Device for performing fine machining on annular workpiece

A ring-shaped workpiece and equipment technology, applied in the direction of metal processing equipment, ultra-finishing machine, metal processing machinery parts, etc., can solve the problems of expensive and complicated technology, and achieve small first-level and second-level shape deviation, low Effect of fluctuation, excellent dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

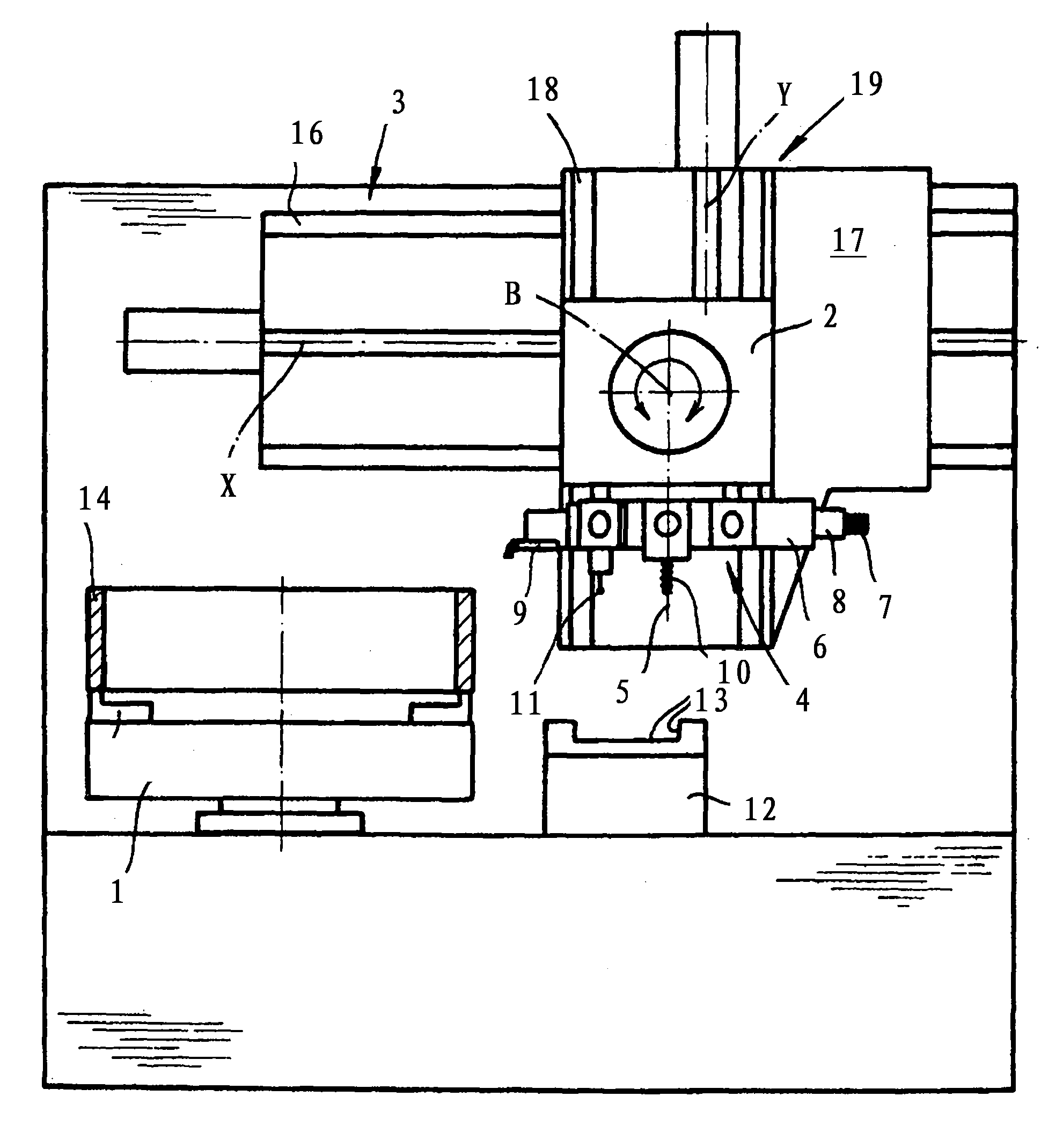

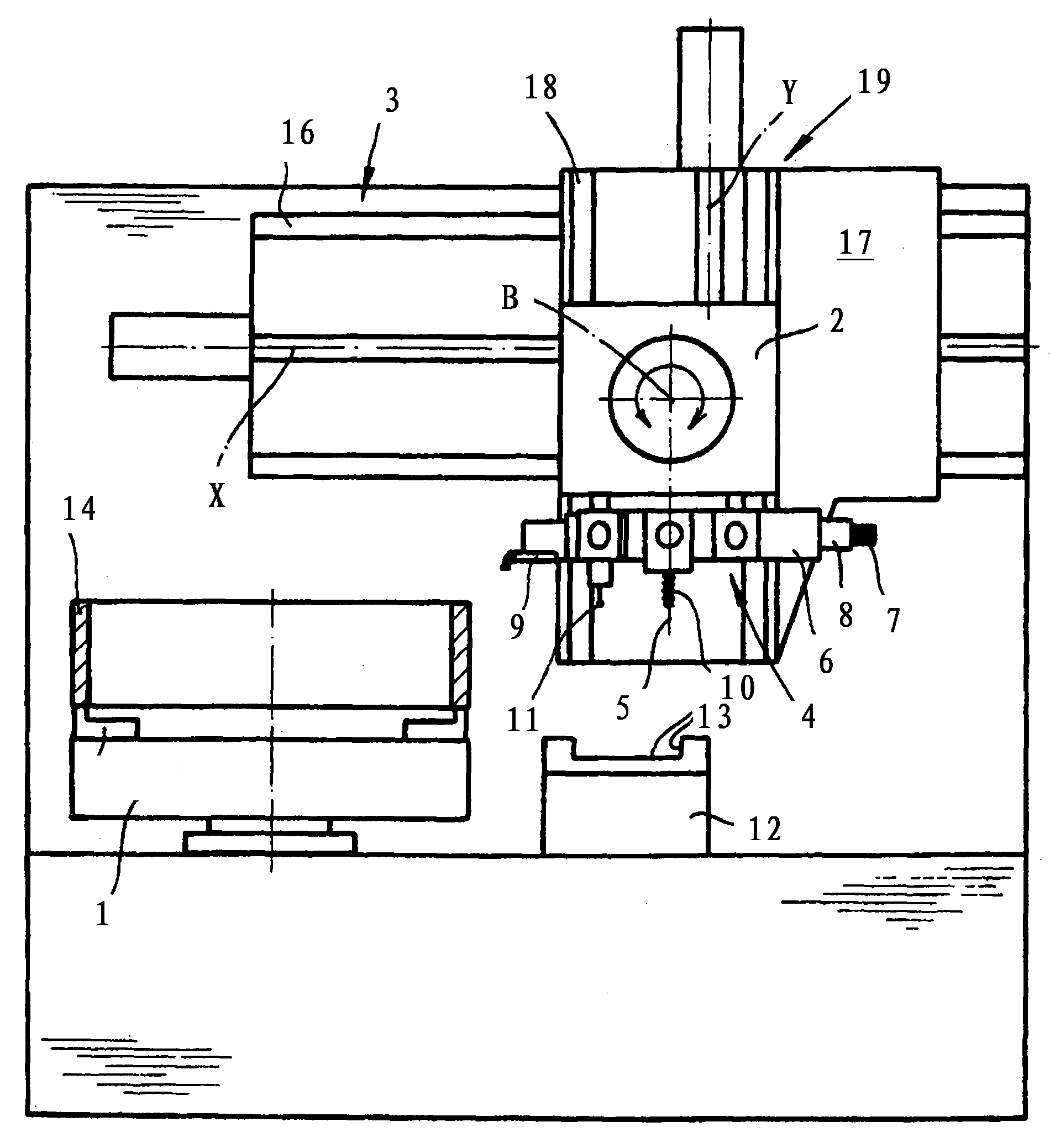

[0015] The basic design of the device shown in the figure comprises a rotatably drivable workpiece carrier 1, a two-axis basic machine tool 3 comprising a rotary unit 2, and a turret 4, which allows the rotation The unit 2 performs a linear feed movement along the horizontal axis X and the vertical axis Y, the turret 4 is connected to the rotary unit 2, the turret 4 comprises an axis of rotation 5 and a plurality of tool holders, which are arranged circumferentially in the rotation on axis 5. The rotary unit 2 comprises a rotary axis B arranged perpendicularly to the two linear axes X, Y. The axis of rotation 5 of the turret 4 is arranged perpendicular to the axis of rotation B of the swivel unit 2 such that the turret 4 performs a swivel movement on the axis of rotation B when the swivel unit 2 is activated. The turret 4 may comprise up to twelve tool holders designed as standard round arbor holders. At least one tool holder of the turret 4 comprises a device 6 for short-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com