Superfine grinding oscillation mechanism

An oscillating mechanism and fine grinding technology, applied in the field of grinding processing, can solve the problems of aggravating the oscillation instability, unable to achieve a smooth transition of the end stroke of the reciprocating motion, and aggravating the instability without mass balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

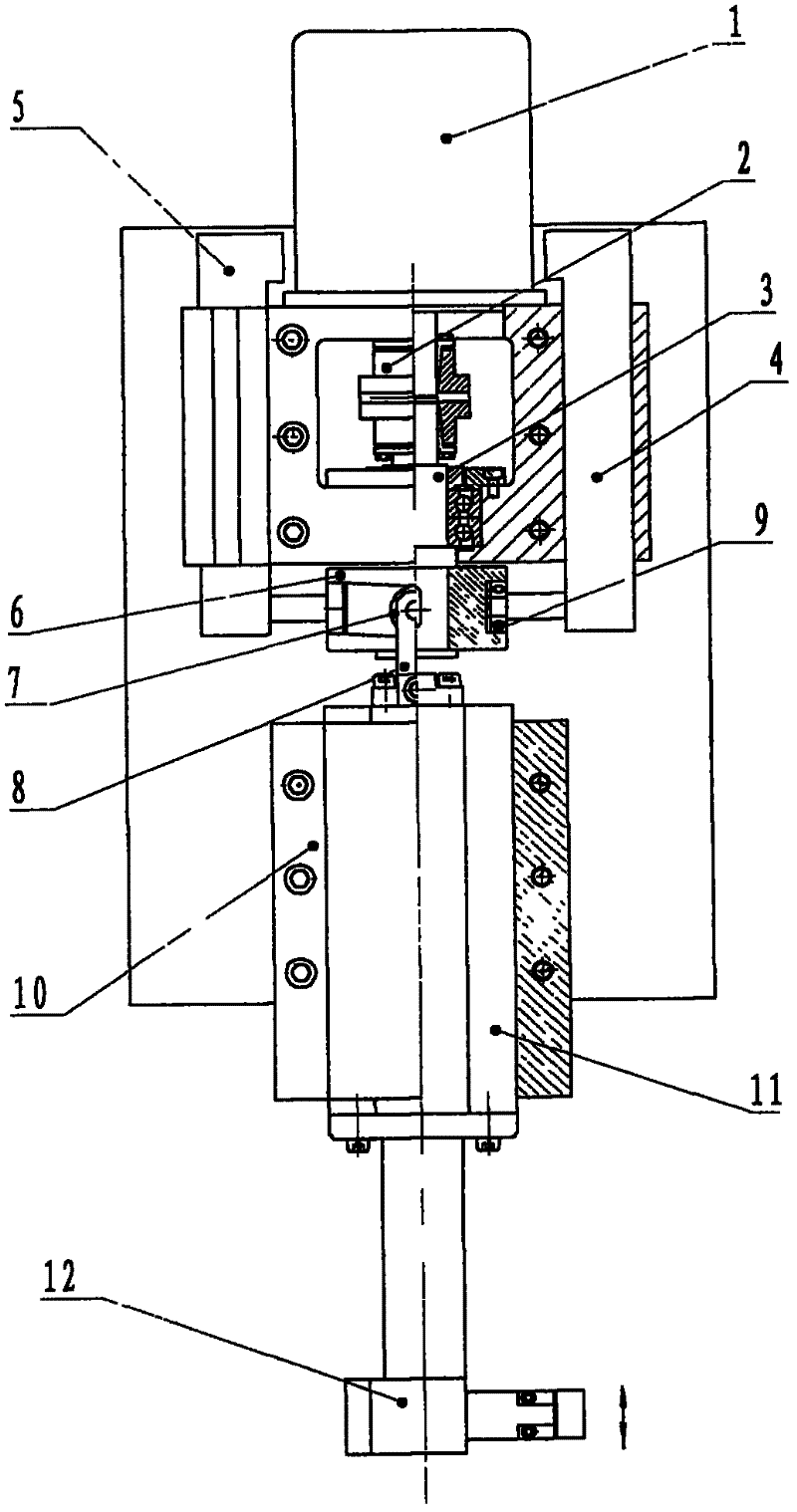

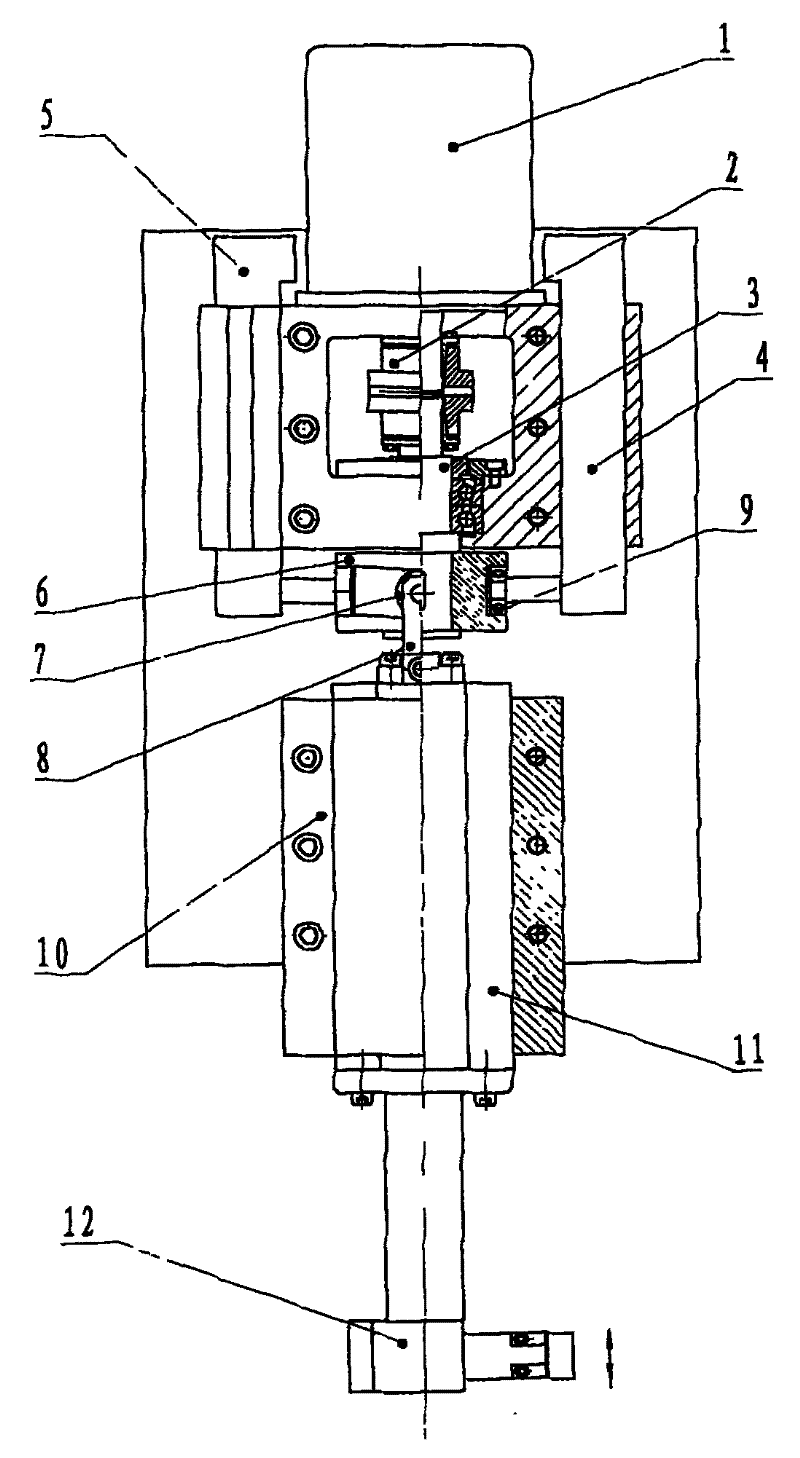

[0005] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is an improvement to the prior art, and it includes a motor 1, a shaft coupling 2, a rotating shaft 3, a right balance weight 4, a left balance weight 5, a balance wheel 9, and a sliding seat 10 , ram 11, oil stone clamp 12, the main improvement point is that a sheave 6 is connected with bearings and bearing seats on the left and right balance wheels respectively, and a drive wheel is installed on the rotating shaft on both sides of the sheave symmetrically protruding from the shaft surface. Wheel 7, drive plate 8 is pivotally connected between the driving wheel and the ram. The present invention replaces the eccentric shaft drive of the crank with a grooved wheel drive, which can optimize the smooth change of acceleration and smooth oscillation conversion, and because the driving wheels of the balance block and ram are installed symmetrically, they are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com