Automatic feeding and discharging device for circuit board laser drilling

An automatic loading and unloading and laser drilling technology, which is applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of circuit board wrinkles, uneven suction board, low efficiency, etc., and reduce the loading and unloading time , Improve the efficiency of loading and unloading, and improve the effect of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

[0016] The reference signs in the accompanying drawings of the specification include:

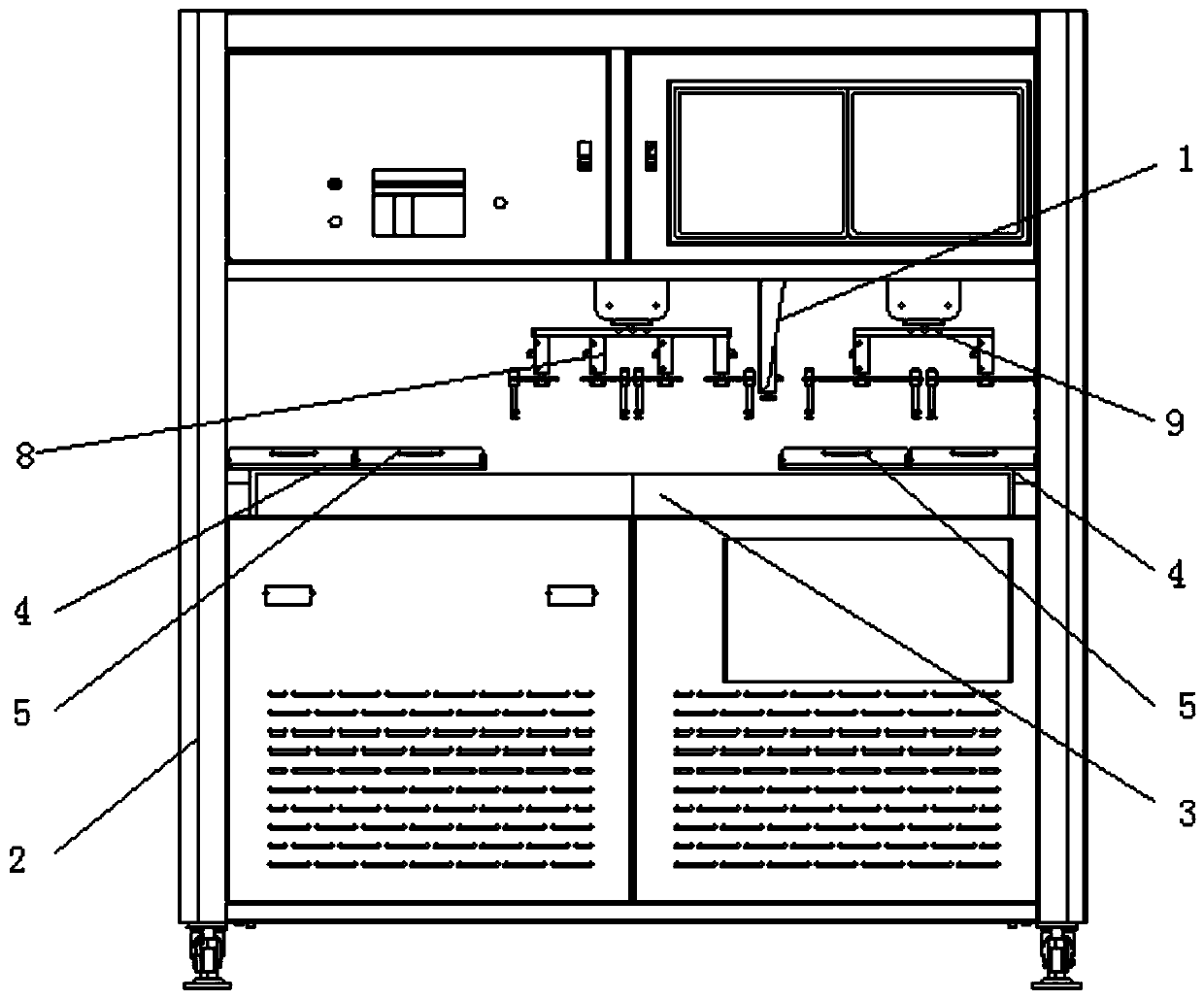

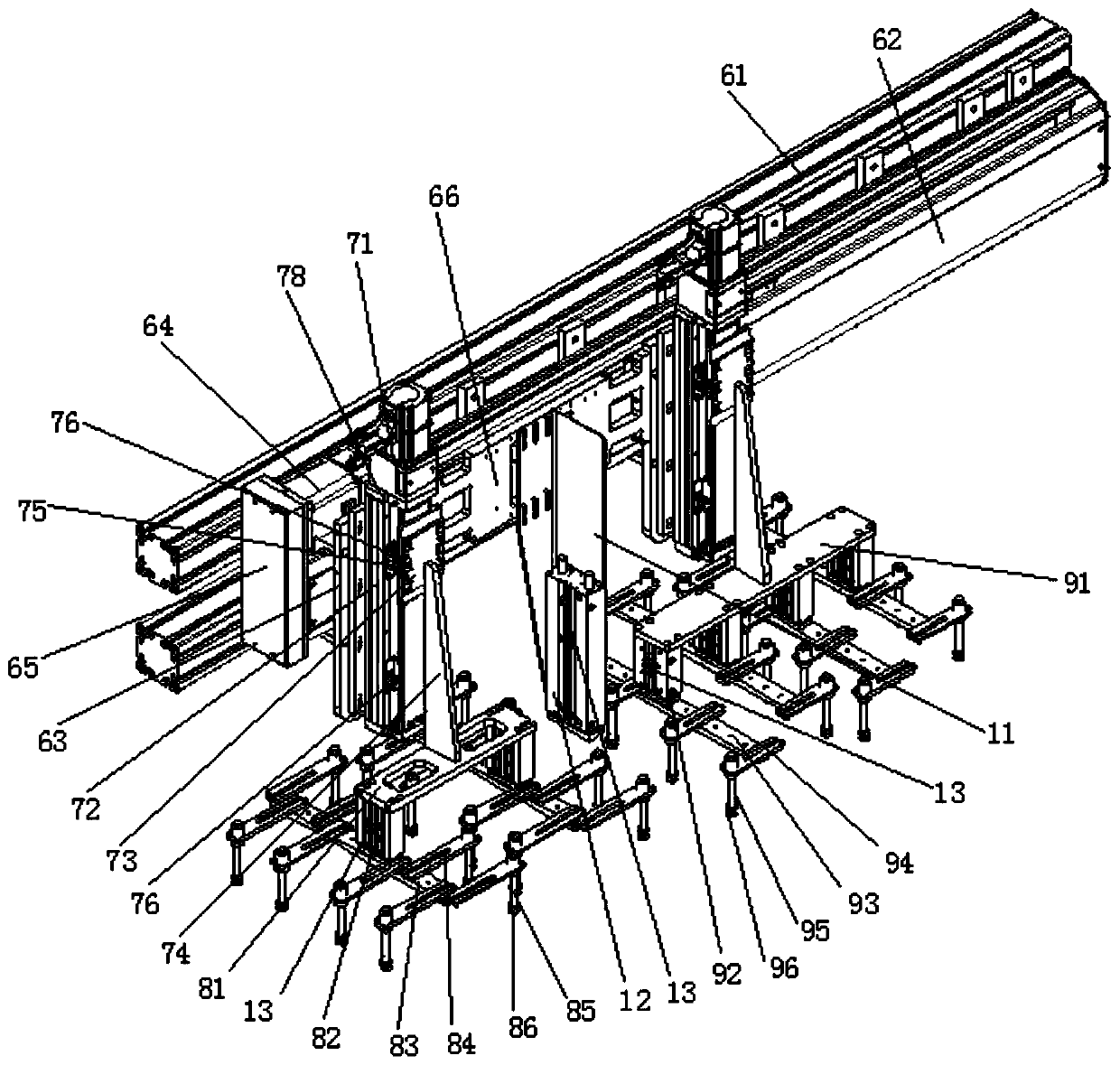

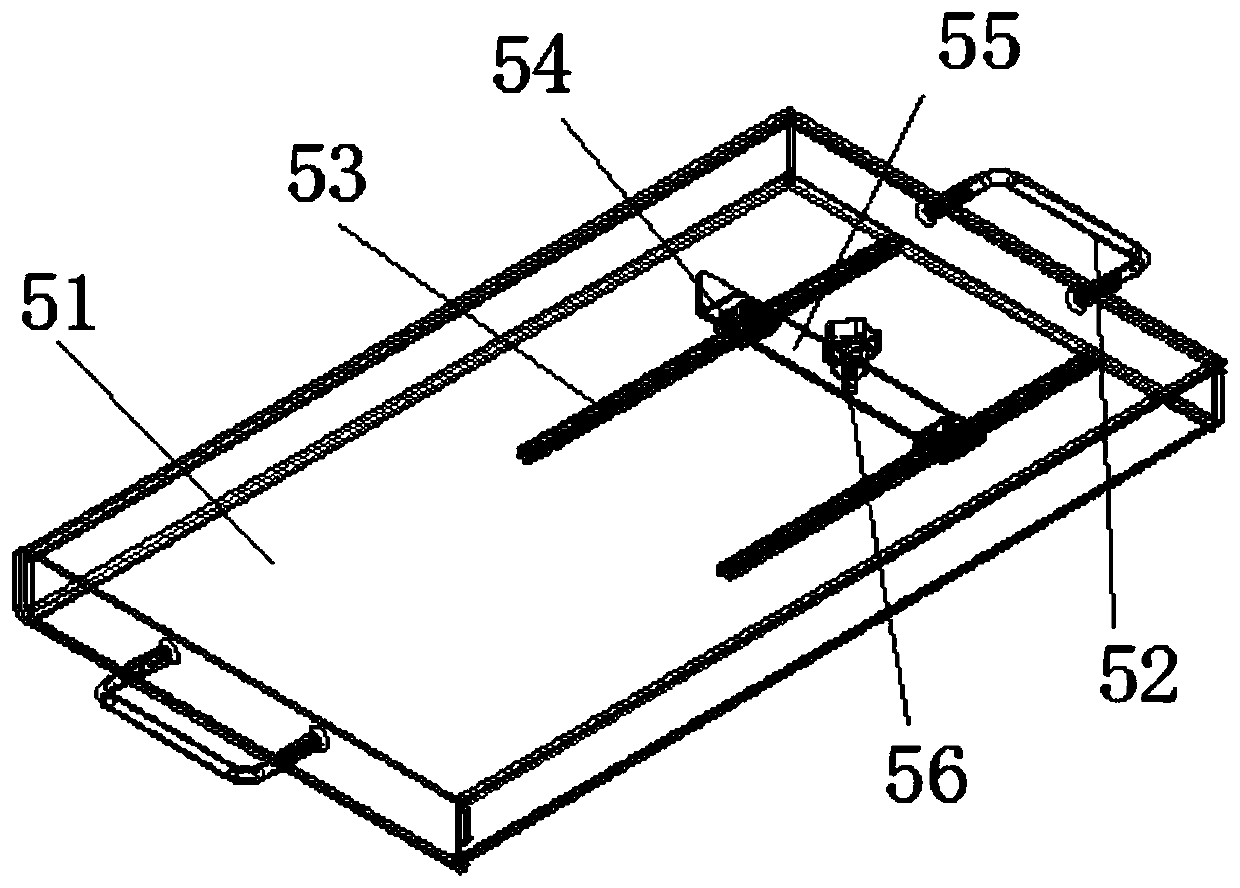

[0017] 1. Sweeping module, 11. Connection plate, 12. Sweeping cylinder, 13. Magnetic switch, 2. Rack, 3. Laser drilling machine, 4. Bracket, 5. Material box assembly, 51. Tooling material box , 52. Handle, 53. Guide rail, 54. Guide block, 55. Baffle plate, 56. Fixing bolt, 6. Moving component, 61. Fixed rod, 62. Slide rail, 63. Slider, 64. Servo motor, 65. Reducer, 66. Support plate, 7. Pushing module, 71. Servo motor, 72. Vertical guide rail, 73. Vertical slider, 74. Fixed plate, 75. Inductive sheet, U-shaped photoelectric sensor, 8. Down Material module, 81. Loading mounting plate, 82. Loading cylinder, 83. Loading connecting rod, 84. Loading installation rod, 85. Loading connecting pipe, 86. Loading suction cup, 9. Loading module, 91 .Feeding installation plate, 92. Feeding cylinder, 93. Feeding connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com