Automatic welding work station of battery module

A battery module and automatic welding technology, used in welding equipment, laser welding equipment, secondary battery manufacturing, etc. Group production needs, production efficiency and low degree of automation, etc., to achieve the effect of saving input and output time, high integration, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are further explanations and supplements to the present invention, and will not constitute any limitation to the present invention.

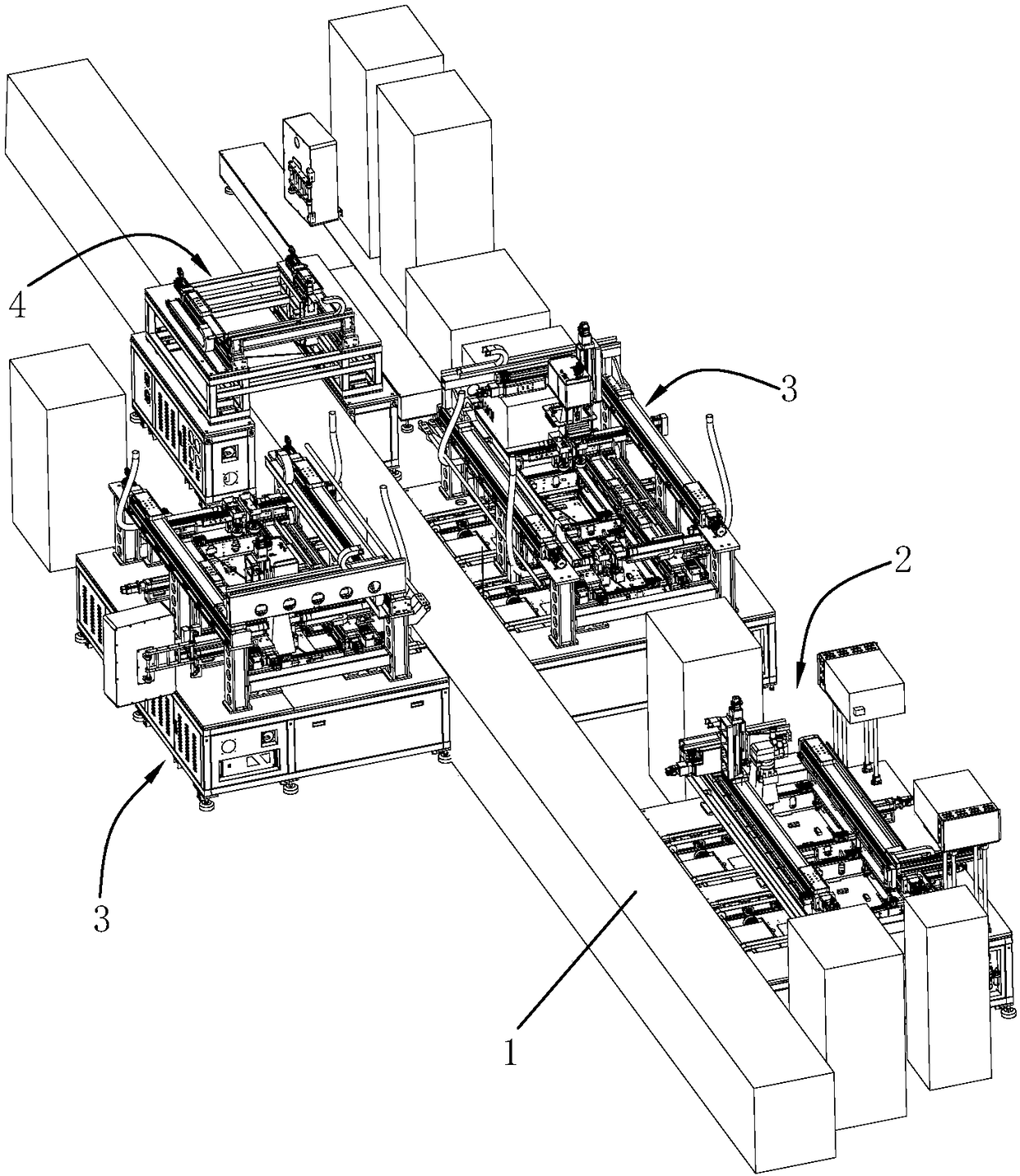

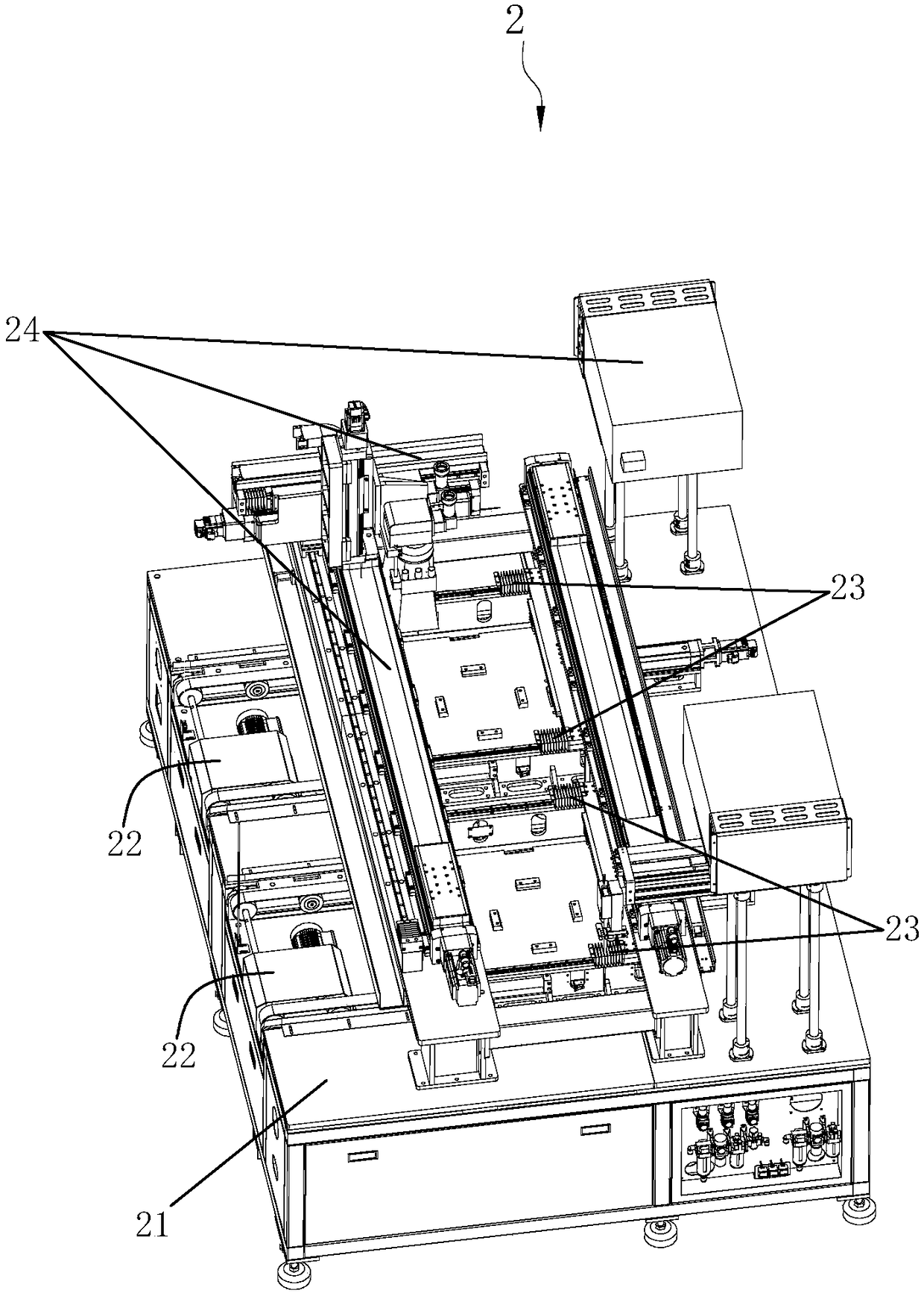

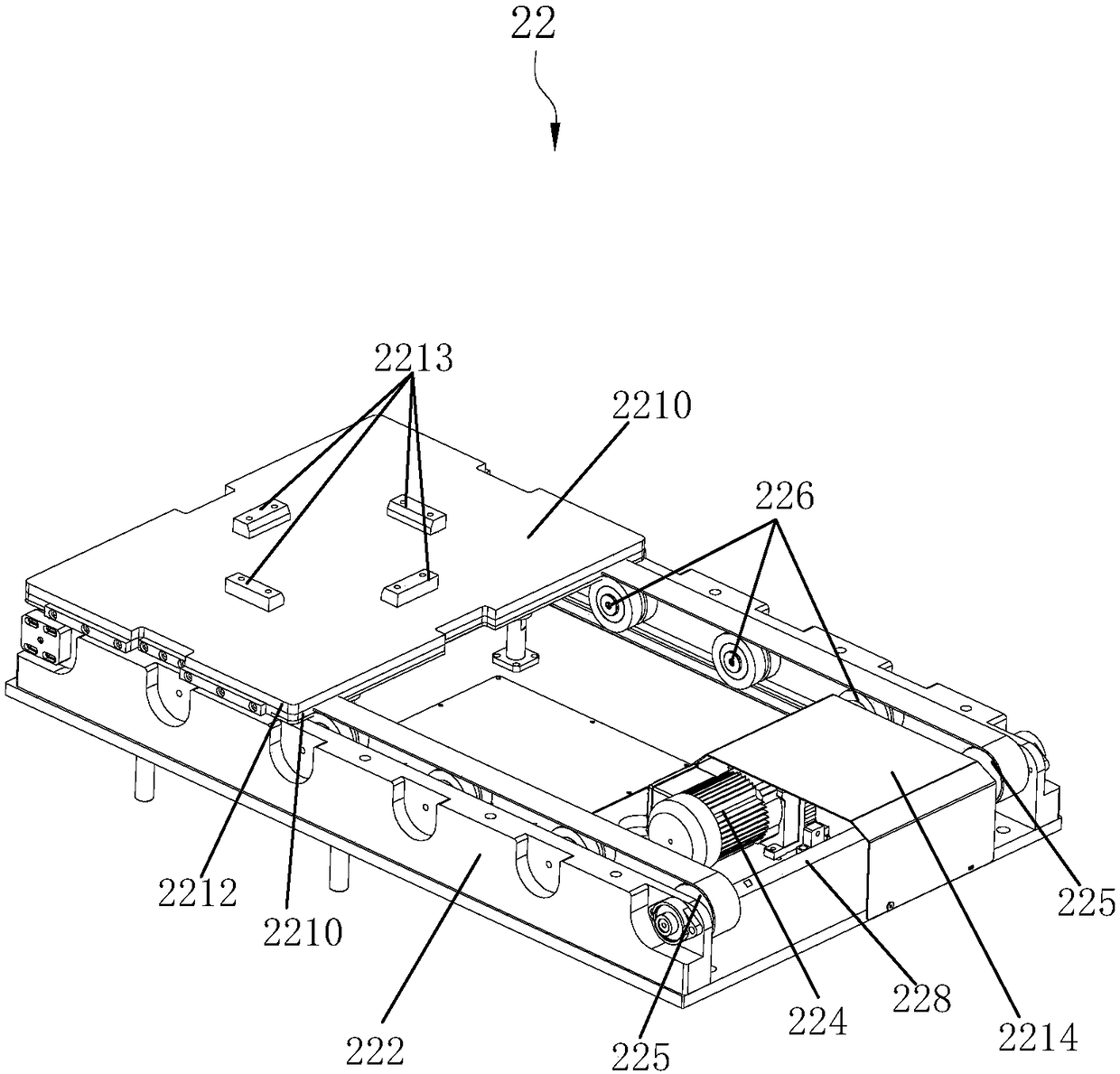

[0027] like figure 1 As shown, the battery module automatic welding workstation of the present invention includes: an assembly line 1 , a laser cleaning device 2 , at least one laser welding device 3 and a post-welding detection device 4 . The assembly line 1 is set in a working room (not shown in the figure), which is used to transport battery modules to be welded. The laser cleaning device 2, the laser welding device 3 and the post-welding detection device 4 are respectively sequentially arranged in the running direction of the assembly line. In this embodiment, the number of the laser cleaning device 2 is one, and it is arranged on the On the side of the entrance of the assembly line, the post-weld detection device 4 is arranged beside the assembly line and away from the end of the laser cleaning device 2. The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com