Forming die in inner-core replaceable form

A forming mold and replaceable technology, applied in the field of forming processing, can solve problems affecting the production efficiency of processing enterprises, mold damage, shortening the service life of molds, etc., achieve high use and promotion value, save loading and unloading time, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

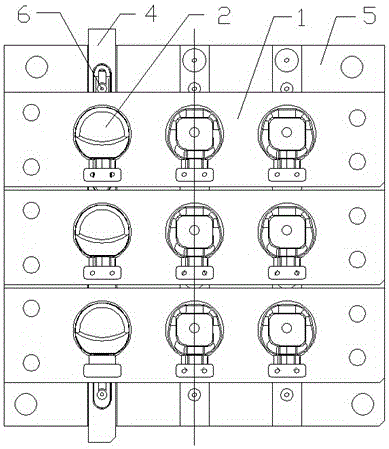

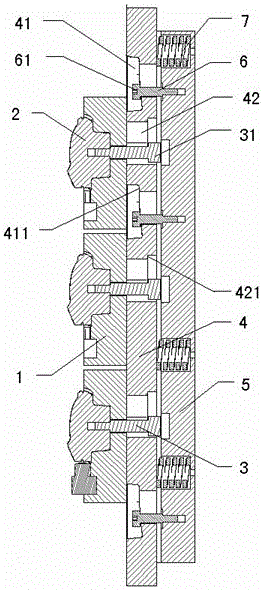

[0022] The invention discloses a replaceable molding die with an inner core capable of realizing rapid replacement of the inner core of the die.

[0023] Such as Figure 1~2 Shown, a kind of inner core replaceable molding mold, comprises the upper mold and the lower mold that match each other, also comprises the lower mold backing plate 5 that is fixedly arranged on the said lower mold and at least two, is movably arranged on the said lower mold The fixed tie rod 4 on the lower mold backing plate 5 is detachably provided with at least one inner core panel 1, and the inner core panel 1 is provided with at least one inner core for product molding 2.

[0024] The upper end surface of the lower mold backing plate 5 is fixedly provided with at least two fixing bolts 6 for fixing the fixing tie rods 4 , and the fixing tie rods 4 are provided with tie rod fixing grooves matching the fixing bolts 6 41 , the fixing tie rod 4 is fixed to the lower mold backing plate 5 through the coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com