Tray-free packing method and tray-free packing device of brick stack

A pallet-free, brick-stomping technology, used in building materials packaging, transportation and packaging, packaging types, etc., can solve problems such as low work efficiency, troublesome recycling, and easy damage to pallets, reducing the intensity of manual labor, and facilitating storage and storage. Transportation, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

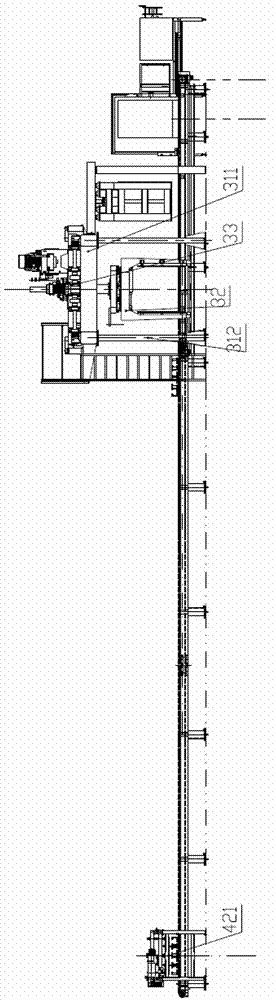

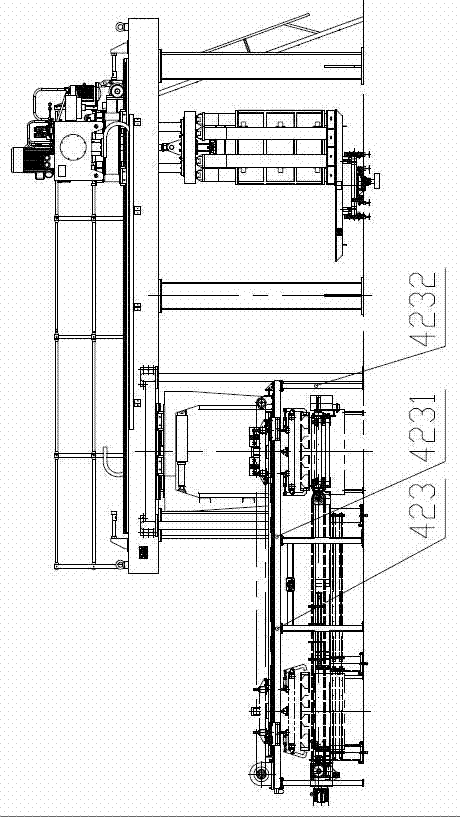

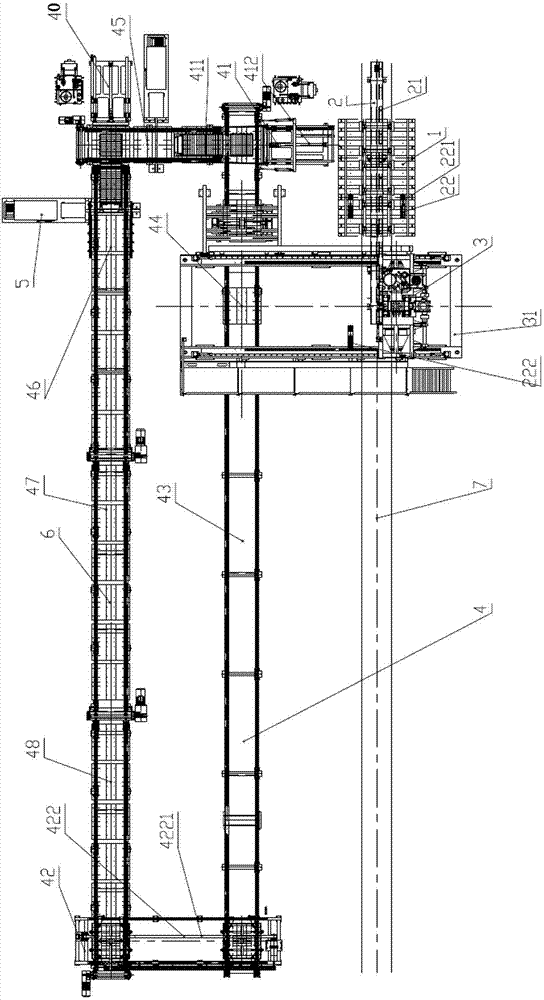

[0023] The piles of bricks placed on the steam curing car 1 are put into the autoclave as a whole and become finished brick piles after being autoclaved. A finished brick is made up of a plurality of bricks. The clamping device 3 clamps the finished bricks on the steam curing car 1 to the transfer tray 6 on the circulating conveying line 4, and the finished bricks on the transferring tray 6 are transported to different stations through the operation of the circulating conveying line 4. After the finished bricks are clamped and transported to the transfer pallet 6 on the circular conveyor line 4, the finished bricks are first folded in the non-clamping direction, and the folded bricks are lifted and pushed, and then transferred to the vertical conveyor chain. Here, the bricks are bound in one direction with a strap, and then the brick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com