Automatic battery loading and unloading device

An automatic loading and unloading, battery technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing and other directions, can solve the problem of automatic loading and unloading, affecting production efficiency, etc., to improve efficiency and reduce loading and unloading. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The battery automatic loading and unloading device of the present invention will be described in detail below with reference to the accompanying drawings.

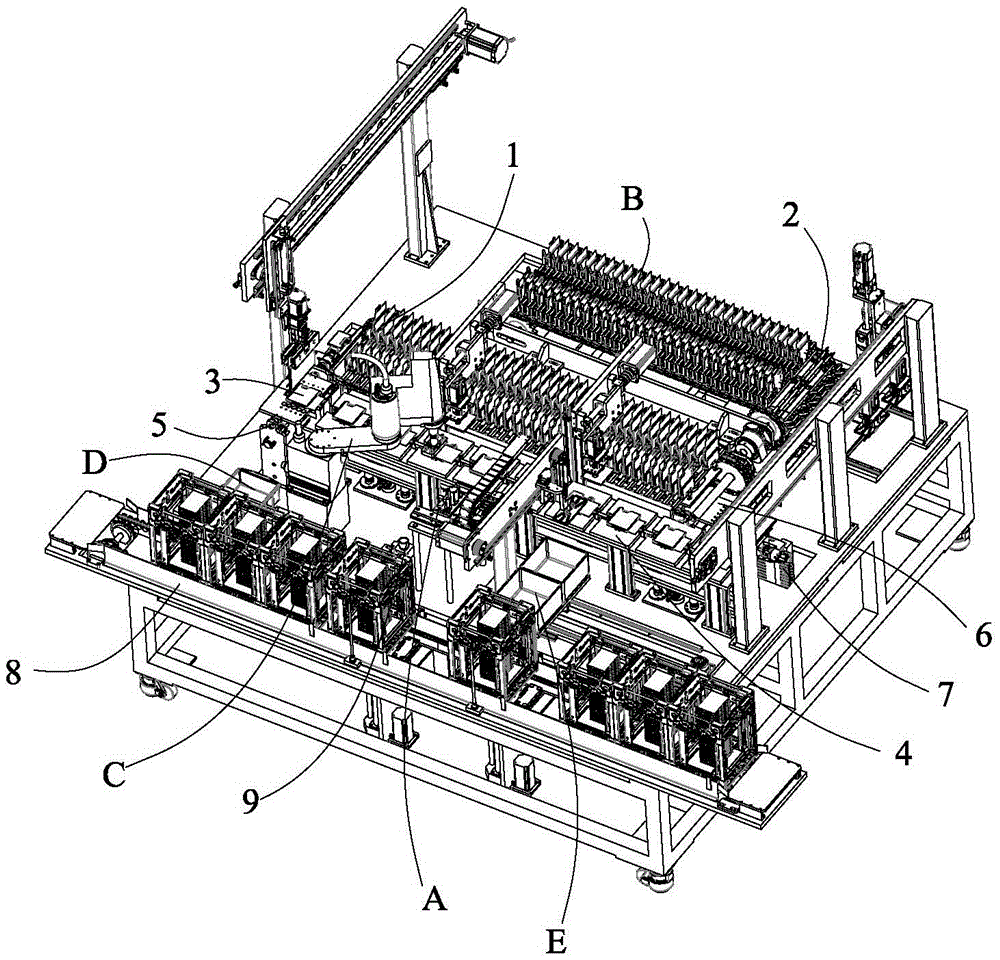

[0037] refer to Figure 1 to Figure 7 According to the present invention, the battery automatic loading and unloading device is used for loading and unloading special-shaped batteries B, including a feeding mechanism 1, a feeding mechanism 2, a plurality of jackets 3 and a jacket return mechanism 4.

[0038] The feeding mechanism 1 collects a plurality of batteries B and simultaneously moves them into external equipment for processing.

[0039] The unloading mechanism 2 collects and removes the battery B after processing.

[0040] Each jacket 3 accommodates and fixes the battery B. As shown in FIG.

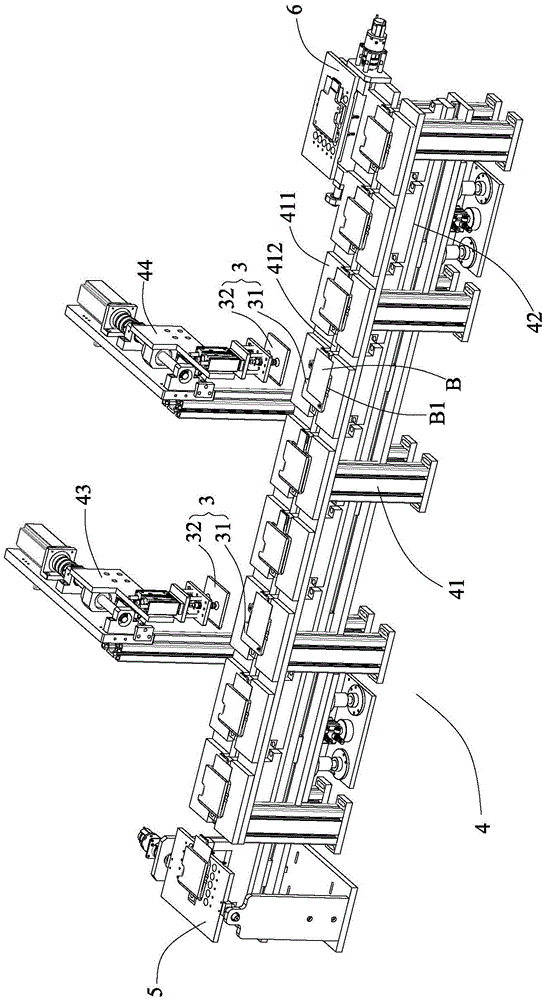

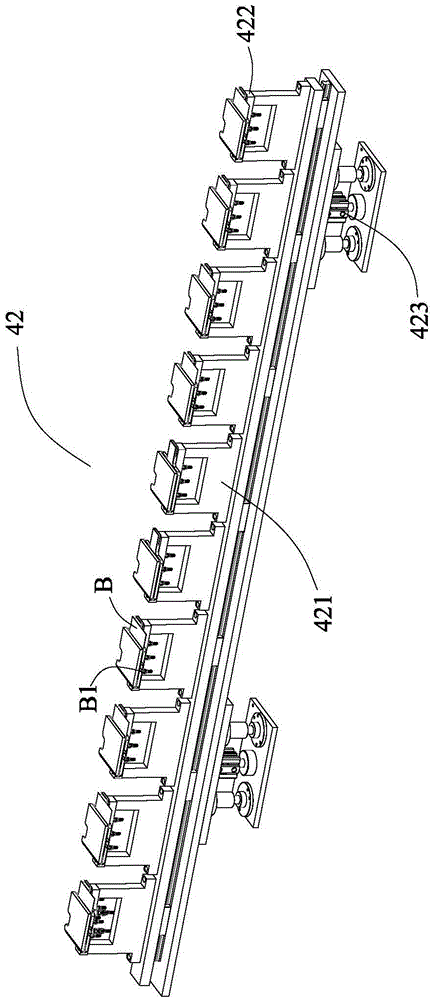

[0041] The jacket return mechanism 4 includes: a frame 41 with a plurality of workbenches 411 for circulation of a plurality of jackets 3 ; a transfer mechanism 42 for fixing and transferring the jackets 3 on the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com