Double edge milling machine with a movable pressing beam

A mobile, edge milling machine technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve the problems of increasing workpiece hoisting and clamping time, inconvenient loading and unloading, low production efficiency, etc., to save loading and unloading. Time, convenient loading and unloading of workpieces, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

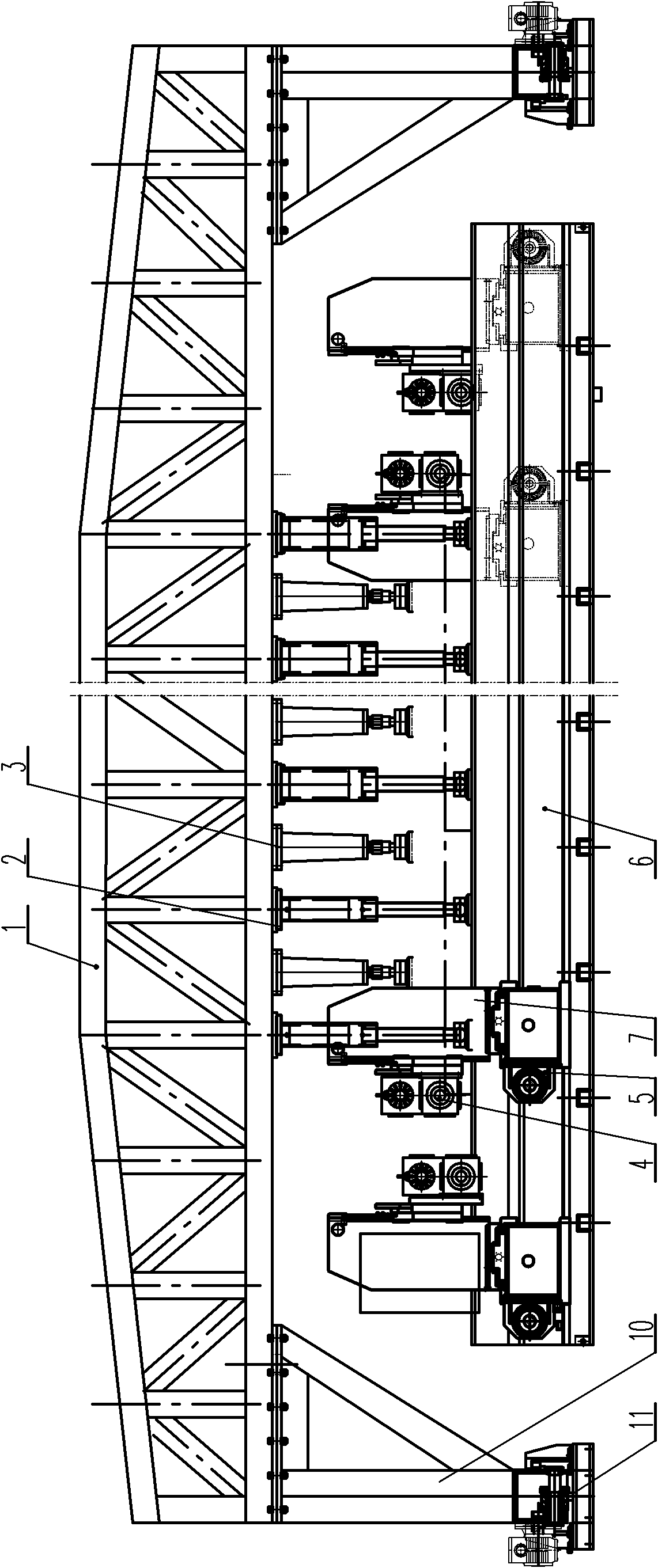

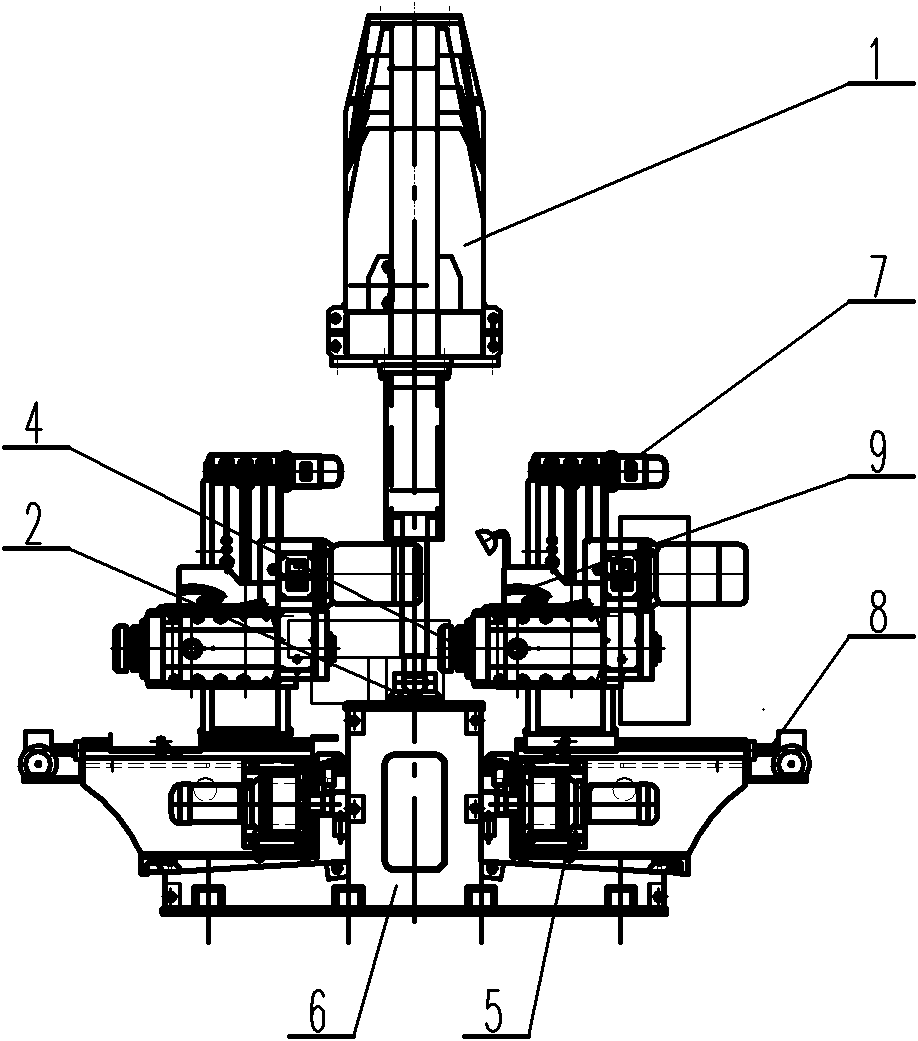

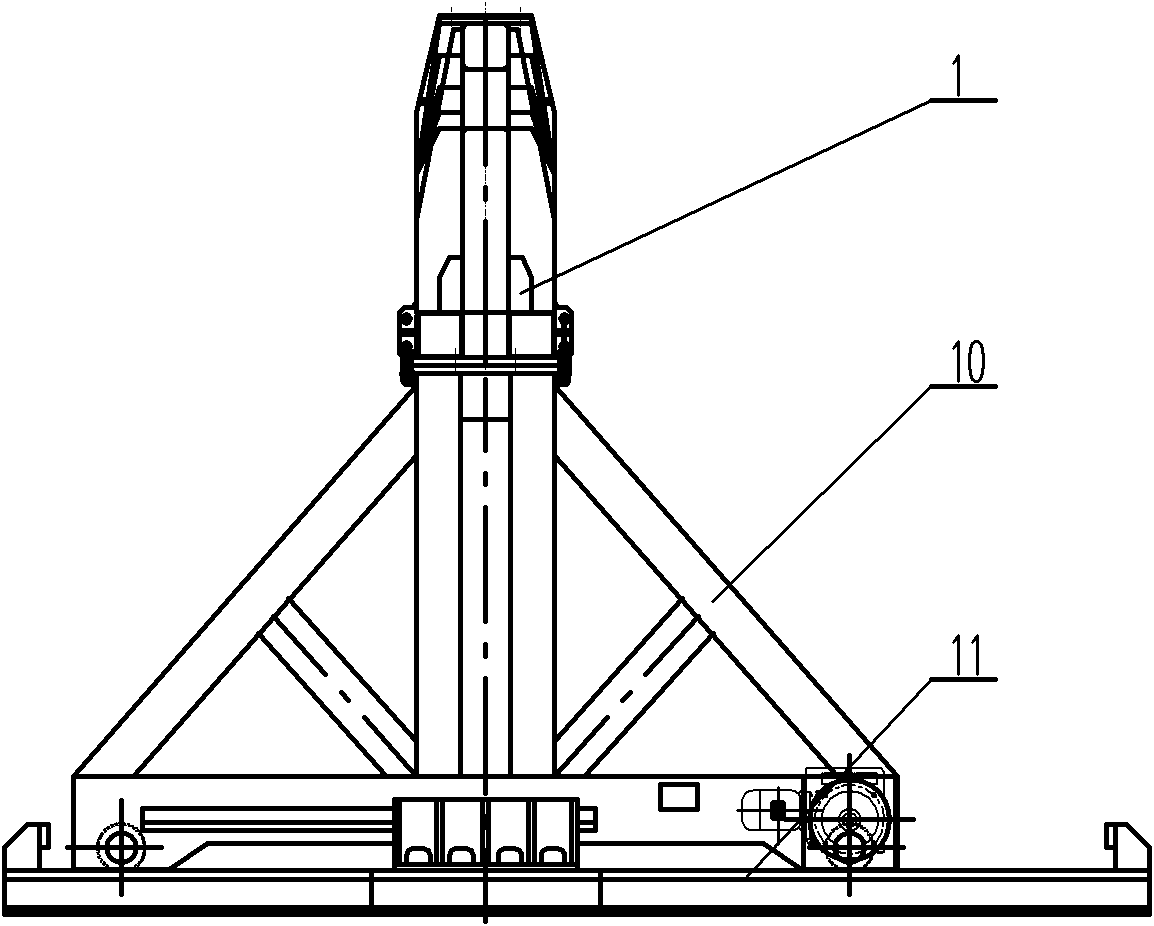

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Figure 1~Figure 3 Among them, including pressure beam 1, hydraulic automatic presser foot 2, screw manual presser foot 3, milling power head 4, X-axis adjustment mechanism 5, bed 6, Y-axis adjustment mechanism 7, Z-axis adjustment mechanism 8, angle adjustment mechanism 9. Pressure beam moving mechanism 10, track 11, etc.

[0014] like Figure 1~Figure 3 As shown, the present invention is a movable pressure beam bilateral edge milling machine, including a bed 6 and a pressure beam 1 above the bed 6 .

[0015] Two sets of X-axis adjusting mechanisms 5 are slidingly fitted on both sides of the bed 6 respectively, and there are four sets of X-axis adjusting mechanisms 5 in total. Each set of X-axis adjustment mechanism 5 is fixed with a set of Y-axis adjustment mechanism 7, and Y-axis adjustment mechanism 7 is fixed with Z-axis adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com