Outer-ring superfinishing machine for four-point contact bearings

A four-point contact, ultra-finishing machine technology, applied in the direction of ultra-finishing machines, grinding machine parts, grinding feed movement, etc., can solve the problems of occupying space, unstable loading and unloading movements, long loading and unloading time, etc. , to achieve the effects of high processing precision, saving loading and unloading time, and short processing hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

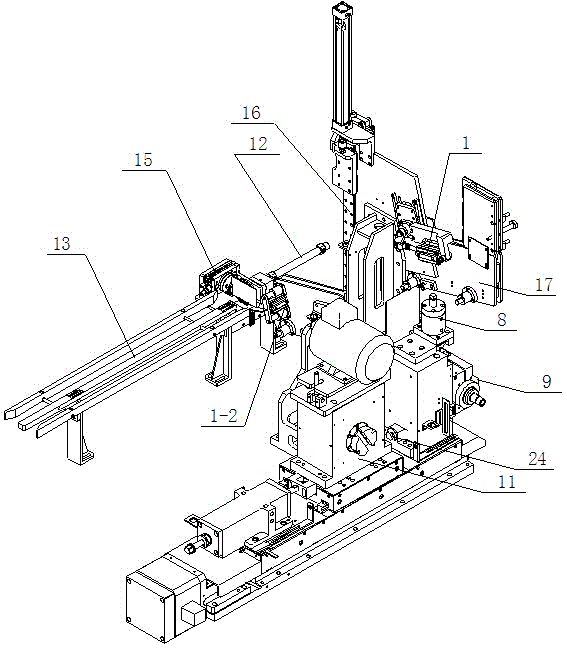

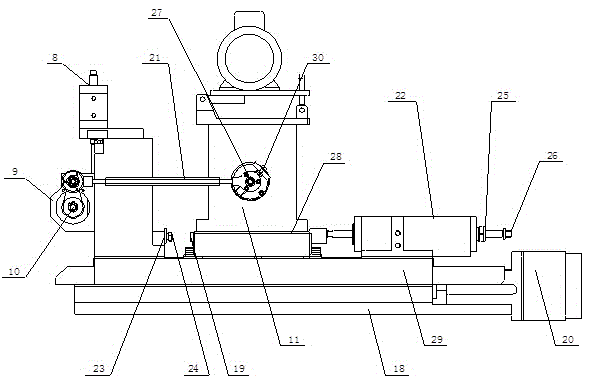

[0028] Such as figure 1 , figure 2 The four-point contact bearing outer ring superfinishing machine shown includes a feeding device, a pressing device, an oscillating device, and a discharge device. The superfinishing machine is also equipped with an angle conversion mechanism; Material center turning mechanism. The feeding device includes a material separation device 1 and a feeding cylinder 2; the pressing device includes a centering pressure wheel 4-1 for the outer ring super-finishing machine, a pressure wheel oil cylinder 5-1 for the outer ring super-finishing machine, and a super-finishing machine for the outer ring super-finishing machine. Head 6-1, outer ring superfinishing machine swing head device 7-1; the oscillation device includes an oscillation frame oil cylinder 8, an oscillation head frame 9, an oscillation spindle 10, and an oscillation box 11; the discharge device includes a discharge cylinder 12, a discharge Road 13 and feeding channel 14. In the dischar...

Embodiment 2

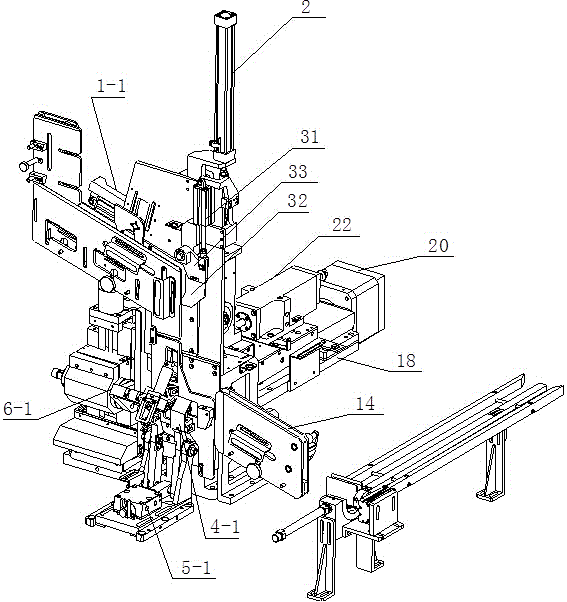

[0038] Such as Figure 6 , Figure 7 The four-point contact bearing inner ring superfinishing machine shown includes a feeding device, a pressing device, an oscillating device and a discharge device, and the superfinishing machine is also equipped with an angle conversion mechanism. The feeding device includes a material separation device 1 and a feeding cylinder 3; the pressing device includes an inner ring super-finishing machine centering pressure wheel 4-2, an inner ring super-finishing machine pressure wheel oil cylinder 5-2, and an inner ring super-finishing machine super-finishing head 6-2. Inner ring ultra-finishing machine oscillating device 7-2; the oscillating device includes an oscillating frame oil cylinder 8, an oscillating head frame 9, an oscillating main shaft 10, and an oscillating box 11; the discharge device includes a discharge cylinder 12 and a discharge channel 13 and the feeding channel 14; the form of the spacer 1 in the inner ring ultra-finishing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com