Dimple-shaped honeycomb hollow plate and manufacturing method thereof

A manufacturing method and dimple technology, applied in chemical instruments and methods, synthetic resin layered products, glass/slag layered products, etc., can solve the problems of deformation under compression, weak, poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

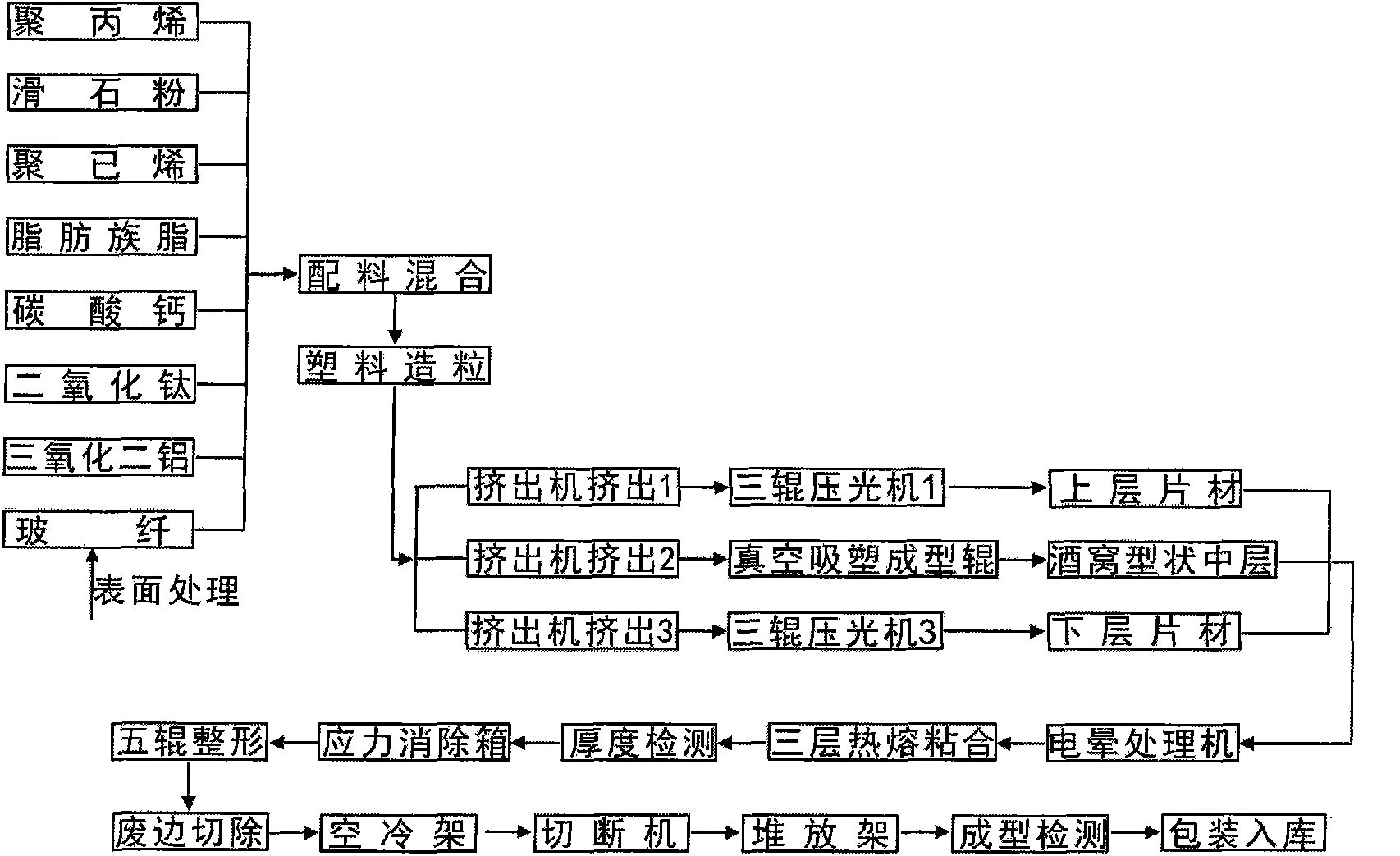

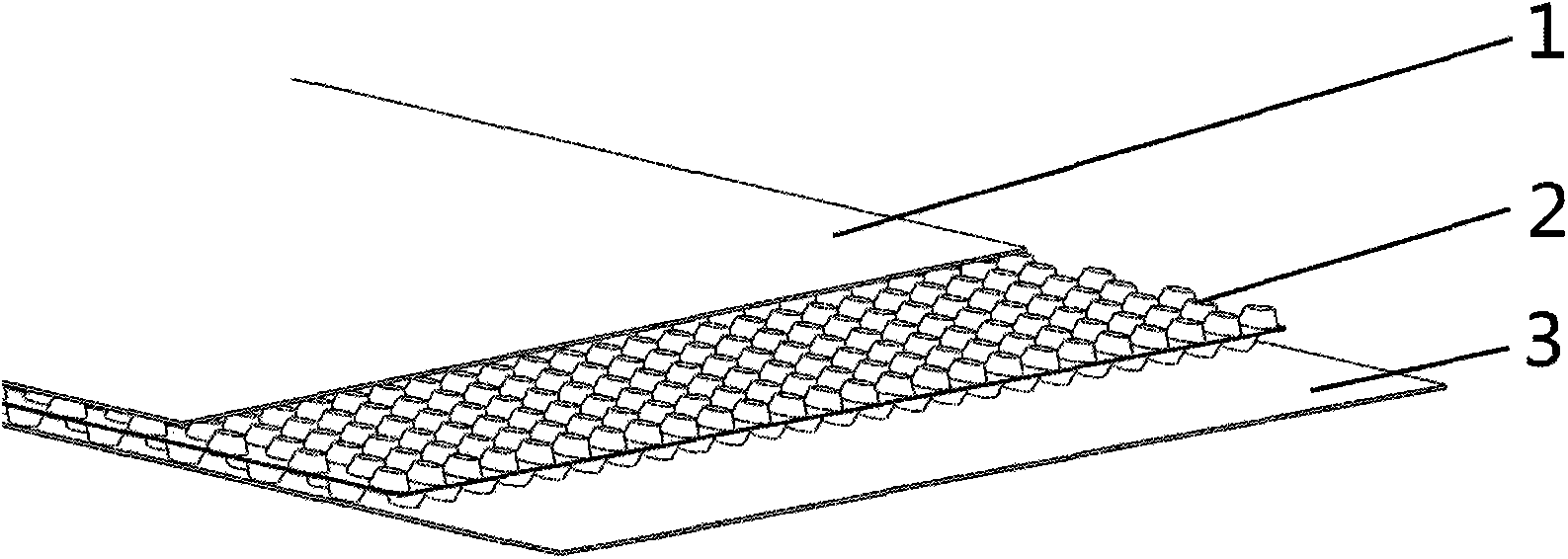

[0022] A dimple-shaped honeycomb hollow panel, its technical process and structure please refer to the attached figure 1 And attached figure 2 .

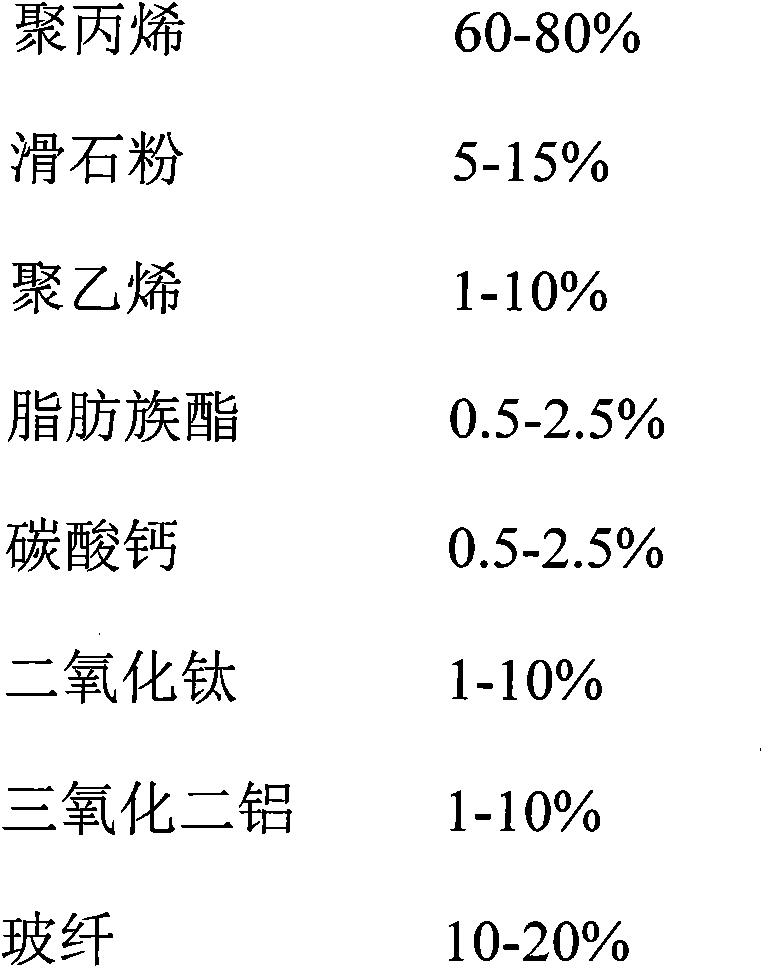

[0023] The percentage weight ratio of each component of the dimple-shaped honeycomb hollow board is:

[0024]

[0025] The components of the dimple-shaped honeycomb hollow panel in Example 1 are calculated based on the percentage weight ratio of the internal structure.

Embodiment 2

[0027] A dimple-shaped honeycomb hollow panel, its technical process and structure please refer to the attached figure 1 And attached figure 2 .

[0028] The percentage weight ratio of each component of the dimple-shaped honeycomb hollow board is:

[0029]

[0030]

[0031] The components of the dimple-shaped honeycomb hollow panel in Example 1 are calculated based on the percentage weight ratio of the internal structure.

Embodiment 3

[0033] A dimple-shaped honeycomb hollow panel, its technical process and structure please refer to the attached figure 1 And attached figure 2 .

[0034] The percentage weight ratio of each component of the dimple-shaped honeycomb hollow board is:

[0035]

[0036] The components of the dimple-shaped honeycomb hollow panel in Example 1 are calculated based on the percentage weight ratio of the internal structure.

[0037] The process steps of manufacturing the above-mentioned dimple-shaped honeycomb hollow board are as follows:

[0038] 1. The formula of the above-mentioned dimple-shaped honeycomb hollow board is prepared according to the weight percentage, and polypropylene, talcum powder, polyhexene, aliphatic ester, calcium carbonate, titanium dioxide, aluminum oxide and surface-treated glass Fibers are mixed in turn, stirring thoroughly evenly.

[0039] 2. Put the evenly stirred raw materials through a plastic granulator and dry them.

[0040] 3. Three sets of ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com