Patents

Literature

99results about How to "Save time for loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

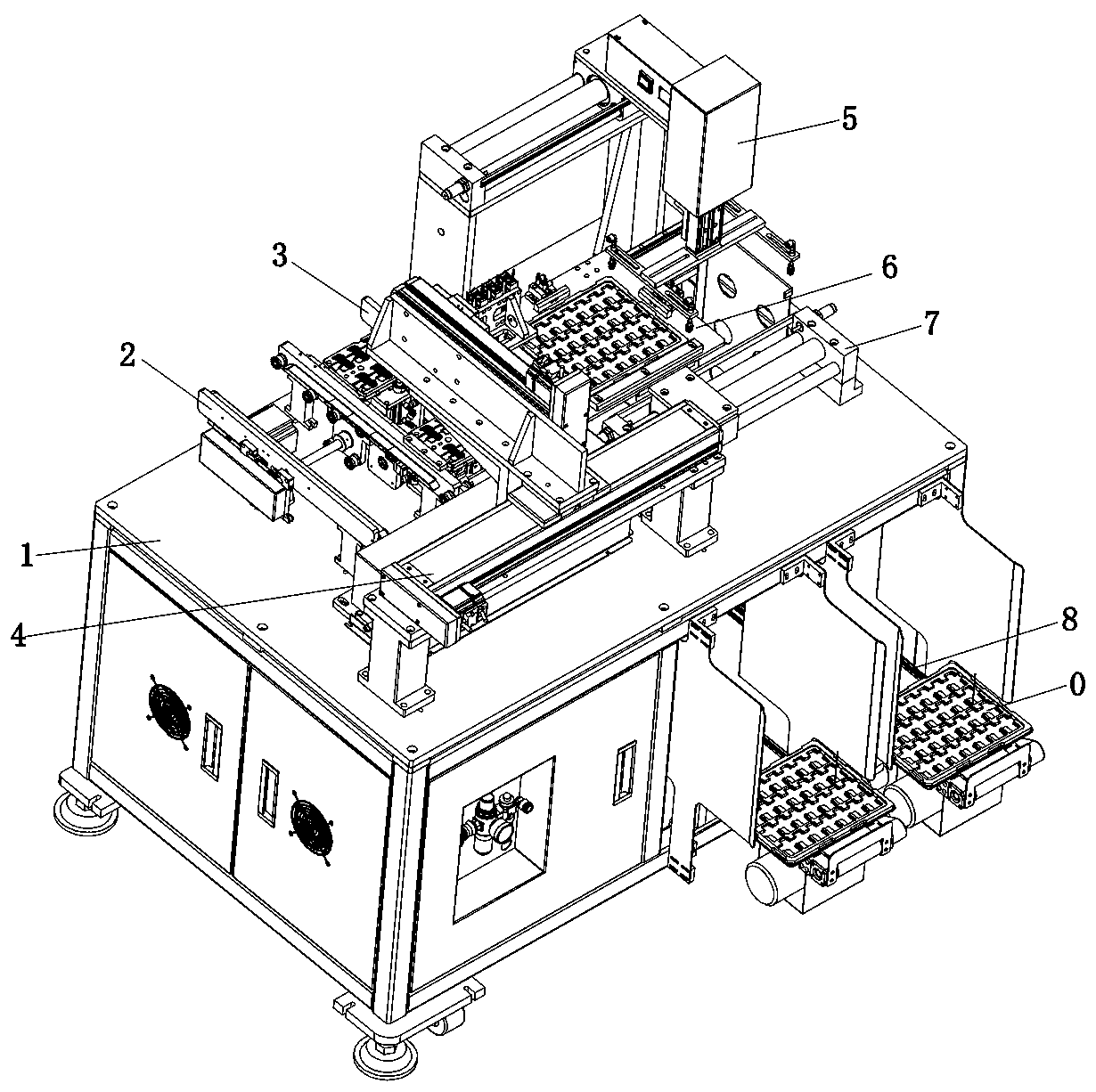

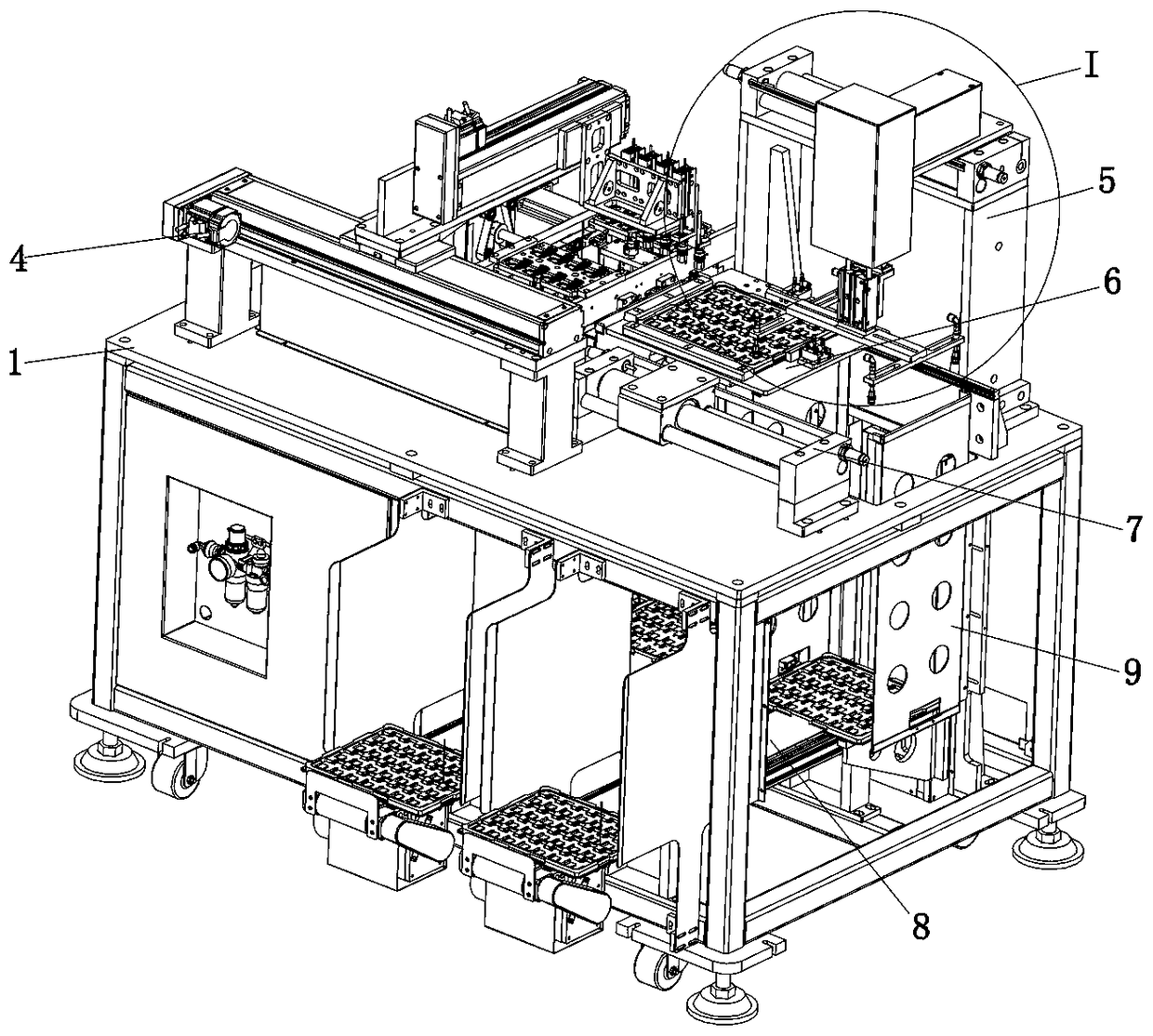

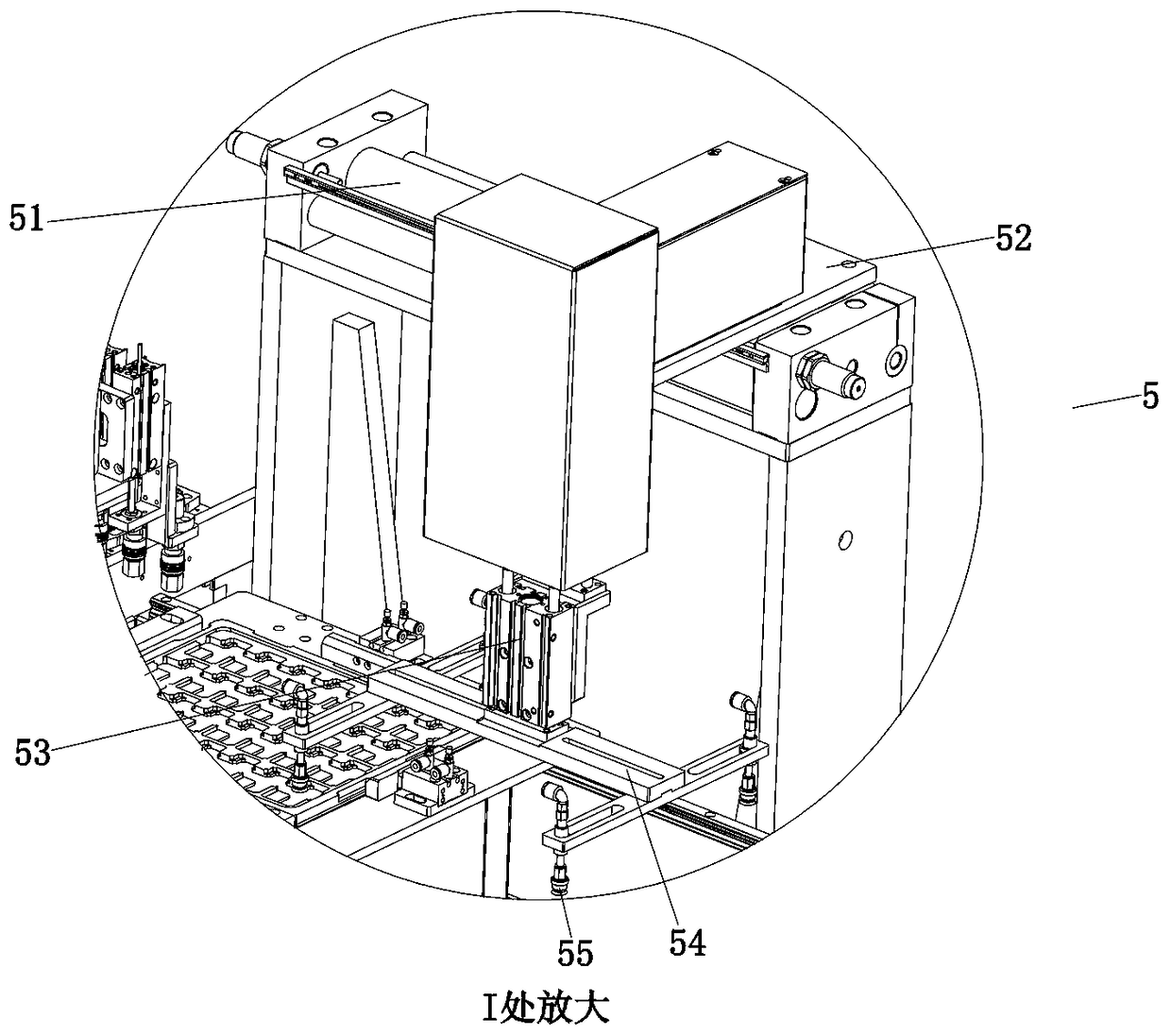

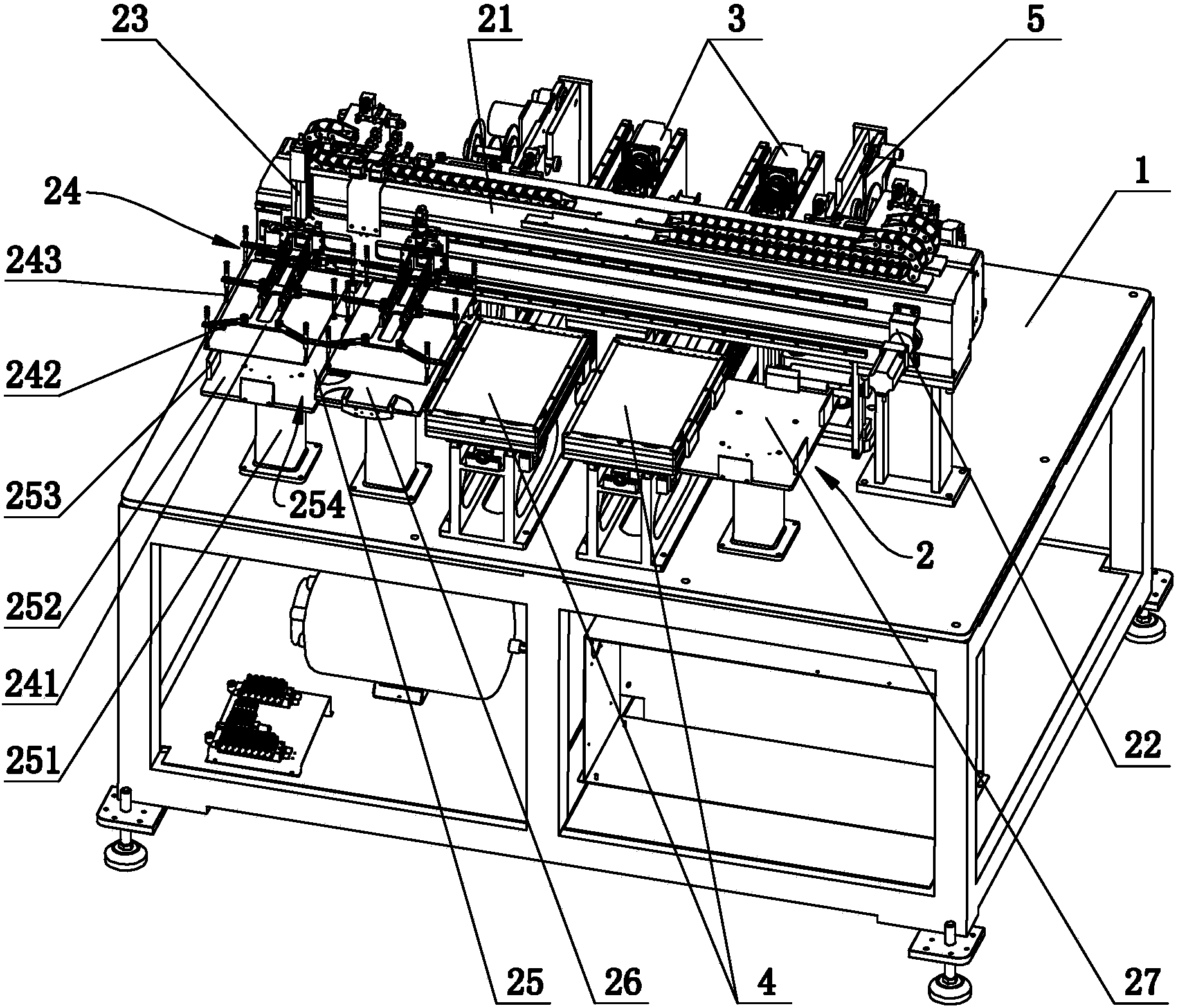

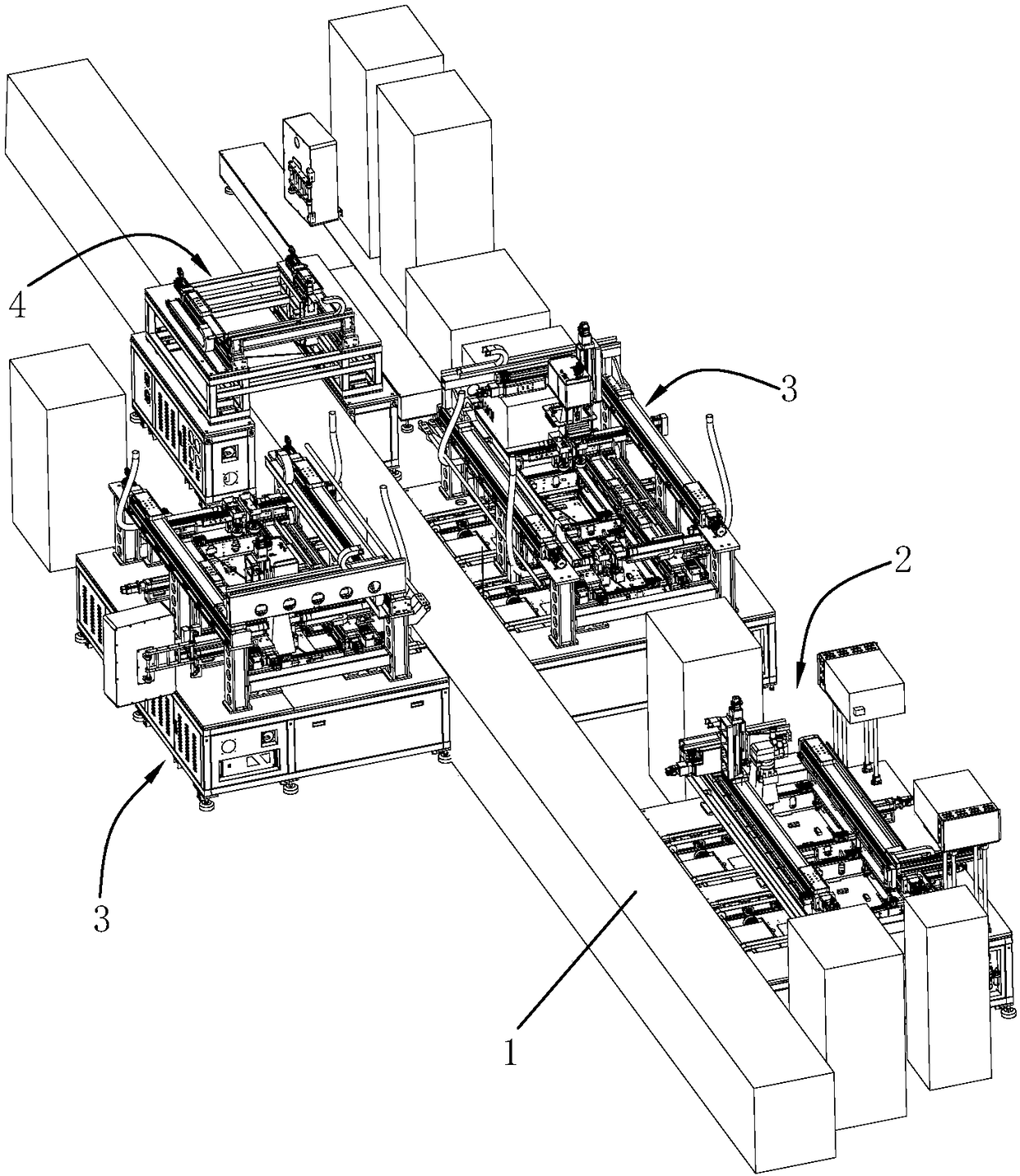

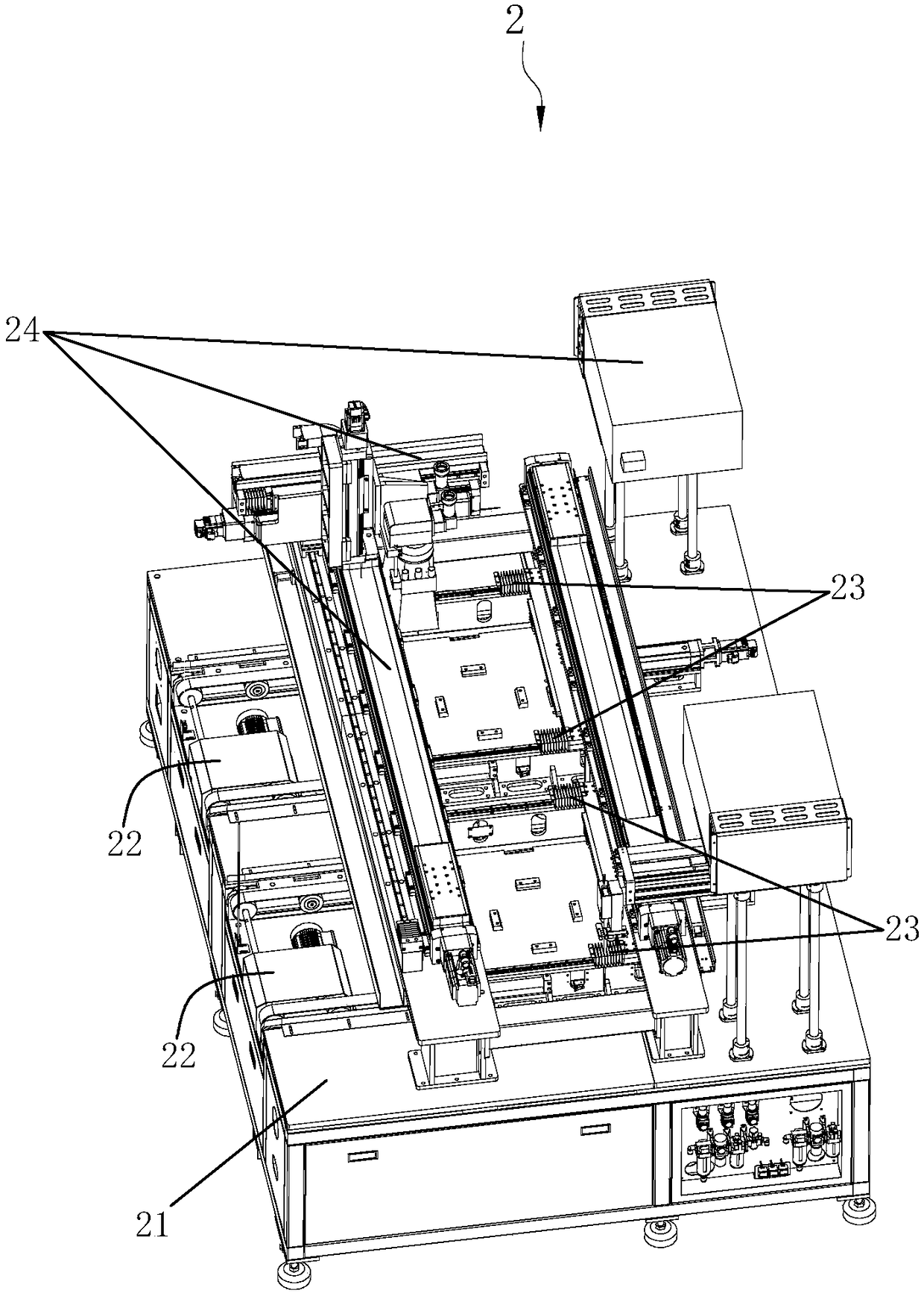

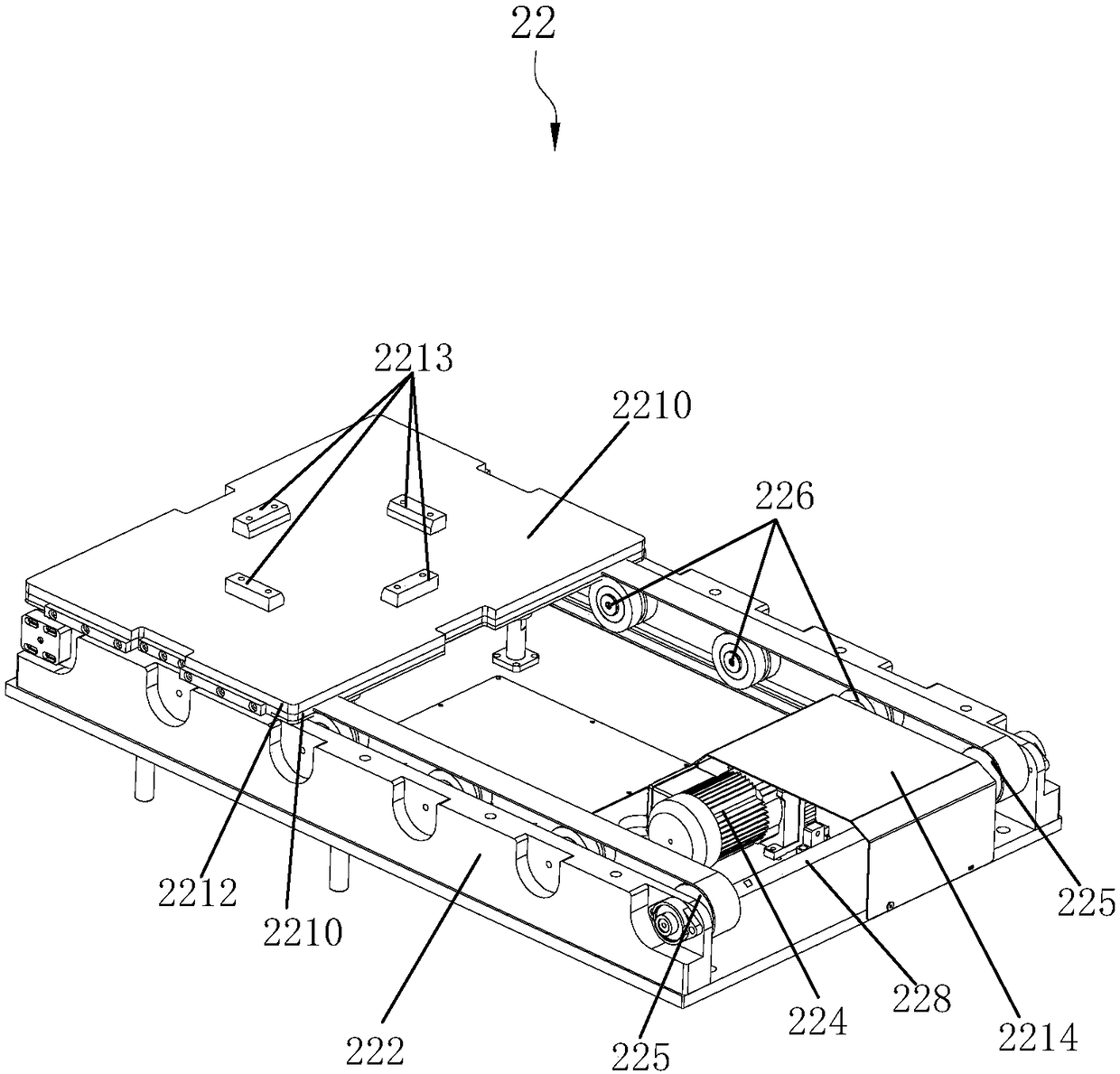

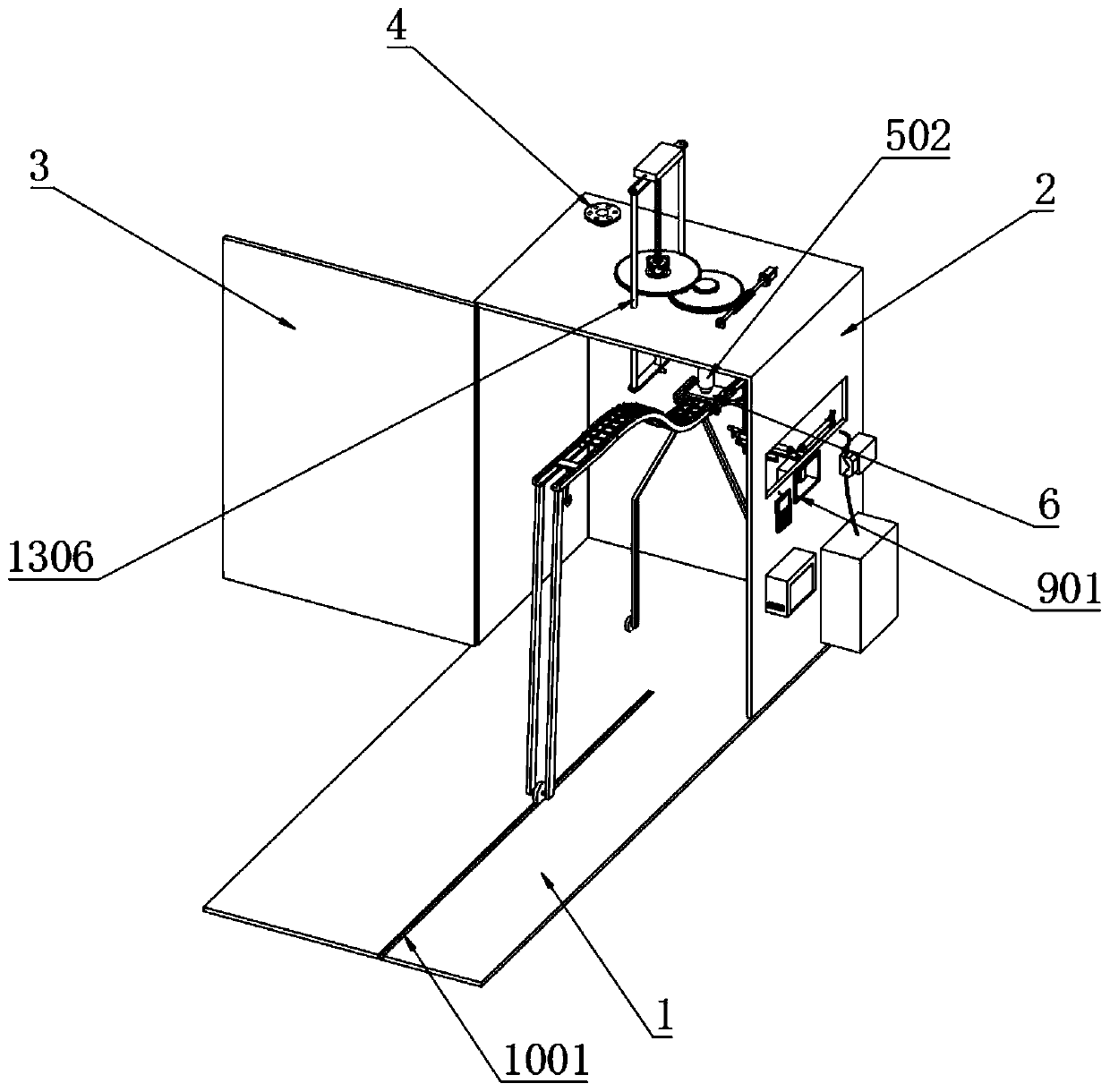

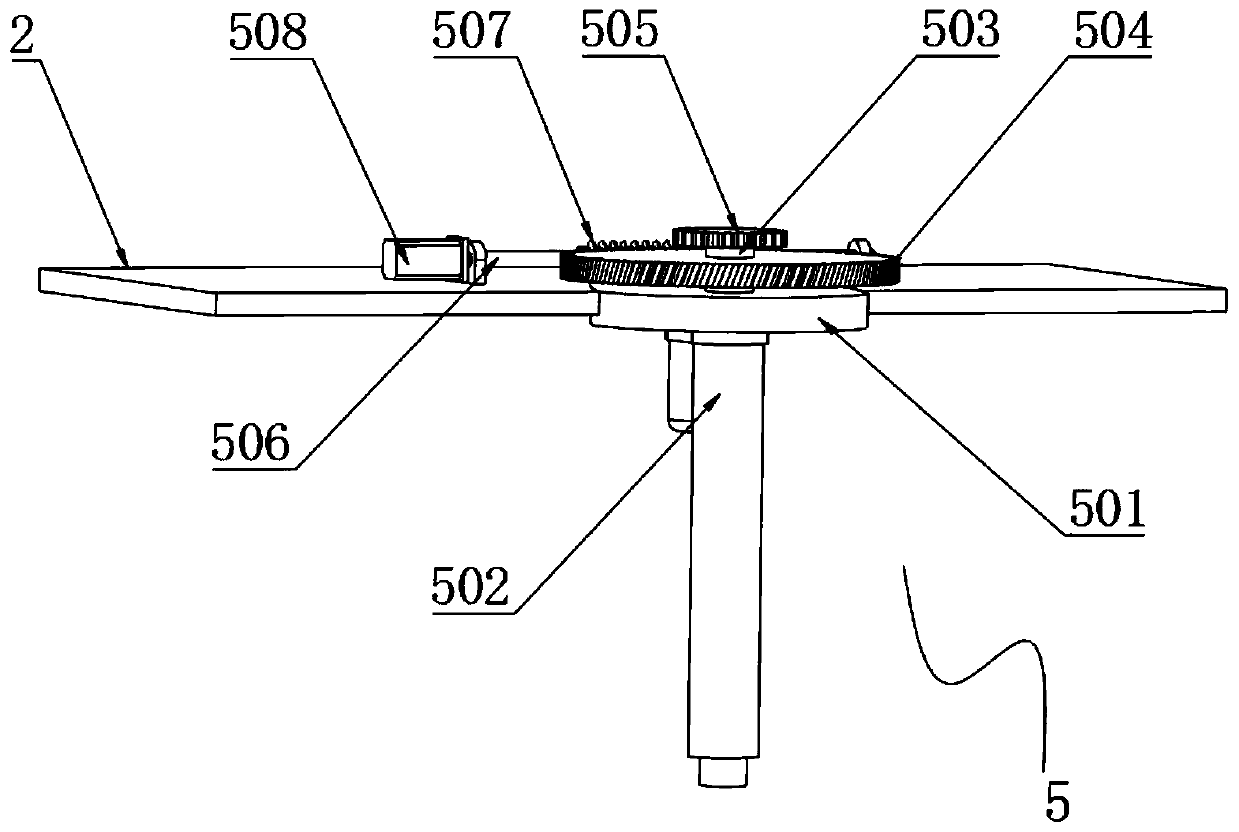

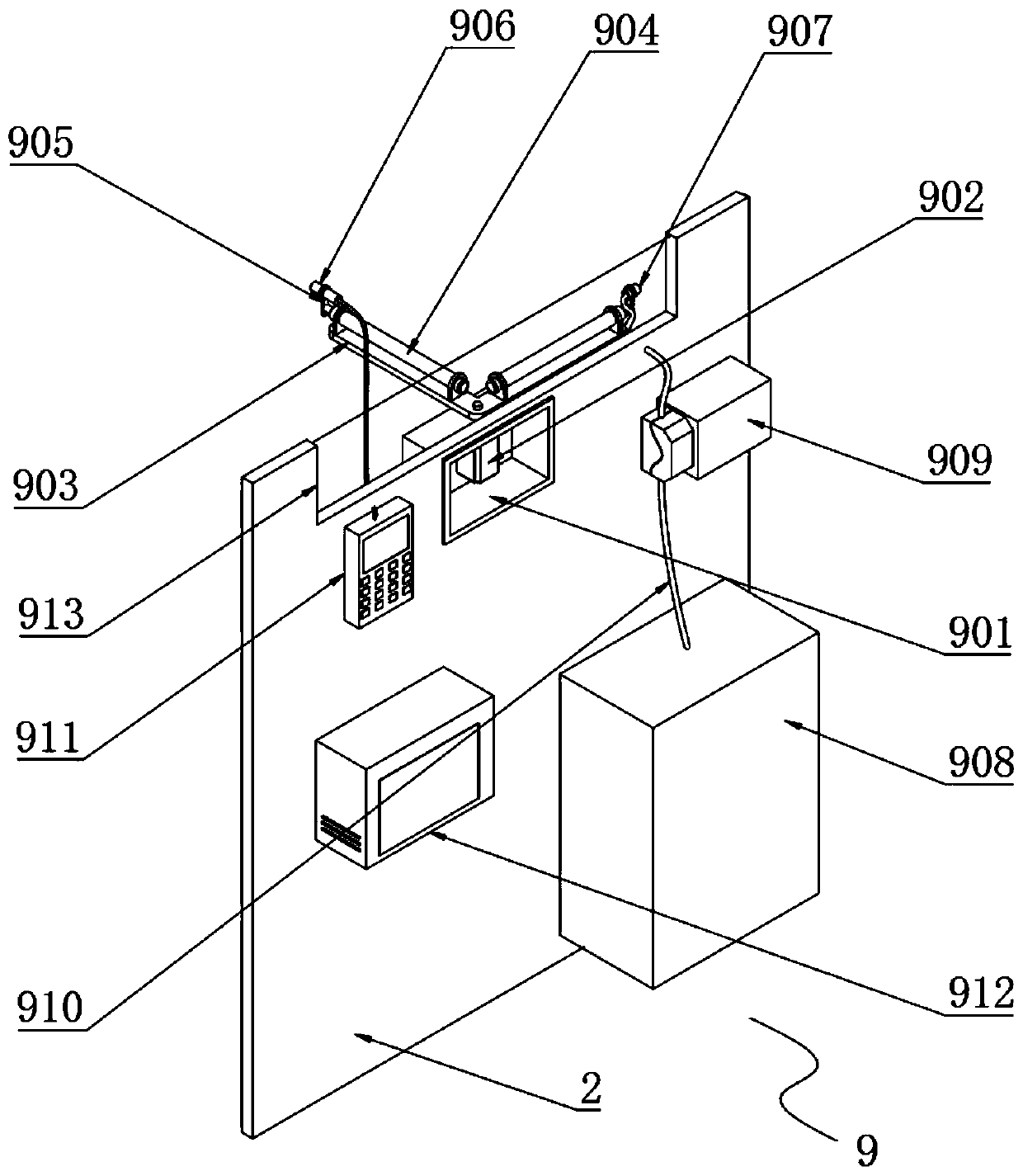

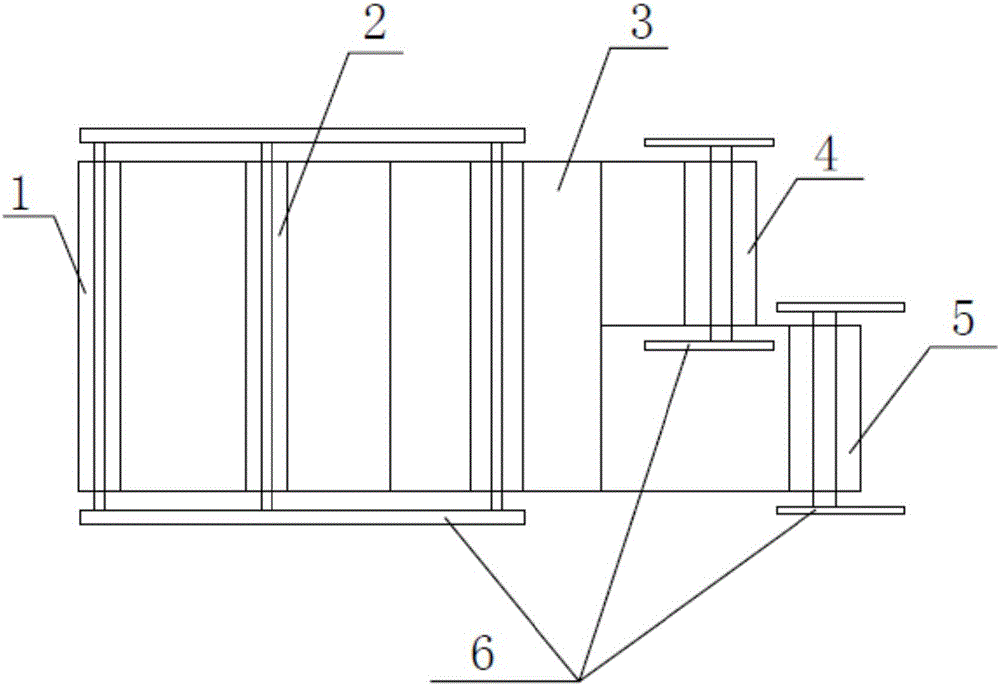

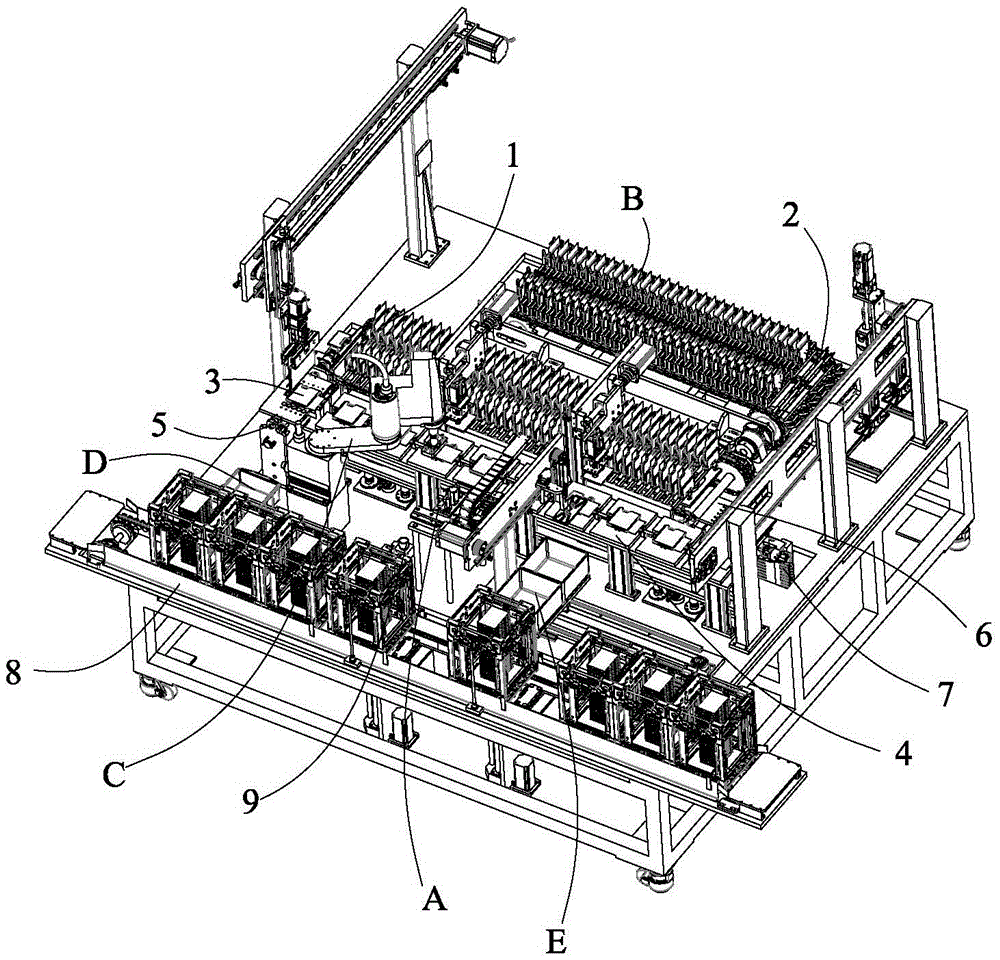

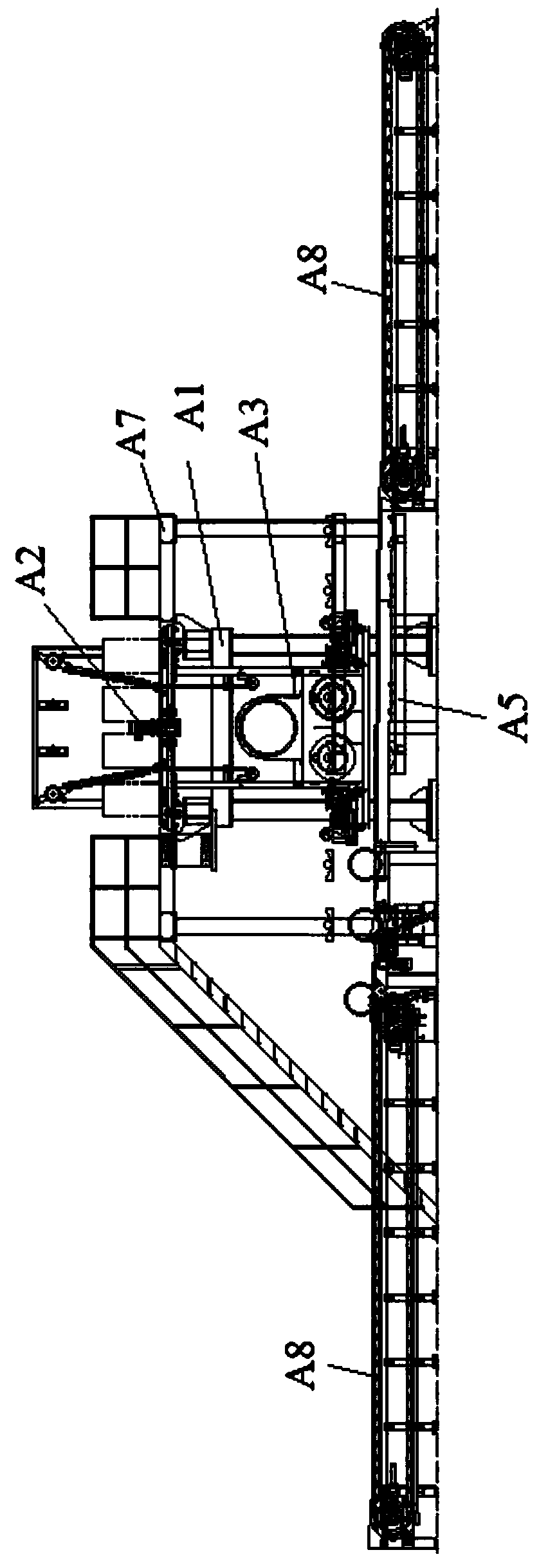

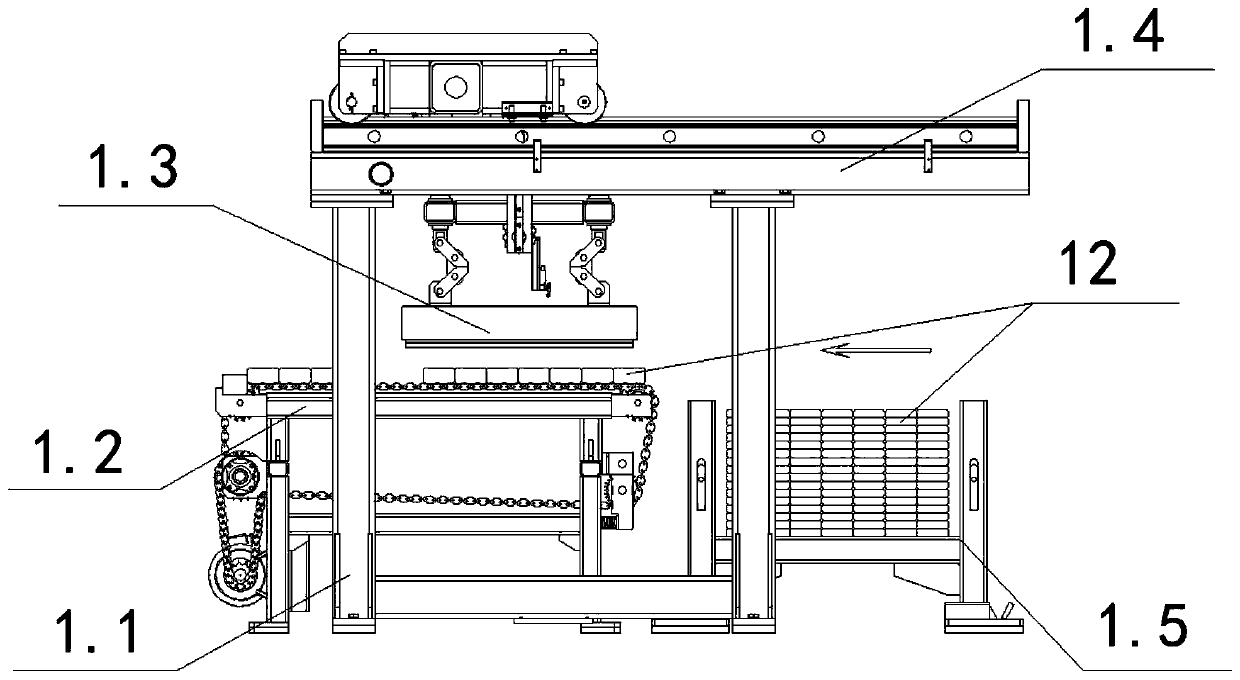

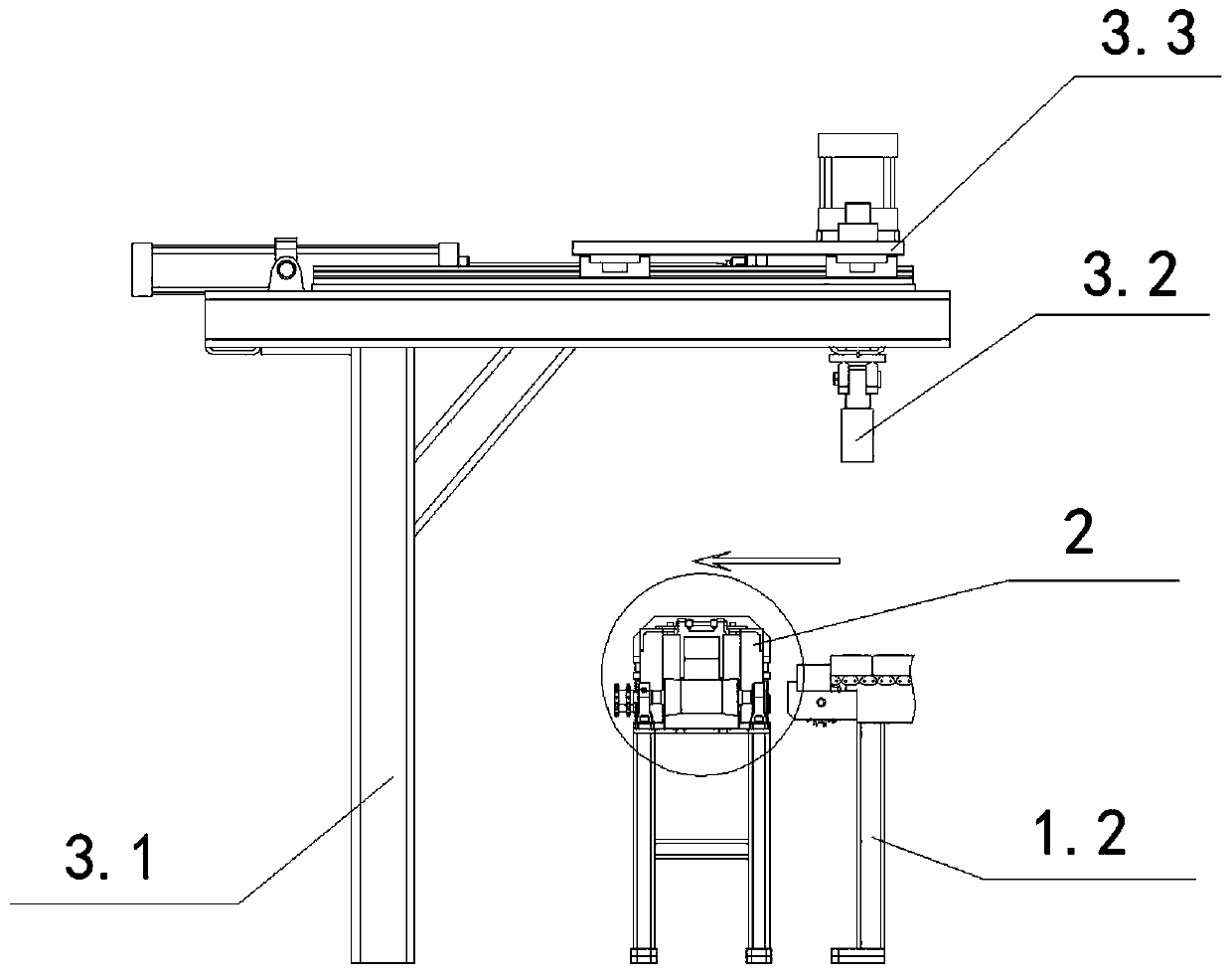

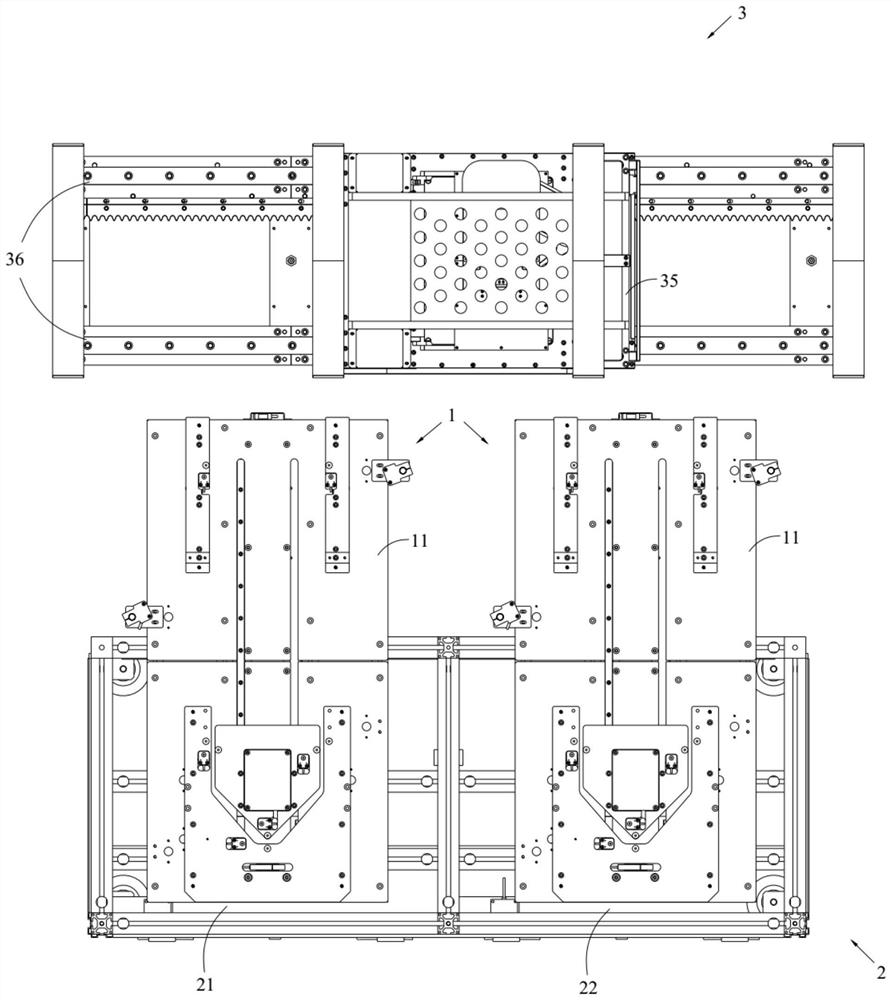

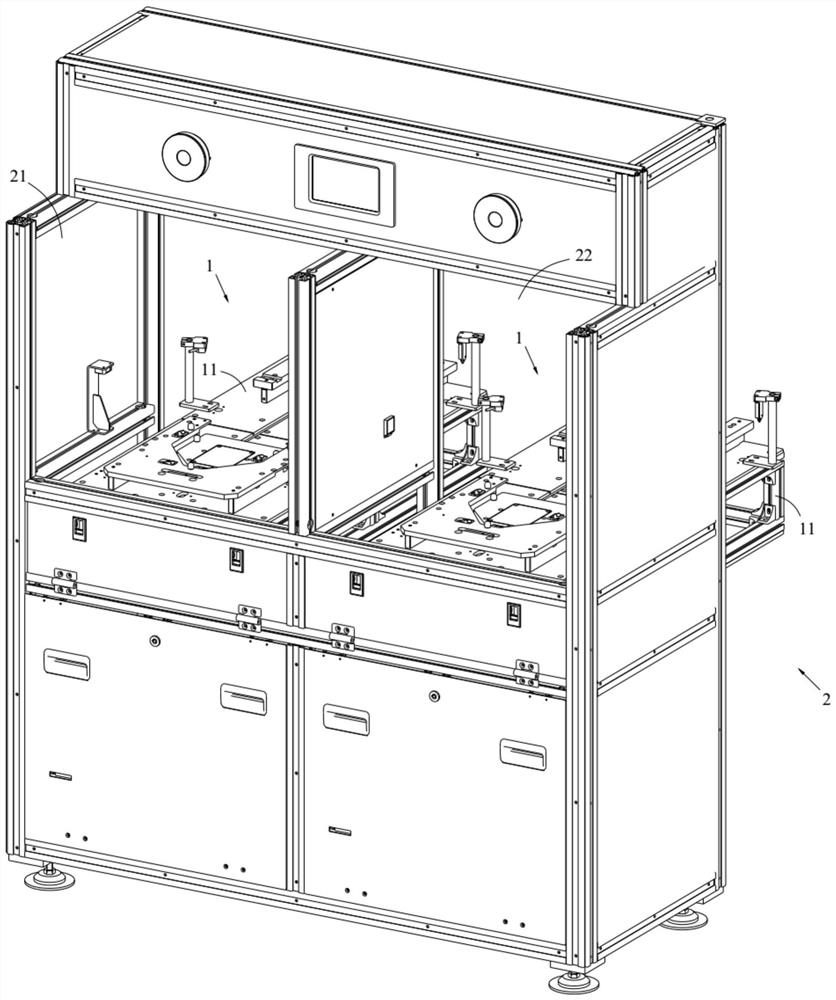

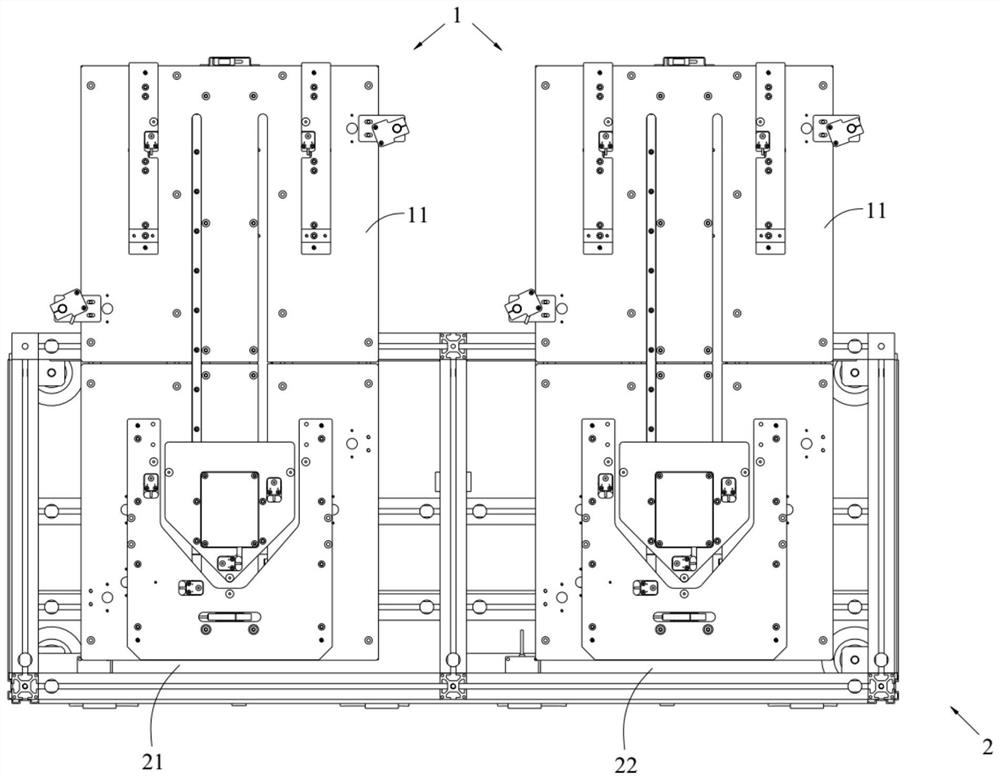

Backflow and circular unloading device for electronic product automatic assembly tools

PendingCN109319494AImprove cutting efficiencyAvoid time costConveyor partsMechanical conveyorsEngineeringTransfer mechanism

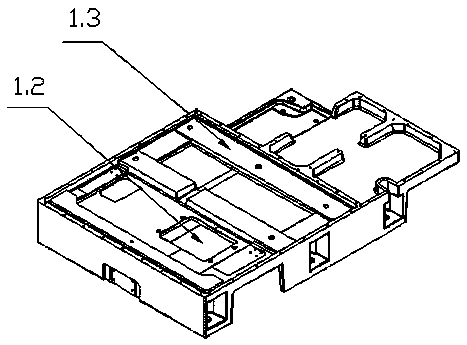

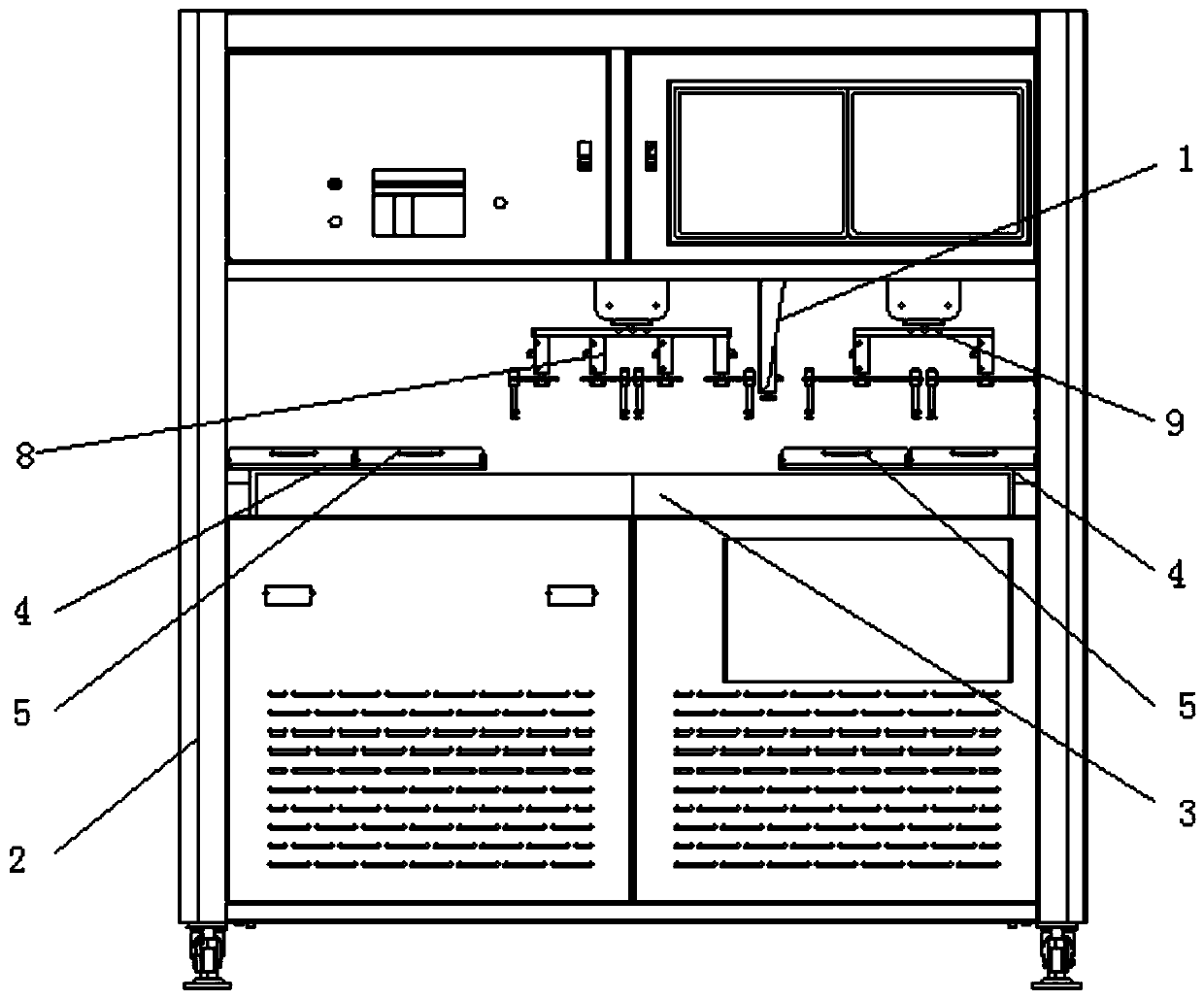

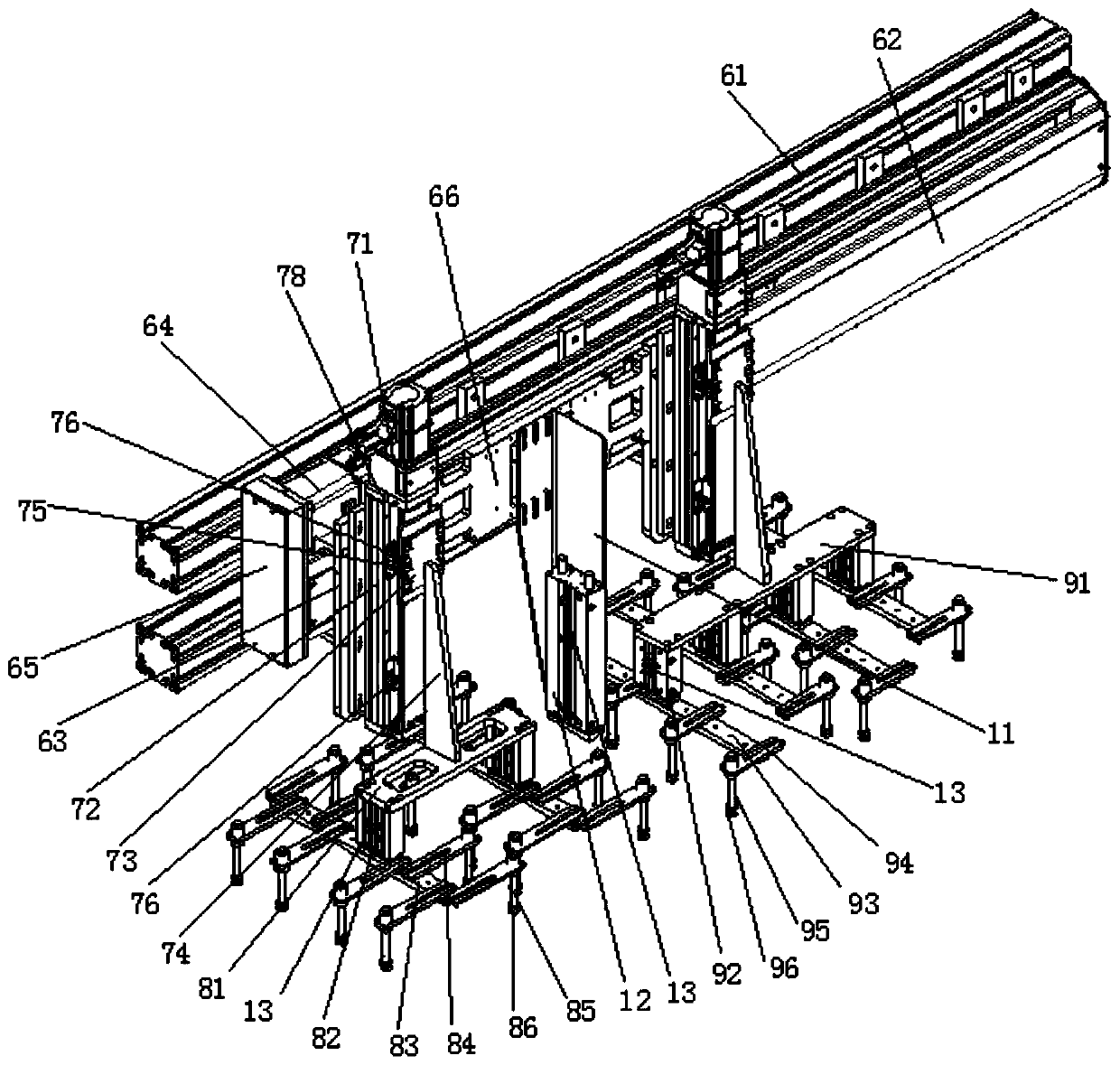

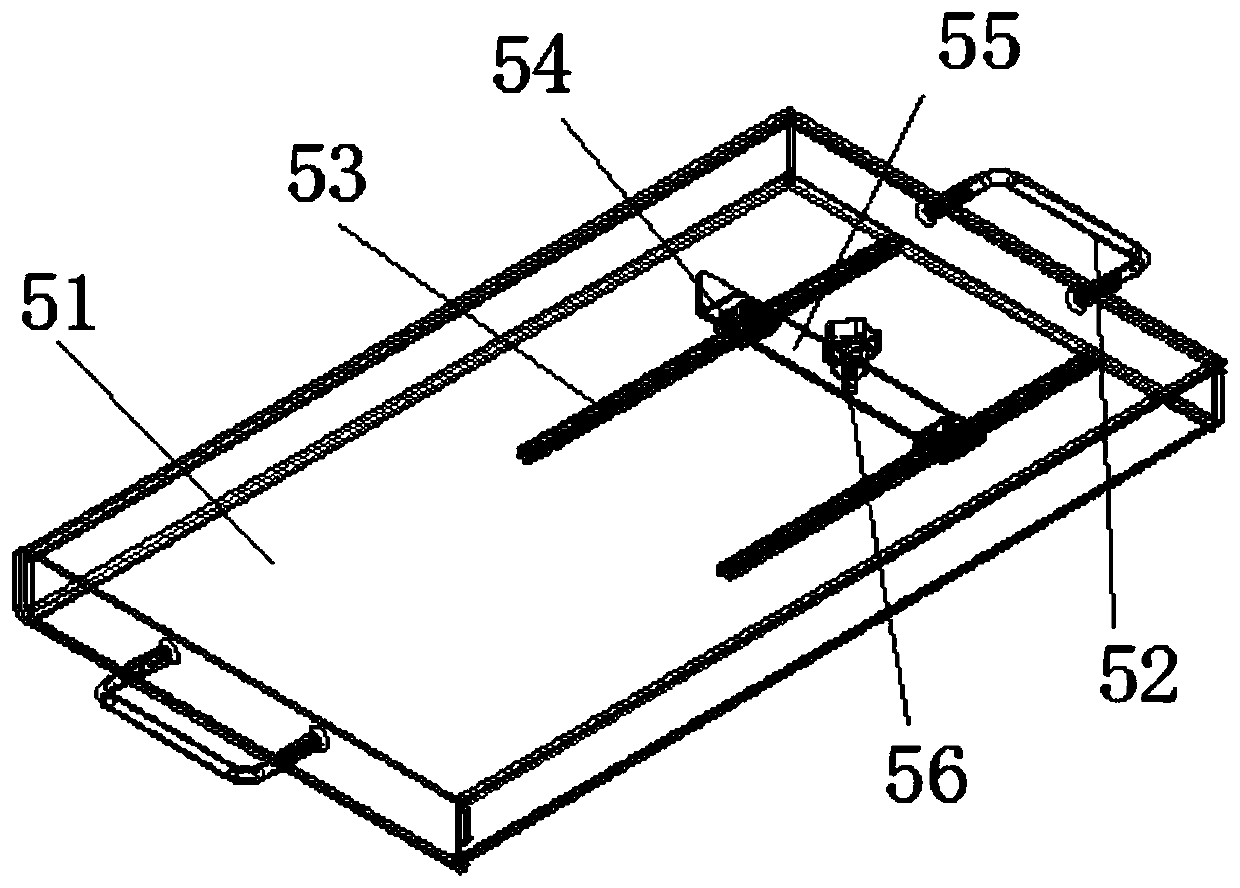

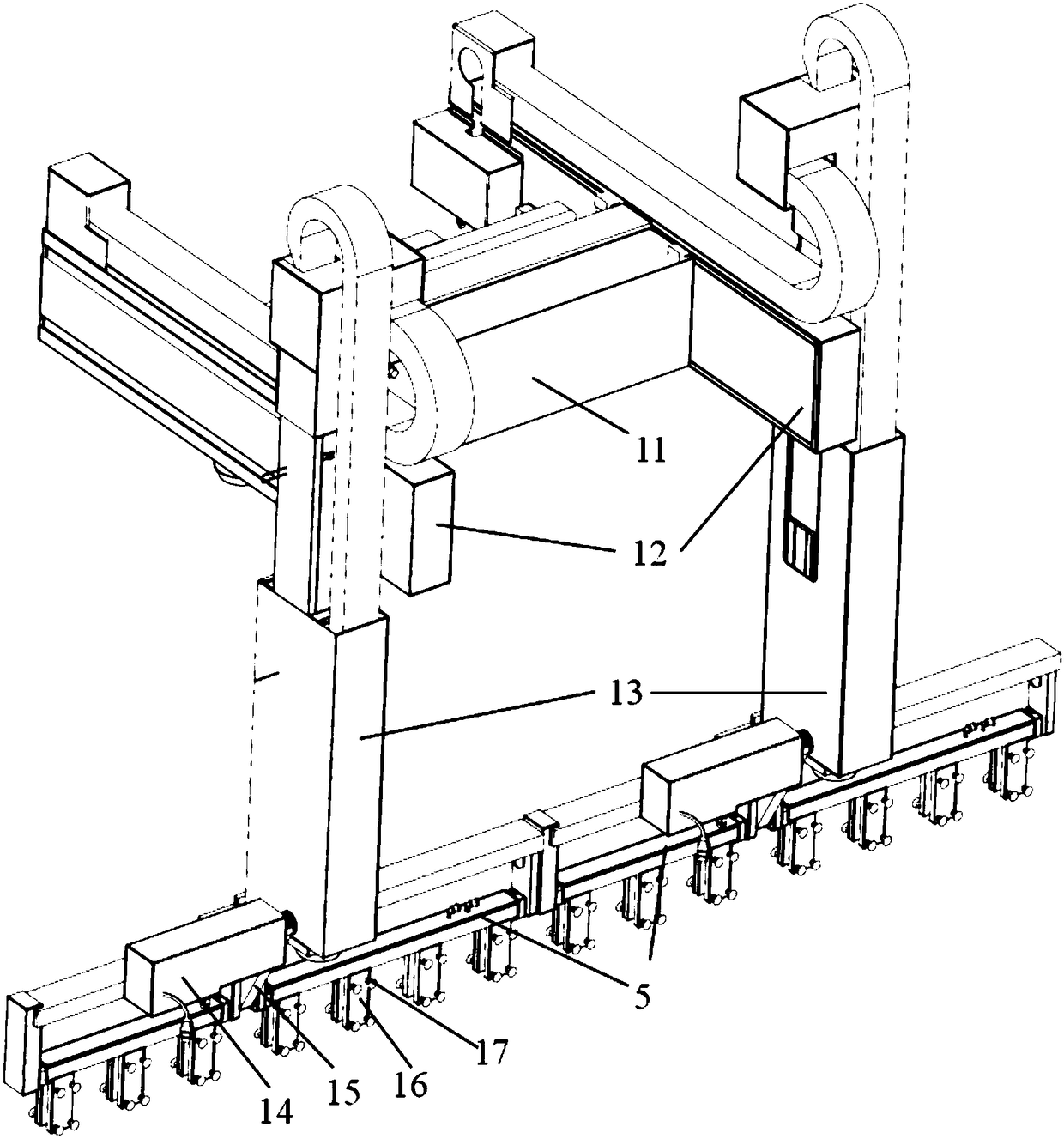

The invention discloses a backflow and circular unloading device for electronic product automatic assembly tools. The device comprises a frame, a conveying mechanism, an unloading manipulator, a traytransfer mechanism and a tray unloading mechanism; the conveying mechanism is arranged on the frame; tools for loading products are placed on the conveying mechanism; the tools circularly flow in theconveying mechanism; the tray unloading mechanism is arranged on one side of the conveying mechanism; a material waiting station and an unloading station are arranged in the tray unloading mechanism;the tray transfer mechanism is arranged in the material waiting station or the unloading station, and slides back and forth between the material waiting station and the unloading station to shift trays fully filled with the products in the material waiting station to the unloading station; the trays are stacked up and down by multiple layers in the unloading station for centralized unloading; andthe unloading manipulator is spun between the conveying mechanism and the tray unloading mechanism. The device shortens the tool loading and unloading time, realizes centralized unloading and loadingof multiple products once, shortens the replacement and refitting time of the trays, and effectively improves the overall production capacity.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

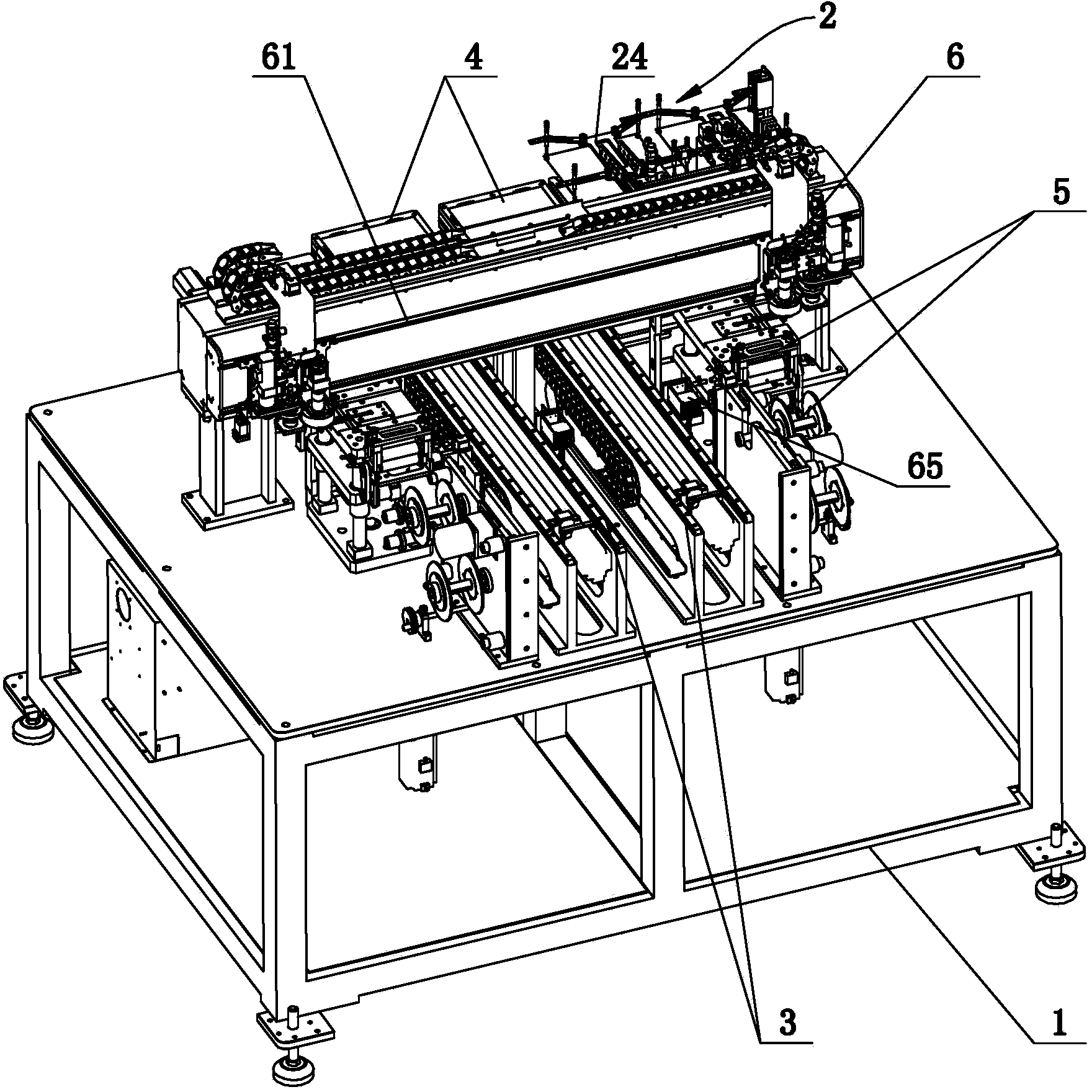

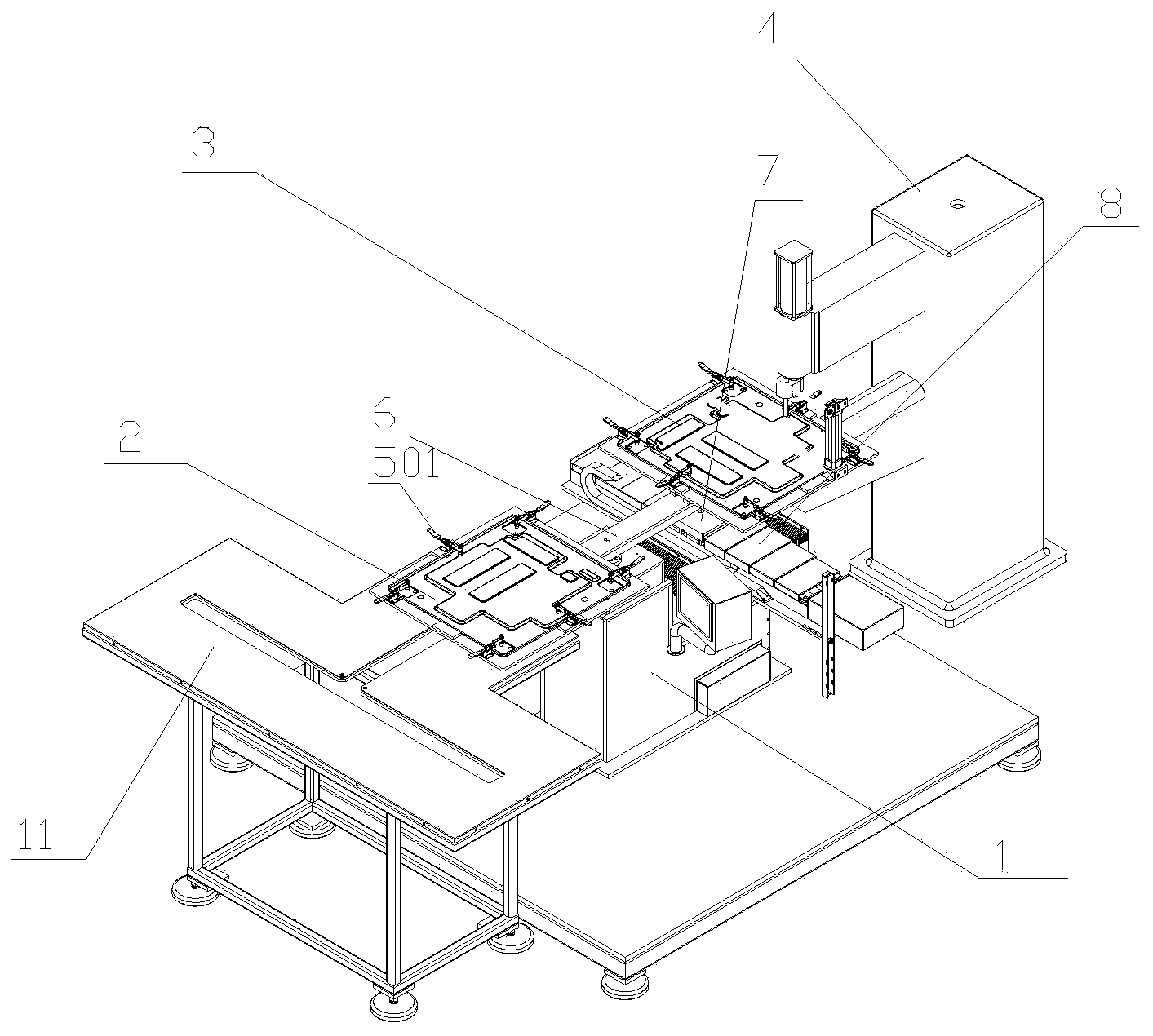

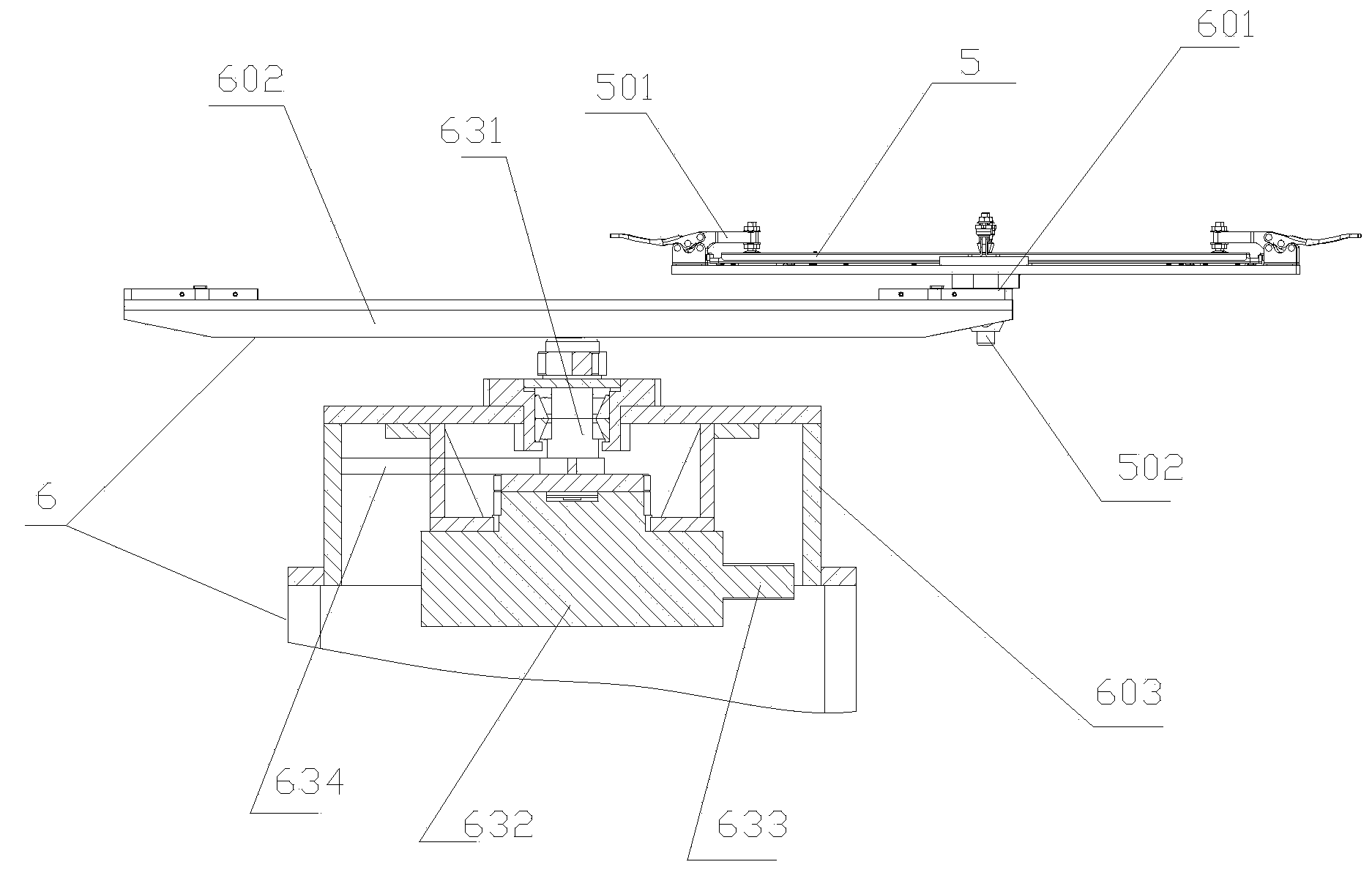

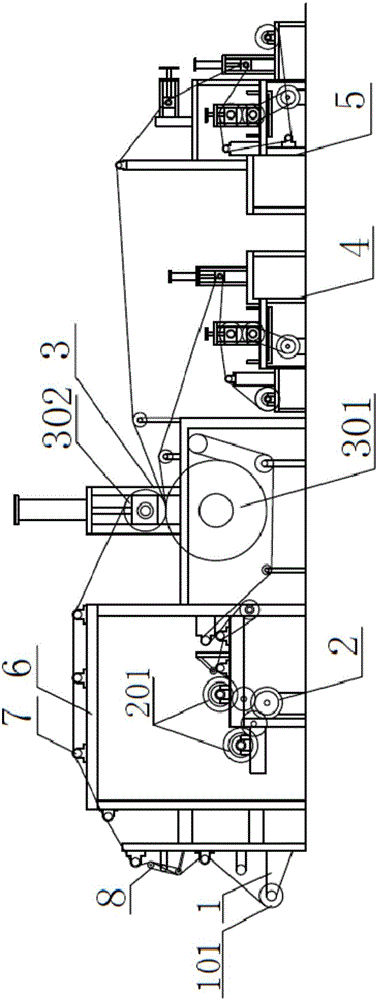

Full-automatic reinforcement plate pre-lamination machine

ActiveCN104113987ATo achieve singleRealize automatic loading and unloadingPrinted circuit manufactureEngineeringMachining

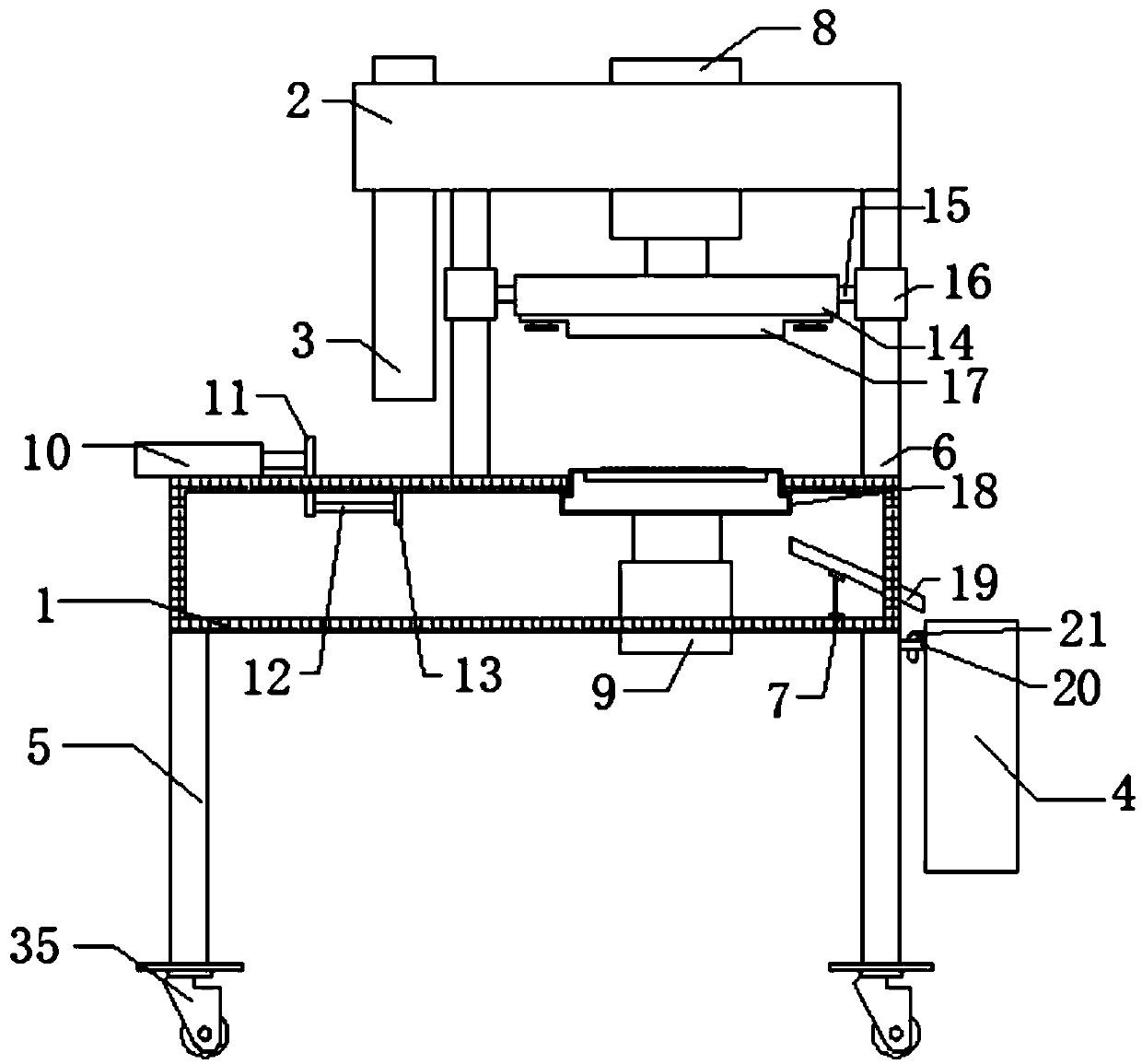

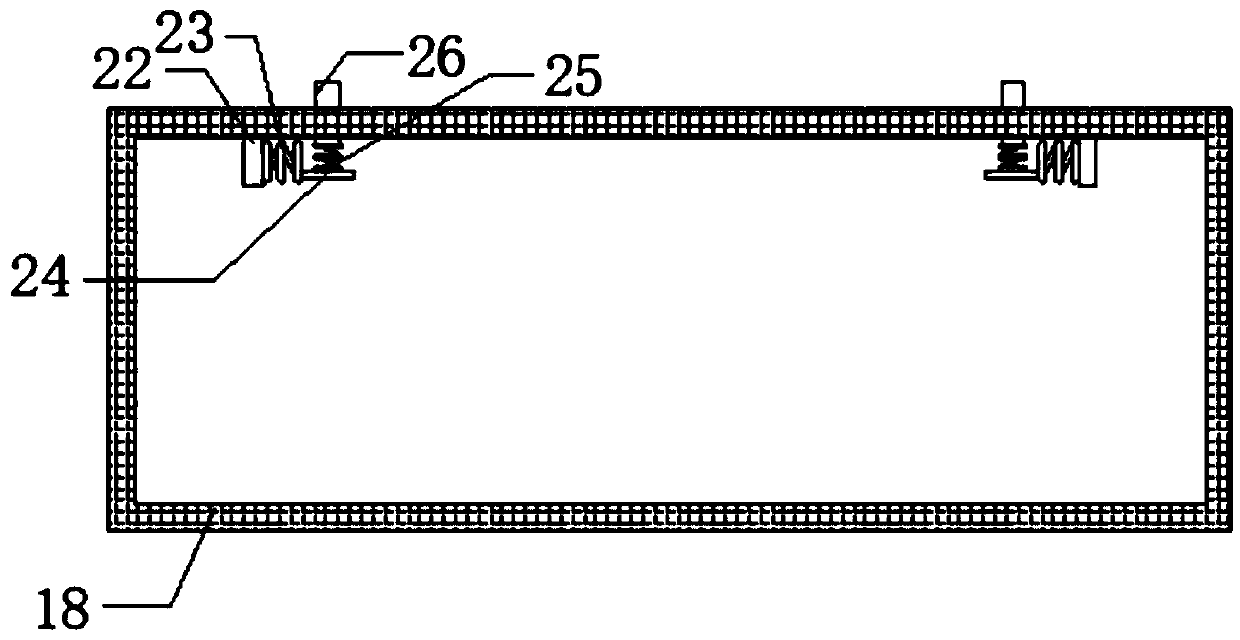

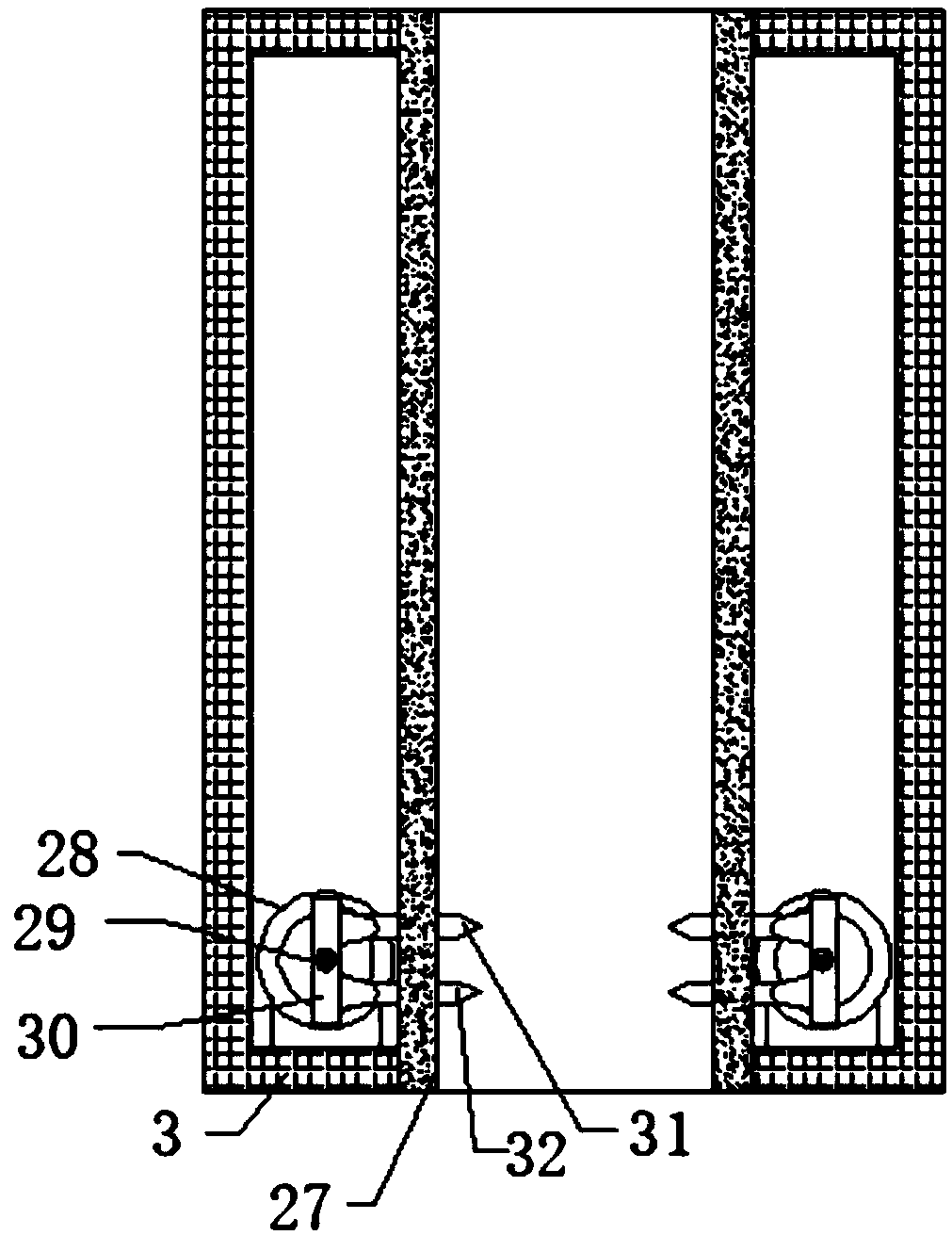

The invention discloses a full-automatic reinforcement plate pre-lamination machine and belongs to the technical field of FPC (Flexible Printed Circuit) machining equipment. The full-automatic reinforcement plate pre-lamination machine comprises a frame which is provided with a feeding and discharging mechanism; the feeding and discharging mechanism comprises a supporting beam; the first side of the supporting beam is provided with a first Z direction motion mechanism which is driven by a first X direction motion mechanism; the first Z direction motion mechanism is provided with a FPC suction nozzle; a feeding cabin, an FPC positioning mechanism and a storage cabin are arranged along the frame portion in turn, wherein the frame portion is arranged below a motion path of the FPC suction nozzle; the frame portion which is located between the FPC positioning mechanism and the storage cabin is provided with an FPC heating platform which is driven by a Y direction motion mechanism; the frame is provided with a feeding mechanism and a lamination mechanism. According to the full-automatic reinforcement plate pre-lamination machine, the automatic feeding and discharging of an FPC is achieved, the consistency of the mechanisms is good, and accordingly the production efficiency is improved, the production cost is reduced, and the degree of automation is high.

Owner:GOERTEK INC

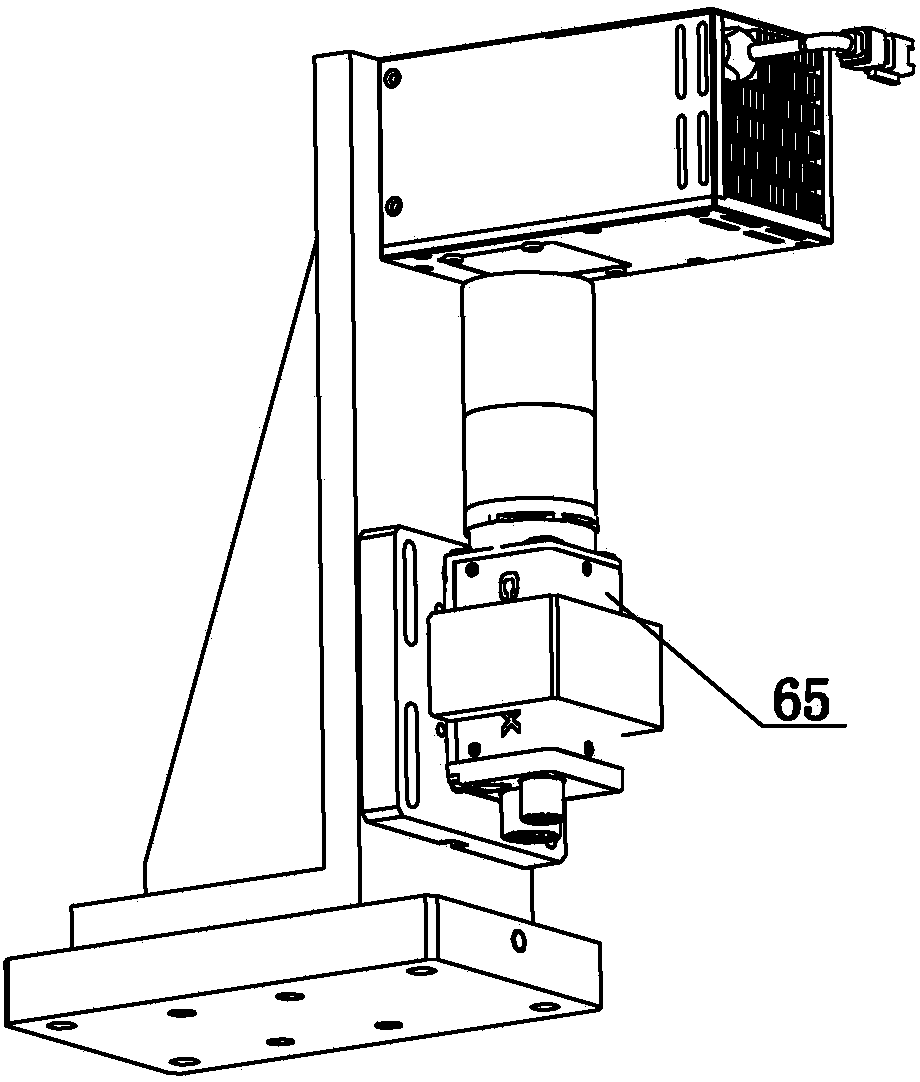

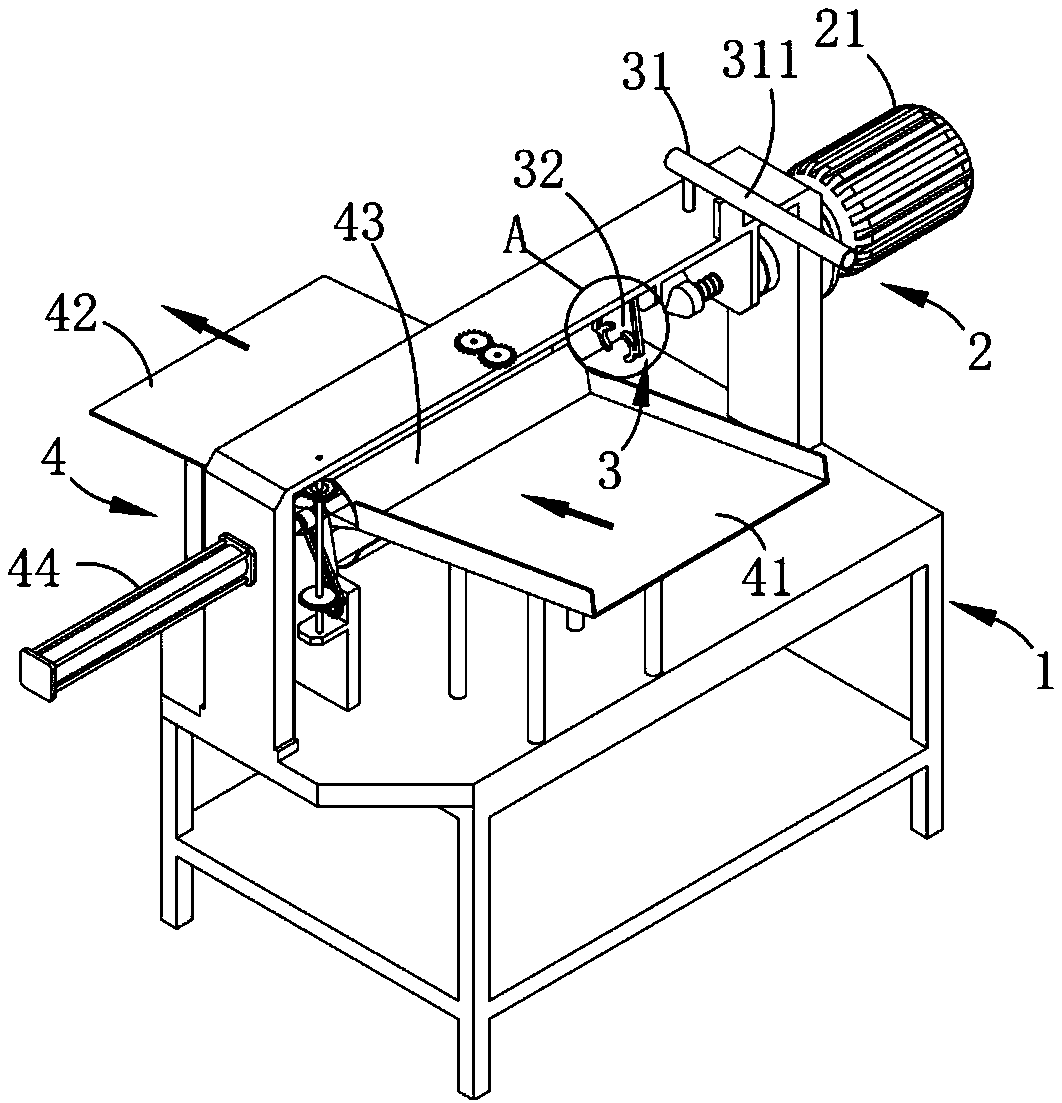

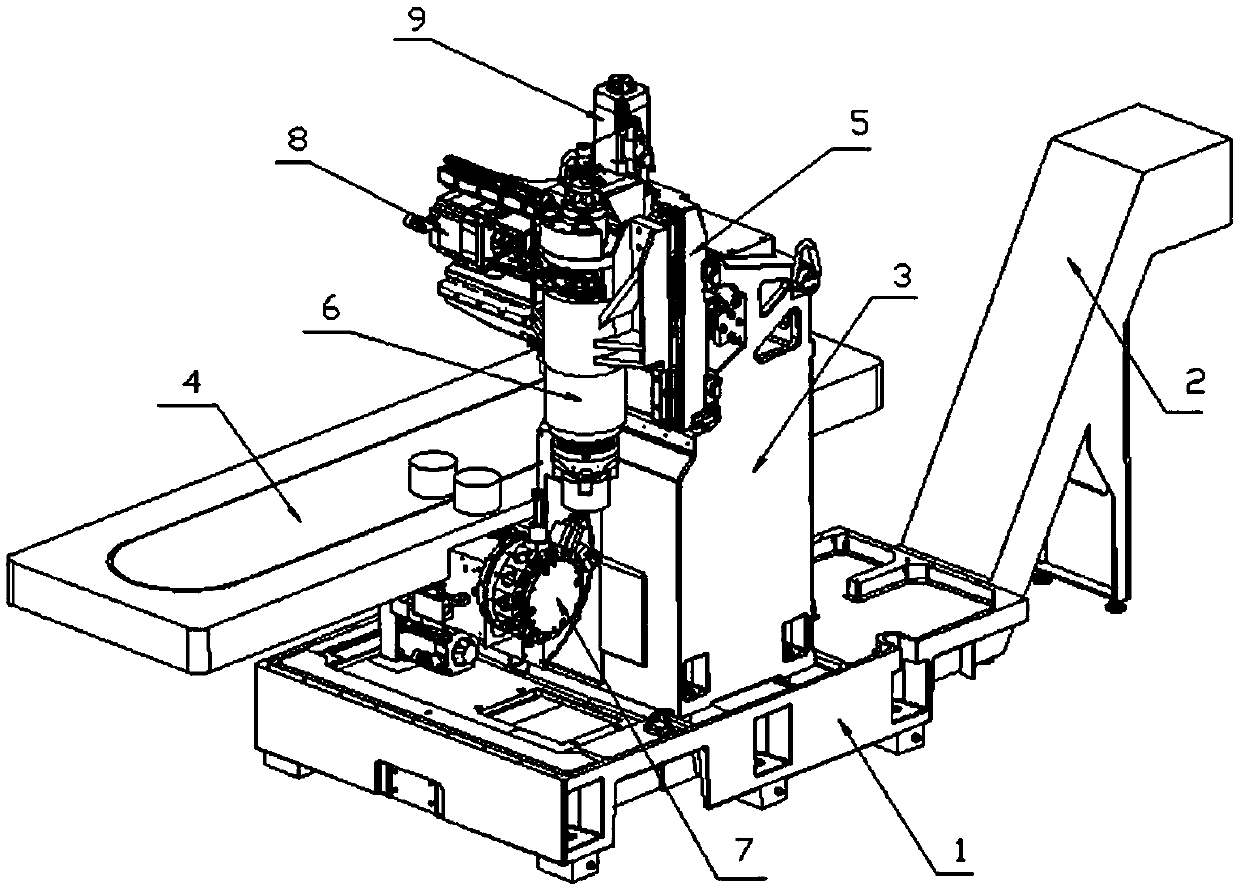

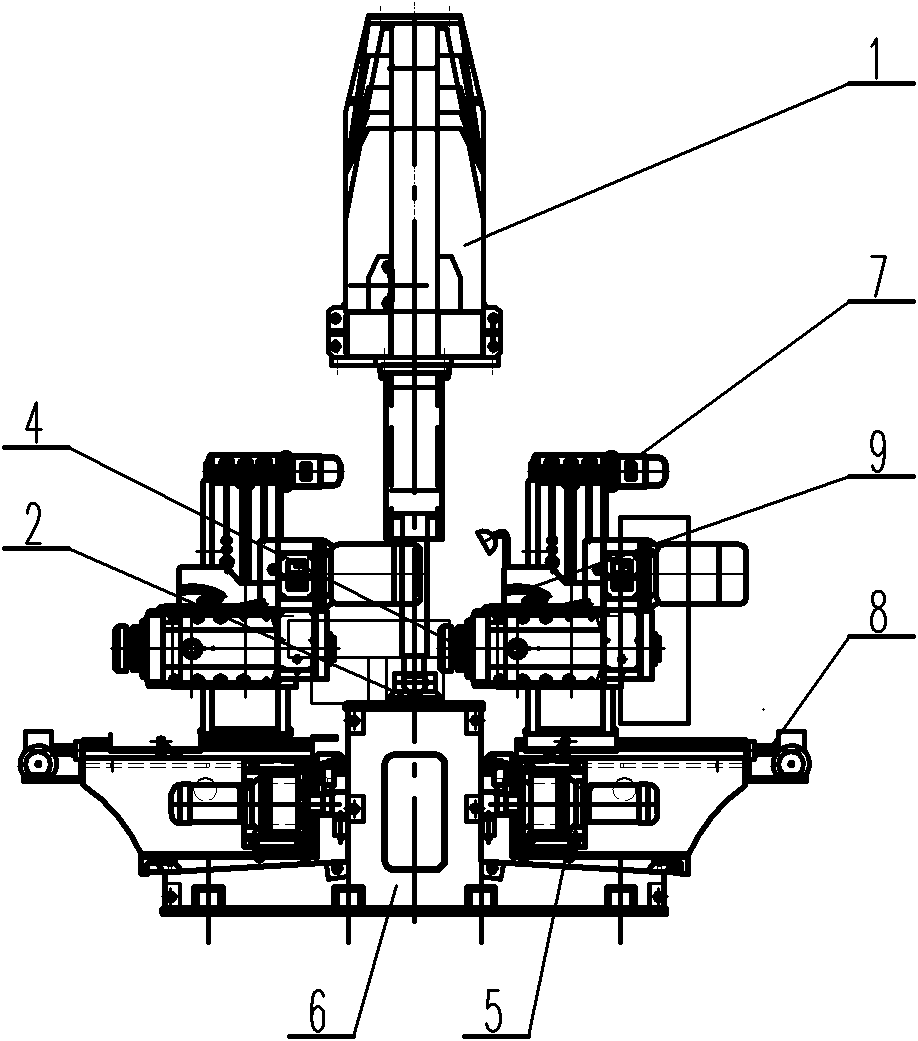

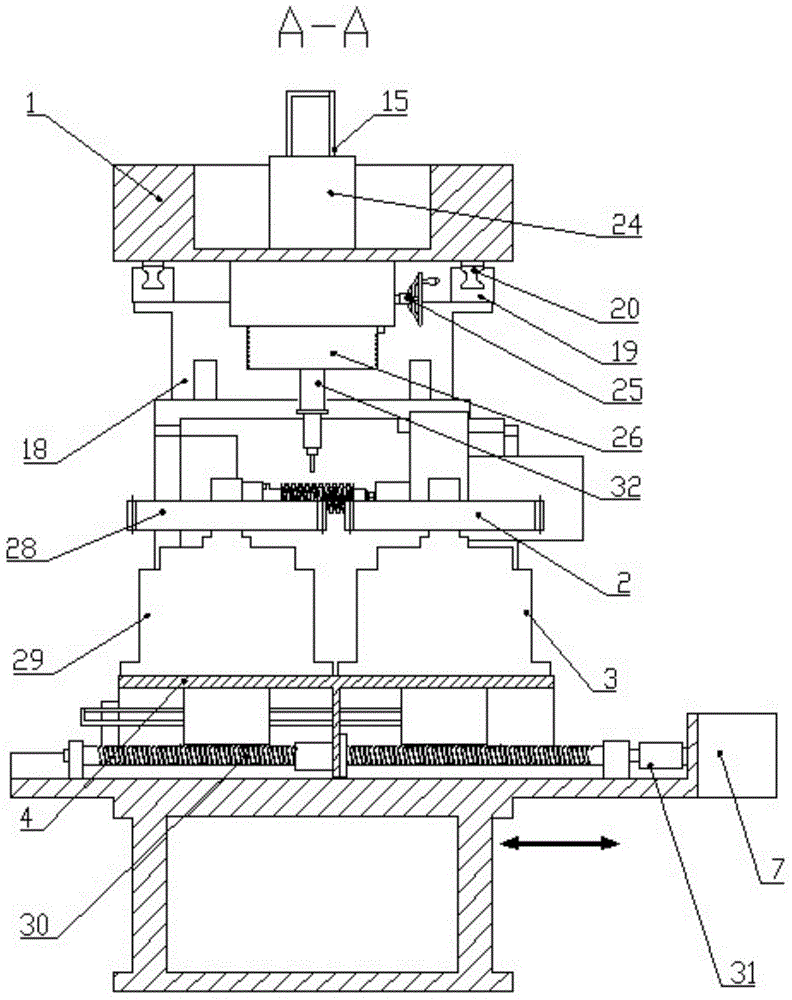

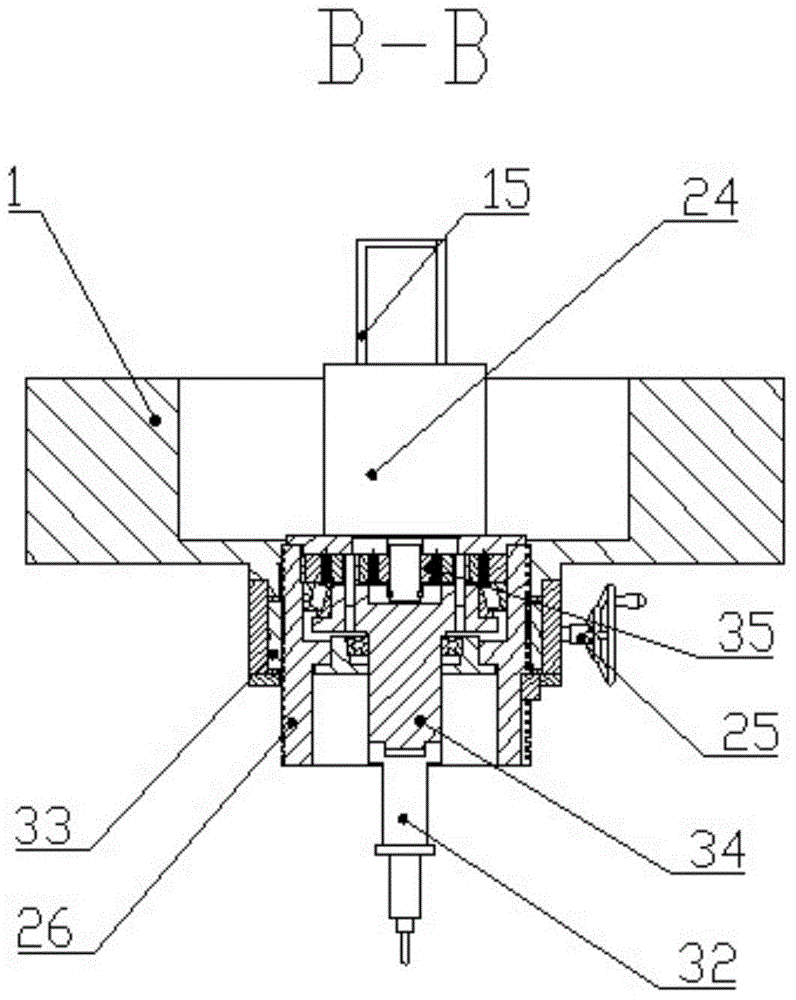

Automatic contact welding machine

ActiveCN104002033AExpand the scope ofSave time for loading and unloadingResistance welding apparatusRotational axisFree rotation

The invention discloses an automatic contact welding machine. The automatic contact welding machine comprises a base, a first tooling fixture, a second tooling fixture, a contact welding mechanism, a clamping platform deck, a rotating platform, a rotating shaft module, a transversal moving mechanism, a longitudinal moving mechanism, and an up-down moving mechanism, wherein the clamping platform deck is movably connected with the rotating platform; the rotating platform and the up-down moving mechanism are sequentially installed on the base from left to right; the first tooling fixture is movably connected with the rotating platform; the longitudinal moving mechanism is installed on the up-down moving mechanism; the transversal moving mechanism is installed on the longitudinal moving mechanism; the rotating shaft module is installed above the transversal moving mechanism; the clamping platform deck departs from the rotating platform and then is movably connected with the rotating shaft module; the rotating shaft module is connected with the second tooling fixture; the second tooling fixture is located on the right side of the rotating shaft module; the contact welding mechanism is located on the right side of the second tooling fixture. The automatic contact welding machine disclosed by the invention can freely rotate a work piece, as well as expand a welding range of the work piece, save time and reduce labour cost.

Owner:深圳市川菱科技有限公司

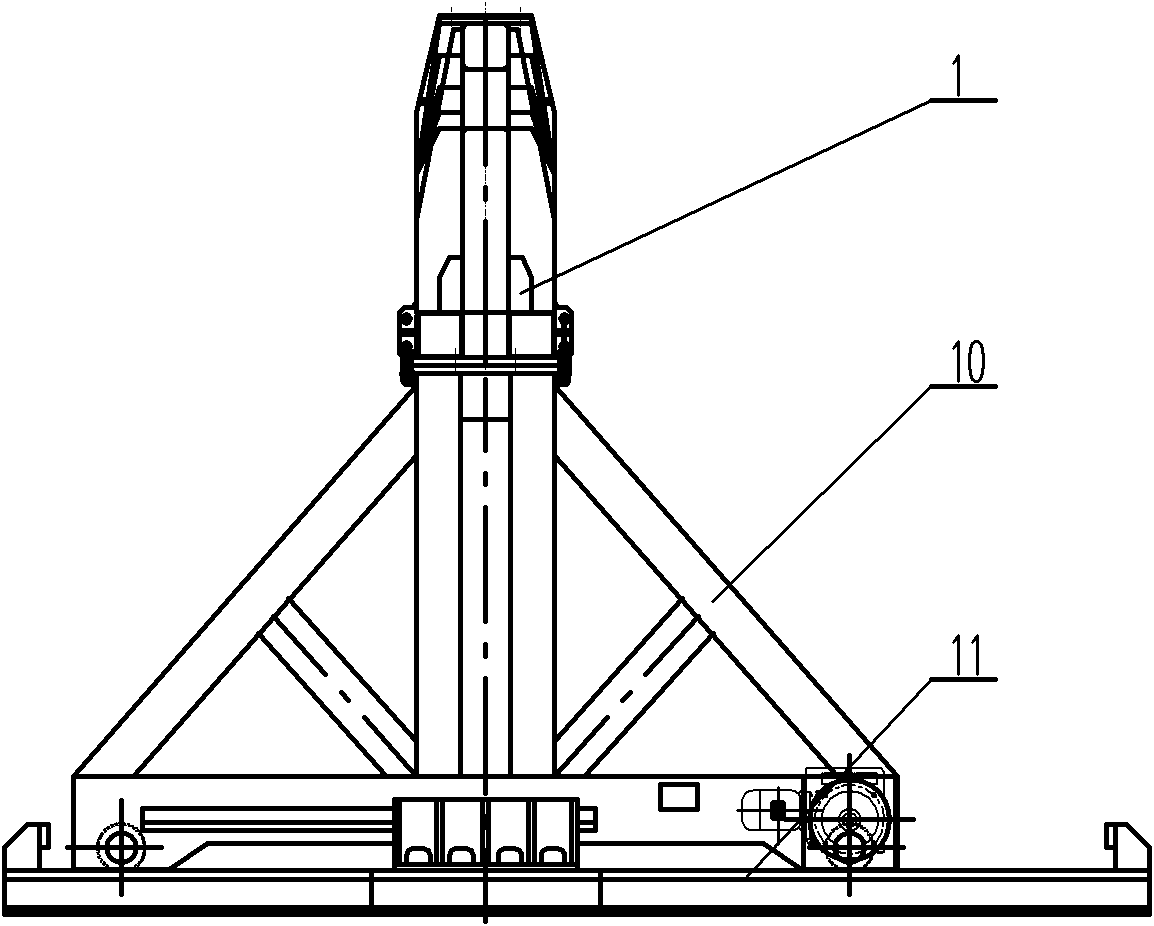

Automatic welding work station of battery module

PendingCN108539243AHighly integratedImprove cleanlinessFinal product manufactureCylindrical casing cells/batteryAssembly lineWorkstation

The invention discloses an automatic welding work station of a battery module. The automatic welding work station comprises an assembly line for conveying a battery module to be welded, and a laser washing device, at least one laser welding device and an after-welding detection device which are arranged in sequence along an operation direction of the assembly line, wherein the laser washing deviceis arranged beside the assembly line and is located at an entrance of the assembly line; the laser washing device is used for carrying out laser washing on the battery module to be welded; the laserwelding devices are symmetrically arranged at two sides of the assembly line, are located between the laser washing device and the after-welding detection device and are used for welding a battery cell electrode column on the battery module and a module bus bar; the after-welding detection device is arranged at two sides of the assembly line and is located at one end far away from the laser washing device; the after-welding detection device is used for detecting whether the quality is qualified or not after welding is finished. Compared with traditional module welding equipment, the automaticwelding work station has the characteristics of relatively high automation degree, working efficiency, welding yield and the like.

Owner:UNITED WINNERS LASER CO LTD

Intelligent paint spraying device applied to motor processing

ActiveCN110614186AEasy to useRapid Paint Thickness DetectionAnalysing solids using sonic/ultrasonic/infrasonic wavesSpray boothsEngineeringExhaust pipe

The invention discloses an intelligent paint spraying device applied to motor processing. The device comprises a baseplate, wherein a paint spraying room is welded to one end part of the top end of the baseplate; a seal door is hinged to the front end edge part of the paint spraying room by a hinge; sealed paint spraying space is constituted of the baseplate, the paint spraying room and the seal door and used for avoiding environmental pollution caused by scattering of a paint liquid in air; an exhaust pipe passes through and is installed on the top end of the paint spraying room; and the exhaust pipe is connected to a filtering exhaust system of a plant to discharge polluted air inside the paint spraying room. The intelligent paint spraying device disclosed by the invention has the beneficial effects that the problem that efficiency of motor spraying is greatly reduced when a paint thickness of a motor shell cannot be detected in time during paint spraying in motor processing, the thickness shall be detected with relevant instructions after completion of paint spraying and additional painting shall be conducted on unqualified parts after detection; and the device is applicable forgeneralization and use.

Owner:建首(山东)钢材加工有限公司

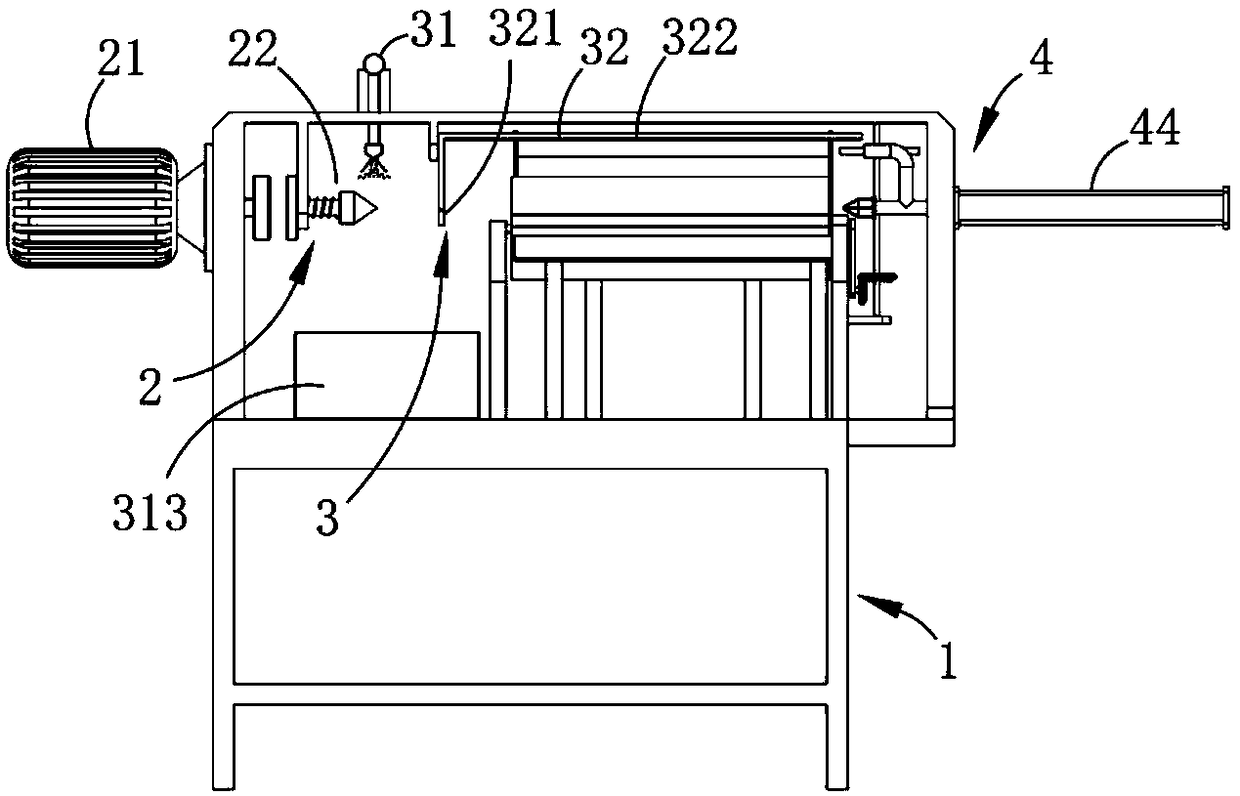

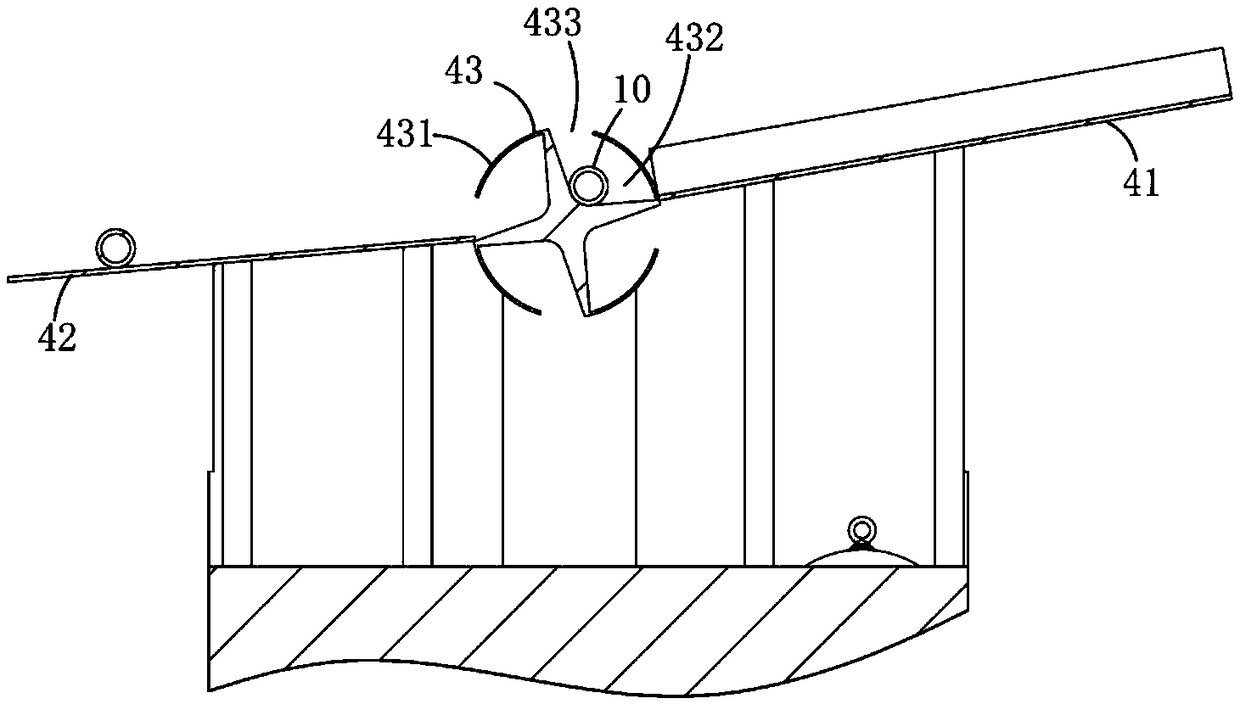

Automatic production device for carrying out rust-proof treatment on end part of steel pipe

InactiveCN108704787ARealize automatic outputUniform coating productionLiquid spraying apparatusReciprocating motionEngineering

The invention relates to the technical field of steel pipe processing and production, in particular to an automatic production device for carrying out rust-proof treatment on the end part of a steel pipe. The automatic production device for carrying out rust-proof treatment on the end part of the steel pipe comprises a rack, a positioning mechanism, an oil coating mechanism and a material transferring mechanism, wherein the oil coating mechanism comprises an oil spraying assembly and a coating assembly located at one end of the oil spraying assembly and is far away from the positioning mechanism; the material transferring mechanism comprises a loading assembly, a blanking assembly for outputting the steel pipe, a limiting assembly arranged between the loading assembly and the blanking assembly and intermittently communicating with the loading assembly and the blanking assembly, and a pushing assembly for transferring the steel pipe in the limiting assembly into the oil spraying mechanism; the limiting assembly is driven by the pushing assembly so as to directionally rotate; the coating assembly is driven by the pushing assembly so as to contact the steel pipe; and during the process that the pushing assembly sprays oil to the steel pipe and conveys the steel pipe through a reciprocating motion way, the steel pipe rotates and is coated with anti-rust oil and automatically outputted, so that the automatic oil coating production of the steel pipe is realized, and the technical problem of low production efficiency in the prior art is solved.

Owner:长兴新亚环保机械科技股份有限公司

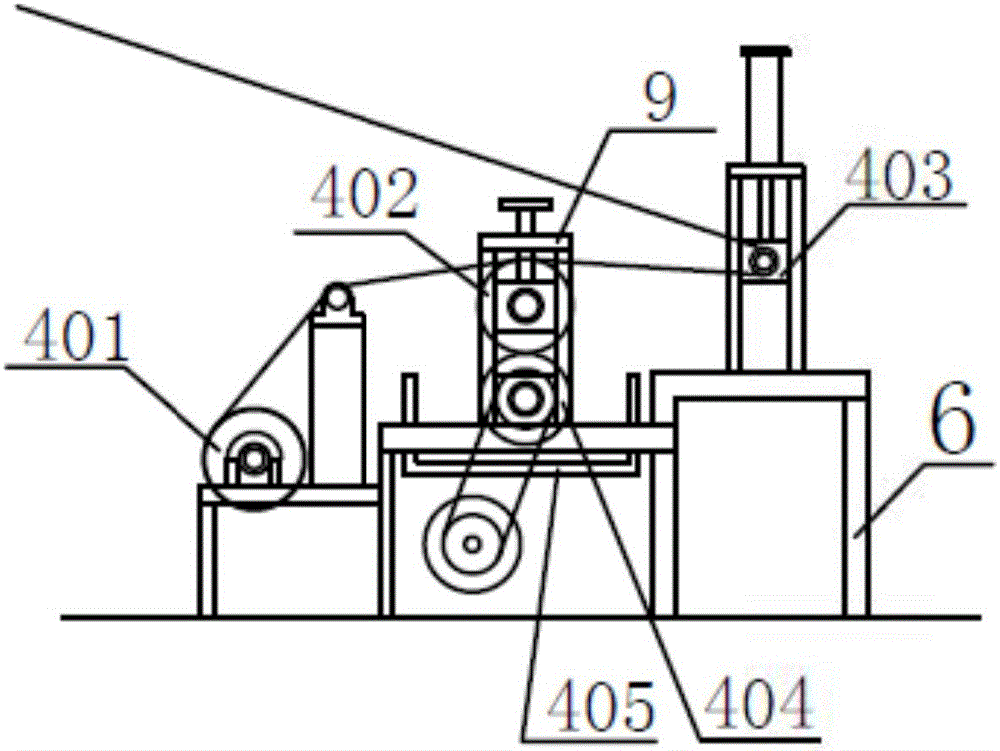

Aluminum foil sticking compound machine

The invention provides an aluminum foil sticking compound machine. The aluminum foil sticking compound machine comprises an uncoiling device, a first gluing device, a second gluing device, a compressing device and a coiling device, wherein the uncoiling device is positioned at the front end of a frame; a cloth uncoiling roller is rotationally connected to the frame; the first gluing device is positioned at the tail end of the frame, and comprises a first glue slot for accommodating glue and a first rubber roller positioned above the first glue slot; the second gluing device is positioned beside the first gluing device, and comprises a second glue slot for accommodating glue and a second rubber roller positioned above the second glue slot; the compressing device is positioned on the middle part of the frame, and comprises an upper compressing roller and a lower compressing roller; the coiling device is positioned beside the compressing device, and is used for coiling compound fireproof cloth through a coiling roller. By adopting the aluminum foil sticking compound machine provided by the invention, larger-width compound fireproof cloth can be produced under the condition that a used aluminum foil raw material is constant in width.

Owner:天津市善文玻璃纤维制品有限公司

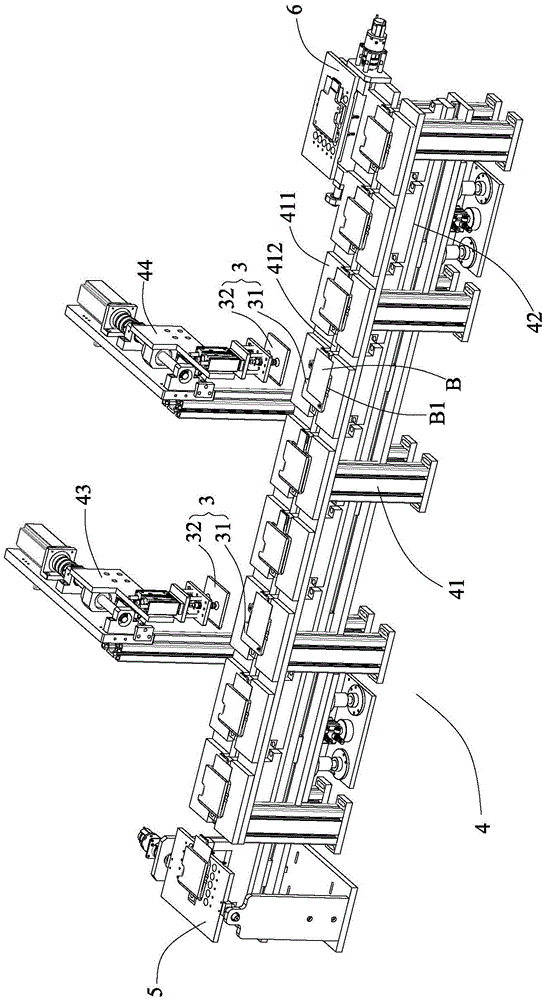

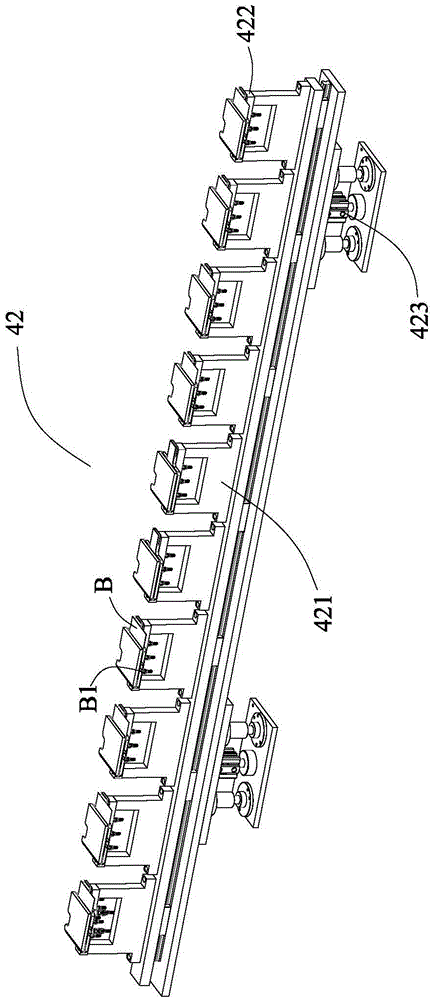

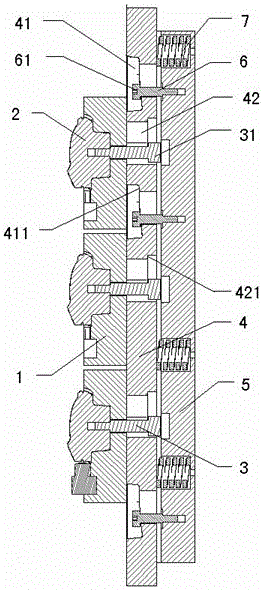

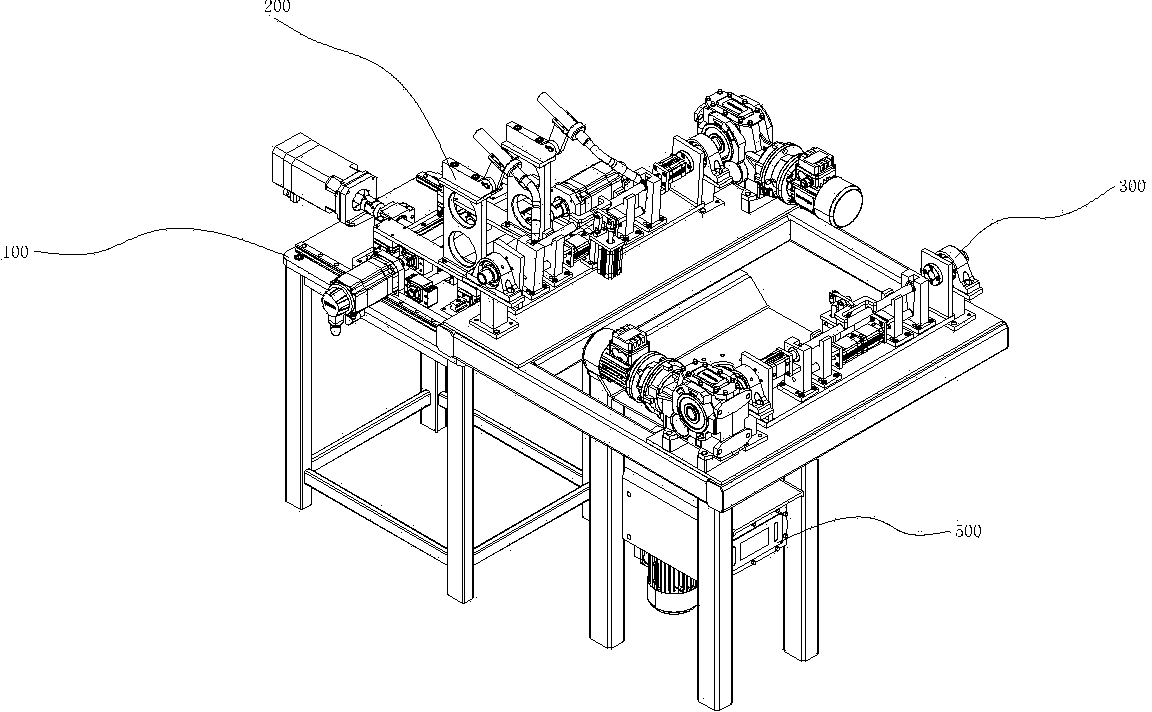

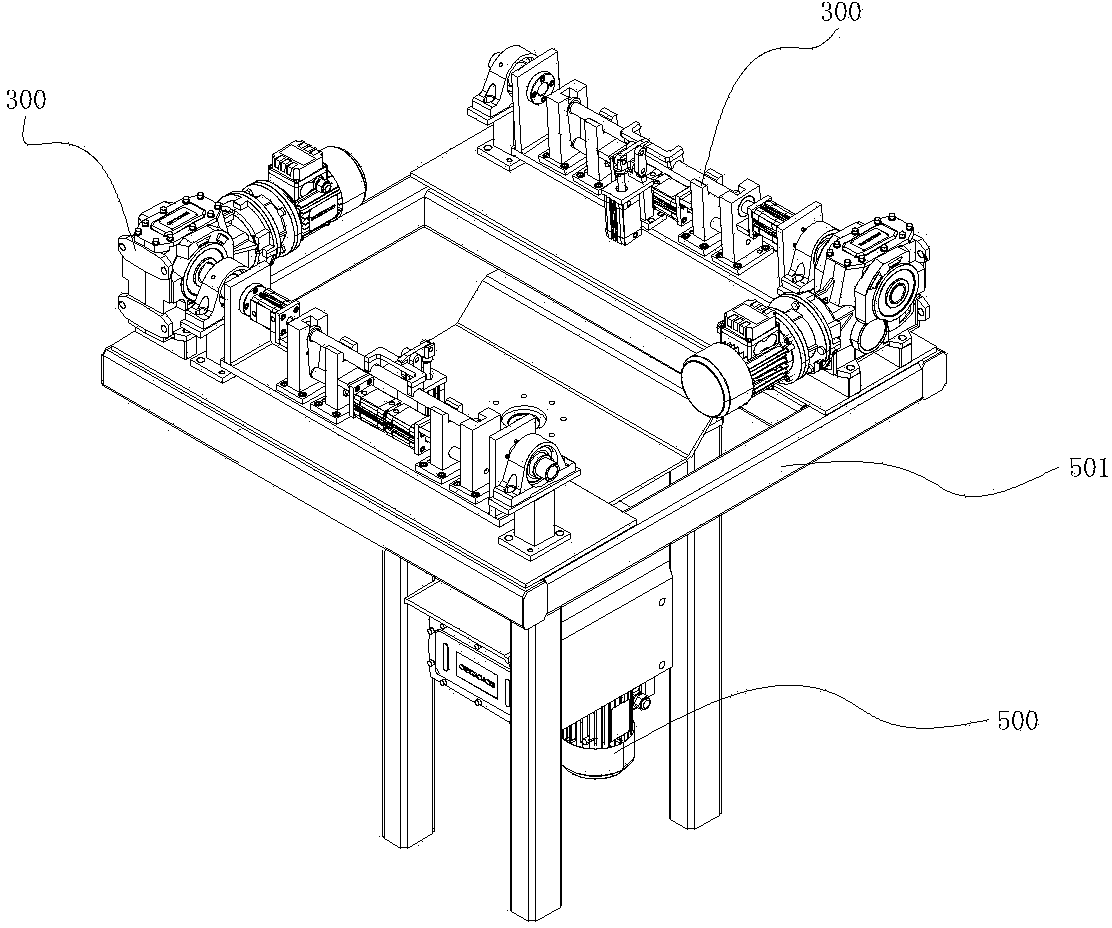

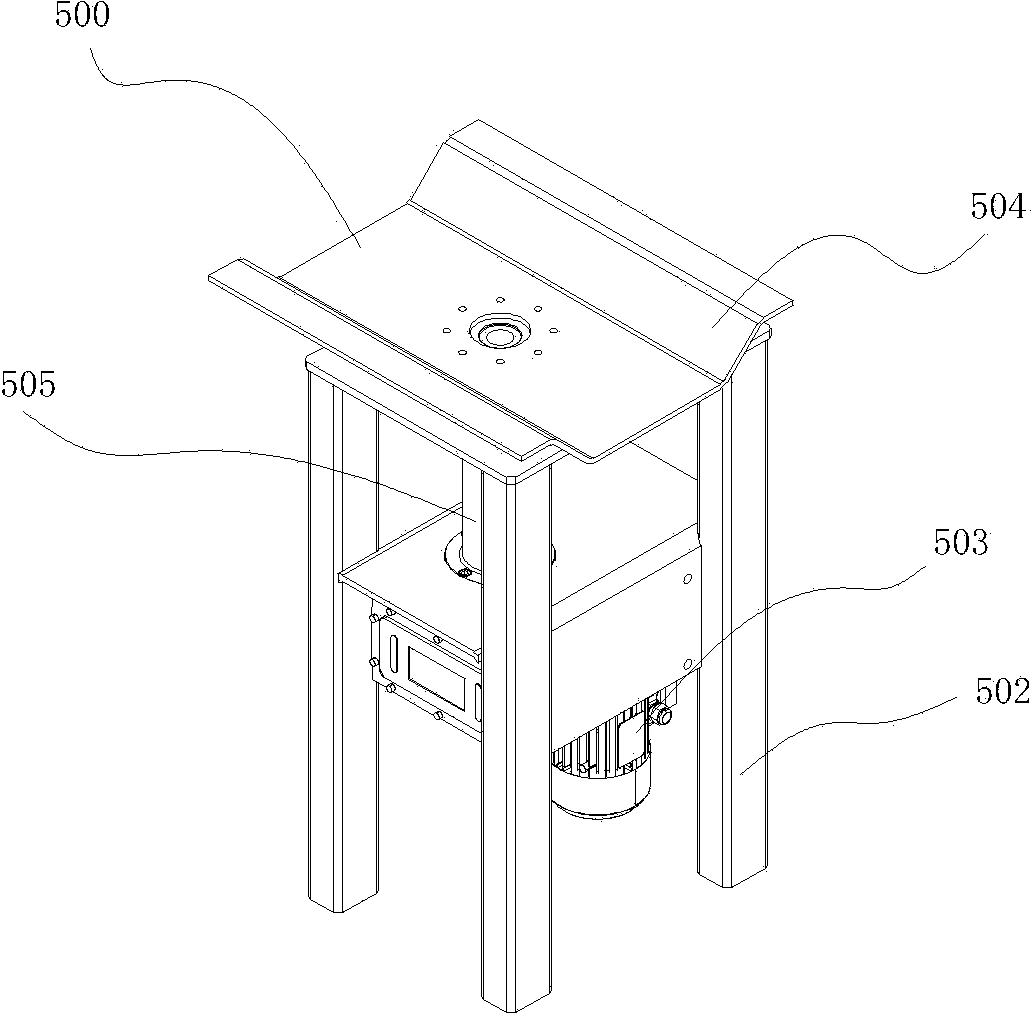

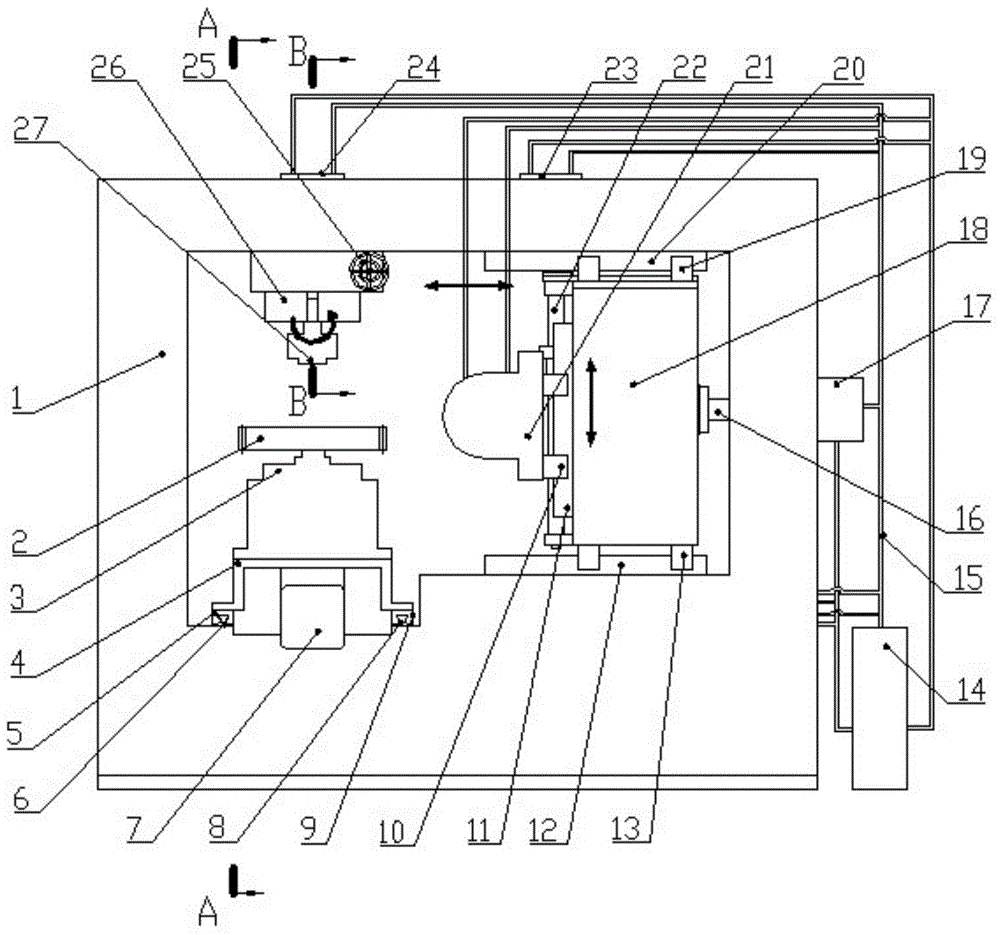

Automatic battery loading and unloading device

ActiveCN105552447ASave time for loading and unloadingImprove loading and unloading efficiencyFinal product manufactureElectrolyte accumulators manufactureEngineeringWorkbench

The invention provides an automatic battery loading and unloading device, used for loading and unloading specially shaped batteries. The automatic battery loading and unloading device comprises a loading mechanism, an unloading mechanism, a plurality of jackets and a jacket return mechanism, wherein the loading mechanism collects a plurality of batteries and moves the batteries into an external device for processing; the unloading mechanism collects and moves out the processed batteries; all the jackets accommodate and fix the batteries; the jacket return mechanism comprises a rack provided with a plurality of workbenches among which the jackets circulate, and a conveyor mechanism used for fixing and conveying the jackets on the workbenches. The automatic battery loading and unloading device can automatically install the specially shaped batteries in the jackets and realize the automatic loading and unloading of the specially shaped batteries, thereby reducing the loading and unloading time of batteries and improving the loading and unloading efficiency of batteries.

Owner:NINGDE AMPEREX TECH

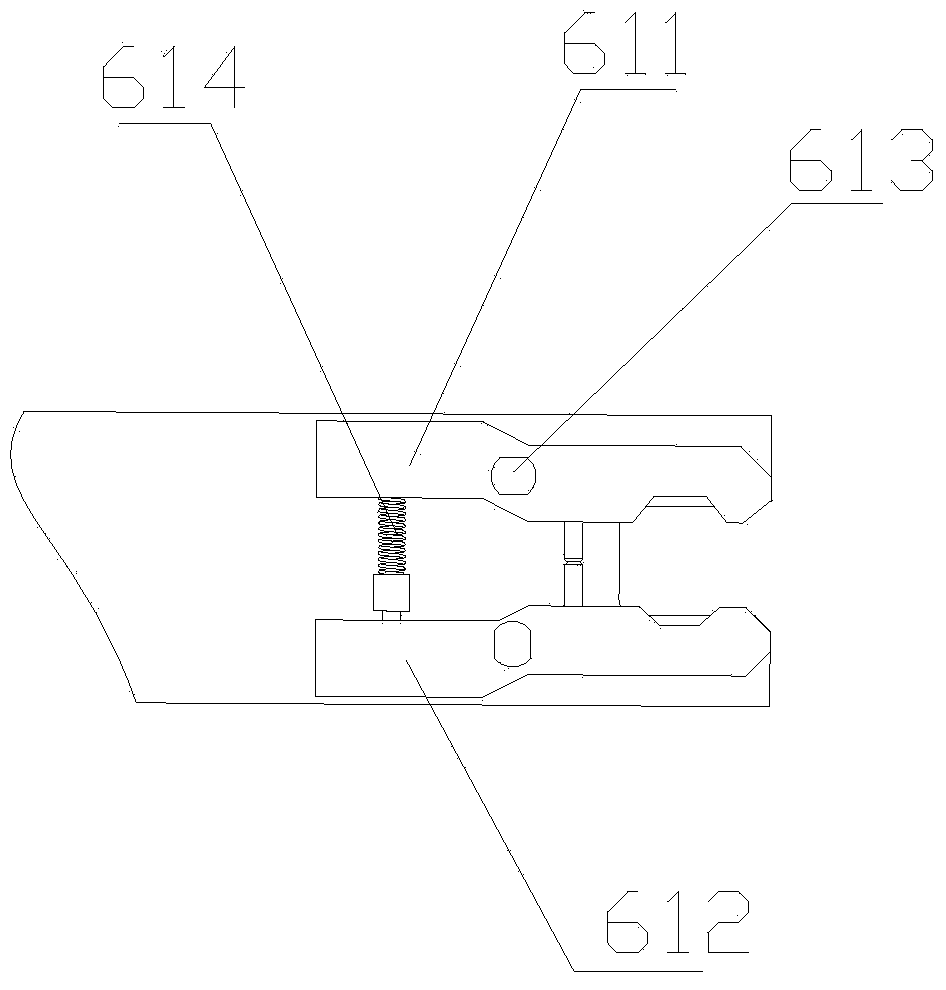

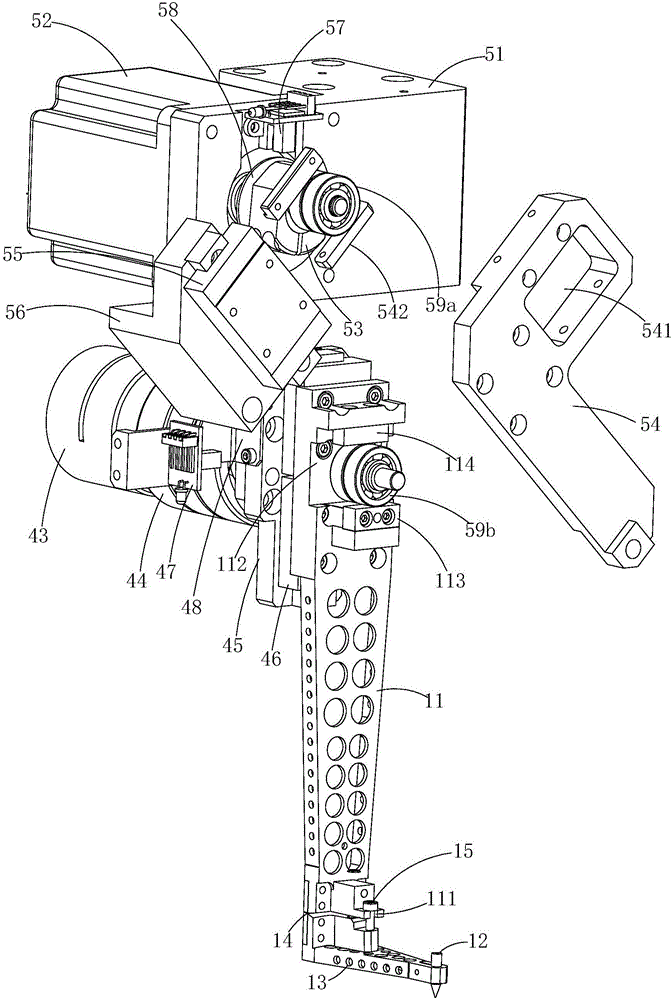

Die bonder and die bonding method

InactiveCN106505141AAddressing Adaptive IssuesMeet individual customization needsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDie bonding

The invention is applicable to the technical field of LED packaging, and provides a die bonder and a die bonding method. The die bonder comprises a worktable system used for moving an LED framework, a wafer positioning system used for positioning wafers, and a die bonding system used for picking up wafers and fixing the wafers on the LED framework, wherein the die bonding system comprises a die bonding arm, a rotary driving mechanism and a telescopic driving mechanism; the worktable system has a worktable; the rotary driving mechanism drives the die bonding arm to be perpendicular to the worktable or drive the die bonding arm and the worktable to rotate in a plane at a certain angle; and the telescopic driving mechanism drives the die bonding arm to perform linear telescopic movement. Moving mechanisms of the wafers and the LED framework are staggered in space layout without causing mutual interference, so that the problem in applicability of the large-dimensional LED framework is solved; therefore, the ultra-big and ultra-wide LED framework can be manufactured while the precision is not affected; original small LED frameworks can be assembled together, so that feeding and discharging time can be reduced, thereby improving the production efficiency.

Owner:深圳市微恒自动化设备有限公司

Double-station cast tube surface zinc spraying machine

The invention relates to a double-station cast tube surface zinc spraying machine. The machine is characterized in that a zinc spraying trolley is arranged on a rack and transversely moves along the rack, wherein a wire feeding adjusting device is arranged on the lower surface of the zinc spraying trolley and connected with the zinc spraying trolley, and spray gun assemblies for spraying zinc on the surface of a cast pipe are arranged on two sides of the wire feeding adjusting device; two pushing and rotating mechanism sets are arranged at the lower part of the rack and are used for clamping two casting pipes and driving the casting pipes to rotate; the wire feeding adjusting device is driven by the zinc spraying trolley to transversely move along the axial direction of the casting pipes in the rotating process of the casting pipes; the spray gun assemblies are capable of spraying zinc on the surfaces of the casting pipes in the transversely moving process; a cast tube feeding and discharging mechanism is arranged at the lower part of the rack and used for feeding the cast tubes to a pushing and rotating mechanism and taking the cast tubes subjected to zinc spraying down from the pushing and rotating mechanism; and a dust removal device is arranged at the upper part of the pushing and rotating mechanism and used for treating zinc mist generated in the zinc spraying processing process. The double-station zinc spraying machine is capable of spraying zinc to two casting tubes at one time, and has the characteristics of wide application range, stable operation, simple operationand the like.

Owner:杭州春风机械工程股份有限公司

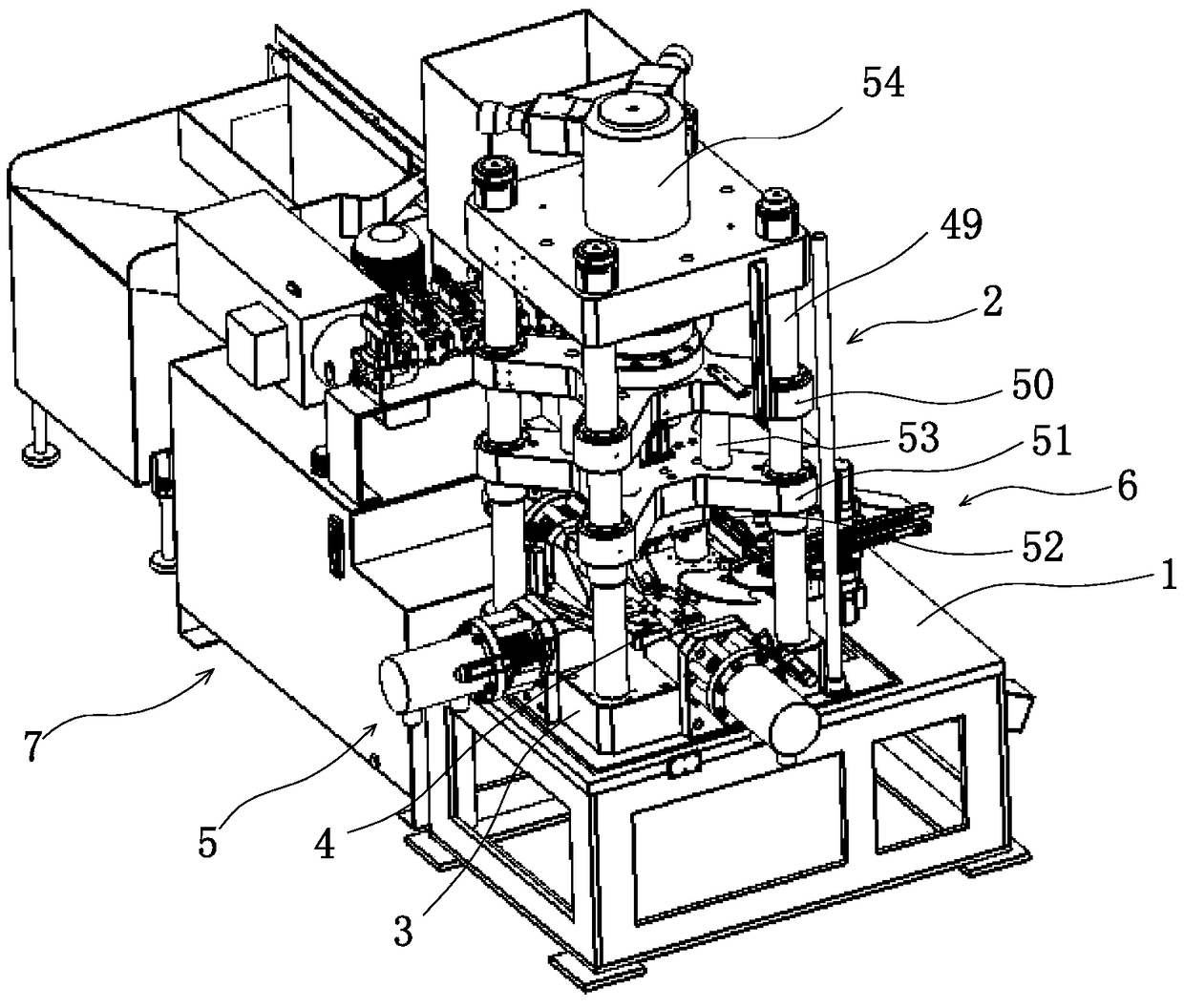

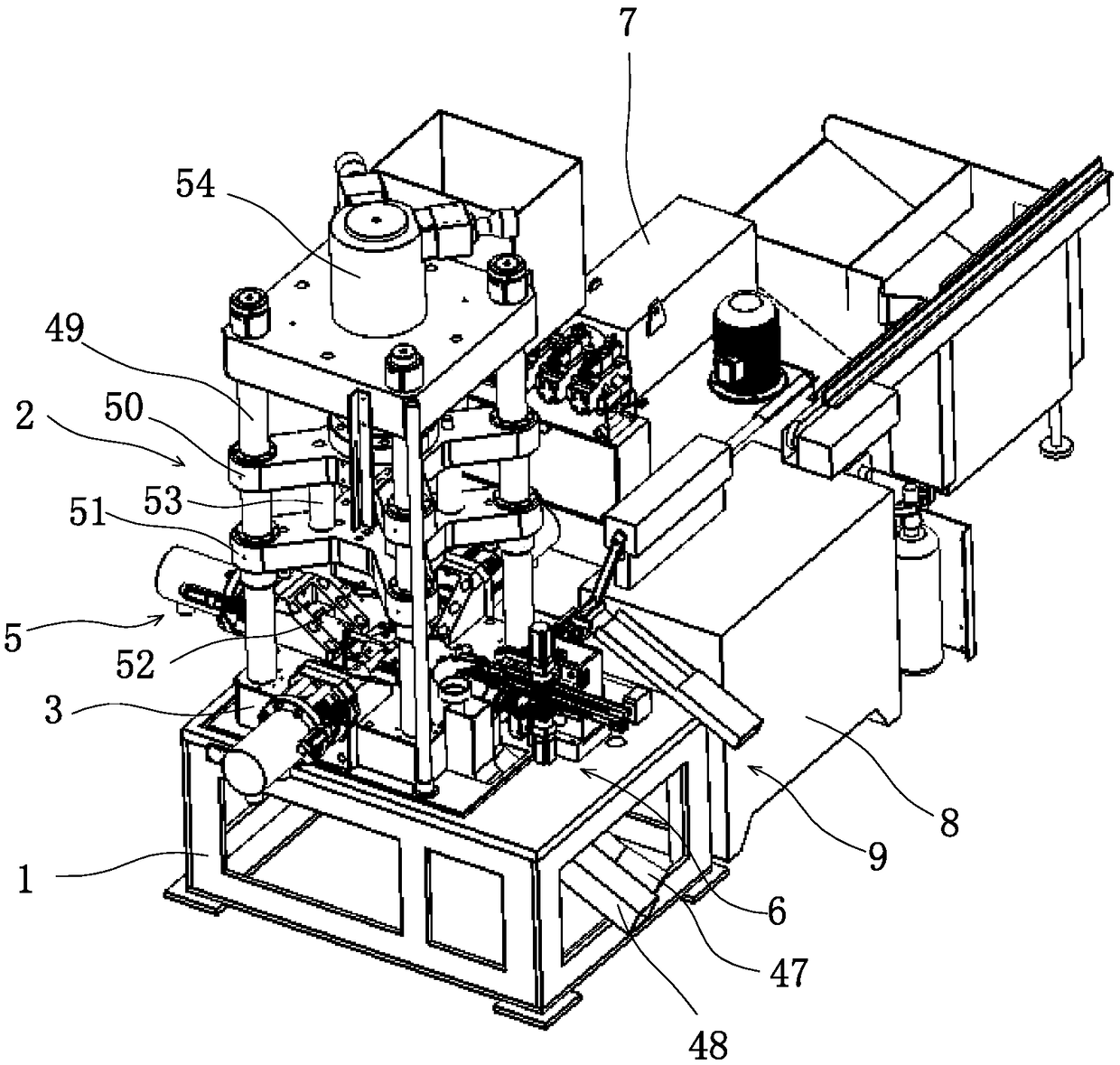

Full-automatic hot-extrusion metal forming machine

PendingCN109226409AClosely arrangedVersatileShaping toolsMetal-working feeding devicesMetal formingEngineering

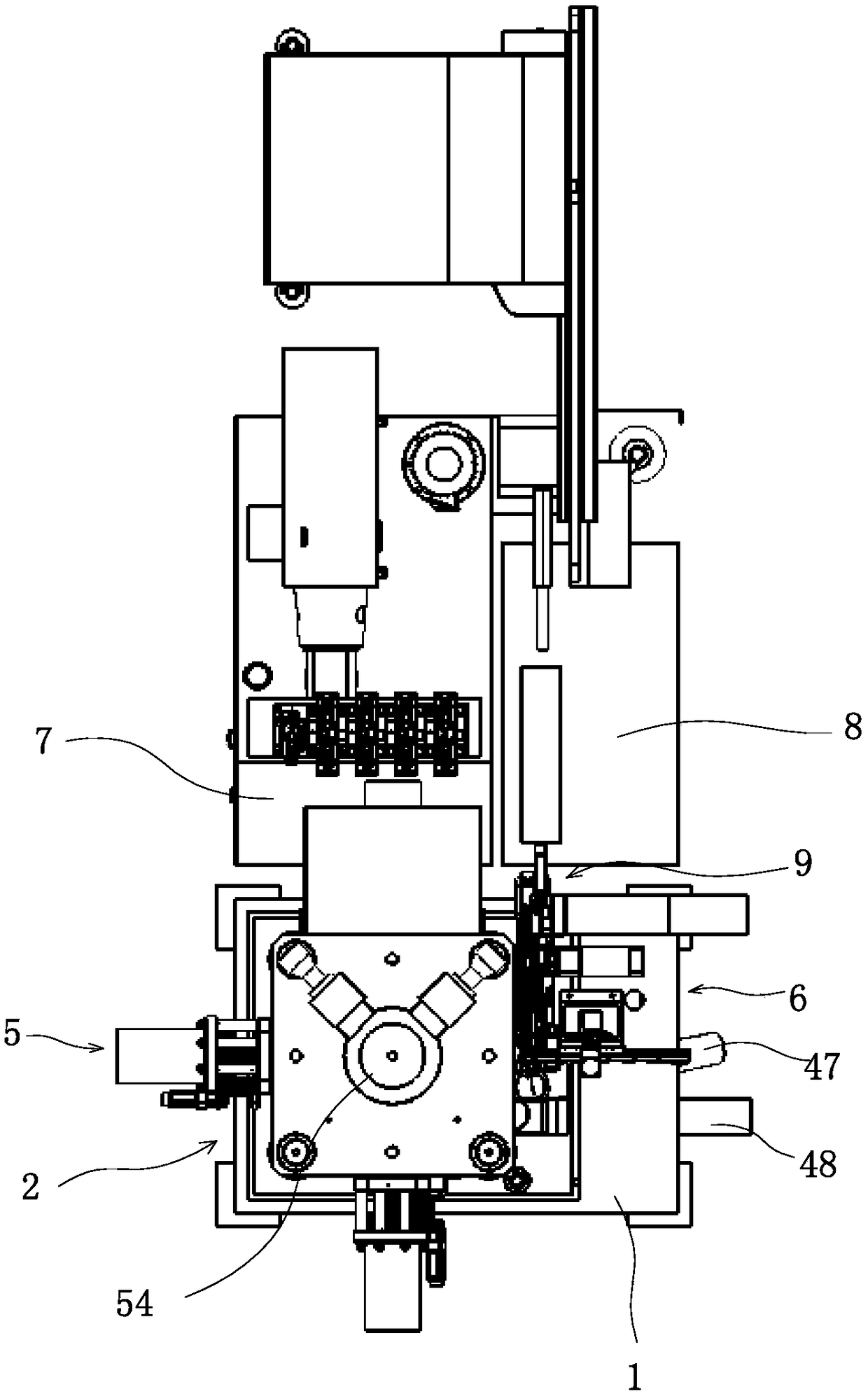

The invention belongs to the technical field of hot-extrusion equipment, and relates to a full-automatic hot-extrusion metal forming machine. The technical problems that in the prior art, the hot-extrusion equipment is huge in size, the space is wasted, and the production efficiency is low are solved. The machine comprises a rack which is provided with a hot-extrusion component, a hot-extrusion platen is arranged at the bottom of the hot-extrusion component, a lower template is arranged on the hot-extrusion platen, at least one group of positioning core-pulling components is arranged on the lower template, the rack is further provided with a loading and unloading component capable of stretching into or retreating from the hot-extrusion component, a hydraulic station and a high-frequency heating furnace are arranged on one side of the rack, a workpiece conveying device is arranged on the side, adjacent to the hydraulic station, of the hot-extrusion component, and the workiece conveyingdevice is connected with the high-frequency heating furnace and the loading and unloading component. Compared with the prior art, the machine has the advantages of being compact in structure, high inproduction efficiency and stable in product quality.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

Automatic feeding and discharging automobile clutch plate flattening machine

ActiveCN109622669APrevent movementSave time for loading and unloadingMetal-working feeding devicesPositioning devicesClutchHydraulic pressure

The invention discloses an automatic feeding and discharging automobile clutch plate flattening machine. A lower box, an upper box, a raw material storage box and a finished product storage box are included. Four landing legs are welded to the four corners of the bottom end of the lower box. Four support rods are welded to the upper surface of the lower box. The upper box is welded to the top endsof the four support rods. A first hydraulic cylinder is arranged on one side of the upper box. A movable plate is fixedly arranged at the output end of the first hydraulic cylinder. A pressing blockis arranged on the lower surface of the movable plate through bolts. A second hydraulic cylinder is arranged in the lower box. A hollow block is arranged at the output end of the second hydraulic cylinder. Two vertical plates are symmetrically welded to the two sides in the hollow block. Through adding of forward and reverse rotation motors and an electric push rod, automatic feeding and discharging can be conducted during clutch plate machining, the feeding and discharging time can be shortened, the work efficiency is improved, in the flattening process, sliding blocks can fix a non-machinedclutch plate, and clutch plate movement is prevented.

Owner:盐城意权汽配制造有限公司

Automatic oil pipe conveying appliance

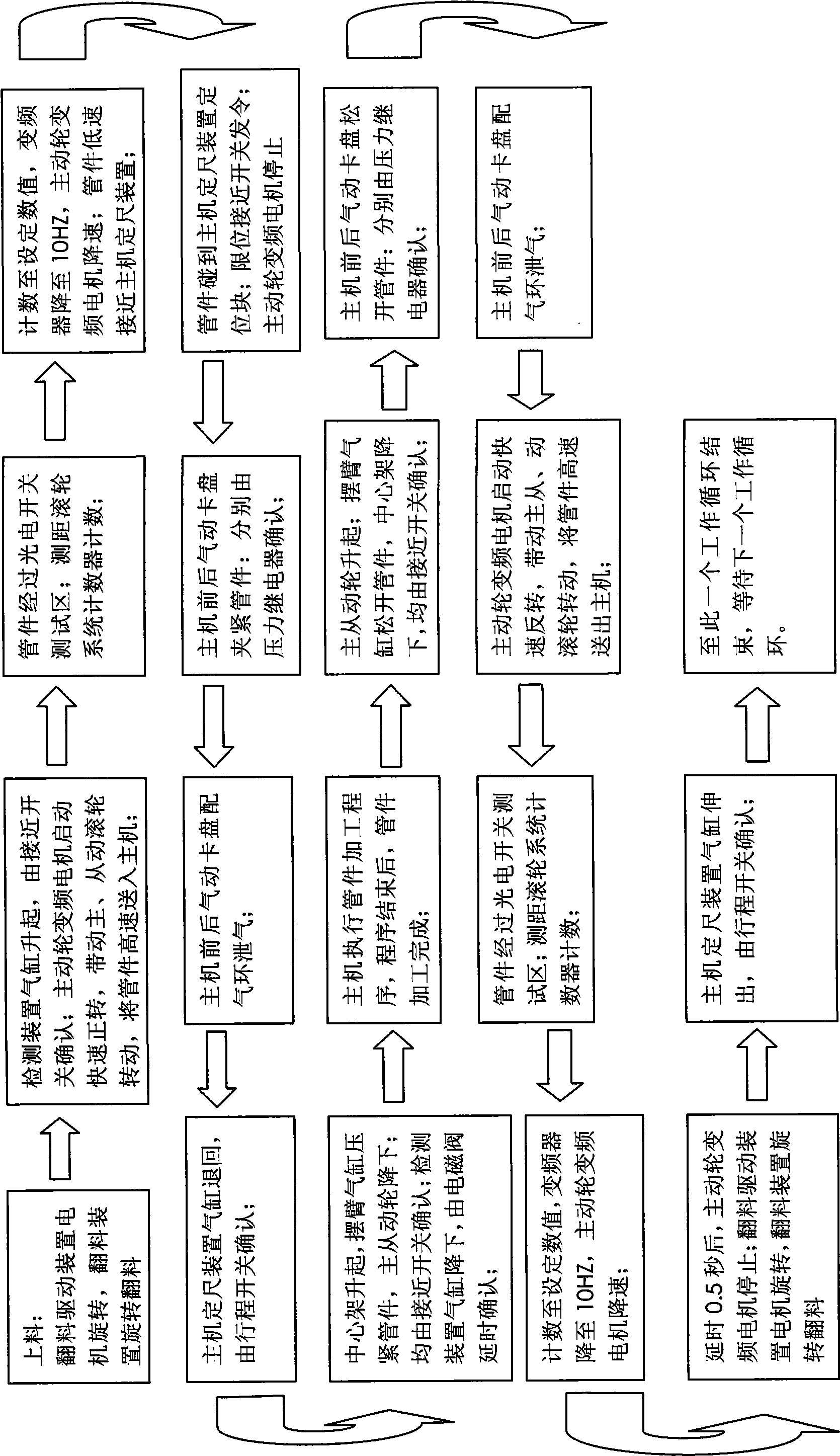

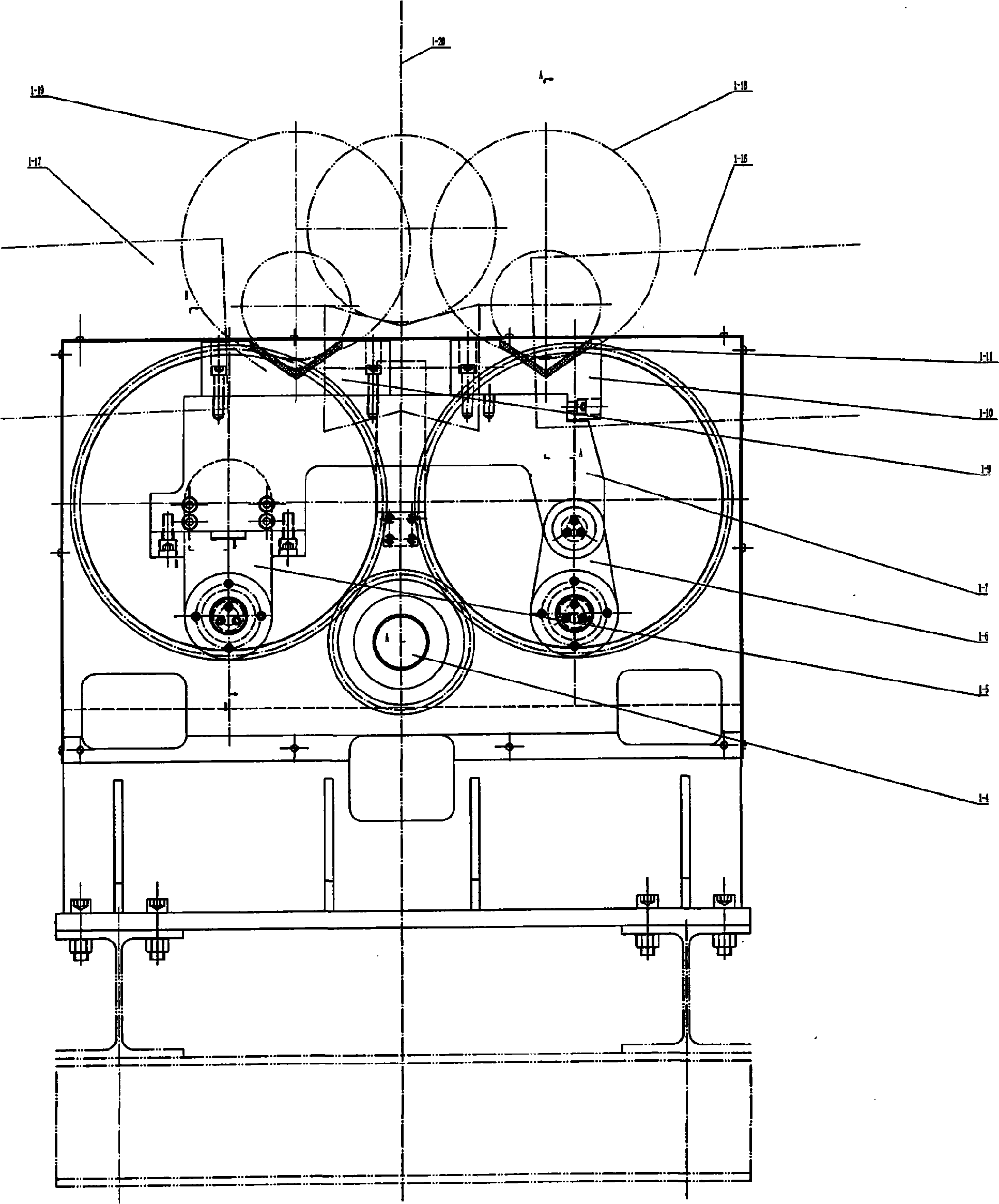

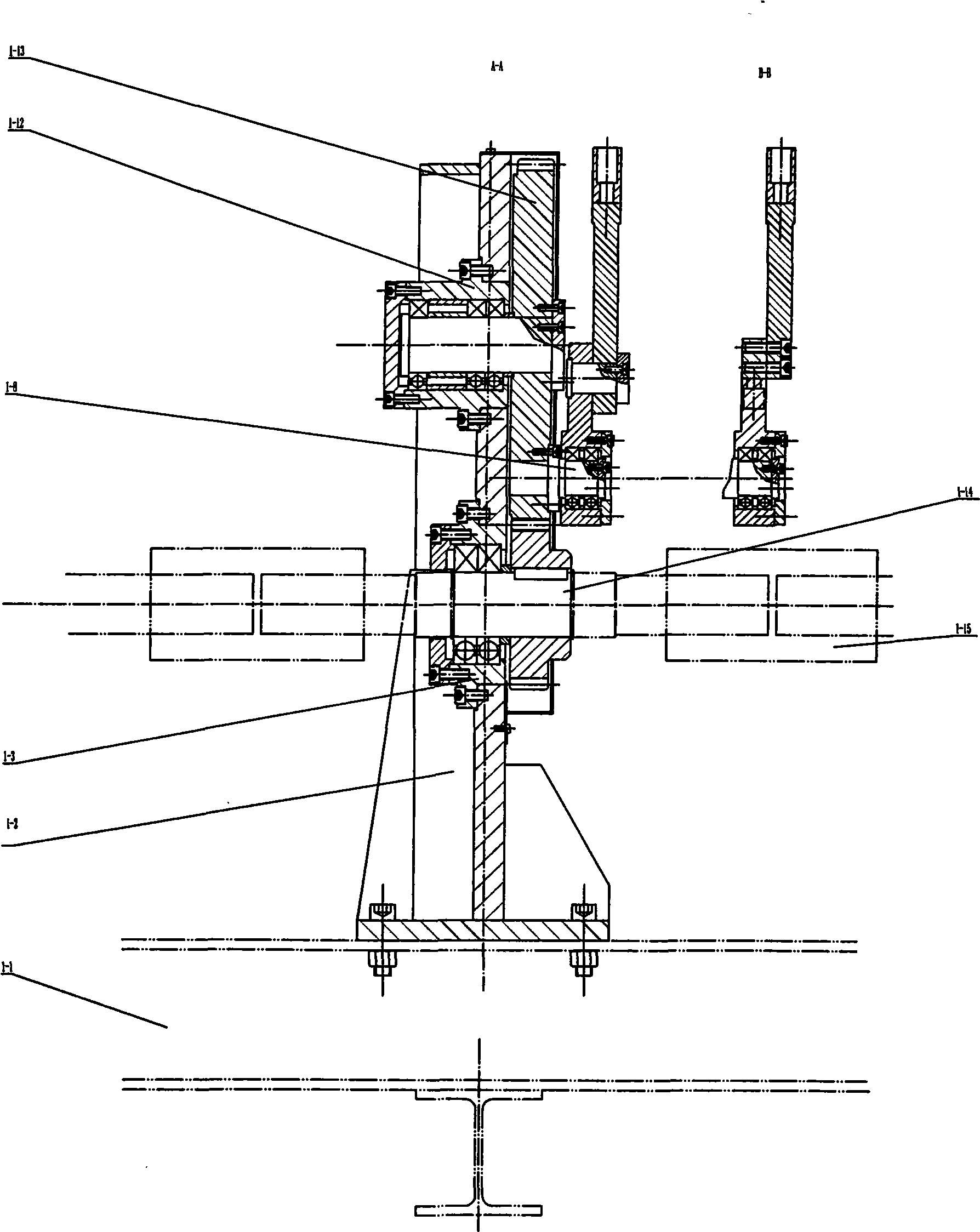

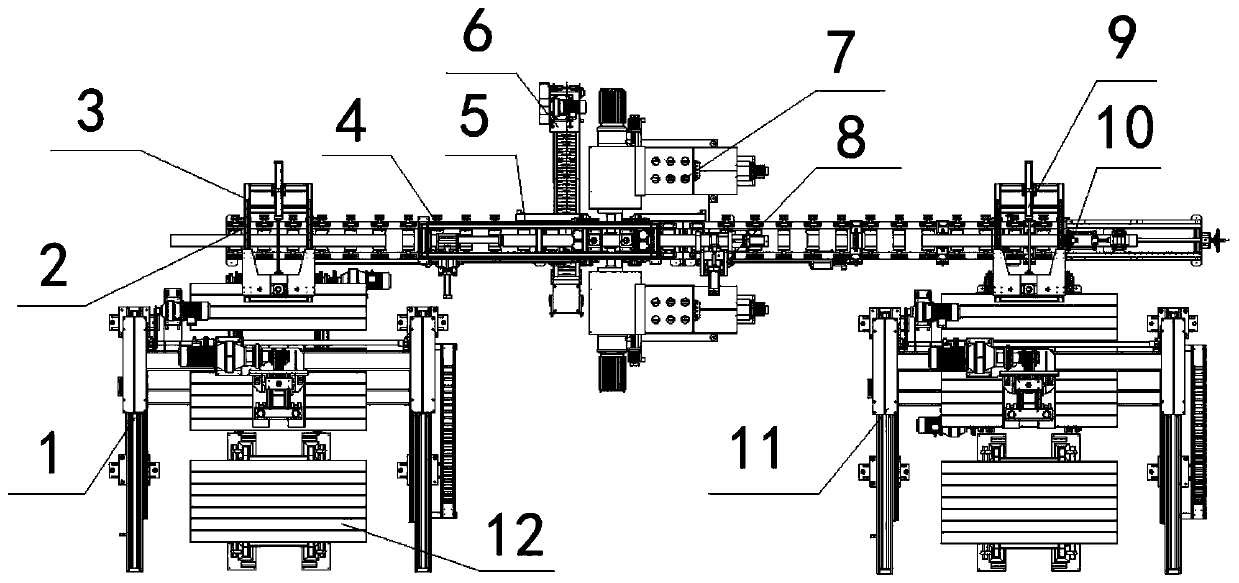

ActiveCN101518828ASave loading and unloading timeImprove processing efficiencyAutomatic conveying/guiding stockMechanical ProcessesEngineering

The invention belongs to the technical field of mechanical process and relates to machine tool auxiliary equipment, in particular to an automatic oil pipe conveying appliance. The appliance comprises a walking beam device part, a center beam device part, a driving wheel device part, a driven wheel device part and a detecting device part; the five parts are combined to realize that parts with long pipes automatically churn, feed and discharge, enter at a high speed from the rear end of a main shaft of a machine tool when feeding, rapidly reduce the speed when approaching to a locating position and stop when a switch is triggered; the parts with long pipes withdraw from the main shaft of the machine tool at a high speed when discharging, and rapidly reduce the speed and stop when approaching to the churning position; and when rotating, a workpiece performs functions of rotation support, clamping roller floating compaction, blockage, and the like to the parts suspending out of the main shaft of the machine tool.

Owner:宁夏新瑞长城机床有限公司

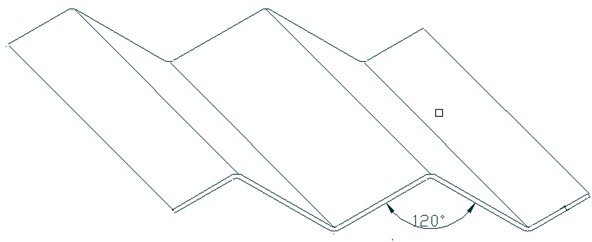

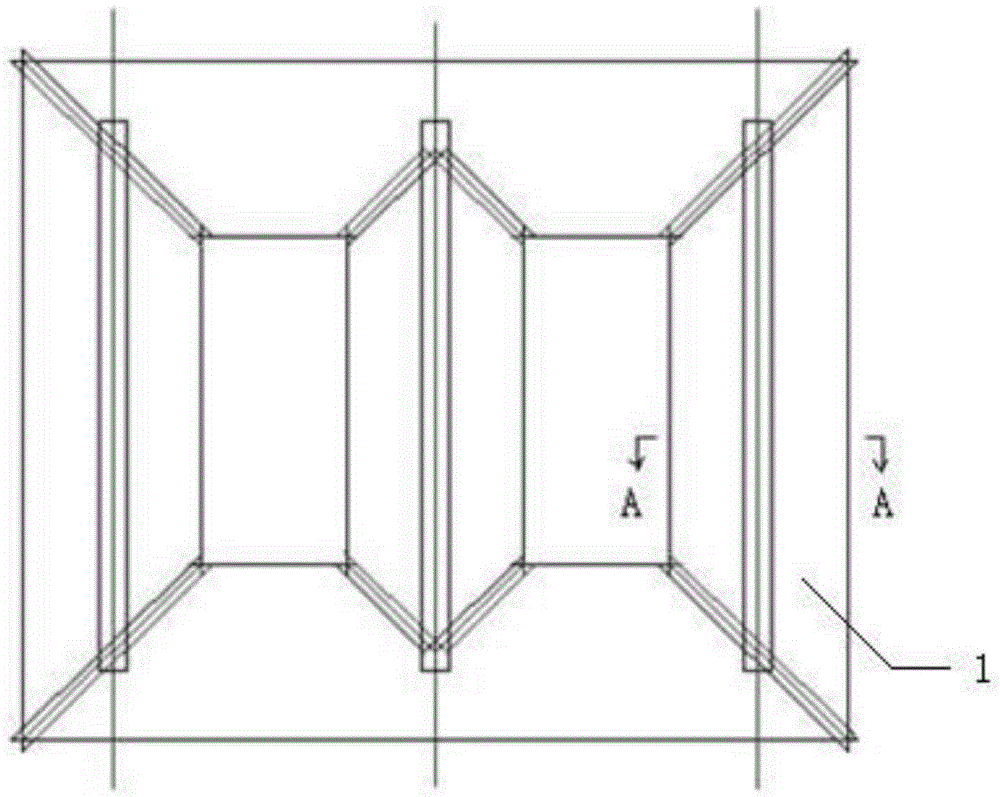

Rolling and cold-bending forming manufacturing method of window-shades for steel structure

The invention relates to a rolling and cold-bending forming manufacturing method of window-shades for a steel structure, relating to the processing technology of metal pieces. The method adopts a rolling and cold-bending forming technology and is characterized in that an upper row and a lower row of rolling wheels are arranged on a rolling and cold-bending forming machine, and the shape of the rolling wheels are gradually changed into window-shades from cylinders from the inlet end to the outlet end of the rolling and cold-bending forming machine; and steel belt coiled materials having the same width with the unfolding materials of the window-shades are sent to the inlet end of the rolling and cold-bending forming machine and are cut off at the outlet end by hydraulic shears. The invention simplifies production routine, greatly enhances production efficiency, improves work efficiency at least over 8 times, abandons manufacture of complex dies, enables the production to be adjusted with the change of materials, enables the quality of products to be stable and reliable and greatly reduces cost.

Owner:JIANGSU HAIXUN IND GROUP SHARE

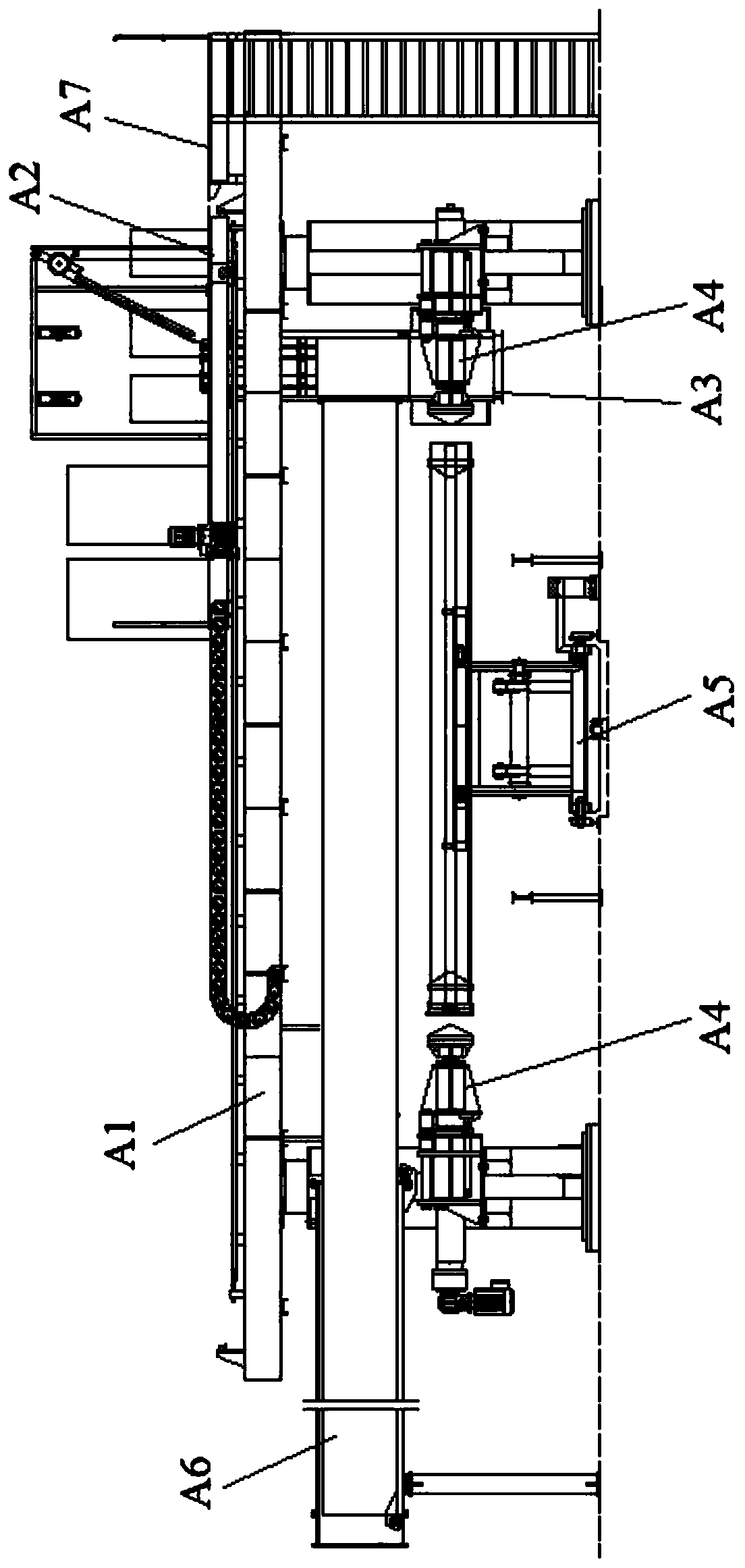

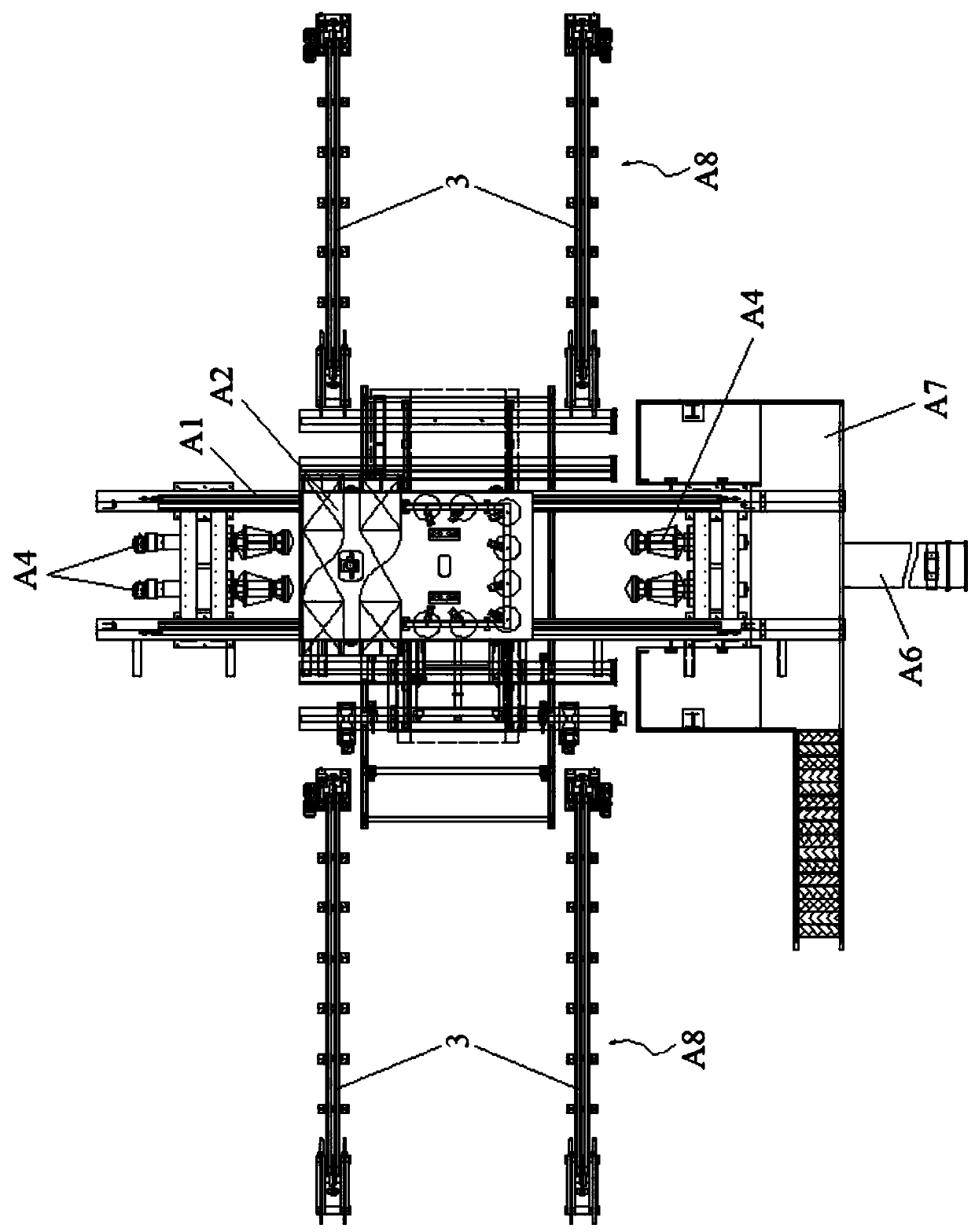

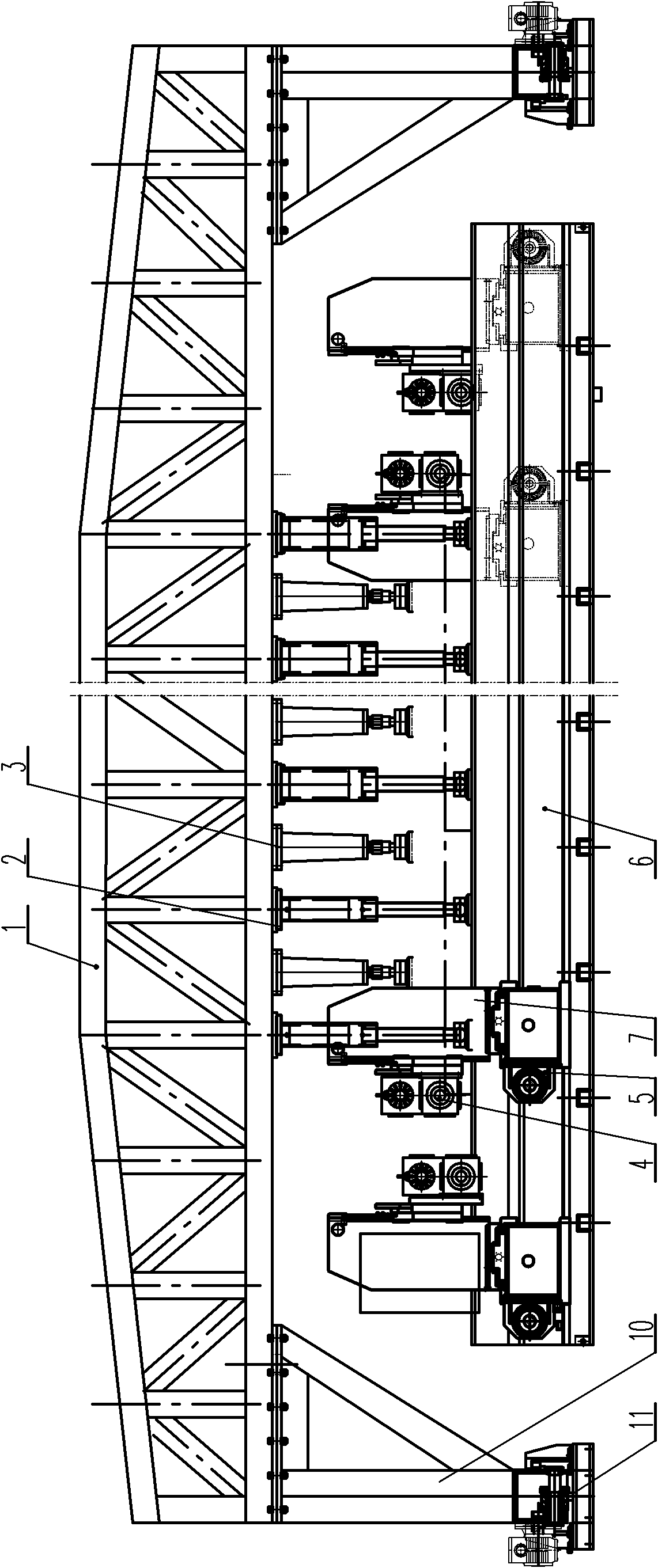

Automobile plate spring width double side edge milling production line and production process

PendingCN110508851AHigh precisionReasonable layoutMilling equipment detailsMetal working apparatusProduction lineMilling cutter

The invention provides an automobile plate spring width double side edge milling production line and a production process. The automobile plate spring width double side edge milling production line comprises an automatic feeding stacking device, a material inlet roller way, a feeding material transferring machine, a material supporting roller way, a centering device, a plate spring chip discharging machine, an edge milling machine, a servo positioning device, a discharging material transferring machine, a discharging roller way and an automatic discharging stacking device. A first feeding horizontal moving device arranged on the automatic feeding stacking device is installed on a first feeding fixing support, a feeding stacking electromagnetic sucker is installed on the first feeding horizontal moving device, a feeding roller way is arranged at the lower middle position of the first feeding horizontal moving device, a feeding frame used for carrying plate springs is arranged on one side of the feeding roller way, and the material inlet roller way is arranged on the side face of the feeding roller way. Different installation manners are adopted in designed milling tool seats, a single plate spring can be milled by milling cutters, and multiple plate springs can be stacked to be milled by the milling cutters at the same time; the plate springs can be positioned accurately in thelength direction and the width direction due to a rear blocking device, the servo positioning device and the centering device which are designated, the precision of machined finished products is high,and the product qualification rate is increased.

Owner:山东森德数控机械有限公司

Turing center with inverted spindle

ActiveCN105500105ASmall footprintReduce the numberLarge fixed membersMetal working apparatusEngineeringSlide plate

The invention relates to a turning center with an inverted spindle. The turning center comprises a base plate, a rear chip cleaner, a C-shaped machine tool, a feeding device, a slide plate and a cutter holder, wherein the base plate is fixed on a foundation, the rear chip cleaner longitudinally penetrates the bottom of the base plate in a front-back direction, the C-shaped machine tool is connected to the upper end face of the base plate, the feeding device is biased on one side and longitudinally penetrates the machine tool in a front-back direction, the slide plate is arranged on one side of the machine tool, the slide plate is connected with the machine tool through a linear guide rail, a spindle box is arranged on one side of the slide plate, the slide plate is connected with the spindle box through the linear guide rail, the cutter holder is mounted in front of the lower side of the machine tool and located below the feeding device, an X-axis drive system is mounted behind the slide plate, and a Z-axis drive system is mounted in front of the slide plate. The turning center has the advantages that the turning center is compact in structure, machine tool floor space can be reduced favorably, and the automation level of the machine tool is increased.

Owner:希斯机床(沈阳)有限责任公司

Automatic feeding and discharging device for circuit board laser drilling

PendingCN111590221AImprove loading and unloading efficiencySave time for loading and unloadingWelding/soldering/cutting articlesMetal working apparatusControl engineeringDust control

The invention discloses an automatic feeding and discharging device for circuit board laser drilling. The automatic feeding and discharging device comprises a rack, a controller and a laser drilling machine, wherein the laser drilling machine is mounted at the lower part of the rack. The automatic feeding and discharging device further comprises a material conveying assembly and a material box assembly. According to the automatic feeding and discharging device for circuit board laser drilling, automatic feeding and discharging operation can be carried out on circuit boards at the position of the laser drilling machine through a feeding module and a discharging module of the material conveying assembly; meanwhile, a sweeping module can sweep and remove dust on a working table of the laser drilling machine; circuit boards of various sizes can be placed as required through the material box assembly; according to the automatic feeding and discharging device for circuit board laser drilling, the feeding and discharging efficiency of the circuit boards can be improved, the feeding and discharging time of the circuit boards is shortened, meanwhile, the circuit boards cannot be folded andbent, so that the quality of the product is effectively improved, the rejection rate of circuit board drilling is reduced, and the utilization rate of the laser drilling machine is improved; and in addition, the working table of the laser drilling machine can be automatically swept, so that great convenience is brought to a user.

Owner:深圳市本川智能设备有限公司

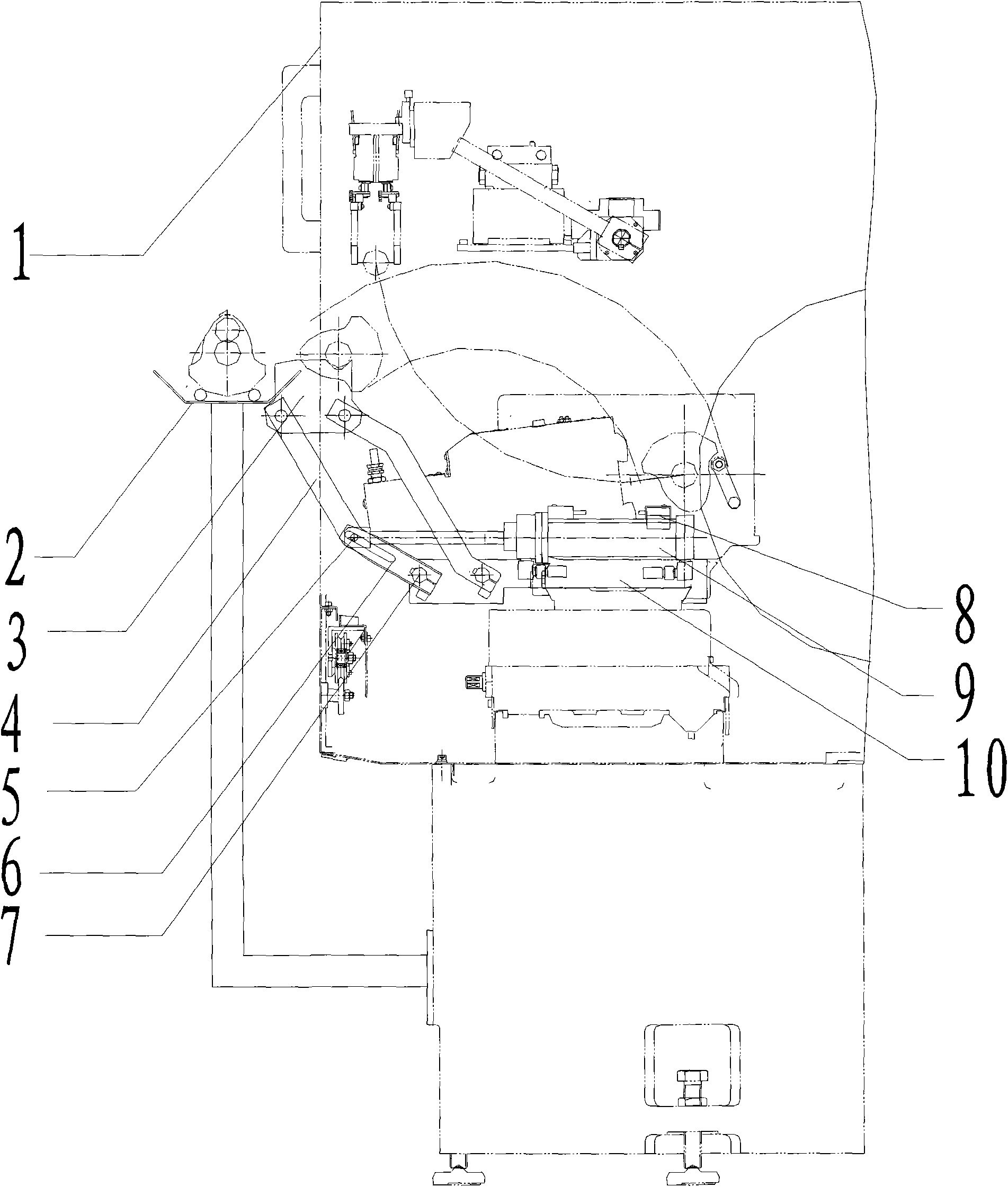

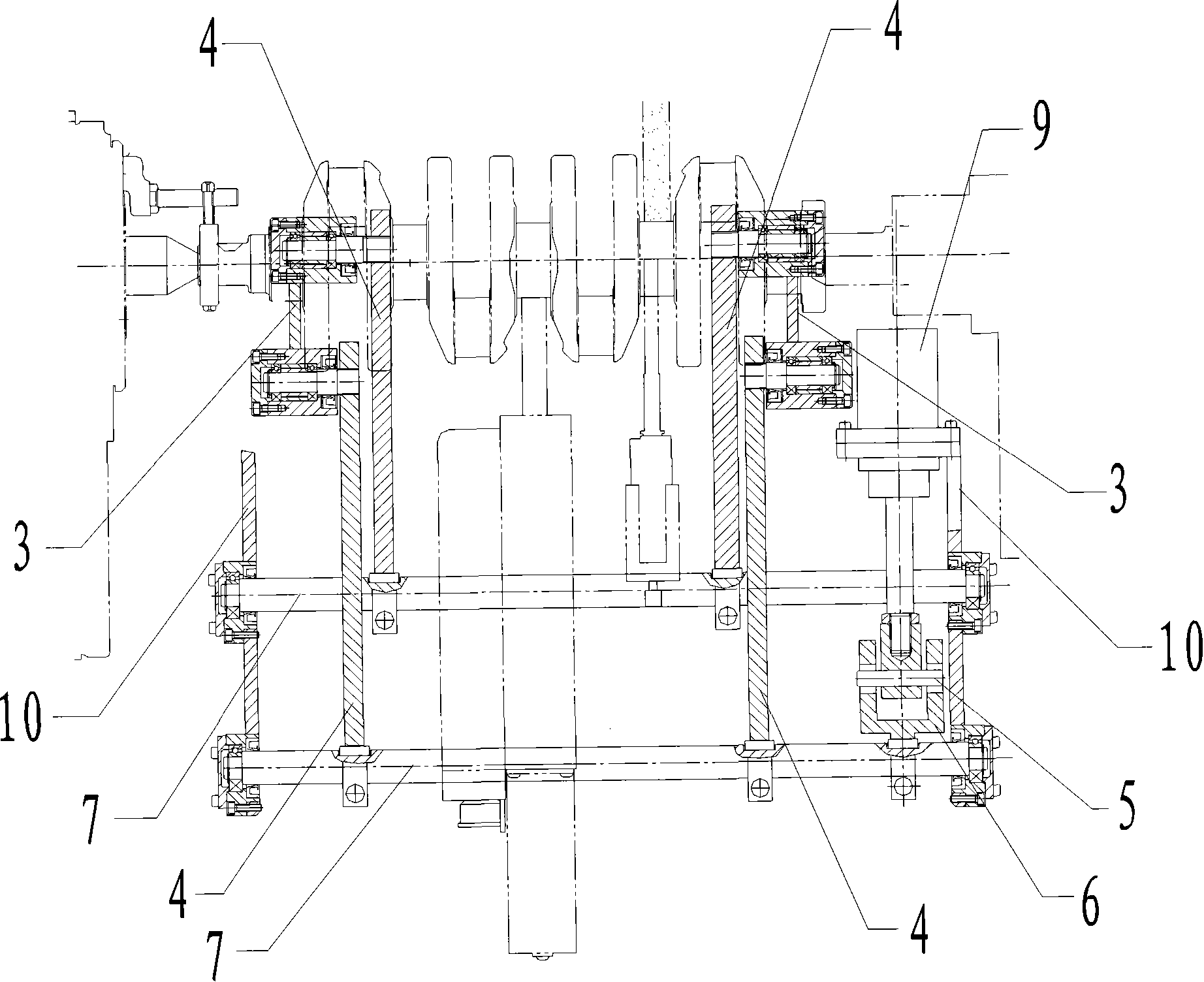

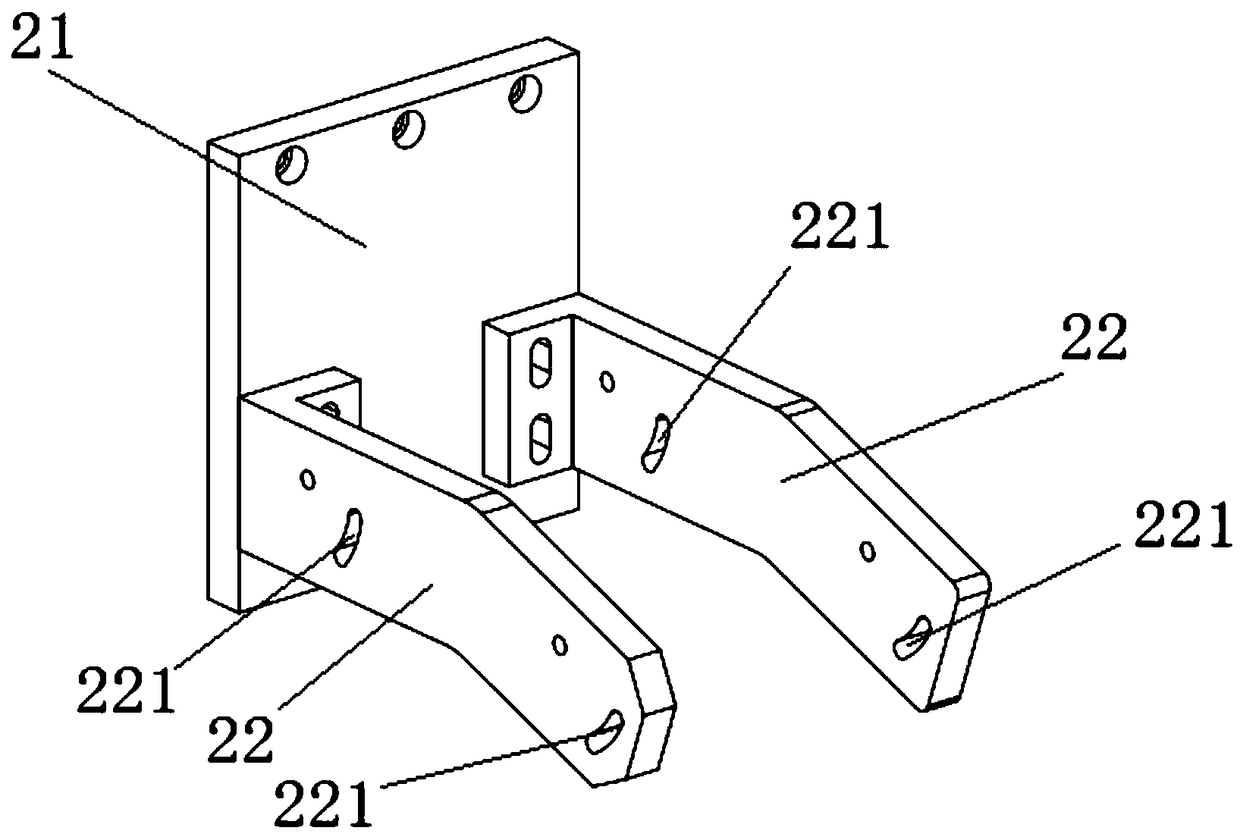

Automatic loading and unloading device aiming at crankshaft

ActiveCN101653914ASave time for loading and unloadingImprove work efficiencyMetal working apparatusCrankshaftControl circuit

The invention relates to an automatic loading and unloading device aiming at a crankshaft, comprising a left swinging bracket and a right swinging bracket, wherein, the swinging brackets are composedof a front swinging arm, a rear swinging arm and a workpiece bracket; two sides of the workpiece bracket are respectively hinged with upper ends of a left swinging arm and a right swinging arm, and lower ends of the left swinging arm and the right swinging arm are respectively connected with a front rotating shaft and a rear rotating shaft; the front rotating shaft and the rear rotating shaft arerotatablely connected with a frame by a bearing; and one of the front rotating shaft and the rear rotating shaft is a driving shaft, the driving shaft is connected with a hydraulic drive mechanism, and the hydraulic drive mechanism is provided with a control circuit. In the invention, a hydraulic cylinder of the hydraulic drive mechanism drives the swinging brackets to swing for automatically loading and unloading, thus improving working efficiency, reducing labor intensity and avoiding scratch possibility on a workpiece during a manual loading and unloading process.

Owner:BEIJING NO 2 MACHINE TOOL WORKS

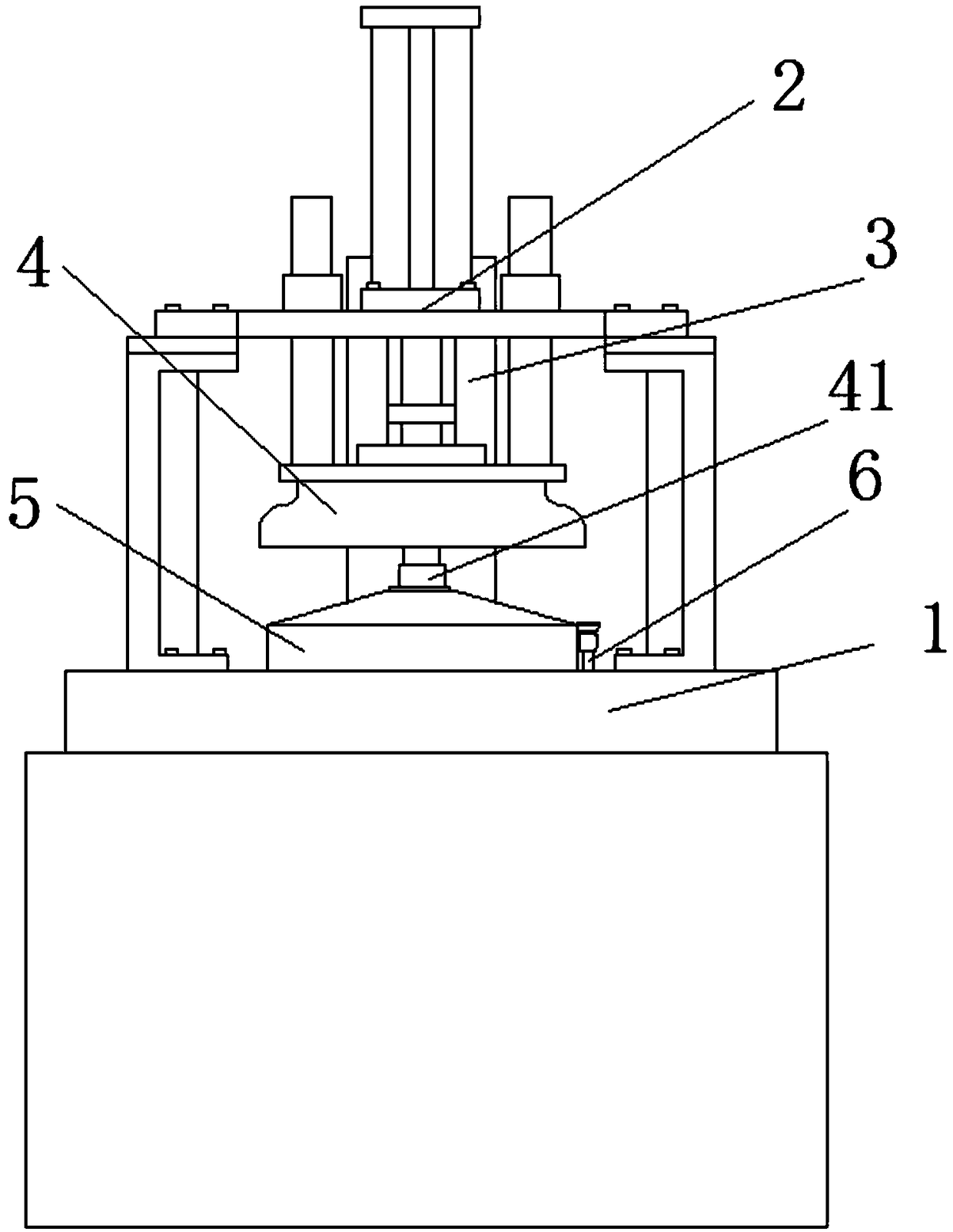

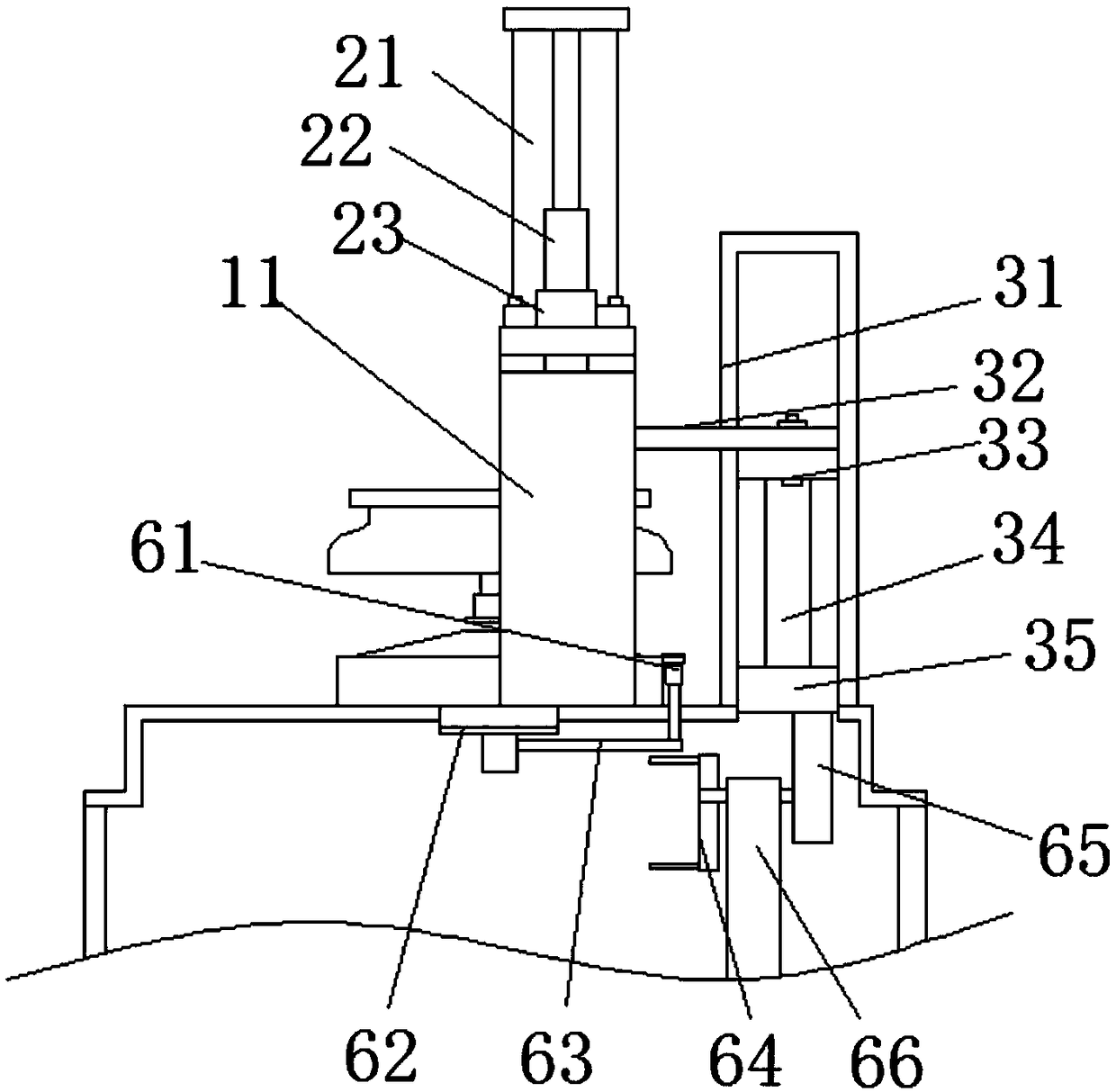

Mold pressing device for round automobile ornaments

ActiveCN108995106AFew stepsSave time for loading and unloadingEdge grinding machinesDomestic articlesEngineeringCam

The invention discloses a mold pressing device for round automobile ornaments. The mold pressing device for the round automobile ornaments comprises a grinding mechanism and a transmission mechanism,wherein the grinding mechanism comprises a small mill, a rotary motor arranged below the top plate of a machine platform, a mill bracket and a bracket overturning mechanism; a mill through groove consistent with the moving route of the small mill is formed in the top of the machine platform; an output shaft of the rotary motor is positioned at the center of a lower mold; the mill bracket is L-shaped and is rotatably connected with the output shaft; the mill bracket comprises a horizontal section and a vertical section; the horizontal section serves as a shaft; the small mill is arranged at theend part of the vertical section; the bracket overturning mechanism comprises a supporting base fixed in the machine platform, a cam arranged on the supporting base and an overturning frame; an overturning frame rotary shaft and a cam rotary shaft are horizontally arranged and in transmission connection with each other; and the overturning frame is provided with a horizontal deflector rod which horizontally stretches out and deflects the mill bracket. After the mold pressing device for the round automobile ornaments is formed, the step of specially grinding the sides of interior trim parts isreduced, the feeding and blanking time is saved and the processing efficiency is improved.

Owner:芜湖文青机械设备设计有限公司

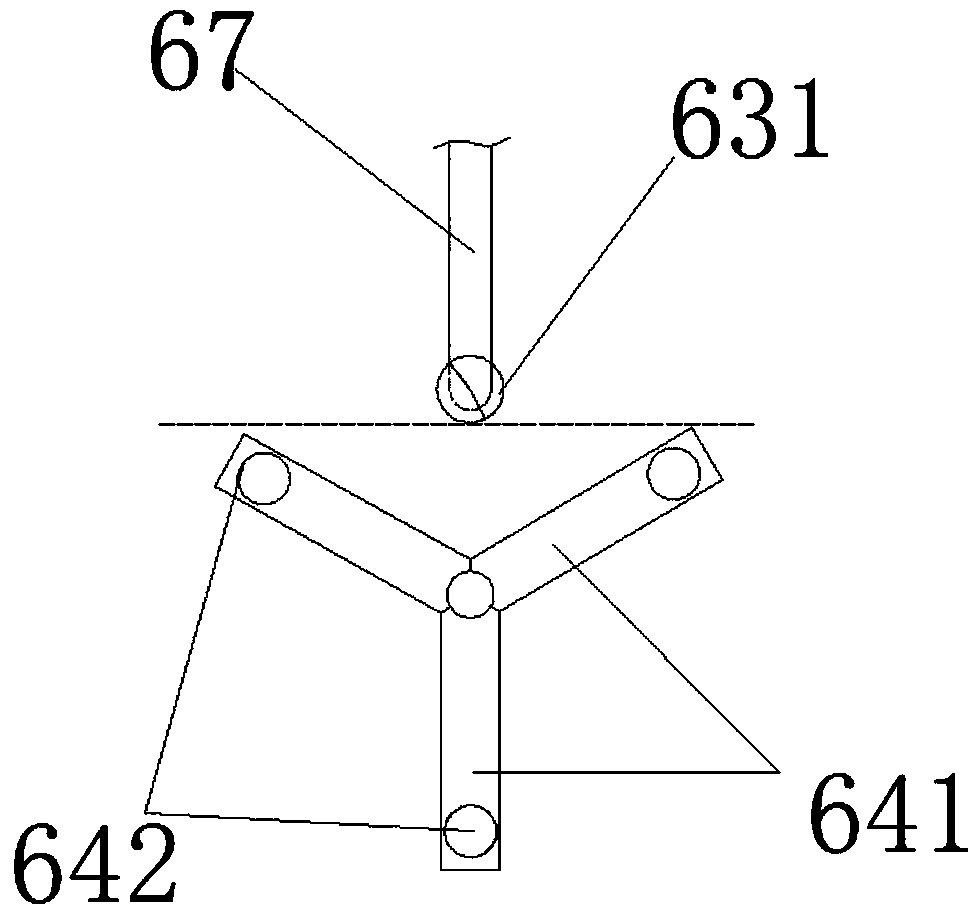

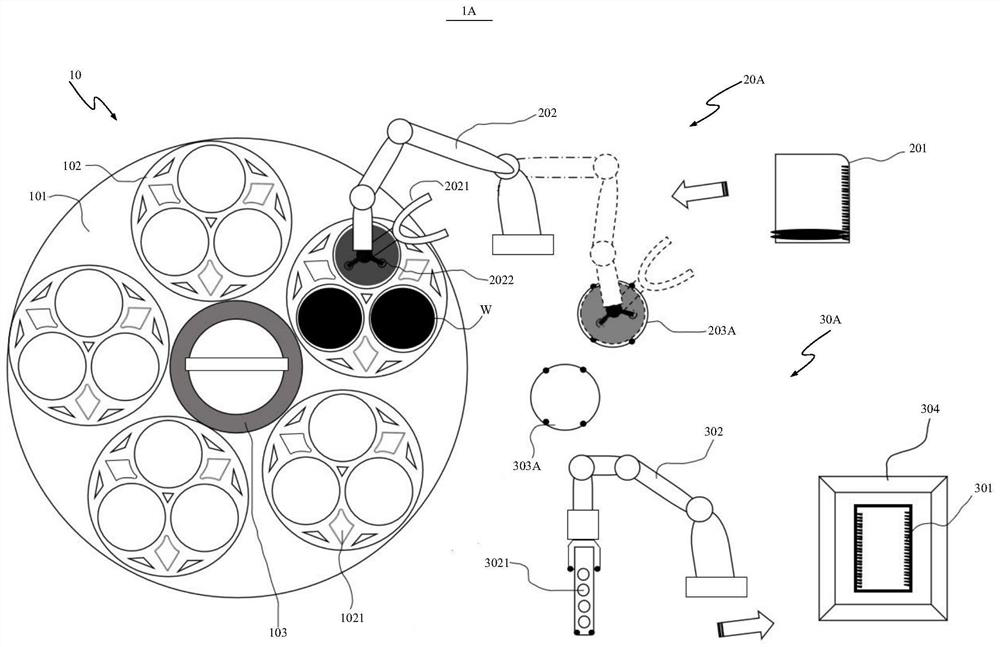

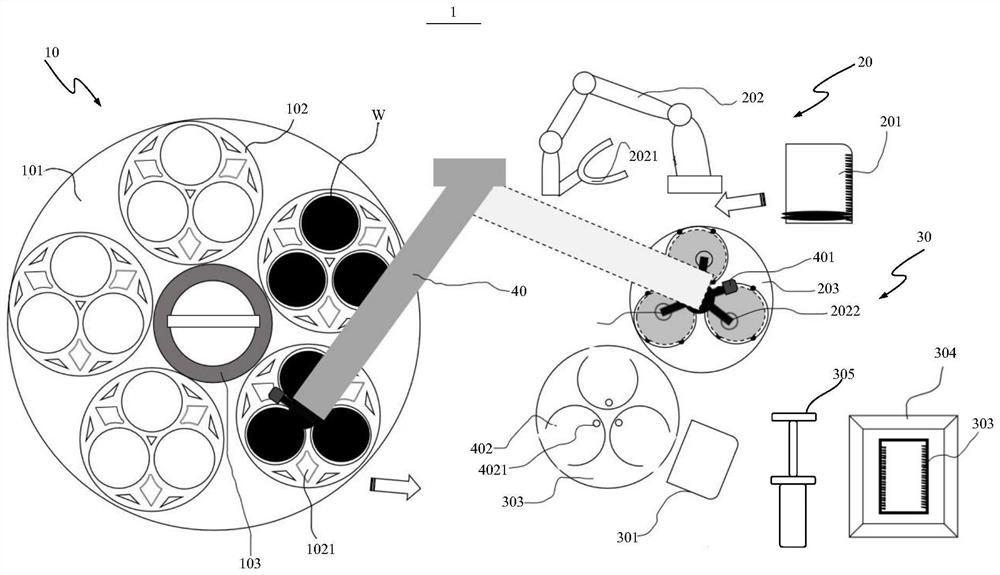

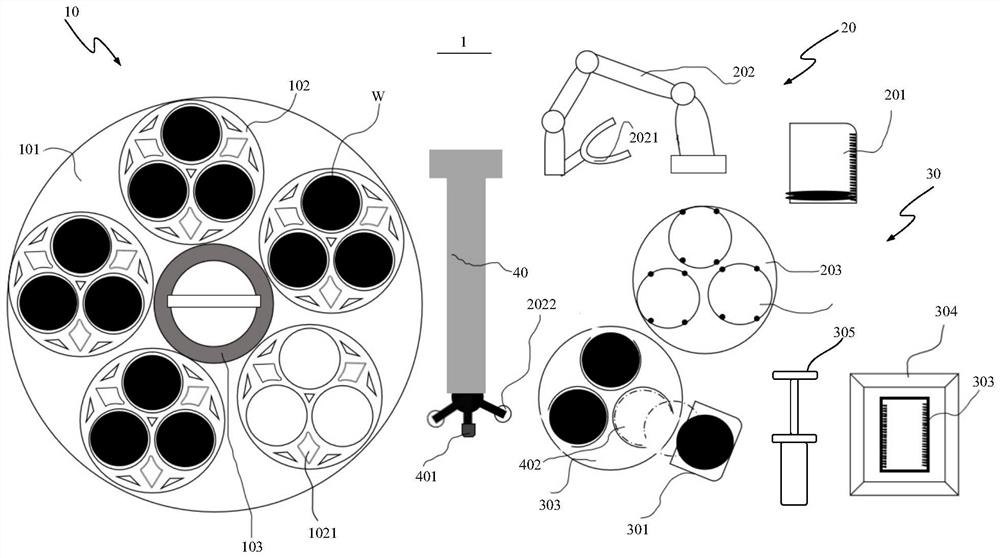

Wafer loading and unloading system and loading and unloading method

PendingCN114261751ASave time for loading and unloadingReduce in quantityConveyor partsWaferStructural engineering

The embodiment of the invention discloses a wafer feeding and discharging system and a wafer feeding and discharging method. The wafer feeding and discharging system comprises a feeding buffer area, a polishing buffer area and a feeding buffer area, wherein the feeding buffer area can temporarily store a plurality of wafers to be polished; the blanking buffer area can temporarily store a plurality of polished wafers; the swinging mechanical arm is used for simultaneously transferring the plurality of wafers to be polished, which are temporarily stored in the feeding buffer area, into the corresponding carriers; and the multiple polished wafers in each carrier are transferred to the discharging cache region at the same time.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

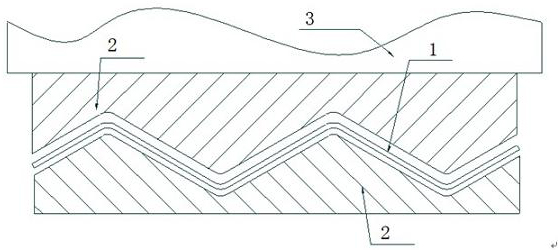

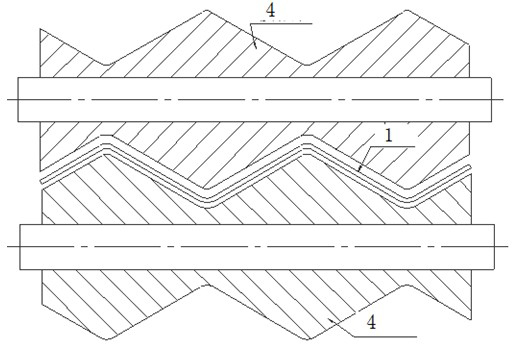

Manufacturing device and manufacturing method of wavy sheet for steel structure of heat exchange system

InactiveCN102319830AEasy to produceIncrease productivityHeat exchange apparatusProcess engineeringIndustrial engineering

The invention provides a manufacturing device and a manufacturing method of a wavy sheet for a steel structure of a heat exchange system, and the device is structurally characterized in that an upper row and a lower row of wavy wheels in the same shape with the wavy sheet, two groups of positioning wheels, one group of leveling wheels, one group of shaping wheels and an adjusting frame are arranged, wherein the shape of each wavy wheel is gradually changed from a cylinder to the shape of the wavy sheet; the two groups of positioning wheels and the one group of leveling wheels are arranged at the front ends of the wavy wheels so as to ensure the correct relative positions of a wavy sheet material and the wavy wheels; and the one group of shaping wheels and the adjusting frame are arranged at the tail ends of the wavy wheels so as to ensure the correct shaping of the wavy sheet. By adopting the manufacturing device and the manufacturing method, the traditional processing mode is thoroughly changed, the complex die manufacturing is abandoned, the stability of the product quality is improved, and the shaping wheels and the adjusting frame can be suitable for different materials so as to enable the product quality to be stable and reliable. The cost is greatly reduced, and a strip-shaped steel coil of the preset fixed size is adopted for replacing the cutting of a steel plate in the traditional process, thereby avoiding the waste of working time and the waste of remnants caused by cutting of the plate.

Owner:JIANGSU HAIXUN IND GROUP SHARE

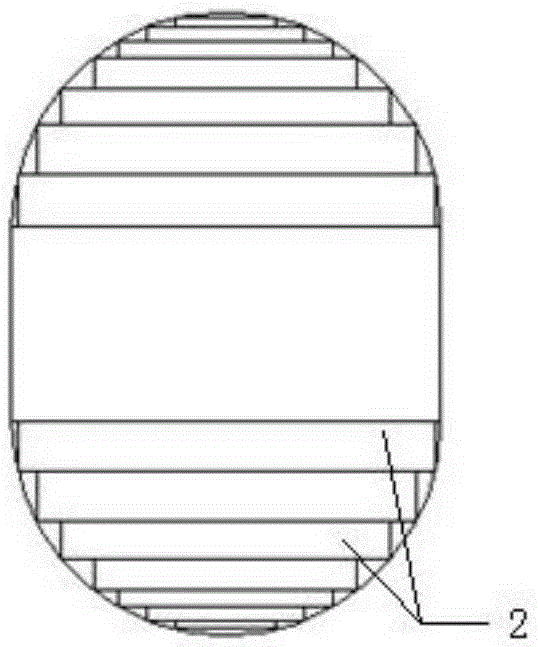

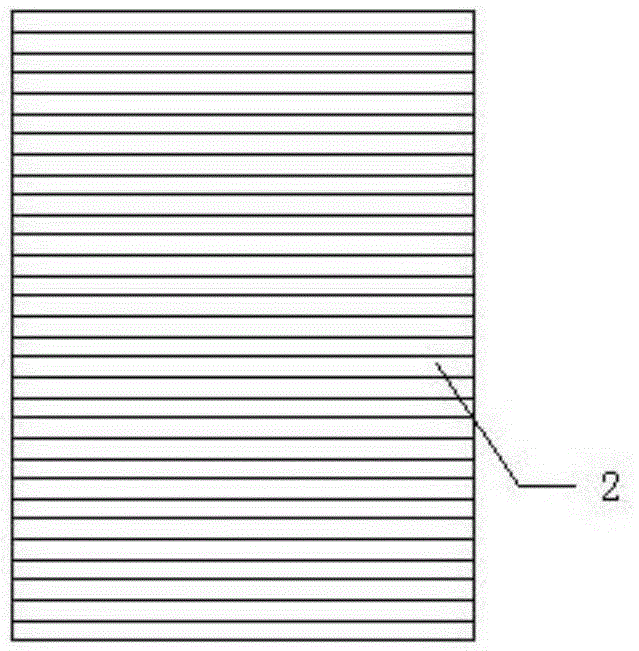

Transformer with rectangular section iron core

InactiveCN105280354AReduce wasteSave time for loading and unloadingTransformers/inductances detailsTransformerEngineering

The invention discloses a transformer with a rectangular section iron core. The transformer comprises the iron core (1) and coils; the coils are provided with two or more of windings; the winding connected with the power supply is a primary winding while the rest of the windings are secondary windings; the iron core (1) is formed by laminating a plurality of silicon steel sheets (2) of the same width; and the section of the iron core (1) is rectangular. According to the transformer, the iron core with the rectangular section is formed by the same-level silicon steel sheets of the same size; the silicon steel sheets are the same in the level of the width, so that the feeding and discharging time in cutting the silicon steel sheets is saved, the waste of pre-material is reduced, and the laminating process is simplified, wherein the area of the rectangular section of the iron core is the same as the area of a long circular or circular section of the iron core.

Owner:JIANGSU HUACHEN TRANSFORMER

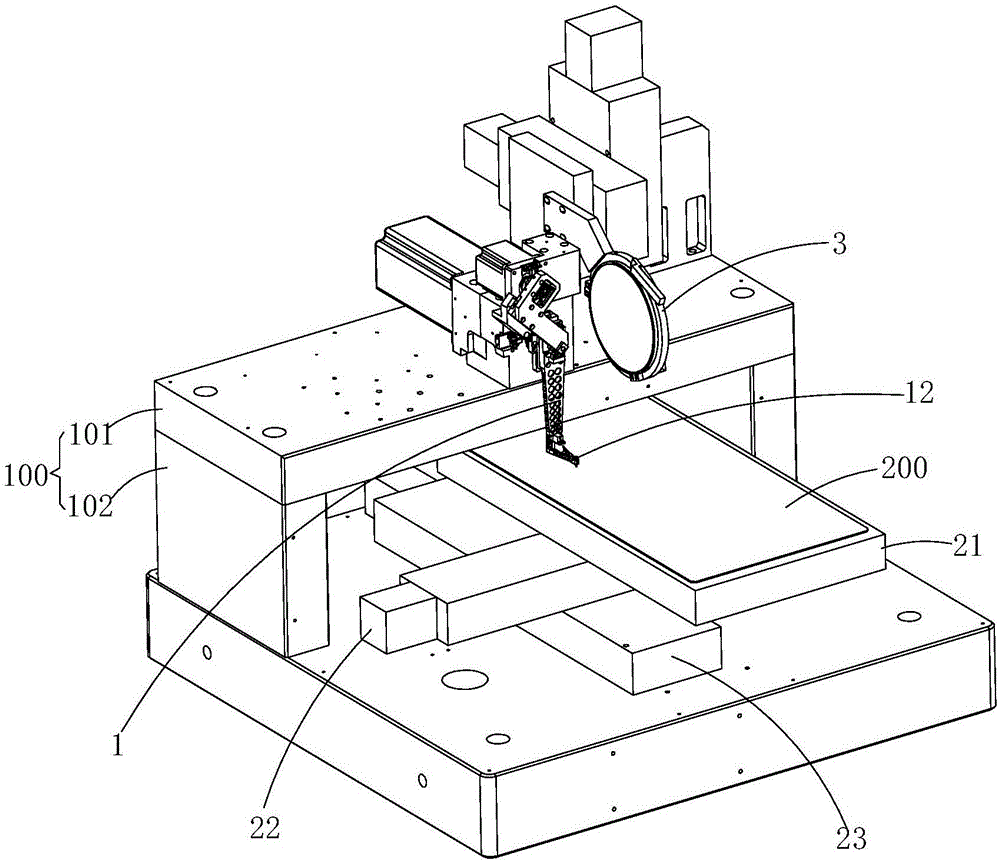

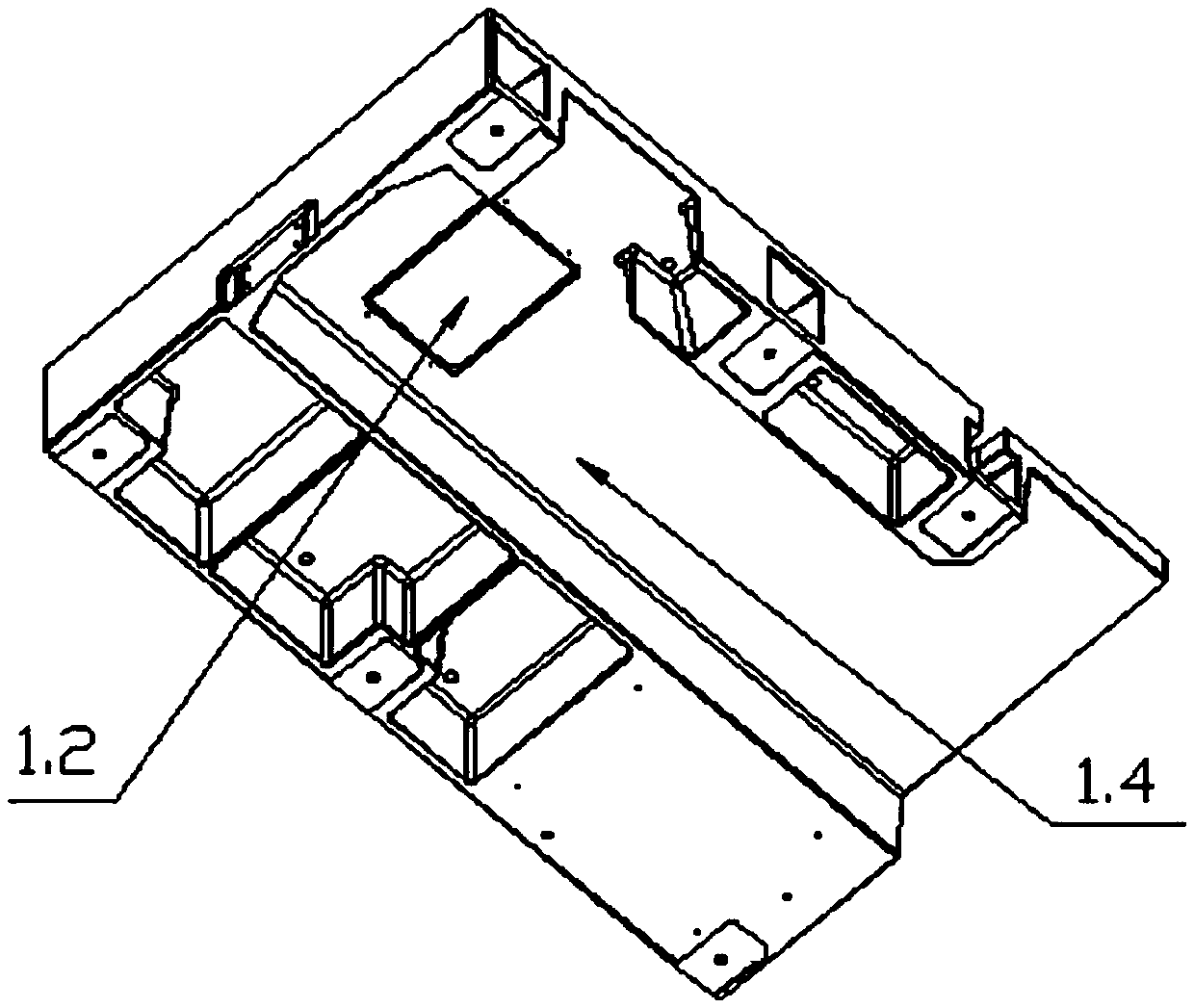

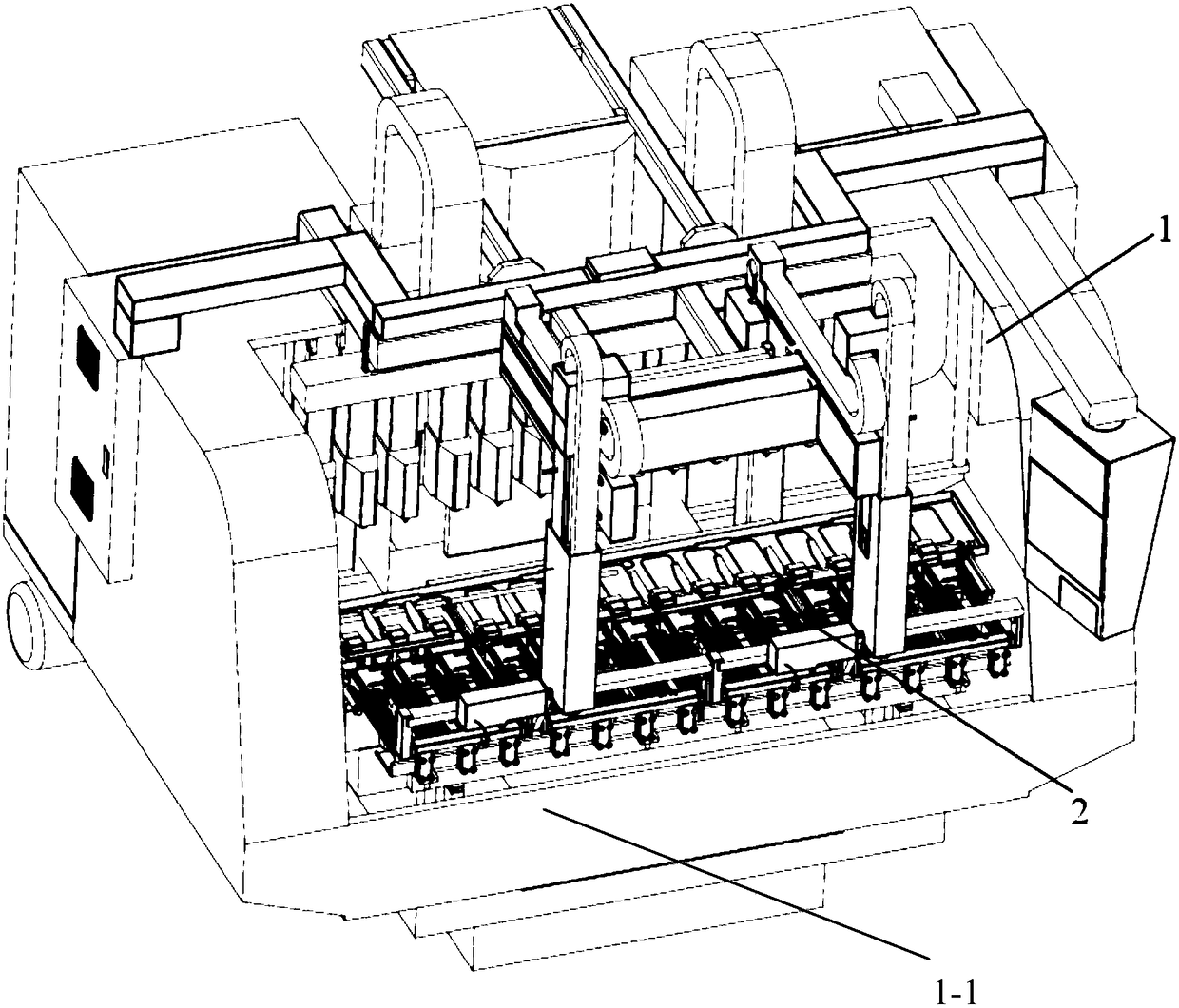

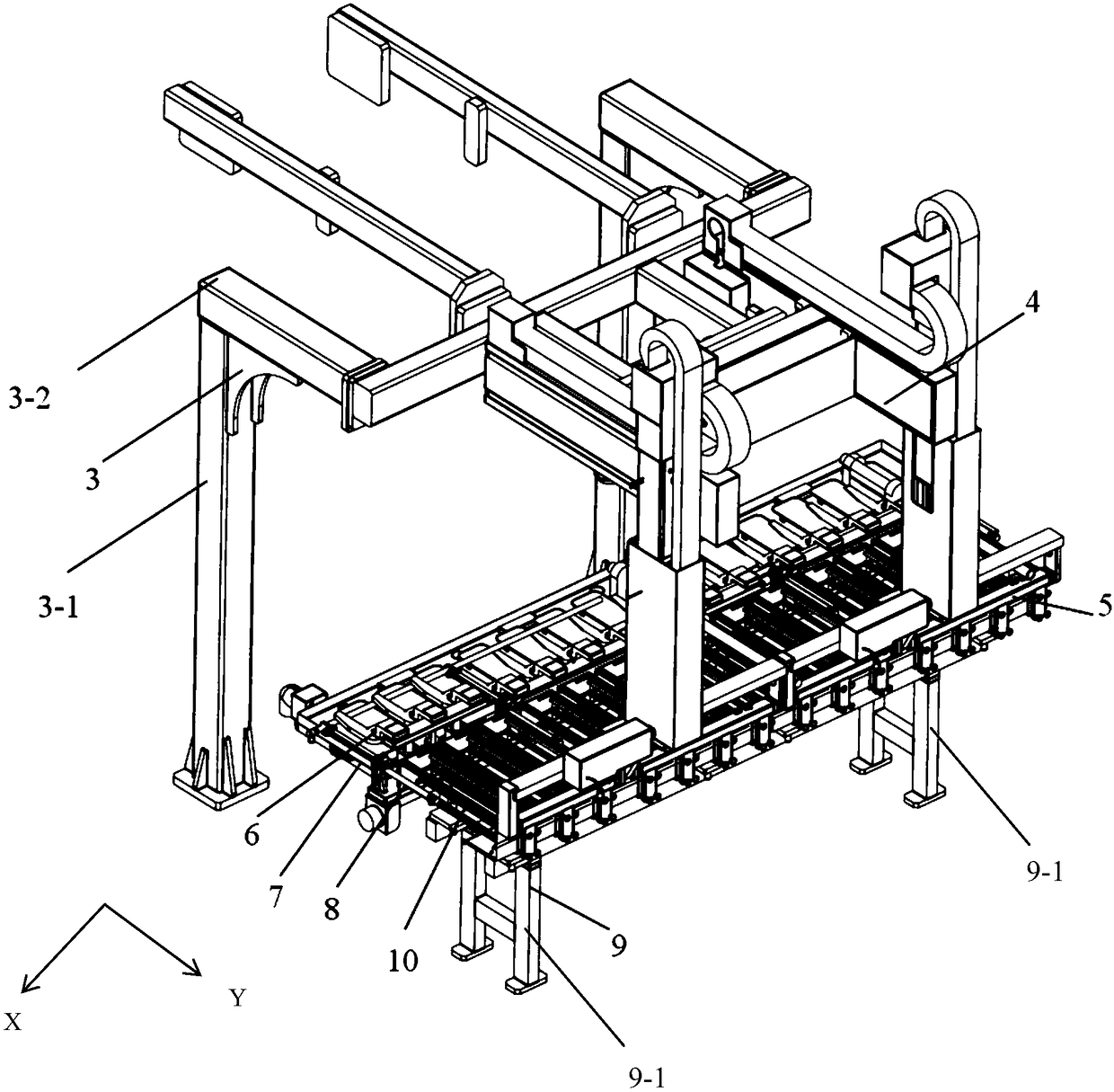

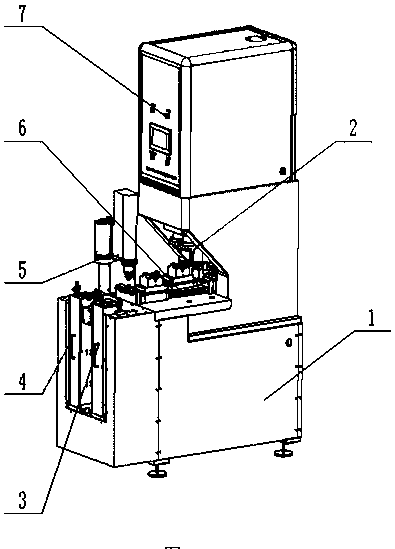

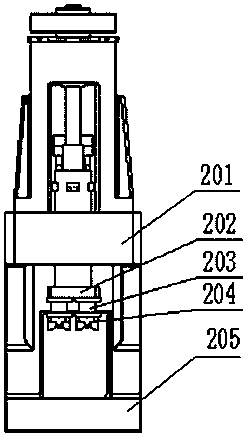

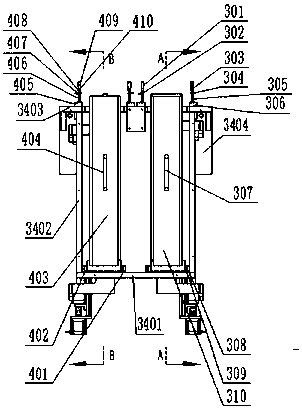

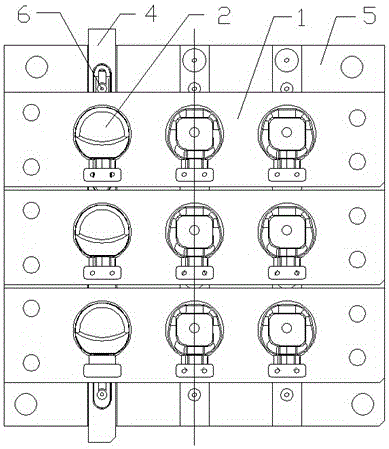

Automatic loading and unloading equipment of multi-shaft finish carving machine

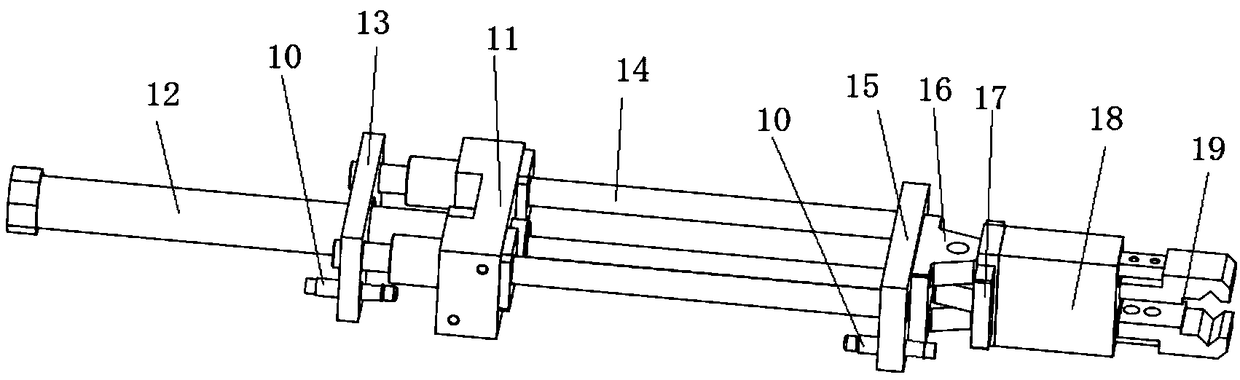

ActiveCN108058523ASave loading and unloading timeIncrease productivityModel makingVertical motionEngineering

The invention discloses automatic loading and unloading equipment of a multi-axis finish carving machine. The equipment comprises a fixed bracket structure, a material frame, a three-axis linear motion mechanism, a glass piece grabbing and overturning mechanism, a positioning mechanism and a vacuum worktable; the fixed bracket structure is connected with the finish carving machine; the material frame is connected with the finish carving machine; the material frame is provided with a material basket; the three-axis linear motion mechanism is connected with the fixed bracket structure; the three-axis linear motion mechanism is provided with a transverse motion mechanism, a longitudinal motion mechanism and a vertical motion mechanism; the glass piece grabbing and overturning mechanism is connected with the three-axis linear motion mechanism; the positioning mechanism is connected above the material frame; and the vacuum worktable is positioned above the material frame, and is positionedbelow the positioning mechanism. The equipment realizes full-automatic multi-station loading and unloading, greatly shortens the loading and unloading time, greatly improves the production efficiency,is delicate and compact in structure, forms a whole with the finish carving machine without increasing the floor area of the finish carving machine to increase the factory building utilization rate,and is precise and reliable in positioning to reduce scratch by glass pieces.

Owner:上海神添实业有限公司

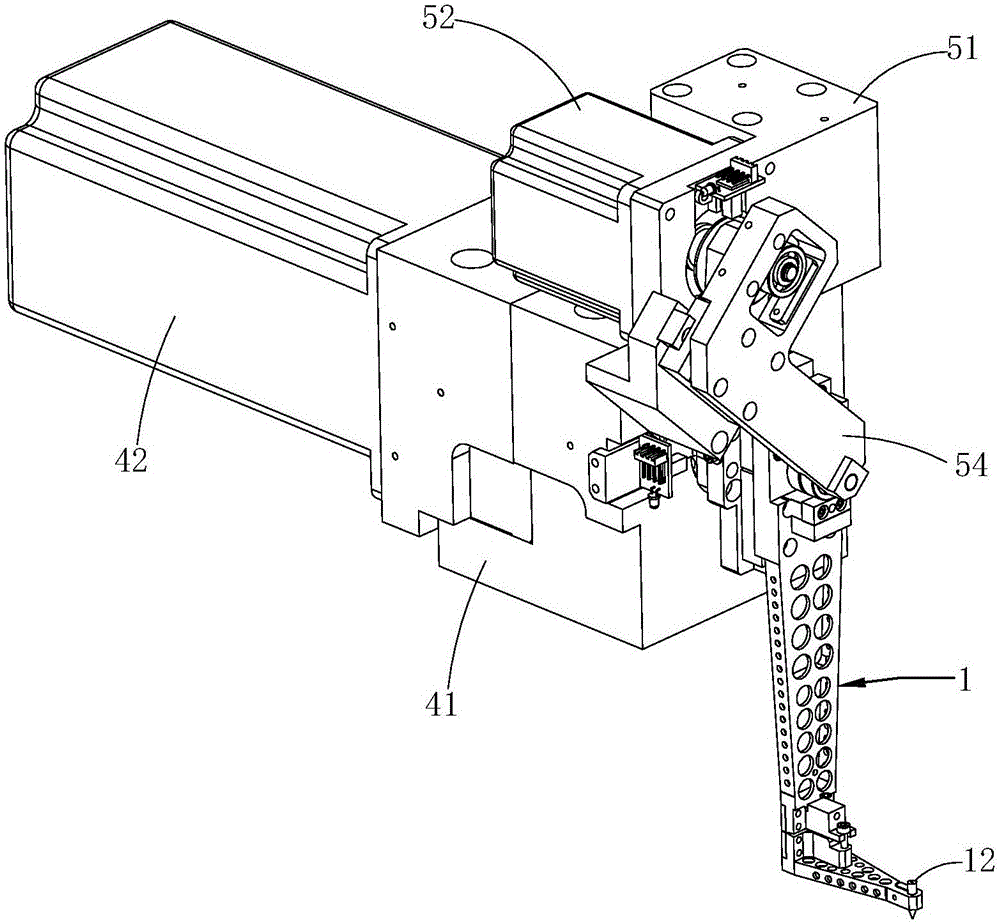

Feeding and discharging mechanical arm of stair forming grinding machine

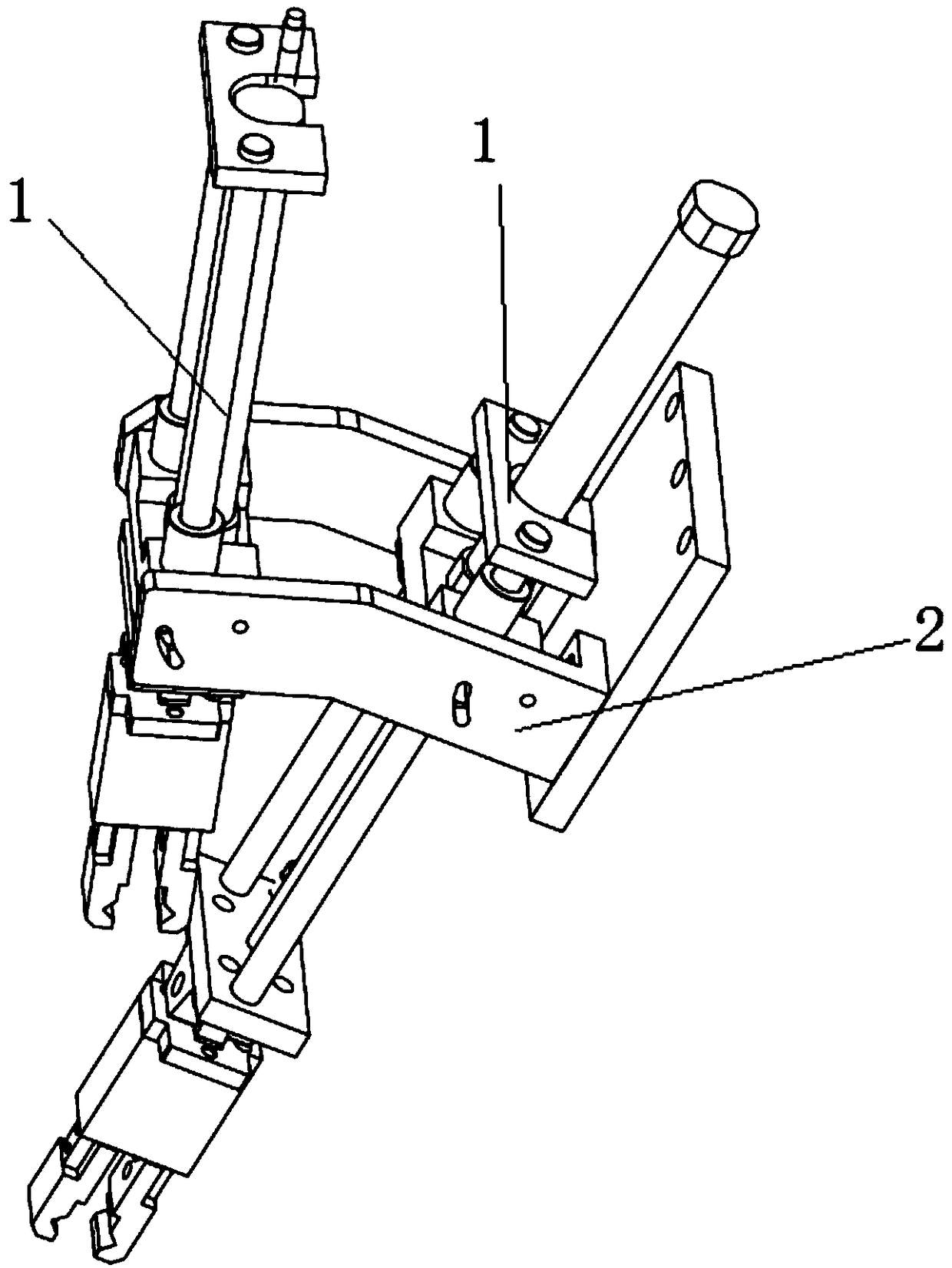

InactiveCN109129054ACompact structureLow costRevolution surface grinding machinesGrinding feedersEngineeringManipulator

The invention discloses a feeding and discharging mechanical arm of a stair forming grinding machine. The feeding and discharging mechanical arm comprises a manipulator mounting bracket and manipulators mounted at the manipulator mounting bracket. The manipulator mounting bracket comprises a manipulator hanging plate vertically fixed to a moving components of the manipulator moving mechanism, anda pair of arm clamping plates fixed to the outer side of the manipulator hanging plate. At least two manipulators are mounted on the manipulator clamping plate through a manipulator adjusting structure. One arm of the manipulator is vertically arranged. The direction of arms of other manipulators is in an included angle with the vertical direction. Claw mechanisms at the lower ends of the manipulators can reach the same intersection point after extending. Compared with the prior art, a driving mechanism driving the manipulators to move is omitted, the component structure is omitted, and the cost is lowered.

Owner:芜湖中驰机床制造有限公司

Blade automatic forming equipment

ActiveCN109550827AImprove product qualitySave time for loading and unloadingMetal-working feeding devicesMetal working apparatusManipulatorEngineering

The invention provides blade automatic forming equipment, which includes a rack, a stamping mechanism, a feeding mechanism, a discharging mechanism, a four-axis manipulator, a sliding rail mechanism and a protective cover. The protective cover is fixed to the upper end face of a power package bracket, the feeding mechanism is installed on the front end face of the rack, and the discharging mechanism is installed on the front end face of the rack and assembled on the left side of the feeding mechanism; and the four-axis manipulator is installed on the edge position of the left side of the upperend face of a working table, the sliding rail mechanism is fixed to the upper end face of the working table and installed on the right side of the four-axis manipulator, and the stamping mechanism isassembled in the rack and installed on the upper side of the sliding rail mechanism. According to the blade automatic forming equipment, the feeding and discharging time is saved, the processing efficiency is improved, the position and pressure are precisely controlled, the quality of stamping forming products is stable, and the accuracy is high.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Double edge milling machine with a movable pressing beam

InactiveCN102248211AIncrease productivityImprove work efficiencyMilling equipment detailsMechanical engineeringDouble edge

The invention relates to a double edge milling machine with a movable pressing beam. The double edge milling machine comprises milling unit heads, a bed body and a pressing beam arranged above the bed body; presser feet are arranged below the pressing beam; two sides of the bed body are respectively provided with two sets of X shaft adjusting mechanism which are in sliding fit with the bed body; each X shaft adjusting mechanism is fixedly provided with a set of Y shaft adjusting mechanism which is fixedly provided with a Z shaft adjusting mechanism that is fixedly provided with one milling unit head; two ends of the pressing beam are provided with pressing beam moving mechanisms. According to the invention, two sides of the bed body are respectively provided with two milling unit heads, and the four milling unit heads can simultaneously mill two ends of a rectangular planking workpiece, thereby improving production efficiency; the pressing beam in the invention is electrically movable, which enables convenience for loading and unloading of workpieces, simple operation and shortened time in loading and unloading of workpieces, thereby further improving working efficiency.

Owner:无锡洲翔重工科技有限公司

Forming die in inner-core replaceable form

The invention relates to a forming die in an inner-core replaceable form. The forming die comprises an upper die and a lower die which are mutually matched; the forming die further comprises a lower die backing plate which is fixedly arranged on the lower die and at least two fixed pull rods which can be movably arranged on the lower die backing plate; at least one inner core fielded panel is detachably arranged on each fixed pull rod; and at least one inner core for forming a product is arranged on each inner core fielded panel. According to the forming die disclosed by the invention, a movable inner core structure in a traditional die is modified into a relatively-fixed structure, so that the problem that the inner core is brought up and falls to crush a parting face of the lower die during die parting is solved, the service effect of the die is guaranteed to a maximum extent, and the service life of the die is prolonged. Meanwhile, the invention also adopts a quick-replaceable structure, so that the whole forming surface of the die can be quickly replaced, further the feeding and discharging time of products is saved, and the production efficiency of processing enterprises is greatly improved.

Owner:SUZHOU YOULONG PLASTIC RUBBER PRECISION MFG CO LTD

High-efficiency automatic welding mechanism

InactiveCN104043926ASave time for loading and unloadingShorten the timeWelding/cutting auxillary devicesAuxillary welding devicesRotational axisElectric machine

The invention discloses a high-efficiency automatic welding mechanism. The high-efficiency automatic welding mechanism comprises a working platform. The high-efficiency automatic welding mechanism is characterized by also comprising a movable welding device which is arranged on the working platform, a rotating device which is arranged at the side edge of the working platform and two sets of workpiece clamping and rotating devices which are arranged on the rotating device; the rotating device comprises a support and an electric motor I which is arranged on the support, the electric motor I is connected with a rotating shaft, a rotating platform is arranged on the rotating shaft, and a support platform is arranged on the rotating platform. The high-efficiency automatic welding mechanism disclosed by the invention has the advantages of high automation degree, reasonable design and time saving and has a wide market prospect.

Owner:佛山市顺德区顺饶五金电器有限公司

Double-workbench and milling gantry lathe bed gear hobbing machine driven by ultra-large oil motor

ActiveCN104057303ASave loading and unloading timeImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersMachine toolComposite function

The invention discloses a double-workbench and milling gantry lathe bed gear hobbing machine driven by an ultra-large oil motor. Double workbenches are adopted for processing, so that feeding and discharging time in processing circulation can be obviously reduced, and processing efficiency is improved; the oil motor is adopted by a feeding system and a milling component as a power source, and a larger output torque can be provided, thereby being suitable for a large hobbing machine tool; the milling component can be used in a multifunctional mode, so that the machine tool has composite functions of hobbing, milling, drilling and the like, and the use ratio and the economic benefit of the machine tool can be improved.

Owner:XI AN JIAOTONG UNIV

Material taking and placing device for automatic stereoscopic warehouse

InactiveCN112849876AInefficient accessImprove access efficiencyStorage devicesMaterials preparationProcess engineering

The invention discloses a material taking and placing device for an automatic stereoscopic warehouse. The material taking and placing device comprises a feeding and discharging support, two sets of conveying mechanisms and material taking and placing mechanisms; the feeding and discharging support is provided with a feeding channel and a discharging channel which are arranged in parallel in a spaced manner; the feeding channel and the discharging channel are each internally provided with one set of conveying mechanism; and the material taking and placing mechanisms are arranged beside the feeding and discharging support, wherein each conveying mechanism is provided with a material preparation station and a feeding and discharging station, and the material taking and placing mechanisms are arranged opposite to the feeding and discharging stations. According to the material taking and placing device, feeding and discharging operation can be independently carried out, material storage and taking can be independently and efficiently carried out, and the situation that the material storage and taking efficiency is low due to mutual interference is avoided.

Owner:成川科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com