Bulk material discharging, storage and transportation equipment and transportation method

A bulk material and equipment technology, which is applied in the field of bulk material transfer and bulk material unloading storage and transportation equipment, can solve the problems of increased material loss, large dust, difficult to control the loading tonnage of transfer vehicles, etc., to prevent dust and suppress The environmental protection effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

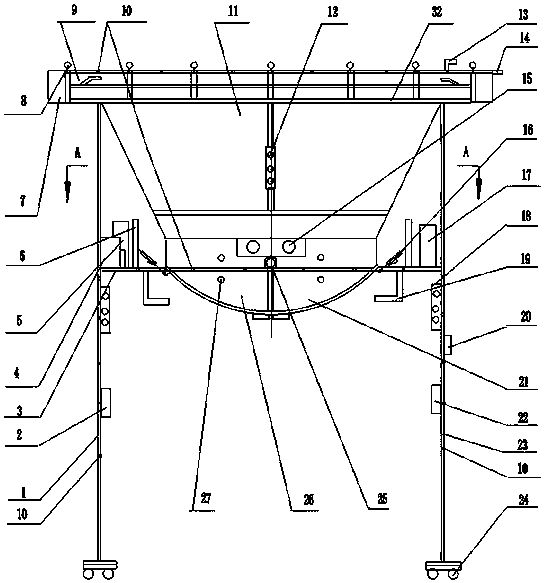

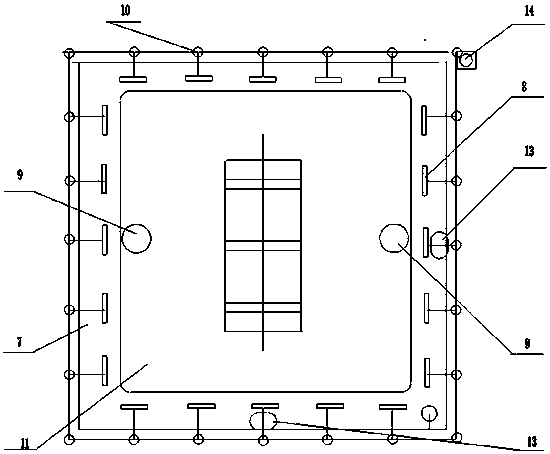

[0095] see Figure 1 to Figure 12 , a kind of unloading storage and transportation equipment for bulk materials, comprising a frame, a transfer hopper 11 installed on the upper part of the frame, the lower end of the transfer hopper 11 is provided with a discharge port 47, and the discharge port 47 is provided with a door that can be opened and closed; It includes the warehouse door switch and detection system connected to the control system, the vehicle positioning indication human-computer interaction system, and the material level detection and indication system of the transfer hopper.

[0096] The frame of the present embodiment is a square support made up of at least four columns, the left front column 1, the right front column 23, the left rear column 30, and the right rear column 31, and a crossbeam 32 is connected between the tops of every two adjacent columns. The hopper 11 is in the shape of an inverted quadrangular prism, and the upper opening is a square or a circl...

Embodiment 2

[0130] The method for transshipping bulk materials by using the unloading storage and transportation equipment for bulk materials described in Embodiment 1 comprises the following steps:

[0131] a) Turn on the automatic control function of the control cabinet 17, the control system starts the warehouse door switch and detection system, the vehicle positioning indication human-computer interaction system, the material level detection and indication system of the transfer hopper, the spray dust suppression system, and the PLC controller controls the warehouse The door is in a closed state; when the visibility is low or when working at night, the LED indicator light 10 on the upper mouth of the transfer hopper 11 is turned on, which is used to indicate the position of the upper mouth of the transfer hopper 11 for the driver of the door operator; To indicate the position of the transfer hopper for the driver of the transfer vehicle; the upper mouth of the transfer hopper 11 is pro...

Embodiment 3

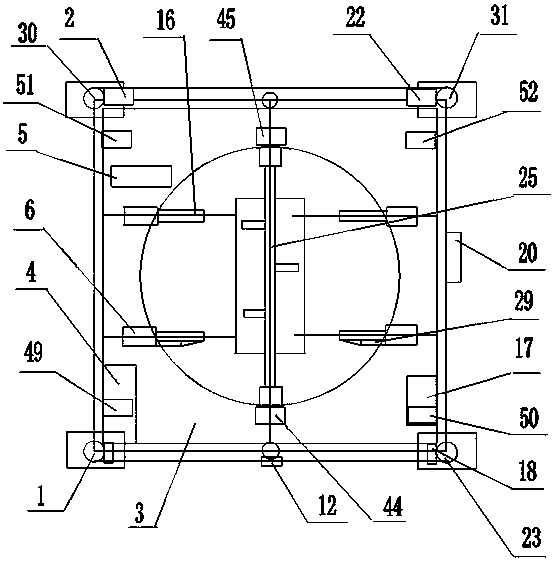

[0147] see Figure 2 to Figure 15, a bulk material unloading storage and transportation equipment, on the basis of Embodiment 1, a material weighing system 28 is added to facilitate the measurement and settlement of goods. Its framework comprises left front column 1, right front column 23, left rear column 30, right rear column 31 at least 4 columns, is provided with material weighing system 28 on the frame, and material weighing system 28 links to each other with control system. Specifically, the weighing system includes one ZFL flange type load cell 285 (two-way tension and compression, Ningbo Zhenhai Sensor Factory ), and the upper connecting seat 286, the lower connecting seat 282, the base 281 and the mobile protective cover 283; Connected, the lower connecting seat 282 is fixedly connected to the top of the base 281, the bottom of the base 281 is provided with a traveling wheel 24, the base 281 is fixedly connected with a mobile protective cover 283, and the load cell 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com