Feeding and discharging mechanical arm of stair forming grinding machine

A technology of a manipulator and a grinder, applied in the field of loading and unloading manipulators, can solve the problems of high cost and many parts, and achieve the effect of reducing the structure of parts, reducing the driving mechanism, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

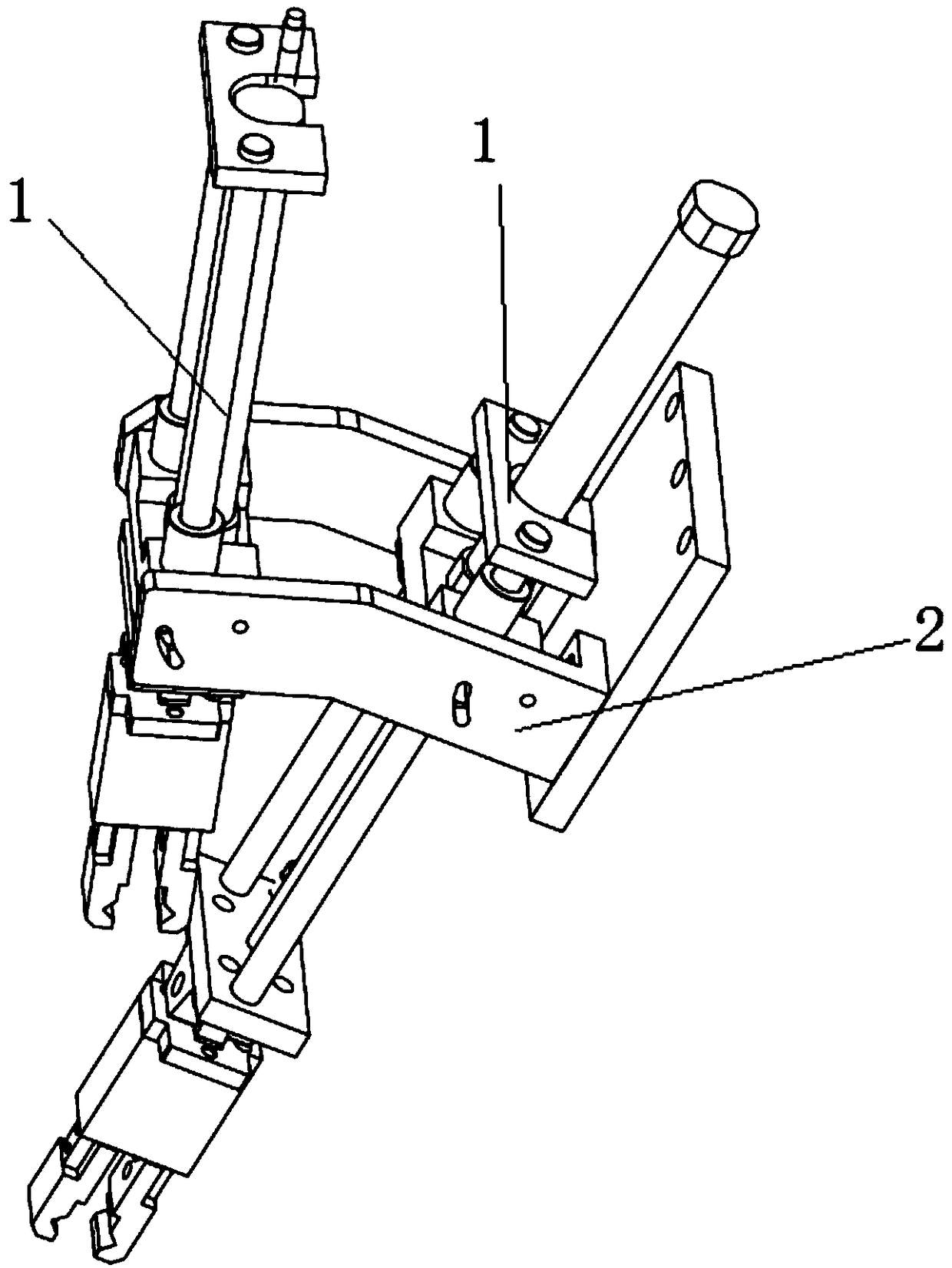

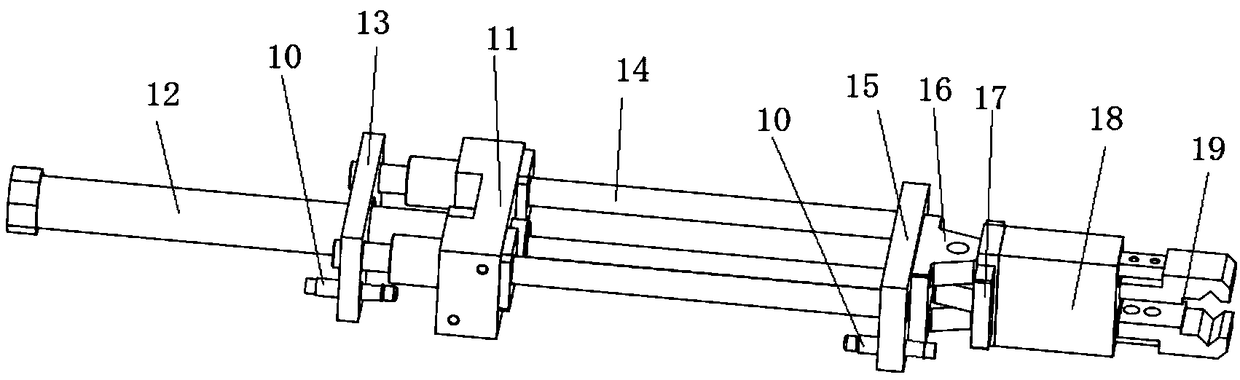

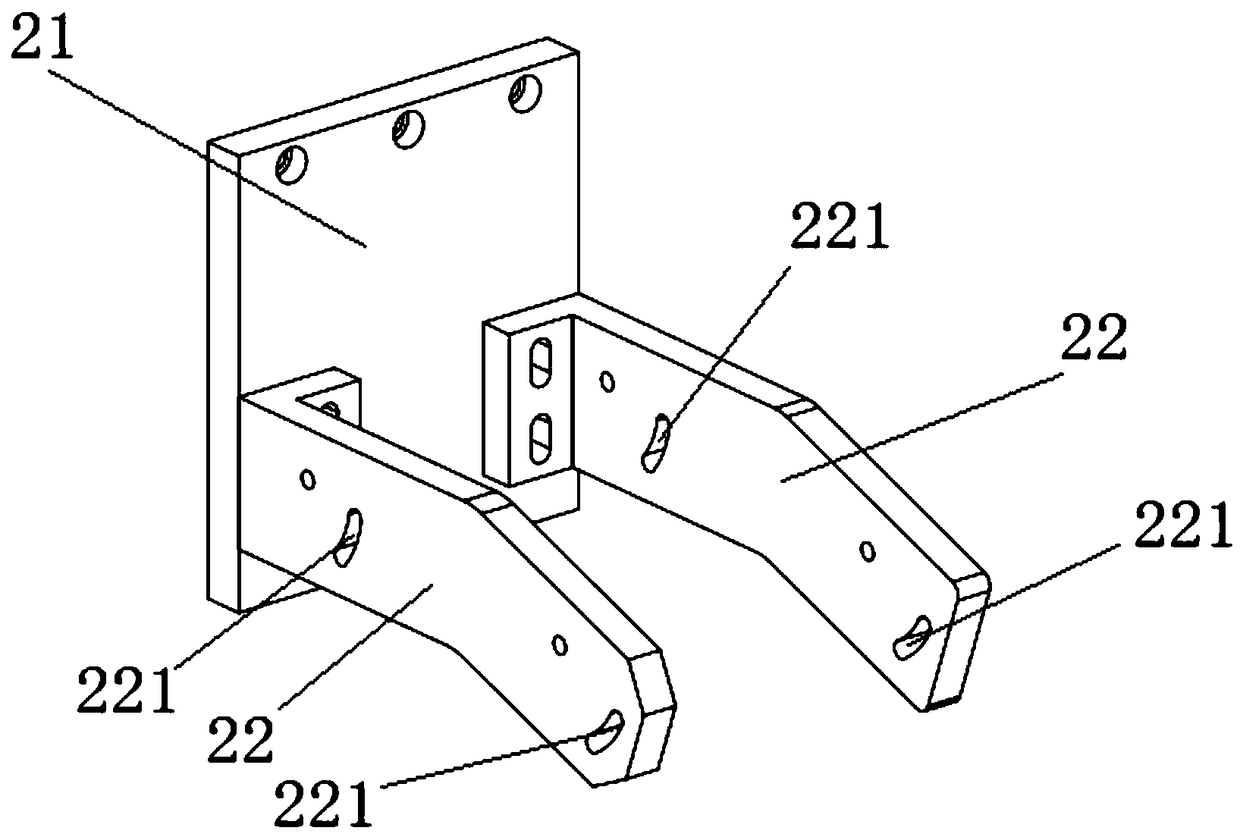

[0020] Such as Figure 1-Figure 3 As shown, the present invention provides a loading and unloading mechanical arm of a step forming grinder, comprising a manipulator mounting frame 2 and a manipulator 1 mounted on the manipulator mounting frame 2, and the manipulator mounting frame 2 includes a vertically fixed The manipulator hanging plate 21 on the moving part of the manipulator moving mechanism and a pair of arm splints 22 fixed on the outside of the manipulator hanging plate 21, the arm splint 22 is equipped with at least two of the manipulators 1 and one manipulator through the arm adjustment structure. The arm of 1 is arranged v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com