Welding tool for engine frame

A welding tooling and engine technology, applied in the field of tooling and fixtures, can solve problems such as easy deformation, internal stress, and unqualified, and achieve the effects of improving production and processing efficiency, reducing defective rate, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

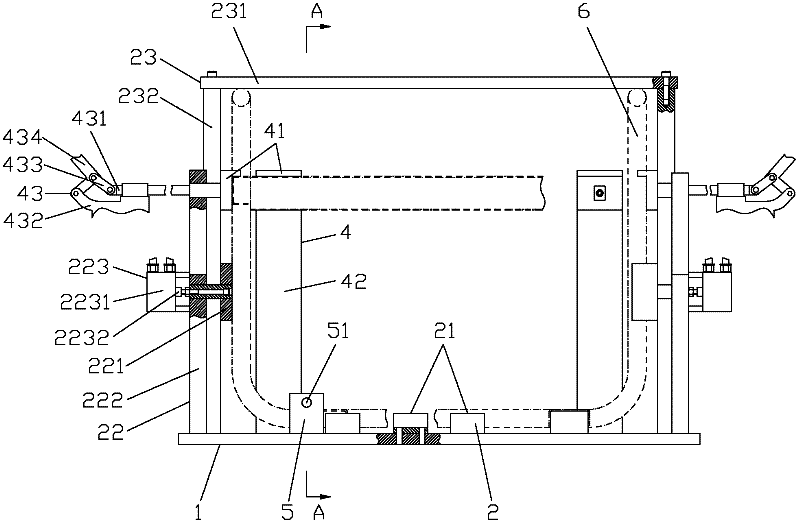

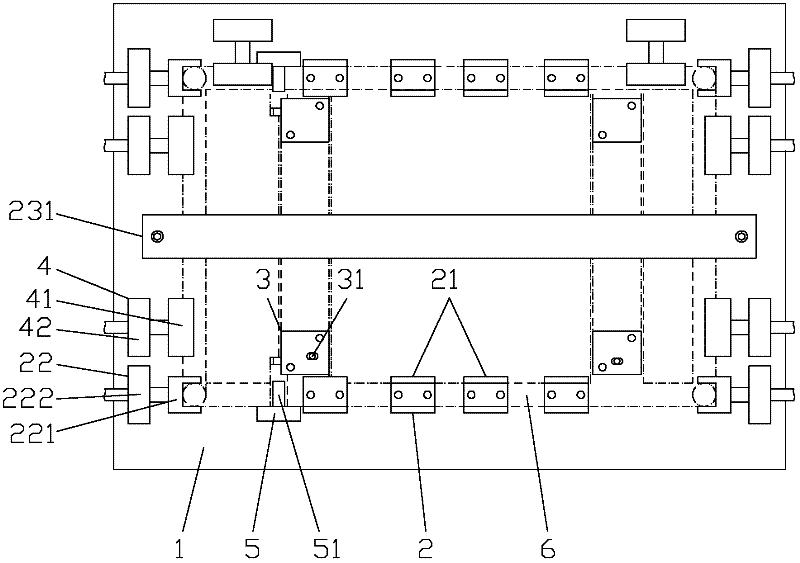

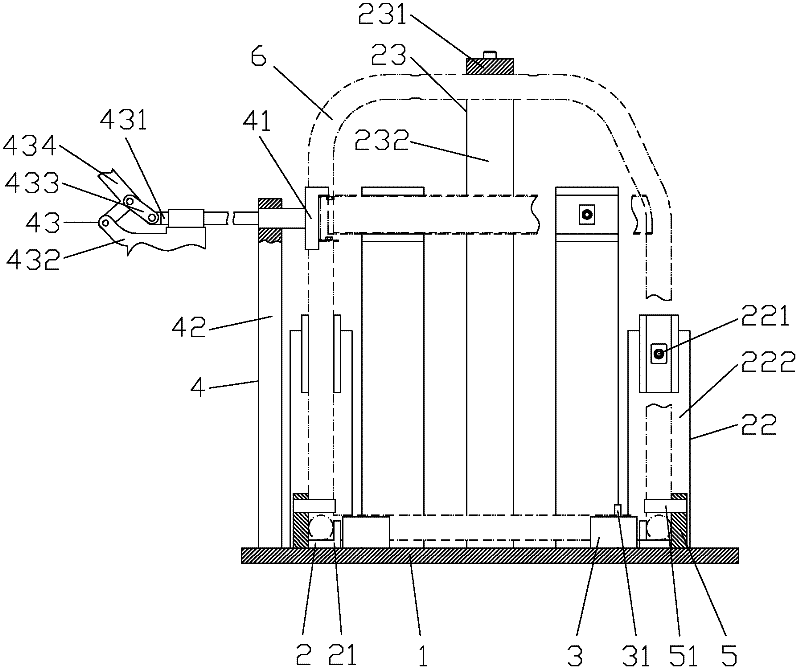

[0016] figure 1 It is the front view of the present invention, figure 2 It is a top view of the present invention, as shown in the figure: subject to the position shown in the figure, the engine frame welding tooling of this embodiment includes a fixed plate 1, a frame elbow positioning assembly 2, a bottom plate positioning block 3, and a beam positioning block 4 and the wheel axle seat positioning block 5, the frame elbow positioning assembly 2 includes concave limit sliders 21 distributed on the front and rear of the fixed plate 1, side positioning blocks distributed on the left and right sides of the fixed plate 1 Block 22 also includes hold-down device 23; Described concave positioning slide block 21 and side positioning block 22 are used to limit the horizontal direction degree of freedom of frame elbow 6, as shown in the figure: frame elbow 6 is made of metal tube Bending, including the bottom horizontal tube, vertical tube and top vertical tube, the bottom horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com