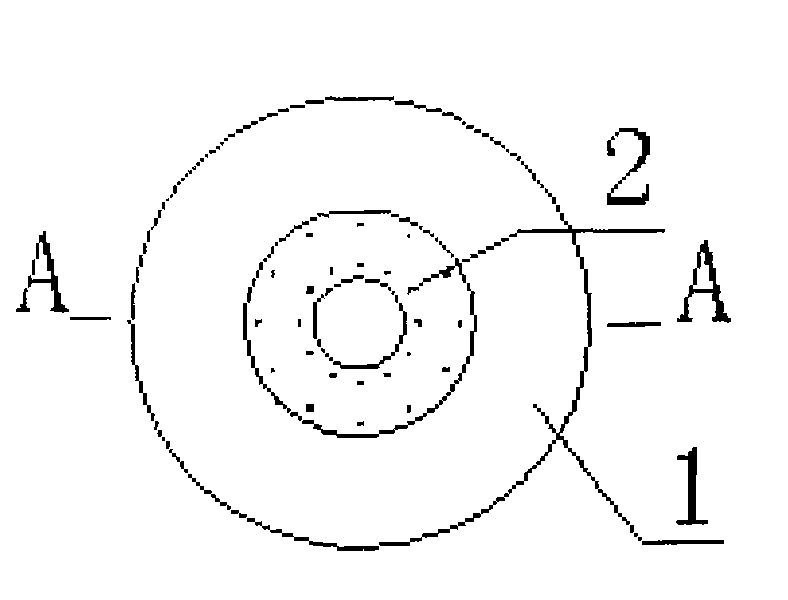

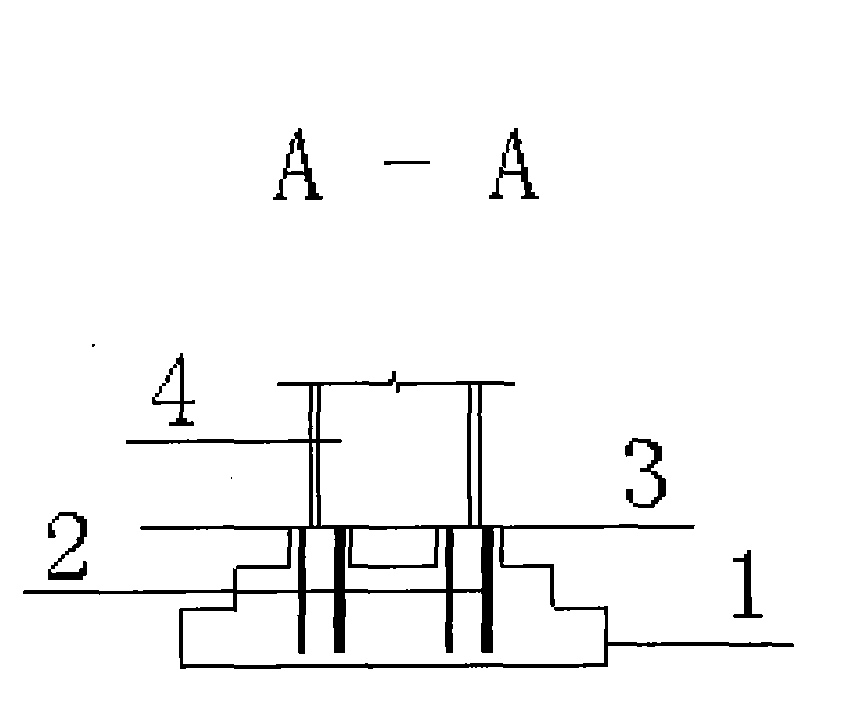

[0025] Embodiment 1 structure such as figure 1 , figure 2 Shown is a schematic diagram of the prestressed structure adopted by the reinforced concrete foundation 1 in the vertical direction, which includes a superstructure 4 and a reinforced concrete foundation 1, and a prestressed steel bar 2 is embedded in the reinforced concrete foundation 1 connected under the superstructure 4. The outer diameter of the reinforced concrete foundation 1 decreases successively from bottom to top and is in the shape of a superimposed circular platform. The upper end of the circular platform is a hollow structure, and the prestressed steel bars 2 are uniformly and vertically distributed on the inner cylinder of the hollow structure. The quantity of embedded vertical prestressed steel bars 2 is 1 / 3-1 / 5 of ordinary steel bars. The number of common steel bars is a well-known technology in the art. The strength of prestressed steel bars is 3 to 5 times that of ordinary steel bars, so the amount...

Embodiment 2

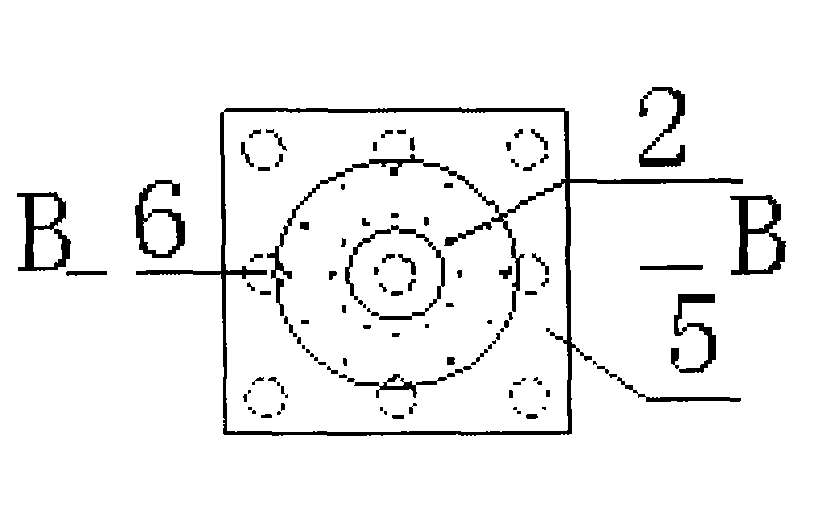

[0026] Embodiment 2 structure such as image 3 , Figure 4 As shown, it is a schematic diagram of the prestressed structure used in the vertical direction of the reinforced concrete pile cap 5. Others include the upper structure 4 and the reinforced concrete pile cap 5, and the reinforced concrete pile cap 5 connected under the upper structure 4 is embedded with a prestressed structure. Stress reinforcement 2. The reinforced concrete pile cap 5 is a hollow cylindrical structure, the hollow cylindrical bottom is a closed plane, and several piles 6 are connected under the closed plane; the prestressed steel bars 2 are uniformly and vertically distributed on the hollow inner cylinder. The quantities, high-strength materials and cross-sectional dimensions used in Embodiment 2 are the same as those in Embodiment 1.

[0027] When in use, construct the foundation as shown in the figure, the reinforced concrete foundation 1 or the reinforced concrete pile cap 5 is different from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com