Automatic loading and unloading equipment of multi-shaft finish carving machine

A technology of automatic loading and unloading and engraving machine, which is applied in the direction of decorative art and processing models, which can solve the problems of large space occupation and large number of material boxes, and achieve the effect of increasing the occupied area, compact and compact structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention provides an automatic loading and unloading device for a multi-axis fine carving machine. In order to make the present invention more obvious and easy to understand, the present invention will be further described below in conjunction with specific implementation methods and accompanying drawings.

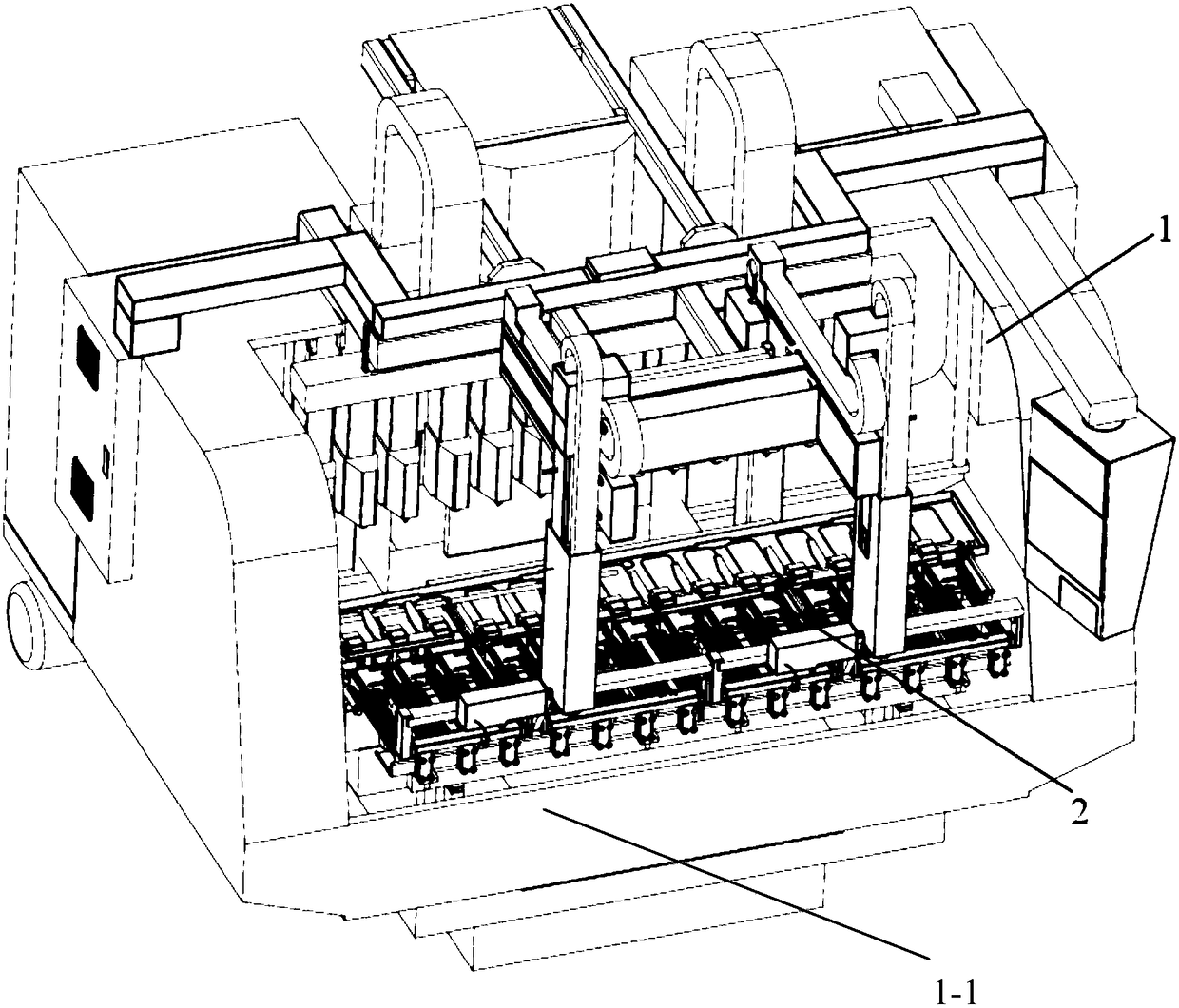

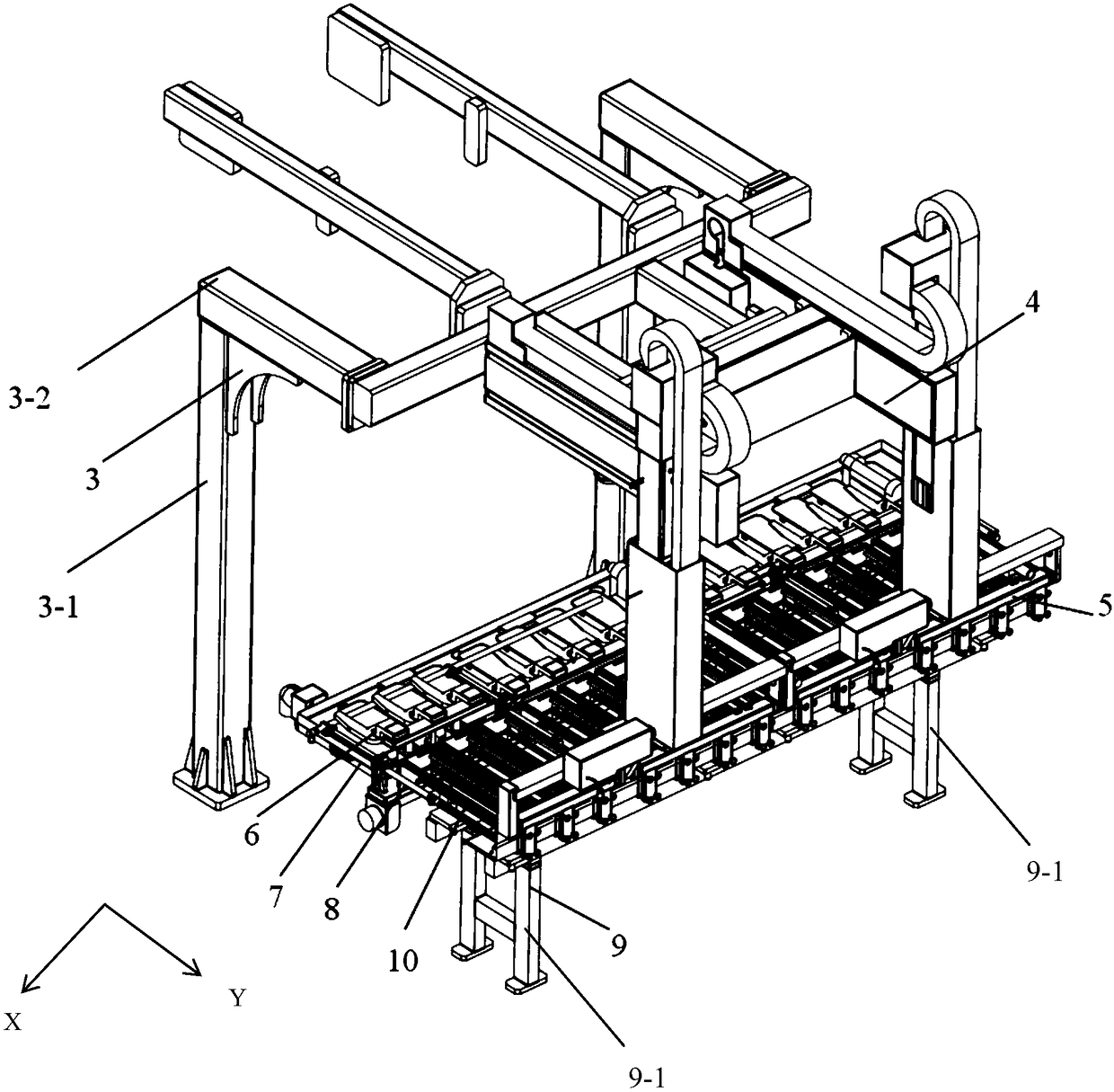

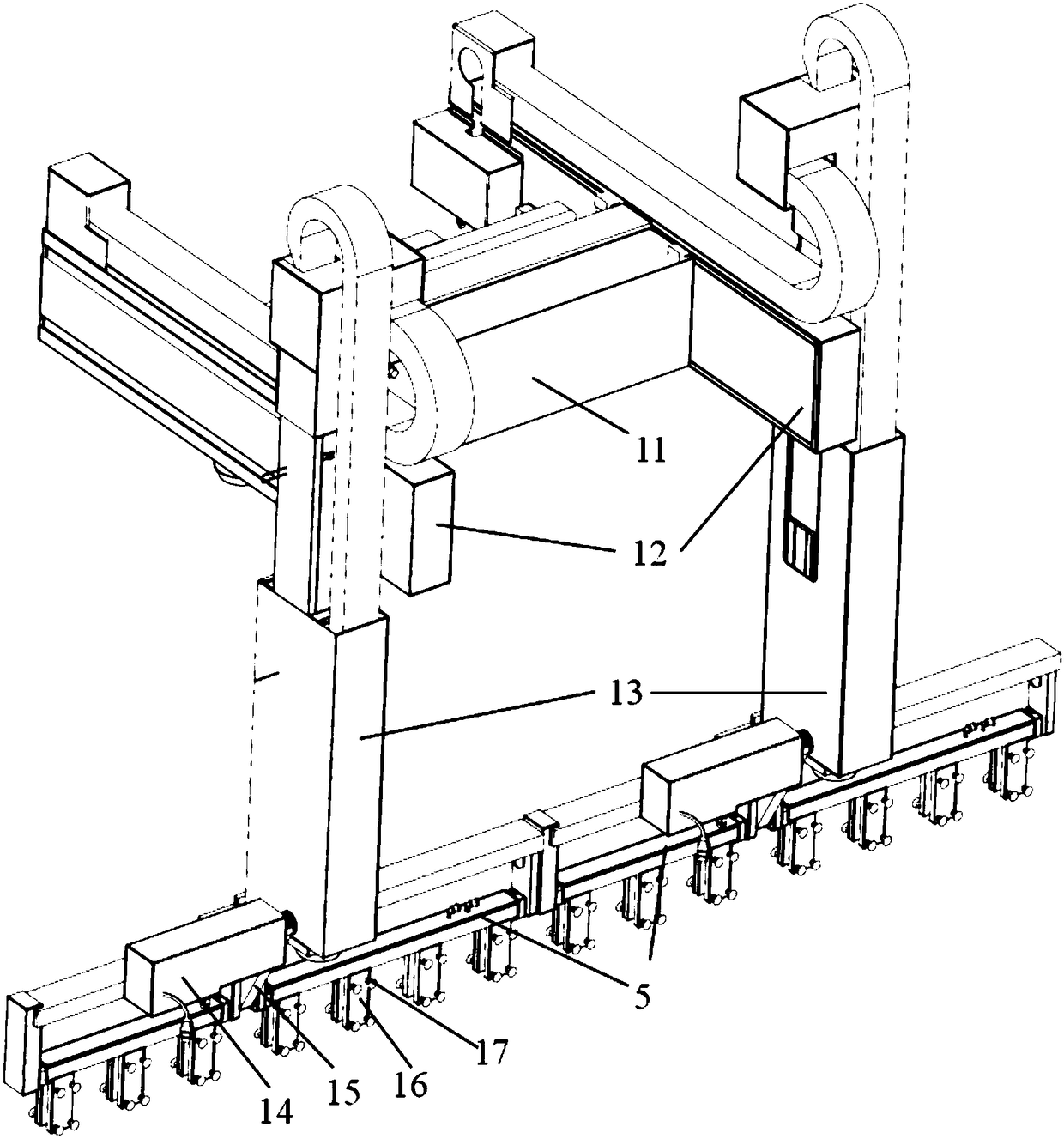

[0047] The loading and unloading equipment 2 of the present invention is a fully automatic loading and unloading equipment, which can provide loading and unloading for the multi-axis glass engraving machine 1 . Such as figure 1 As shown, the loading and unloading equipment 2 is installed inside the engraving machine 1 . Such as figure 2 As shown, the loading and unloading equipment 2 mainly includes: a fixed support structure 3, an XYZ three-axis linear motion mechanism 4, a glass sheet grabbing and turning mechanism 5, a positioning mechanism 6, a vacuum table 7, a cleaning mechanism 8, a material rack 9 and a material frame 10. The loading and unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com