Backboard and curved-surface display device

A curved surface display device and backplane technology, which is applied to identification devices, instruments, etc., can solve the problems of high production cost, unstable surface curvature, and high cost of curved surface molds, so as to prevent springback deformation, reduce production difficulty, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

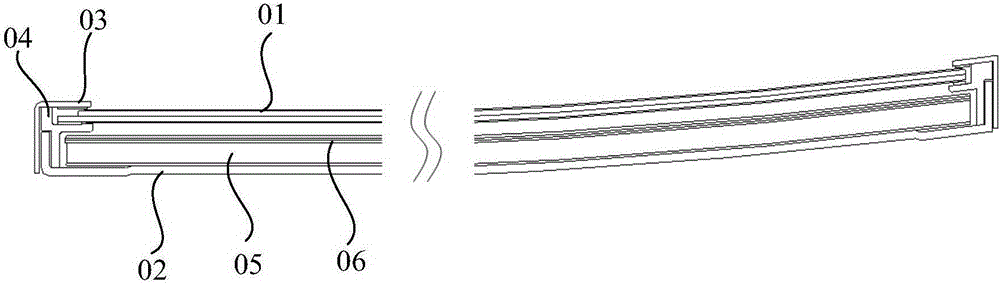

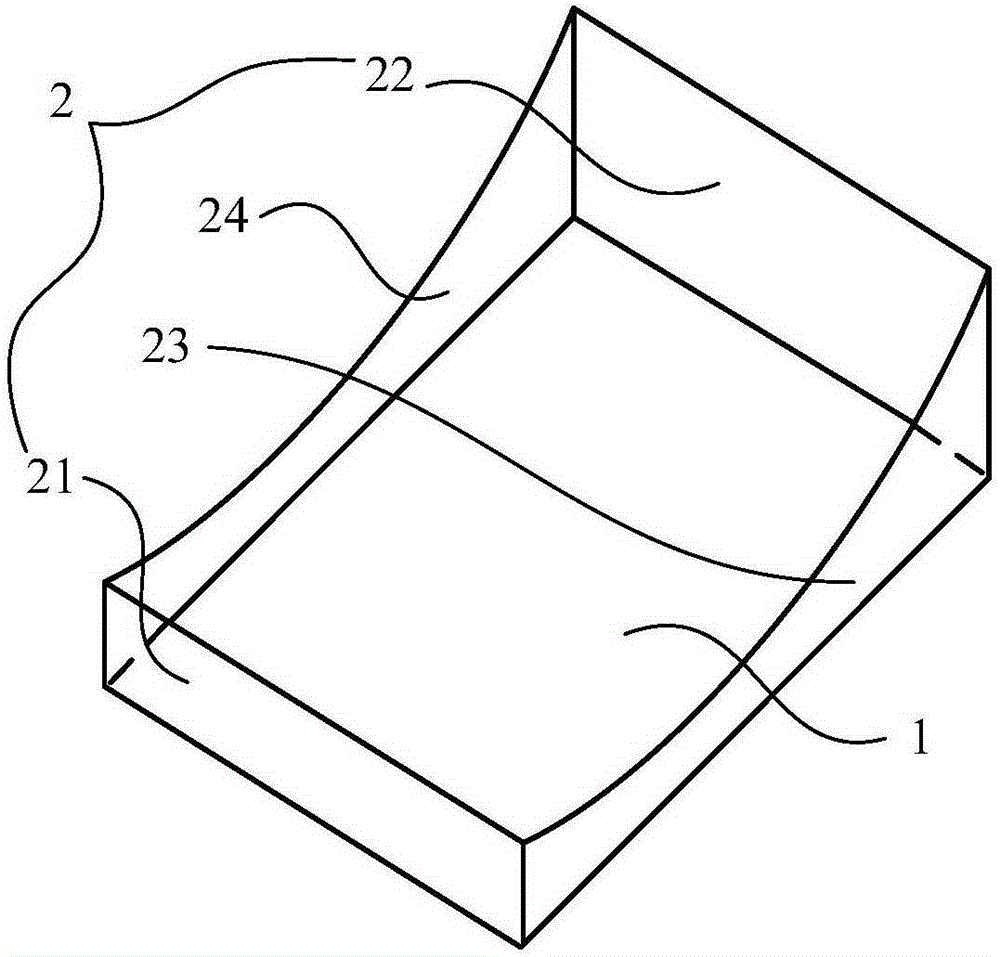

[0040] Embodiment 1: a side-in LED backlight curved surface display device. see Figure 4 , the side wall of the backplane 100 is provided with a light bar (not shown in the figure), and the light guide plate 6 is arranged on the bottom plate 1 of the backplane 100, the lower surface of the light guide plate 6 is a plane, and the upper surface of the light guide plate 6 is a curved surface , the upper surface of the light guide plate 6 is attached with an optical film group 7 , and the curvature of the upper surface of the light guide plate 6 is the same as that of the display panel 5 . In the existing technology, such as figure 1 with figure 2 As shown, the light guide plate 05 is an arc-shaped sheet-like structure with internal stress, so it is easy to deform during high-temperature and high-humidity tests. Figure 4 In the shown embodiment, the lower surface of the light guide plate 6 has a flat structure, which has good structural stability and small internal stress, s...

Embodiment 2

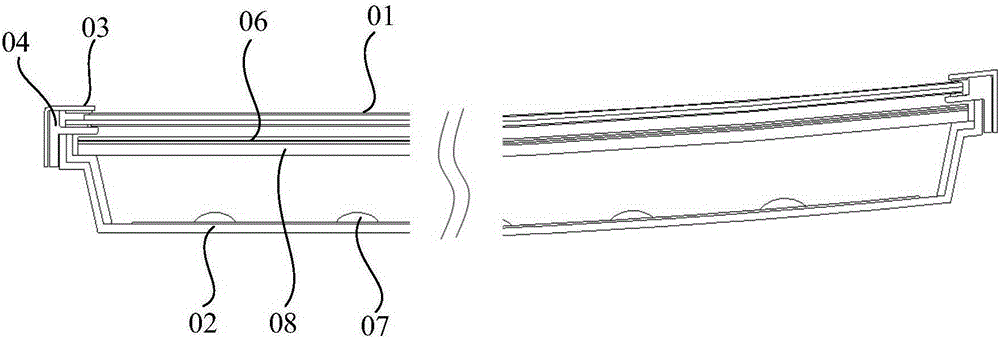

[0043] Embodiment 2: a direct-lit LED backlight curved surface display device. see Figure 5 The bottom of the backplane 100 is provided with a dot-matrix LED light source 8, and an optical cavity is provided directly above the dot-matrix LED light source. The sheet group 7 , the diffusion plate 9 and the optical film group 7 are all curved structures, and the curvatures of the diffusion plate 9 and the optical film group 7 are the same as those of the display panel 5 . Therefore, the backplane structure of the present invention can be applied to a direct-lit LED backlight curved display device, so that the display panel 5 can form a curved surface for curved display.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com