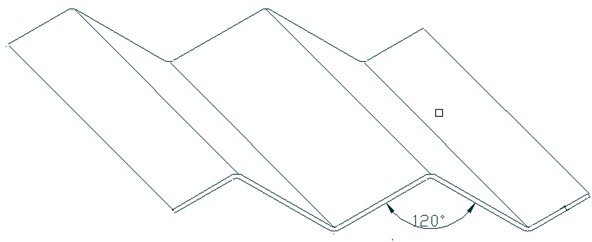

Manufacturing device and manufacturing method of wavy sheet for steel structure of heat exchange system

Technology of a heat exchange system and manufacturing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

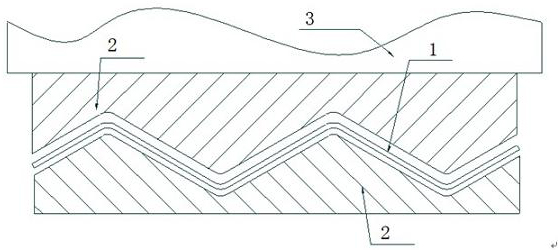

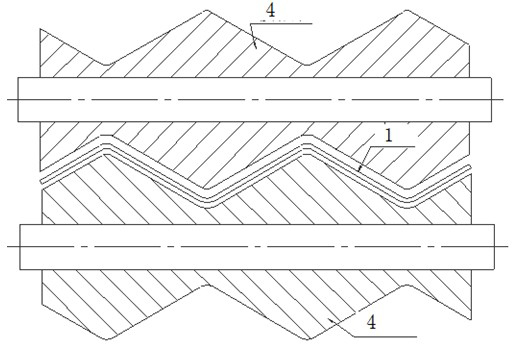

[0032] In the manufacturing device of the corrugated sheet for the steel structure of the heat exchange system of the present embodiment, the following structures are included:

[0033] 1) Up and down two rows of wave wheels 4 with the same shape as the wave sheet, each row has about 12 groups, according to actual needs

[0034] First, the shape of the wave wheel gradually changes from a cylindrical shape to a wave shape.

[0035] 2) In order to ensure the correct positioning of the coil material, two sets of positioning wheels and one set of leveling wheels are set at the front end of the wave wheel

[0036] Wheel, to ensure that the relative position of the wave sheet material and the wave wheel is correct.

[0037] 3) At the end of the wave wheel, set a set of shaping wheels and an adjustment frame to ensure that the shape of the wave sheet is correct.

[0038] The manufacturing method of the corrugated sheet for the steel structure of the heat exchange system of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com