High-efficiency automatic welding mechanism

An automatic welding and high-efficiency technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of shutdown and production efficiency discount, and achieve improved production efficiency, high degree of automation, and saving of loading and unloading materials. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

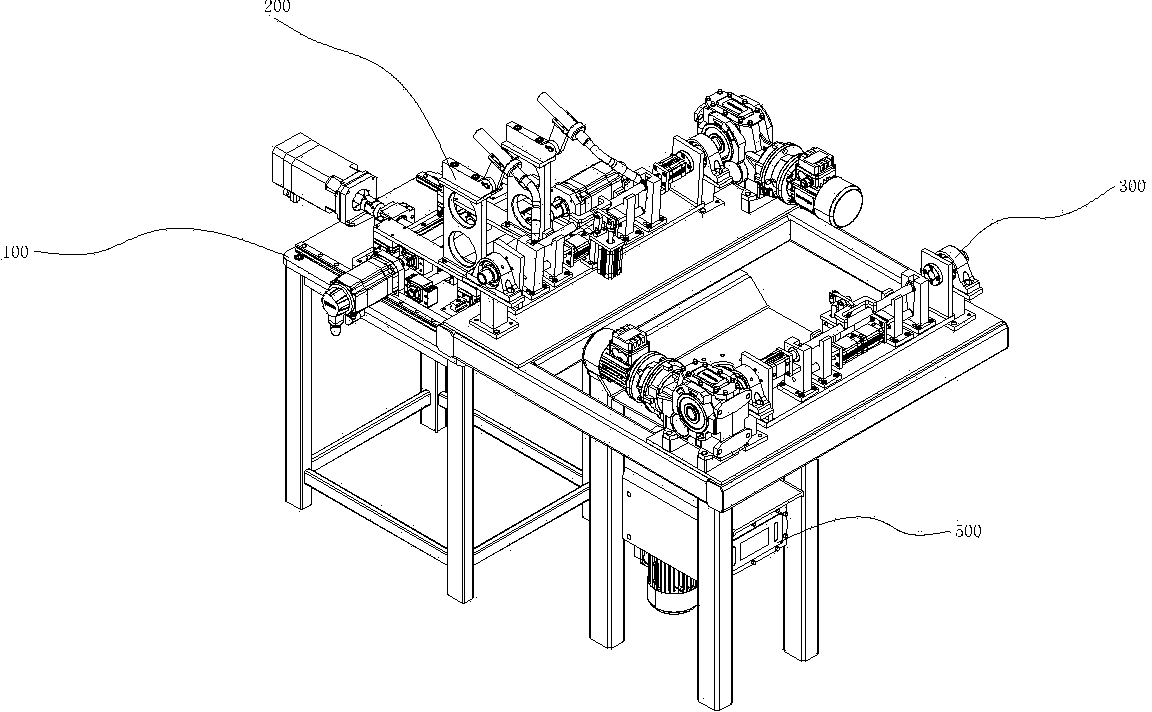

[0020] Such as figure 1 with figure 2 As shown, a high-efficiency automatic welding mechanism, the workbench 100, also includes a movable welding device 200 installed on the workbench 100, a rotating device 500 installed on the side of the workbench 100, and a rotating device 500 installed on the rotating device 500 Two sets of workpiece clamping and rotating devices 300;

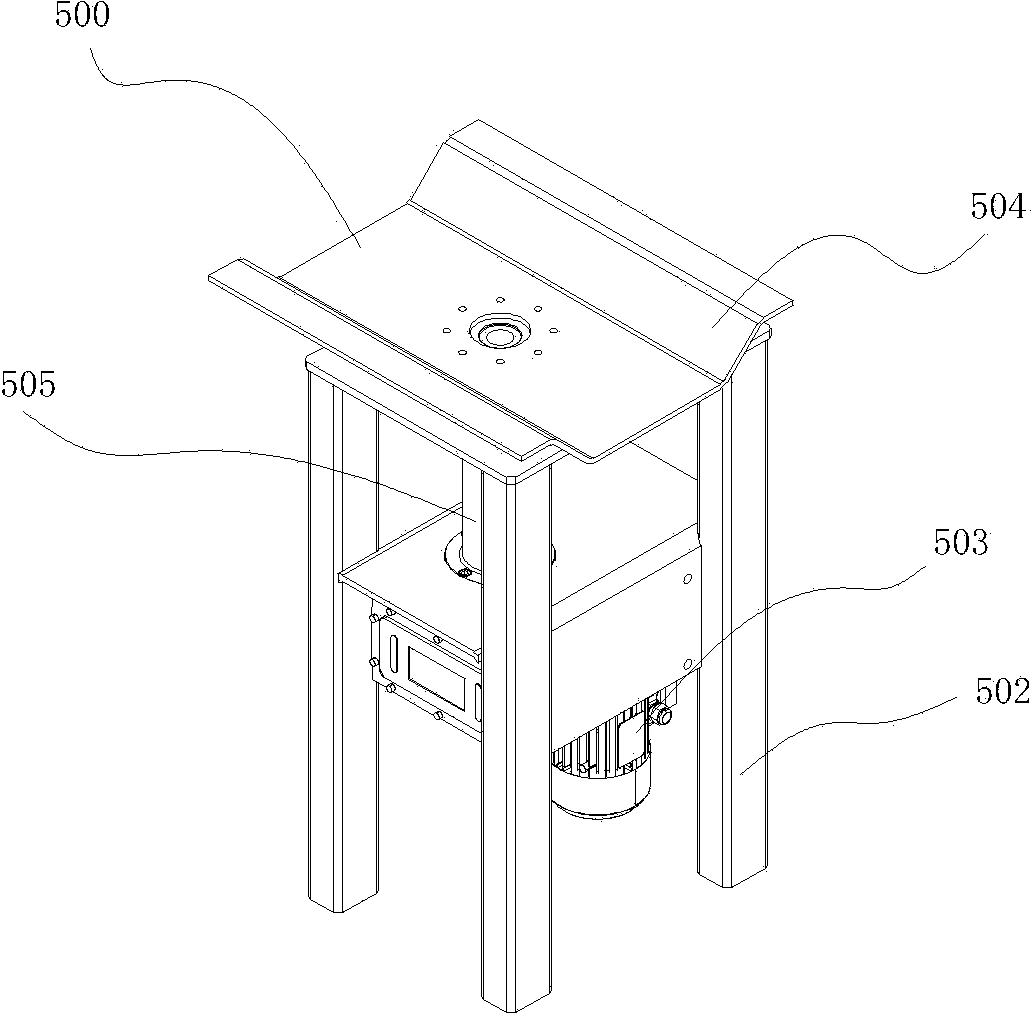

[0021] Such as image 3 As shown, the rotating device 500 includes a bracket 502, a motor 503 mounted on the bracket 502, a rotating shaft 505 is connected to the motor 503, a turntable 504 is mounted on the rotating shaft 505, and a bracket platform is mounted on the turntable 504 501. The motor one 503 drives the rotating shaft 505 to rotate so as to drive the support table 501 to rotate.

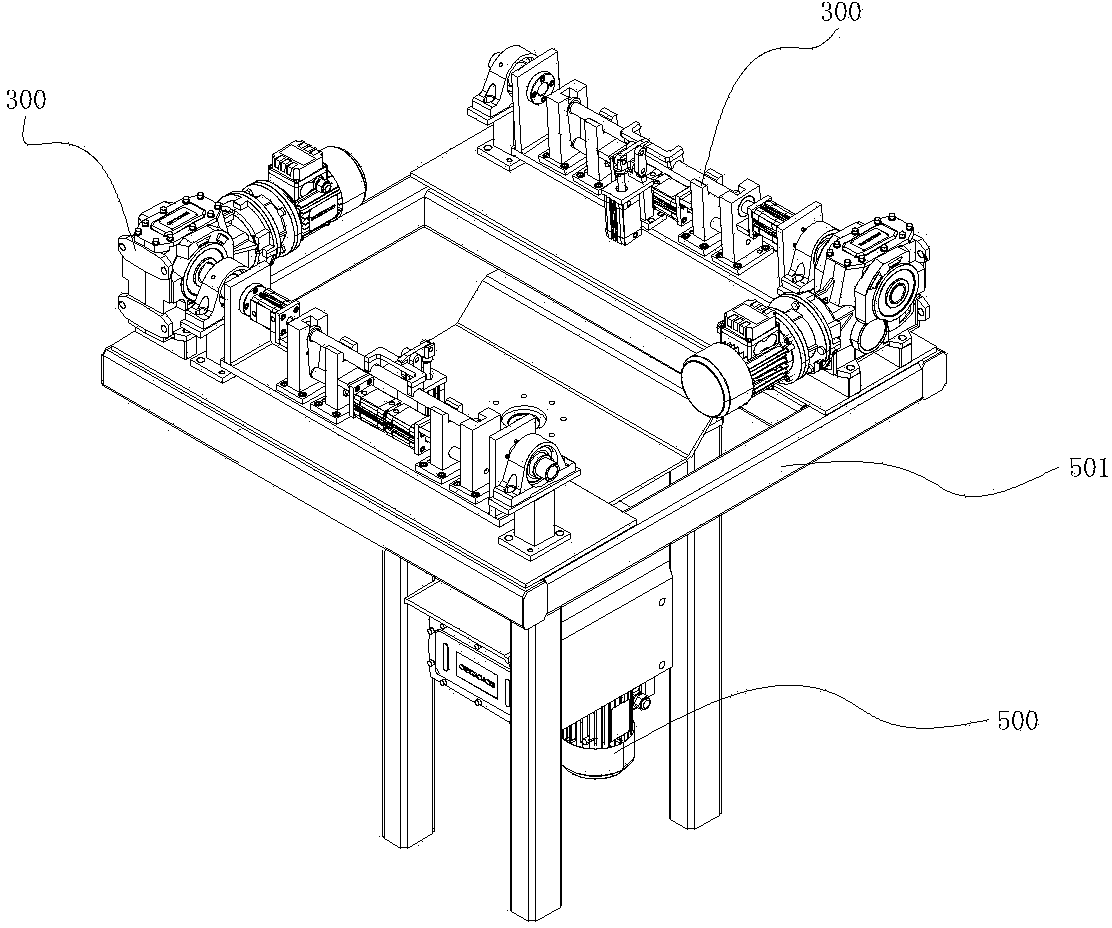

[0022] Such as Figure 4 As shown, the workpiece clamping and rotating device 300 includes a bottom plate 308 fixed on a support table 501, fixed shaft sleeves 310 are installed on both sides of the bottom plate 308, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com