Patents

Literature

94results about How to "Increase working hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

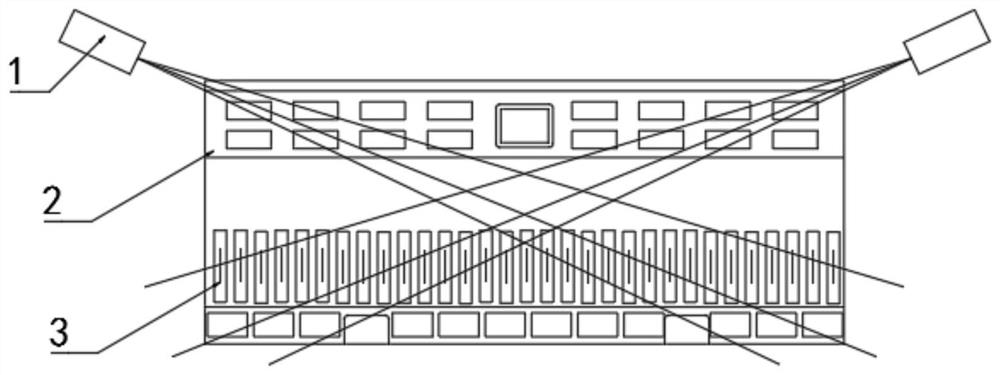

Multi-AGV electric power management system and method based on automatic battery changing

InactiveCN108909514AIncrease working hoursIncrease usageElectric propulsion mountingElectric vehicle charging technologyElectrical batteryElectricity

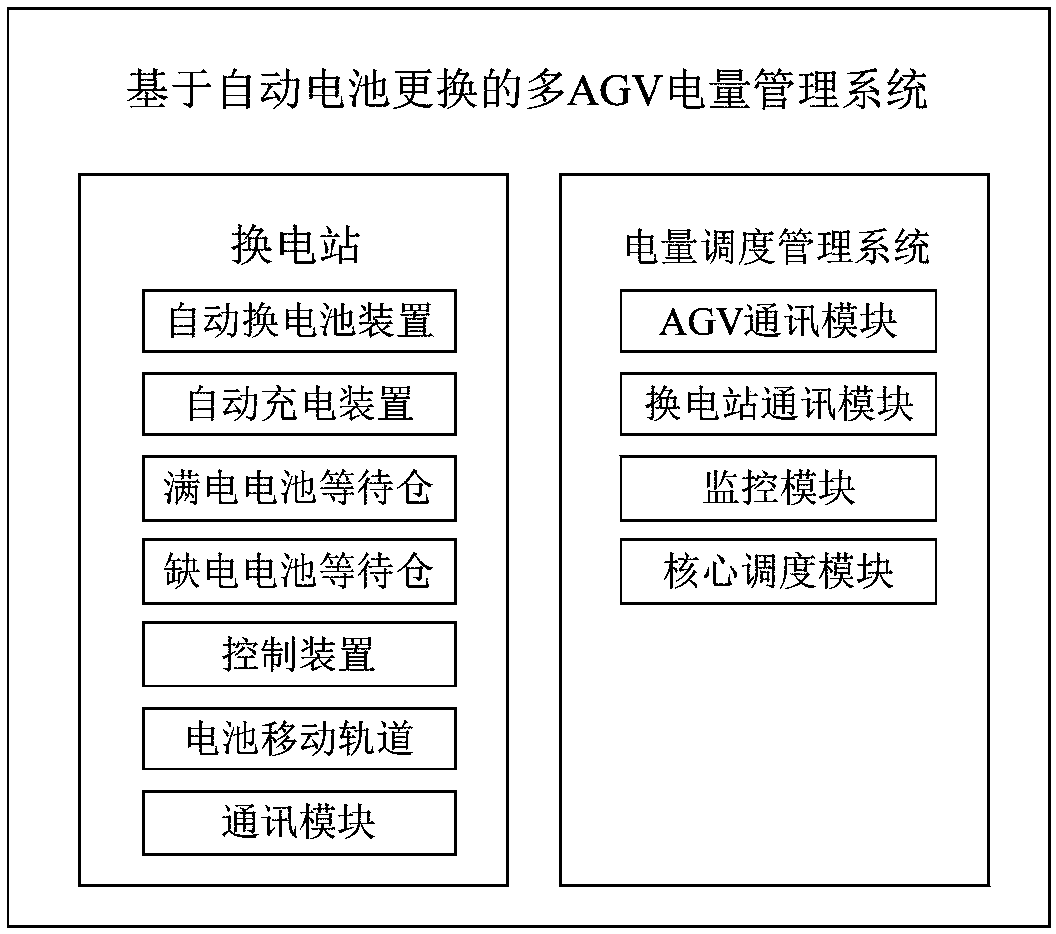

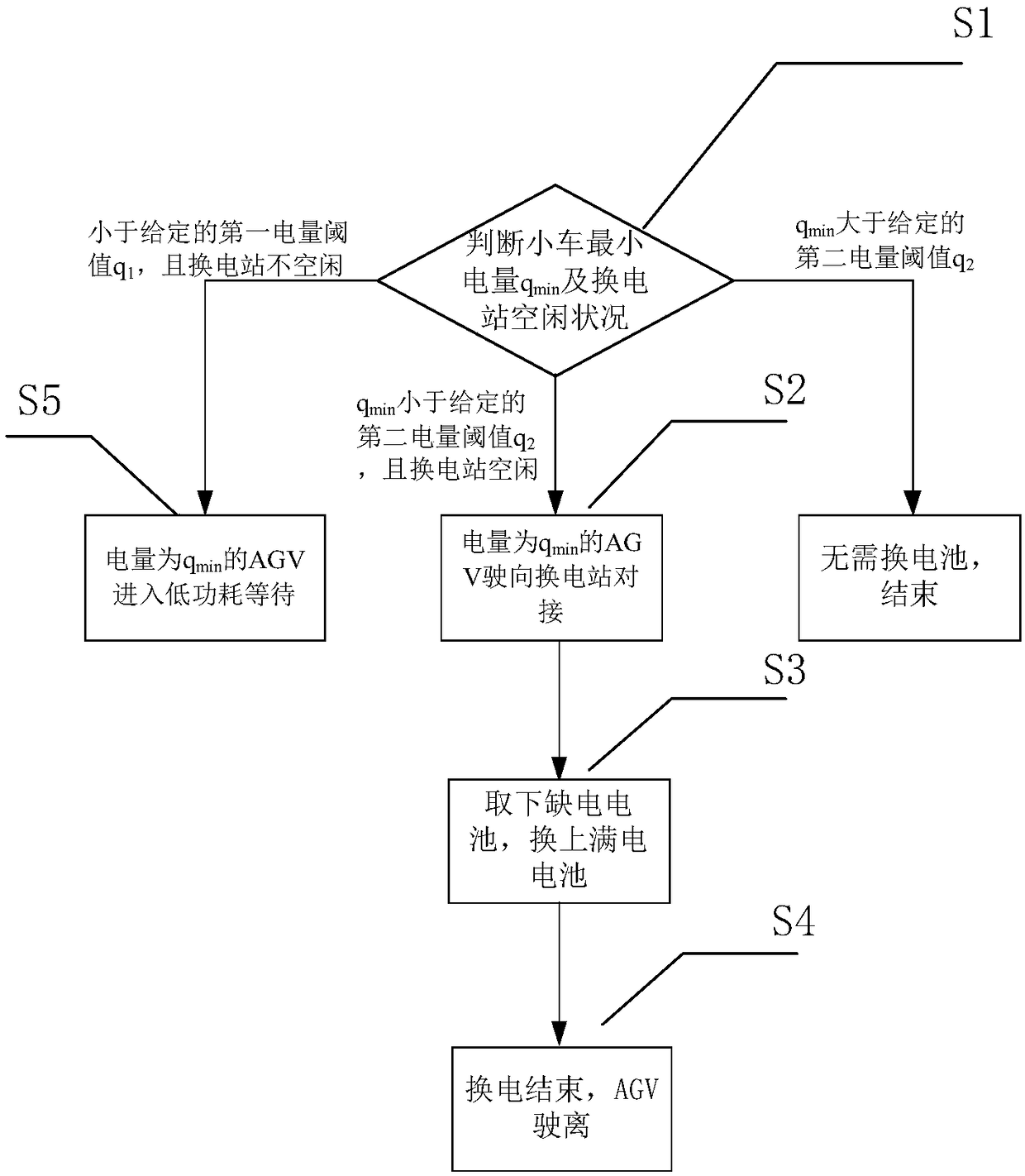

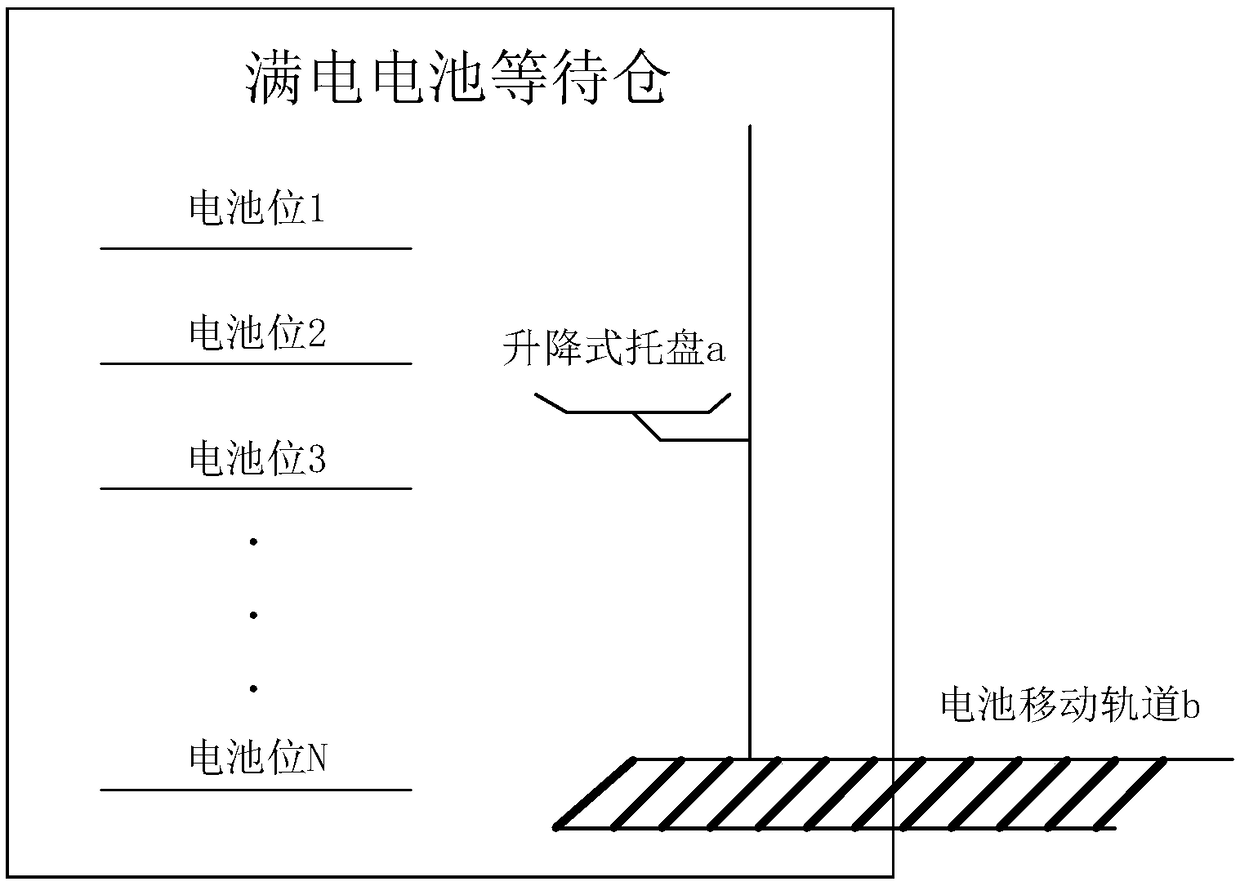

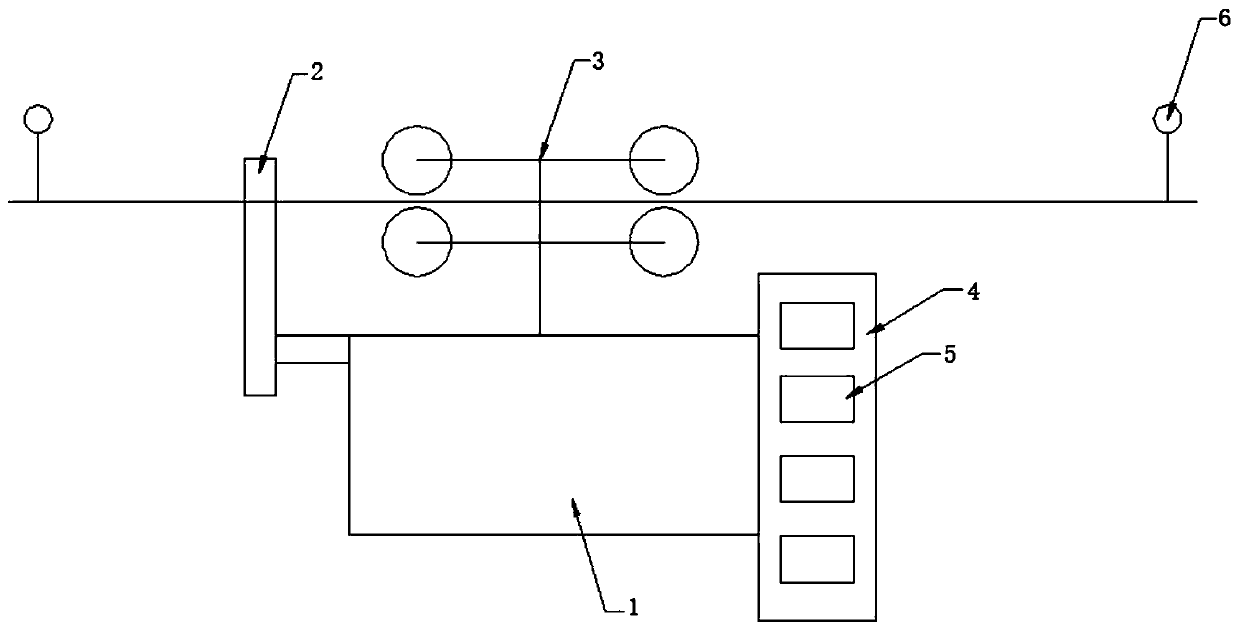

The invention discloses a multi-AGV electric power management system and method based on automatic battery changing. The multi-AGV electric power management system based on automatic battery changingcomprises a battery changing station; the battery changing station has a function of simultaneously charging multiple power-deficient batteries; and a fully-charged battery automatically enters a battery changing waiting area to wait for a next power-deficient AGV to change the battery. The multi-AGV electric power management system based on automatic battery changing further comprises one set ofelectric power management dispatching system. The multi-AGV electric power management system based on automatic battery changing obtains positions of these AGVs and remaining electric powers of the AGVs by communicating with all AGVs in the system and automatically select an appropriate AGV to enter the battery changing station to carry out battery changing operation so as to guarantee that the battery changing efficiency is enhanced while all AGVs runs with safety electric power. Compared with a traditional AGV automatic docking and charging technology, the multi-AGV electric power managementsystem and method based on automatic battery changing has the advantage that the time needed by charging the AGV is greatly compressed by using the battery changing technology. And meanwhile, as thebattery changing station occupying time of single battery changing is very short, the charging waiting time caused by a conflict generated when the multiple AGVs need to be simultaneously charged canbe greatly reduced so that the AGV working efficiency is further enhanced.

Owner:HANGZHOU LANXIN TECH CO LTD

Method for transfer printing, positioning and stamping for fabric or leather

The invention provides a method for transfer printing, positioning and stamping for fabric or leather, which comprises the following steps of: (1) selecting a base membrane, wherein the base membrane is selected from PET (polyethylene glycol terephthalate), BOPP (biaxially-oriented polypropylene), aluminum-plated stamping membrane or paper; (2) printing in a dyeing way; printing one color, firstly drying, and printing next color and carrying out the next drying, till that a preset pattern is formed by printing all color cells; (3) positioning and gluing, and printing the glue on the position to be gilded on the base membrane which is printed by ink, wherein the glue is selected from polyurethane or polyamide; and (4) gilding, gilding the position printed with the glue, and drying under low temperature and rolling simultaneously, so that the base membrane to be transfer printed, positioned and stamped attached with a dyeing pattern is prepared, wherein the drying temperature is from 50 DEG C to 60 DEG C; (5) hot-pressing; and (6) rolling in a separating way. The method has the beneficial effects of: being free from coating release agent, short in labor hour, and low in cost; advanced in gilding mode, quick in speed and good in effect, and capable of being secondly gilded.

Owner:浙江金井贴膜科技有限公司

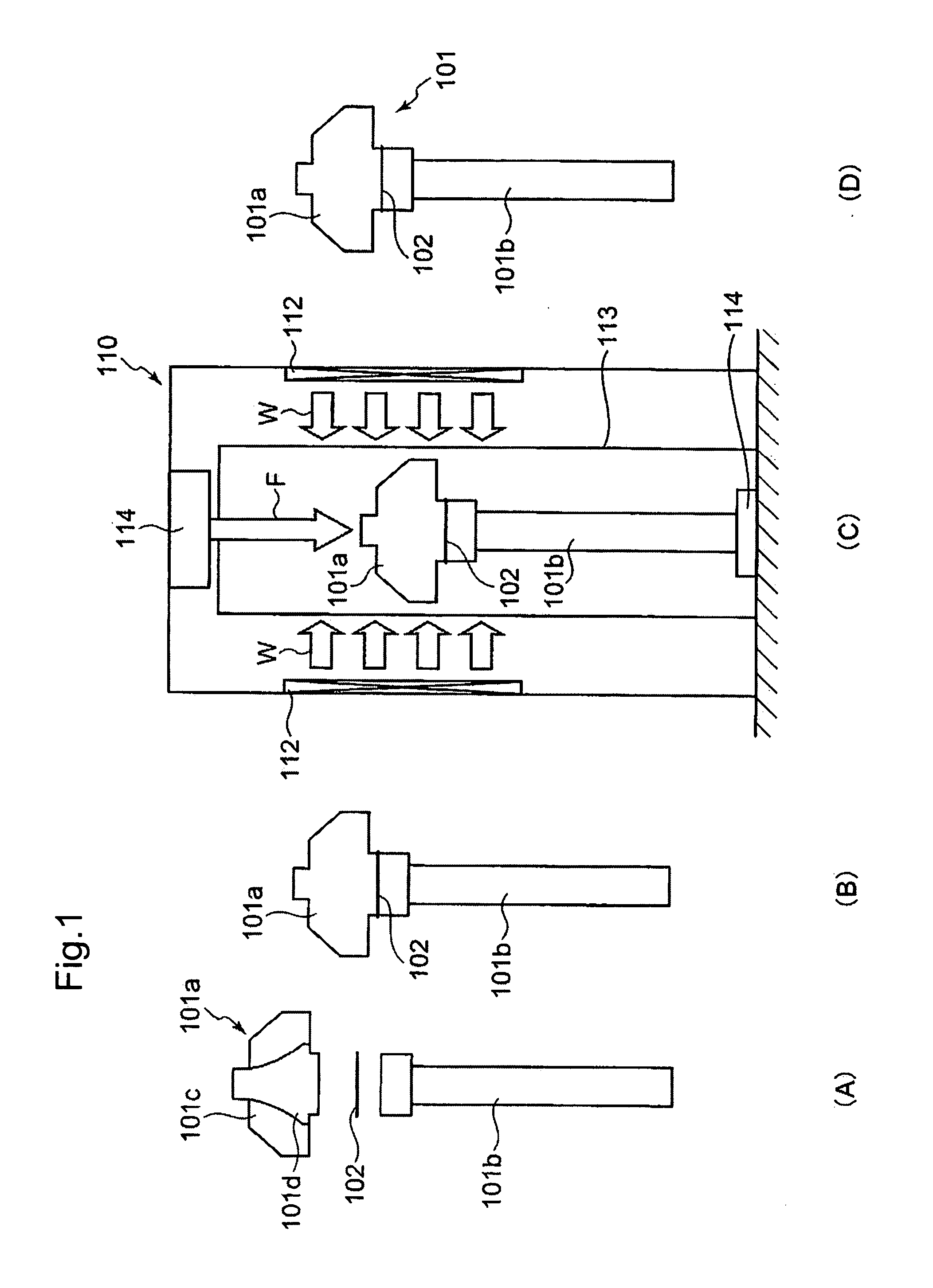

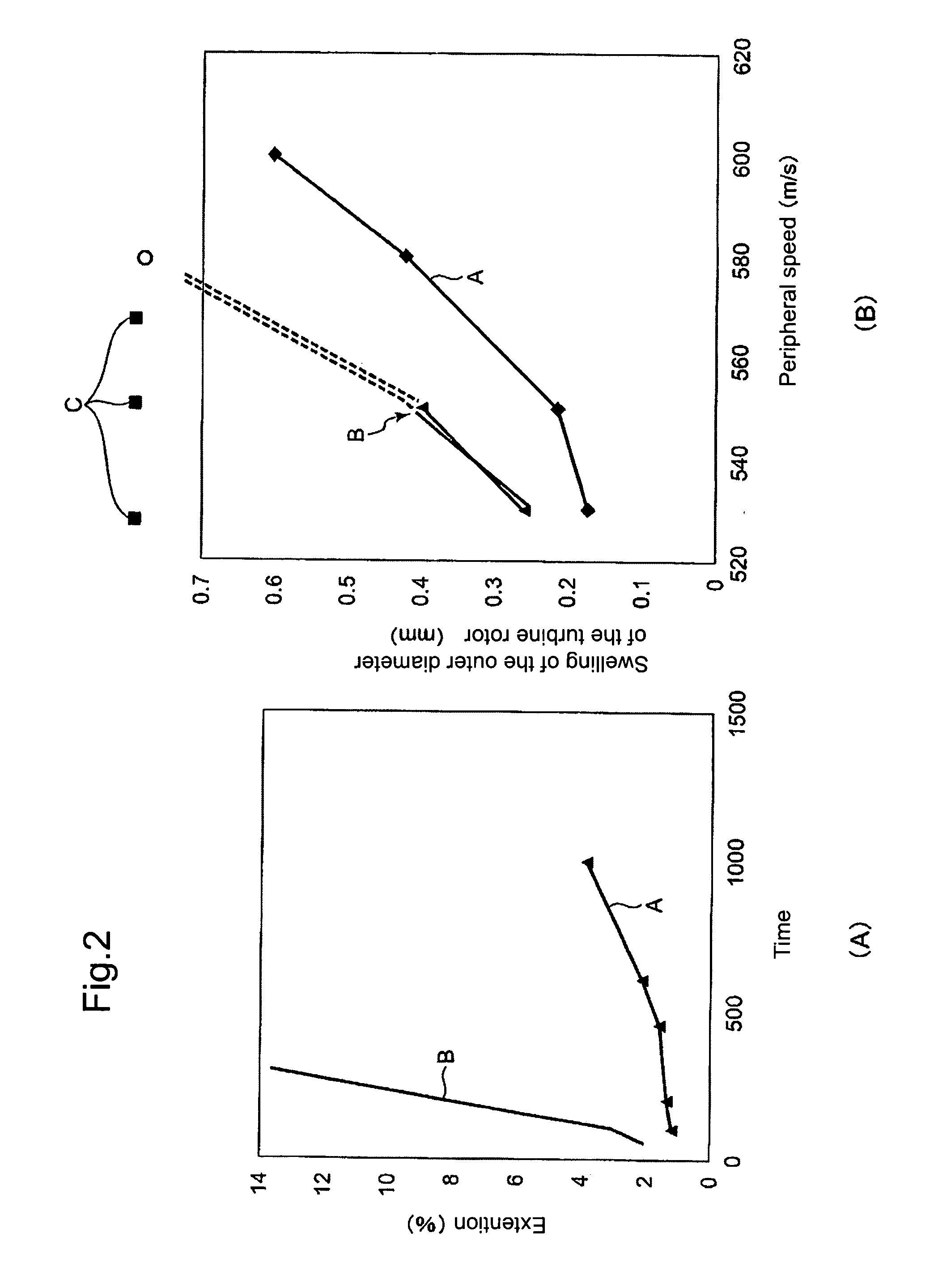

Method of manufacturing rotor and exhaust turbo-supercharge incorporating the rotor

InactiveUS20080199313A1High strengthInhibition strengthPropellersPump componentsCircular discTurbocharger

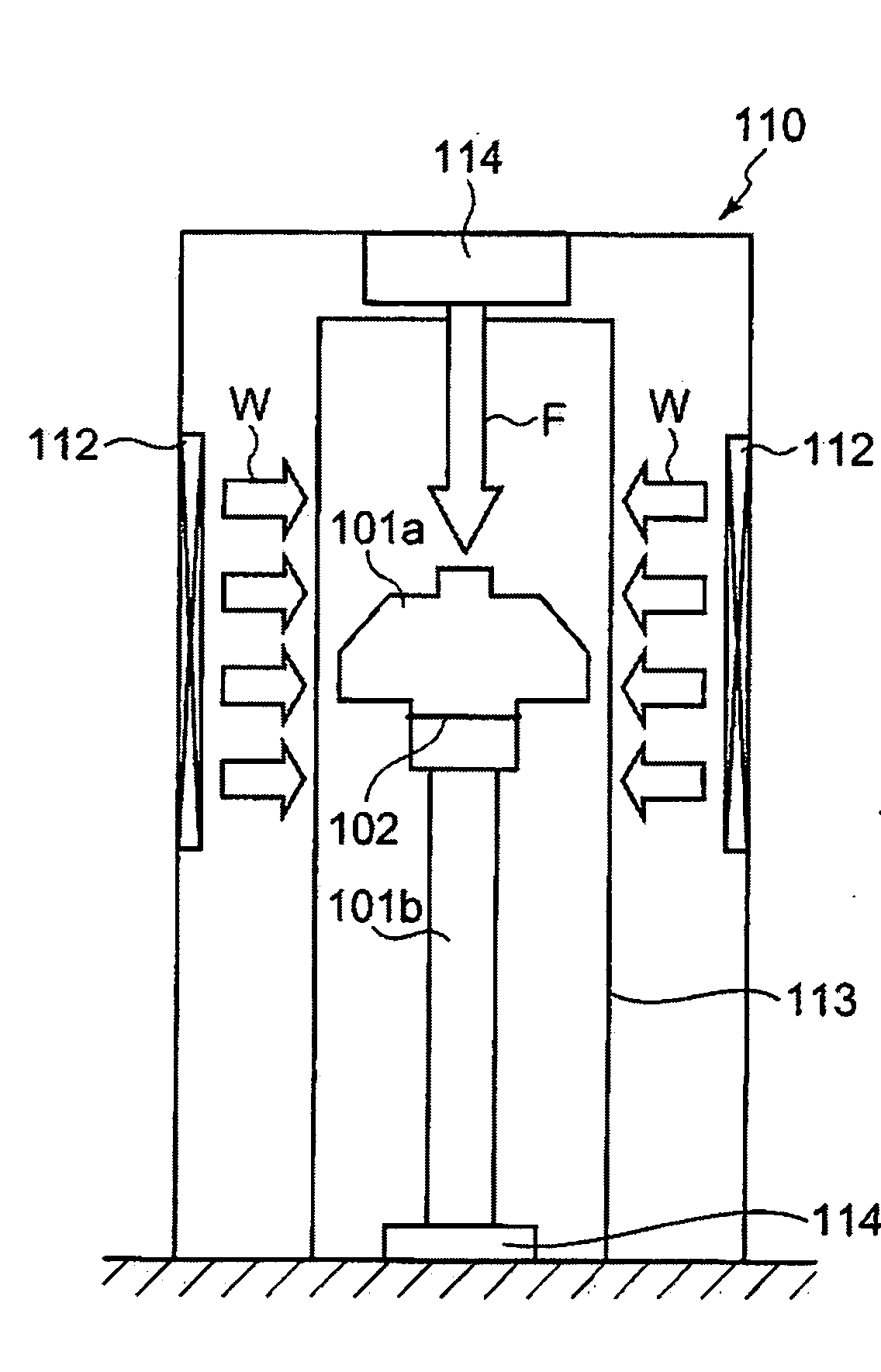

Provided are a method of manufacturing a brazed rotor composed of a wheel and a shaft joined to the former by brazing, having a durability and a reliability which can be enhanced without increasing the manufacturing man hours, and a turbine rotor for an exhaust turbo-supercharger. The wheel having a disc portion formed at its outer periphery with blades, and a rod-like shaft are arranged in a furnace, being opposed to each other at their surfaces to be joined with a brazing solder being interposed therebetween, and infrared radiation is irradiated onto a side part of the wheel so as to heat the surfaces to be joined up to a temperature in a range from 1,000 to 1,080 deg. C. in order to melt the brazing solder, thereby the wheel and the shaft are joined by brazing to each other at their surfaces to be joined.

Owner:MITSUBISHI HEAVY IND LTD

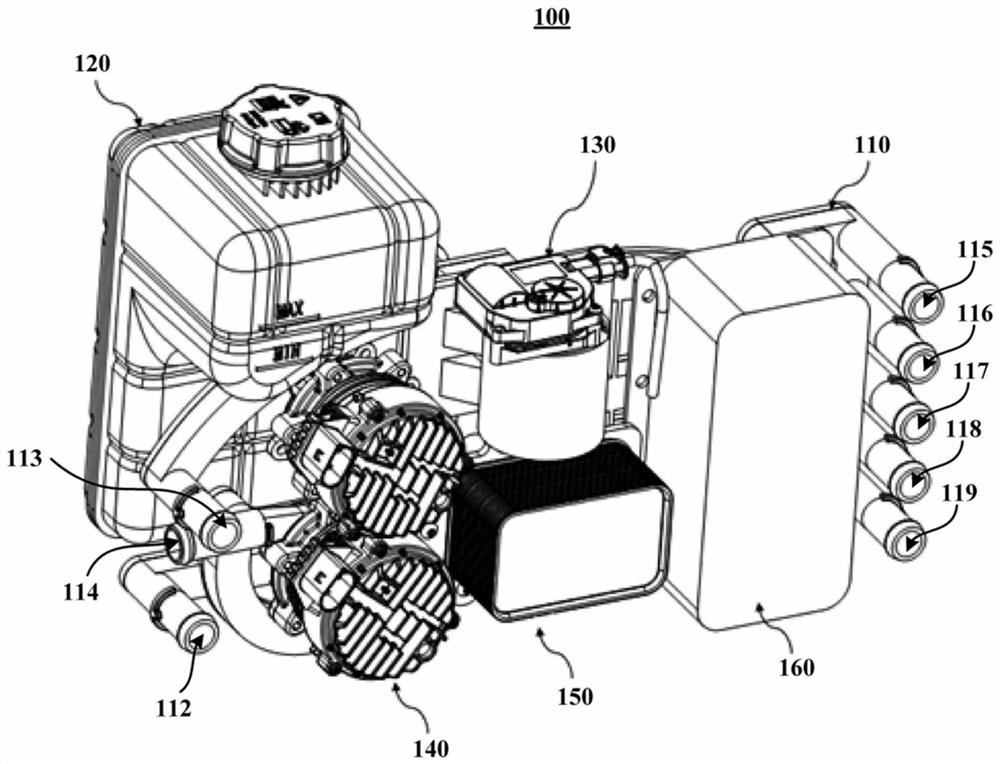

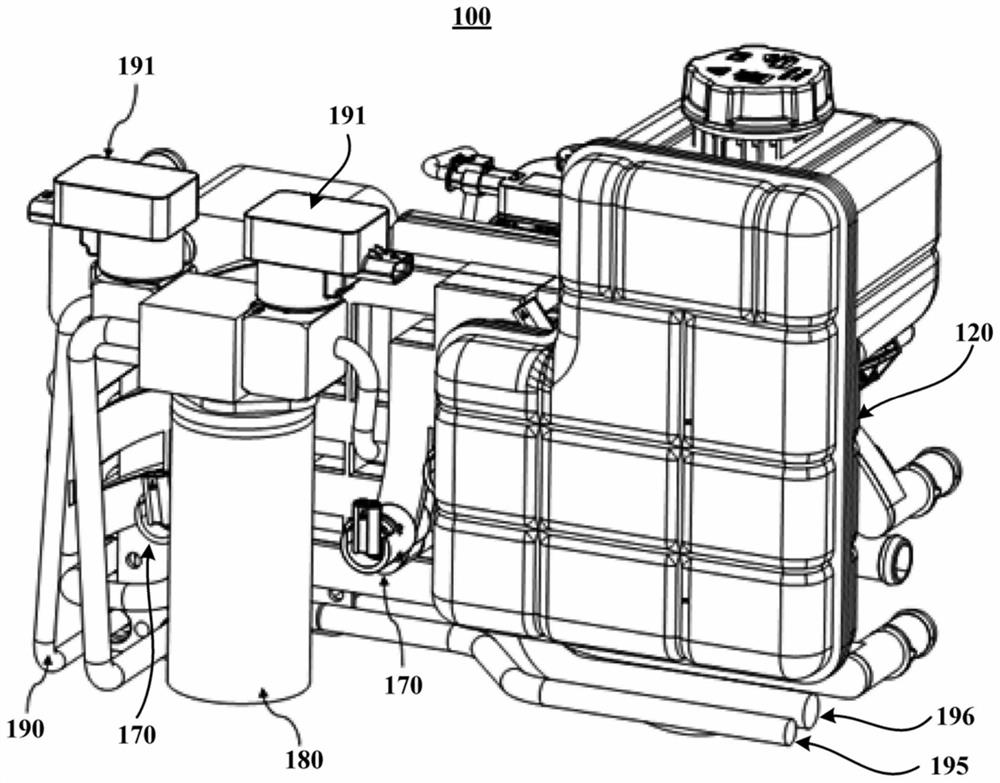

Thermal management integration module and electric vehicle

ActiveCN113276630ALow costReduce weightAir-treating devicesVehicle heating/cooling devicesHeat managementElectric cars

The invention provides a thermal management integration module and an electric vehicle, and relates to the technical field of vehicles. The thermal management integrated module comprises a multi-channel integrated board, a plurality of cooling connecting pipelines are formed in the multi-channel integrated board, and the multi-channel integrated board is configured to serve as a bearing part of the thermal management integrated module; and the at least two thermal management parts are mounted on the multi-channel integrated board and are connected with each other through the cooling connecting pipeline. By adopting the design of the multi-channel integrated board, the multi-channel integrated board not only can be used as a connecting channel between different thermal management parts, but also can be used as a bearing part of the whole integrated module, so that the thermal management parts can be integrated on the multi-channel integrated board, and the thermal management integrated module which is low in cost, light in weight and small in arrangement space is formed. In addition, the thermal management integration module can supply goods in a modularized mode, so that supplier management and working hours of production workers are greatly optimized.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

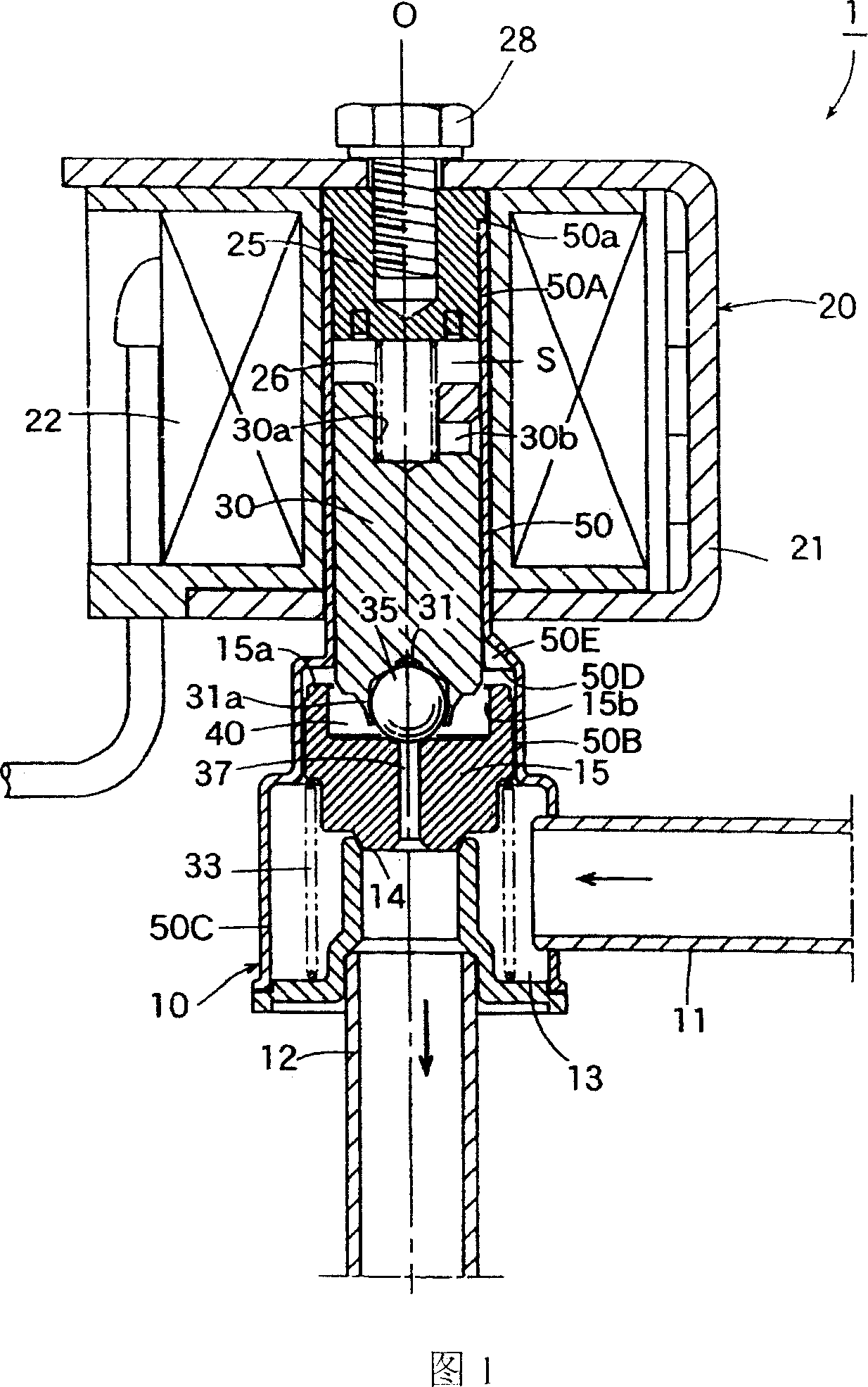

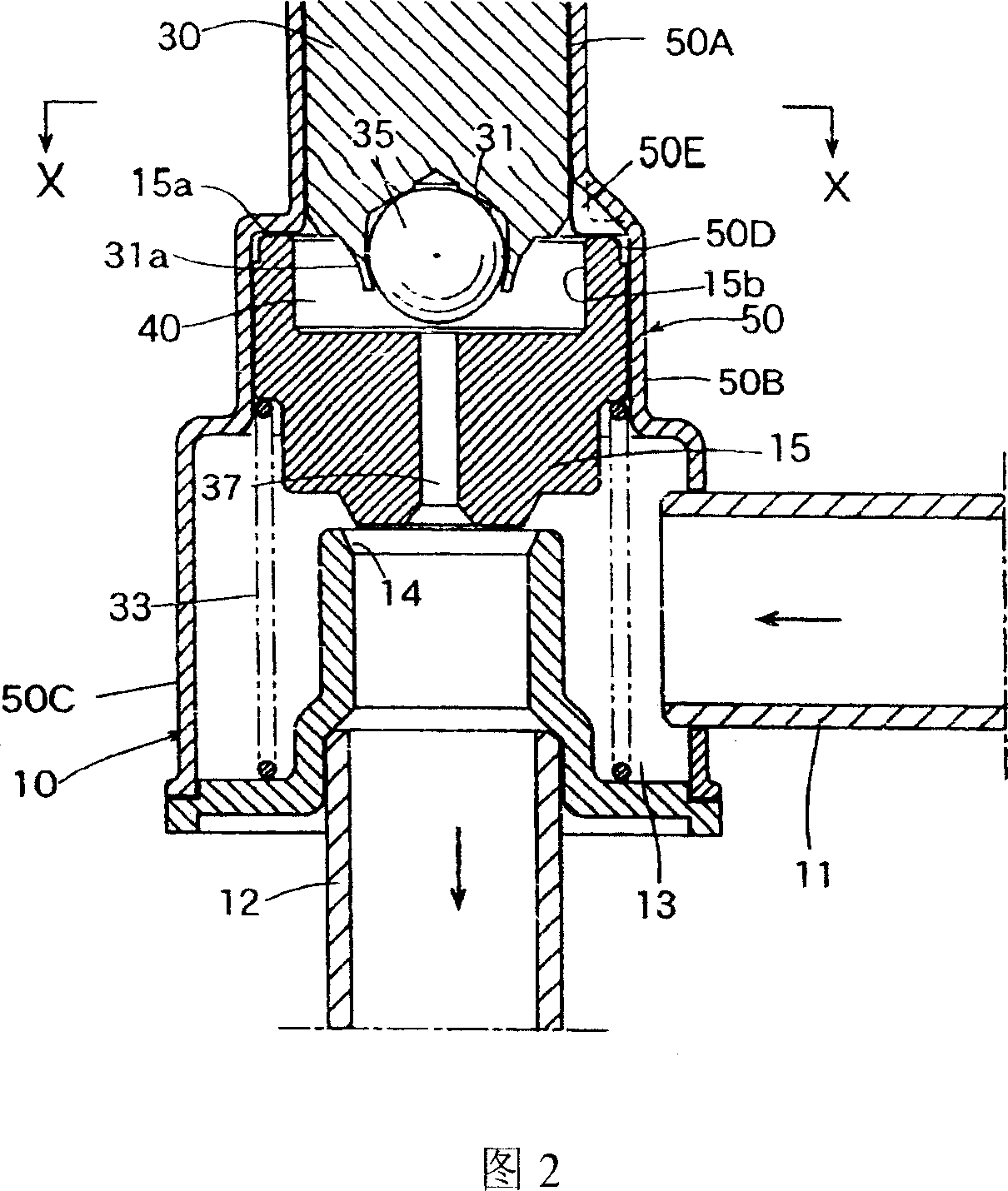

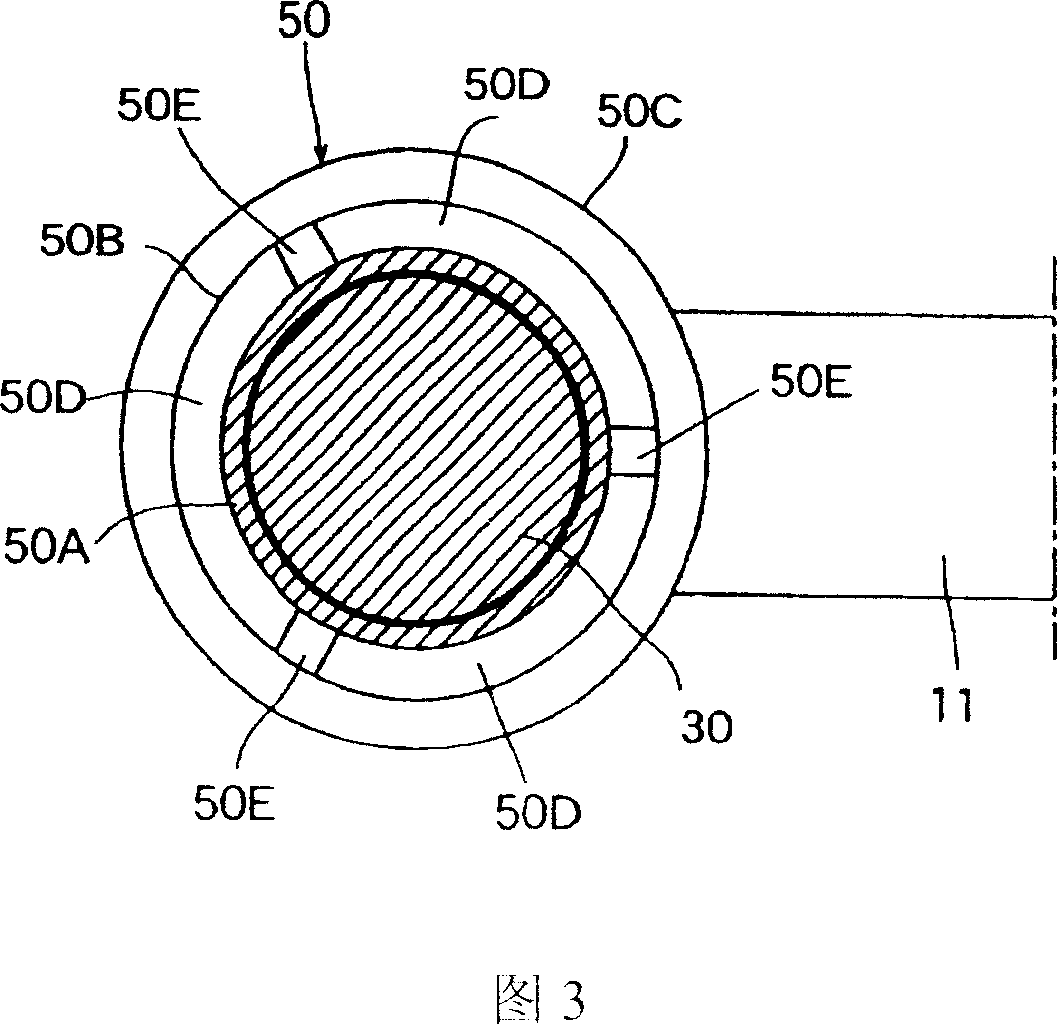

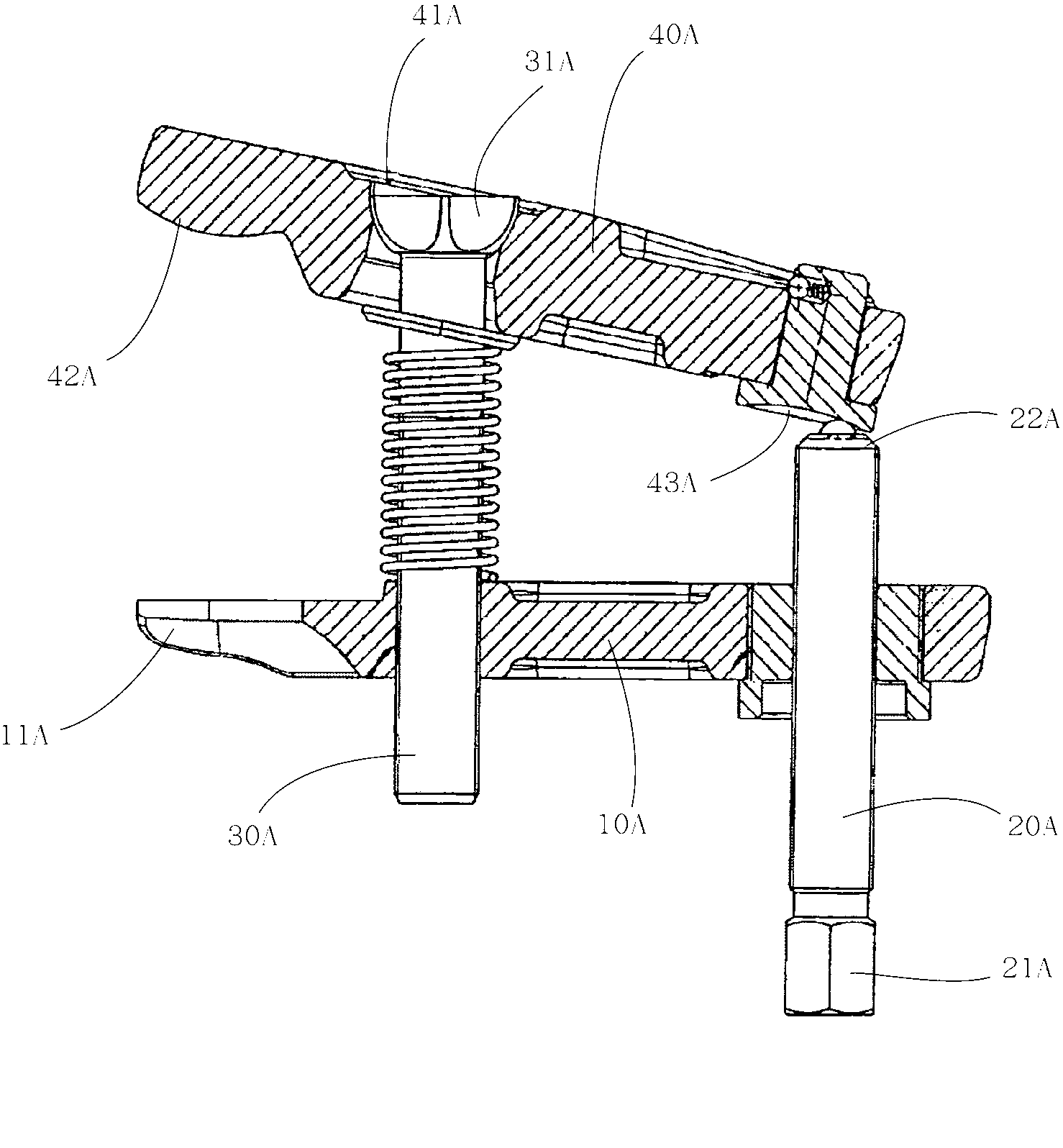

Guide valve type electromagnetic valve

InactiveCN1940358ALow costCost containmentOperating means/releasing devices for valvesLift valveMan-hourPilot valve

The present invention provides a pilot type solenoid valve capable of preventing the main valve element from not returning certainly without bringing about increase in the number of component parts, man-hours, or the cost. The pilot type solenoid valve 1 of the present invention executes opening and closing driving of the pilot valve core 35 by an electromagnetic actuator 20. A main valve element15 opening and closing complies with the motions of the pilot valve core 35. The pilot type solenoid valve 1 has a stopper preventing the main valve core 15 from moving in the opening direction, wherein the stopper is composed of a stopper surface part 50D where the end face of the main valve core 15 runs against and a recessed part 50E recessing from the stopper surface part 50D to the opening direction of the main valve core.

Owner:FUJIKOKI MFG CO LTD

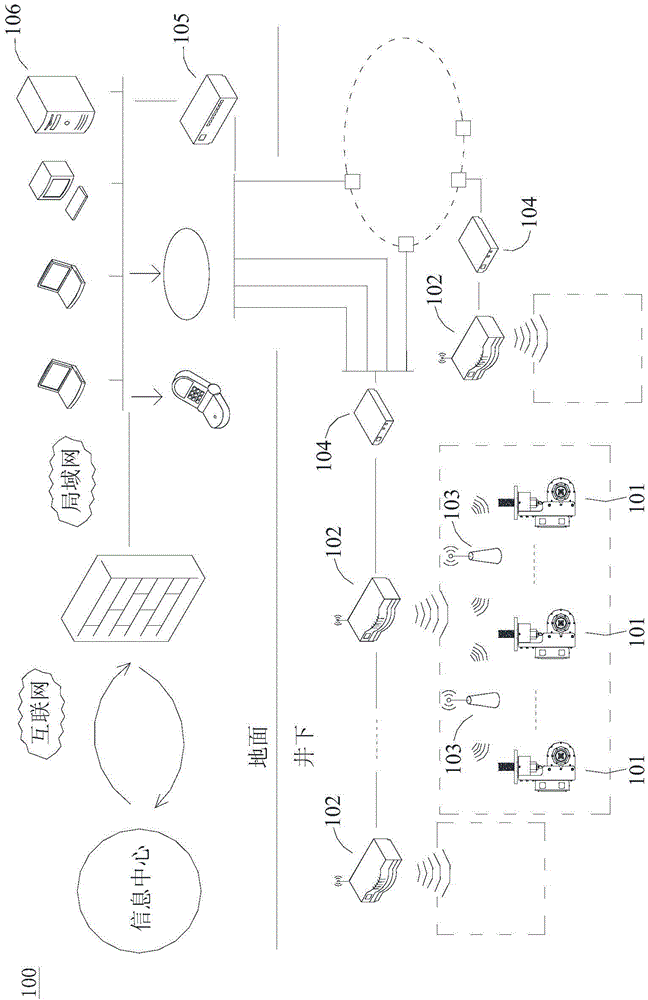

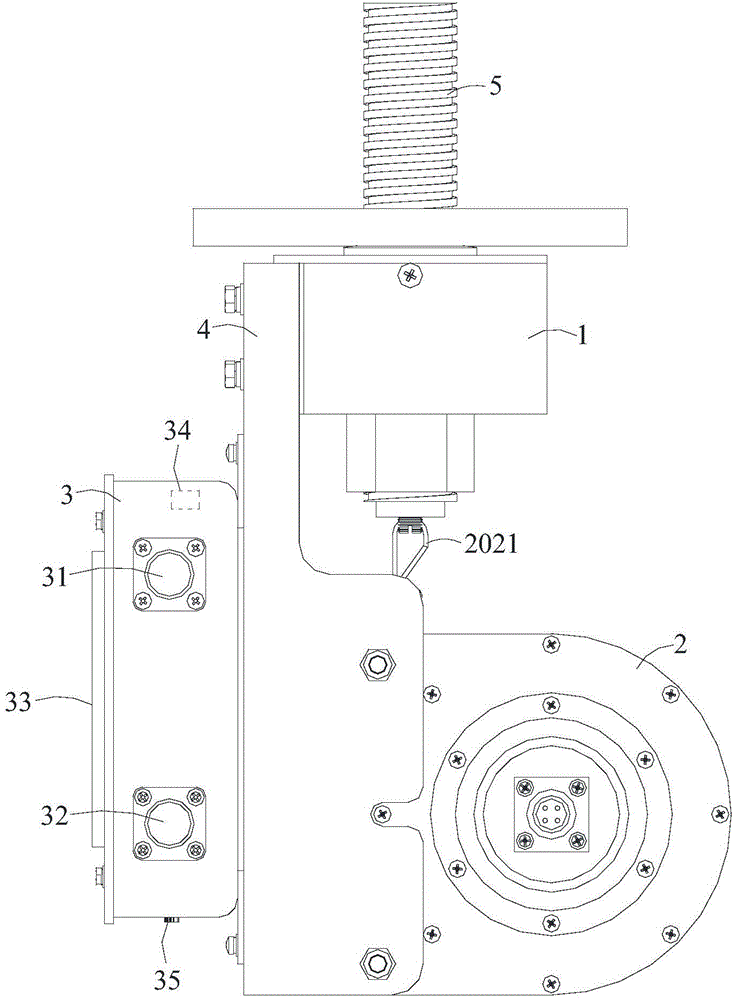

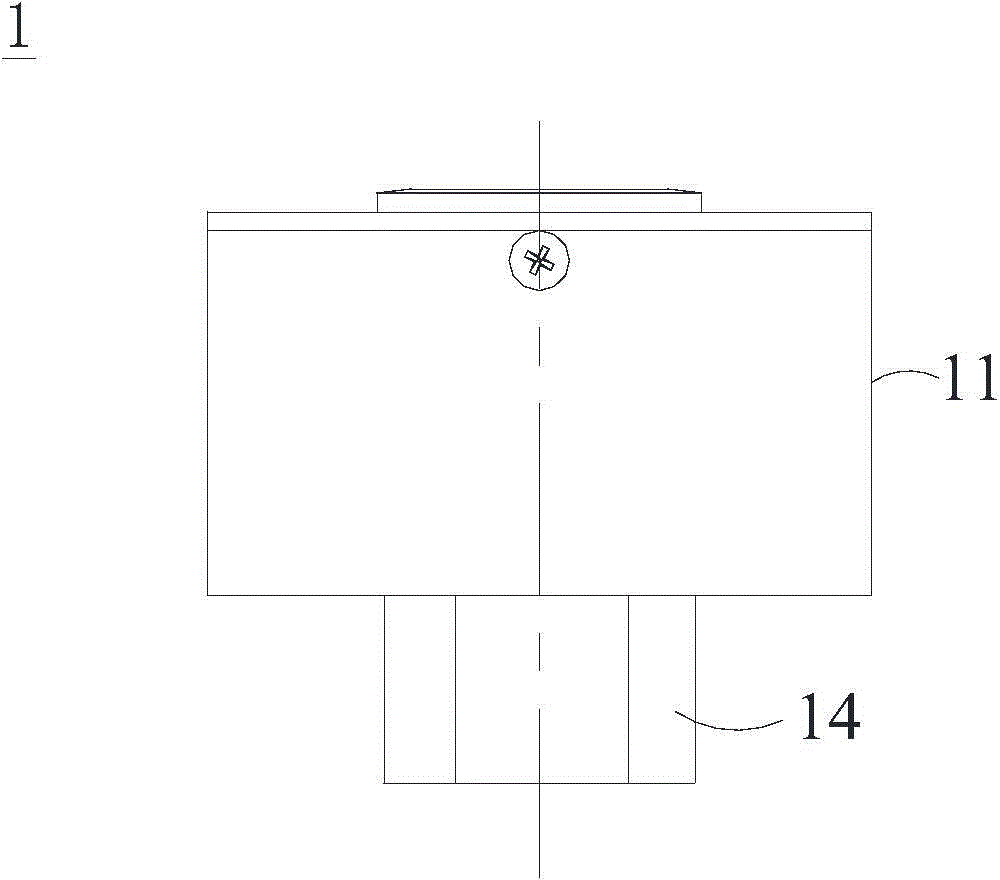

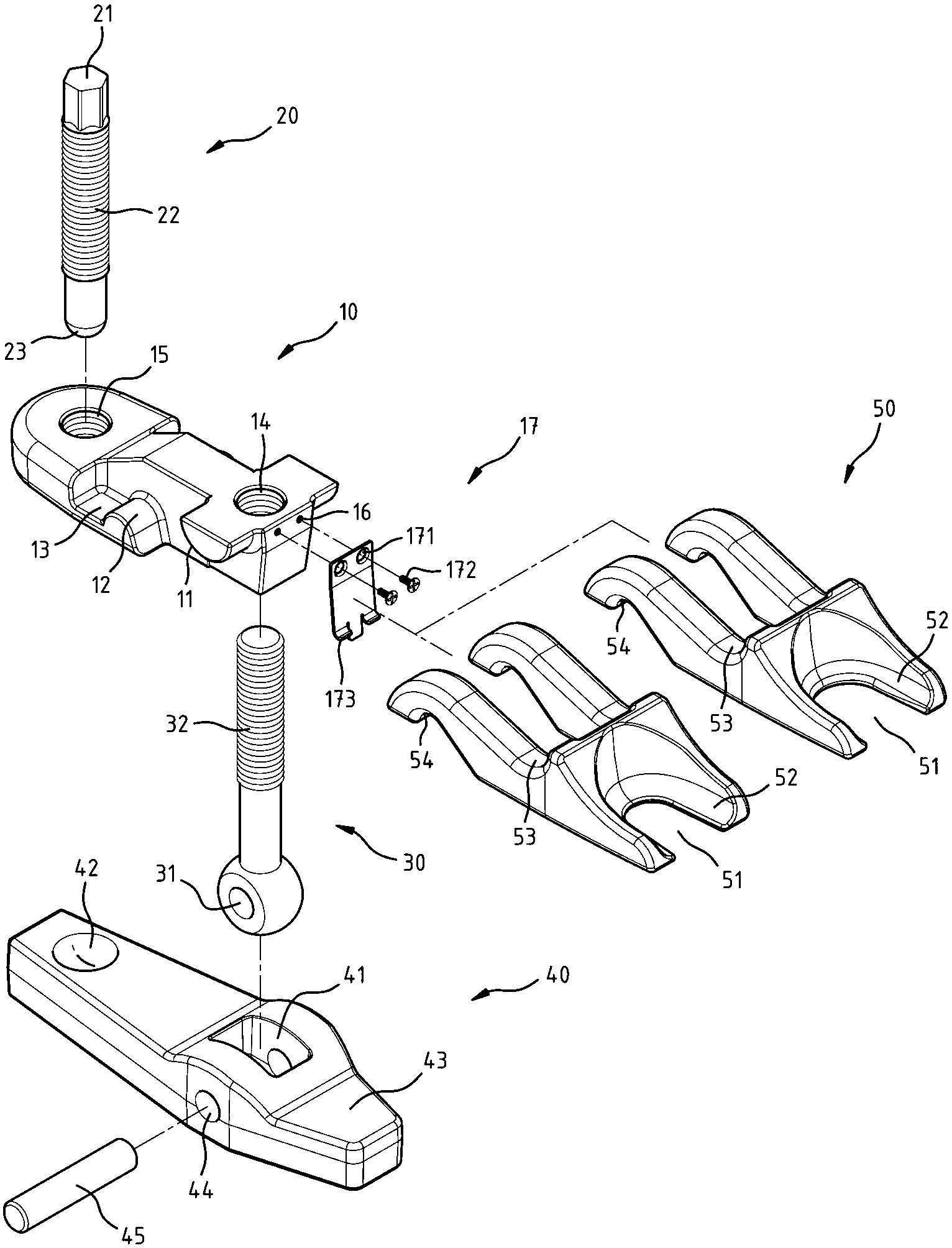

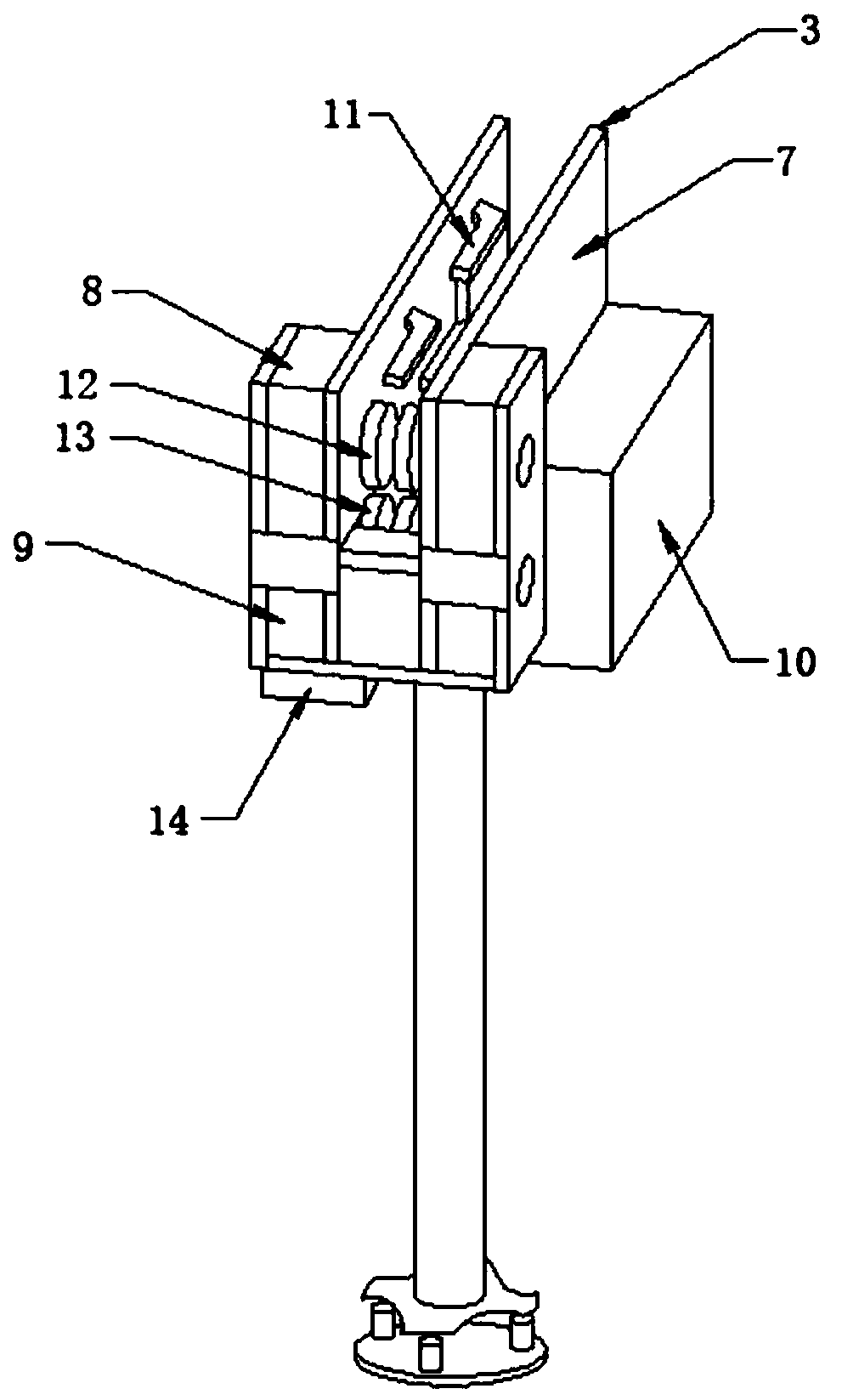

Deformation anchor rod/ anchor cable monitor, monitoring system and monitoring method

ActiveCN104913818ASpeed upIncrease spaceMeasurement devicesTransmission systemsMonitoring systemLandslide

The invention relates to a deformation anchor rod / anchor cable monitor, monitoring system and monitoring method. The deformation anchor rod / anchor cable monitor comprises a pressure sensor, a displacement sensor and a monitoring instrument, wherein the pressure sensor and the displacement sensor are arranged on an integration platform and are connected with the monitoring instrument arranged on the integration platform. The displacement sensor comprises a rolling assembly and a sensing device. The rolling assembly is externally wound by a haulage rope, wherein the open end of the haulage rope is connected with the end portion of a deformation anchor rod / anchor cable; the rolling assembly is internally provided with an elastic component to enable the rolling assembly to reset; the rolling assembly is connected with the sensing device; when the anchor rod / anchor cable deforms, the rolling assembly is driven to rotate via the haulage rope, and the sensing device detects the displacement amount of the rolling assembly and transmits the data to the monitoring instrument; and the monitoring instrument can carry out sound-light alarm according to the measured data. The deformation anchor rod / anchor cable monitor is simple in structure, convenient to use and timely in feedback, and can effectively improve production efficiency and reduce the occurance of geological disaster accidents of mine safety accidents and landslides and the like.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST +1

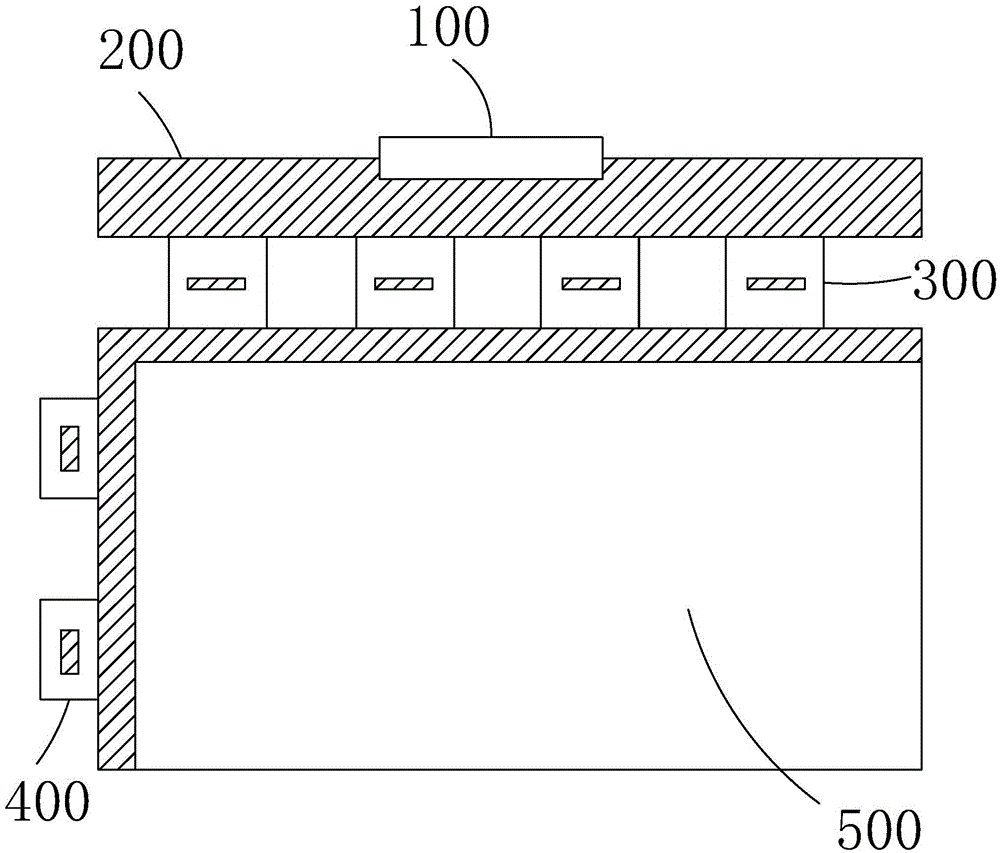

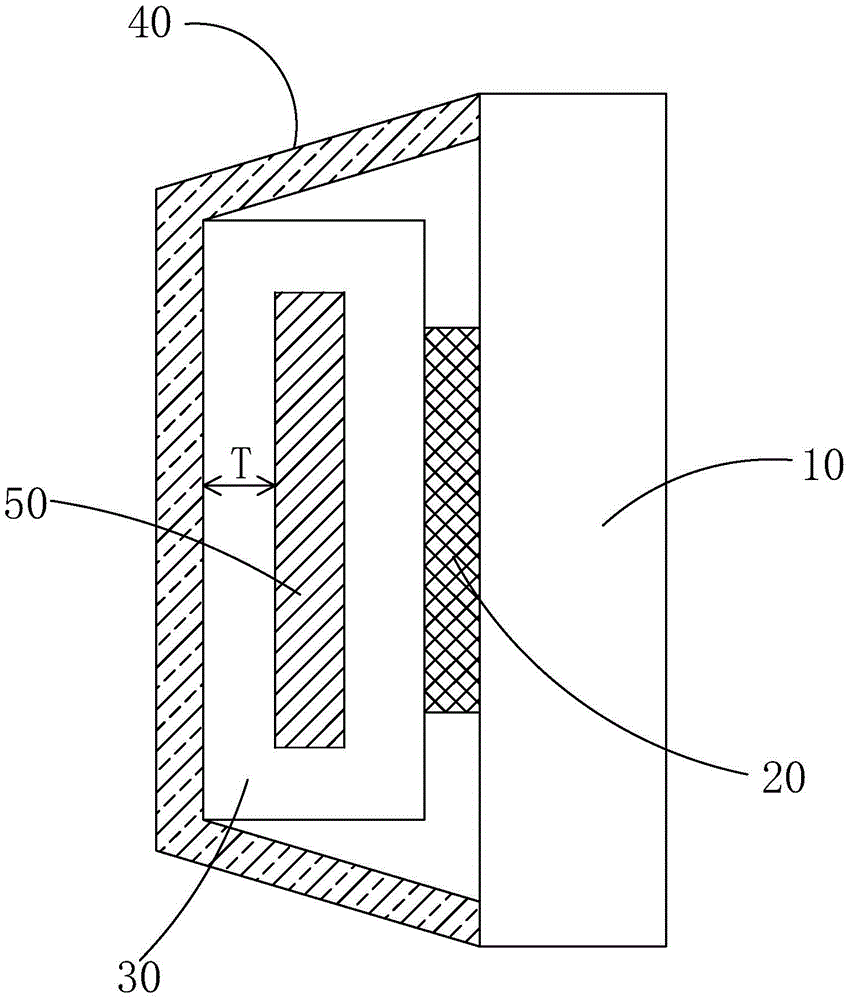

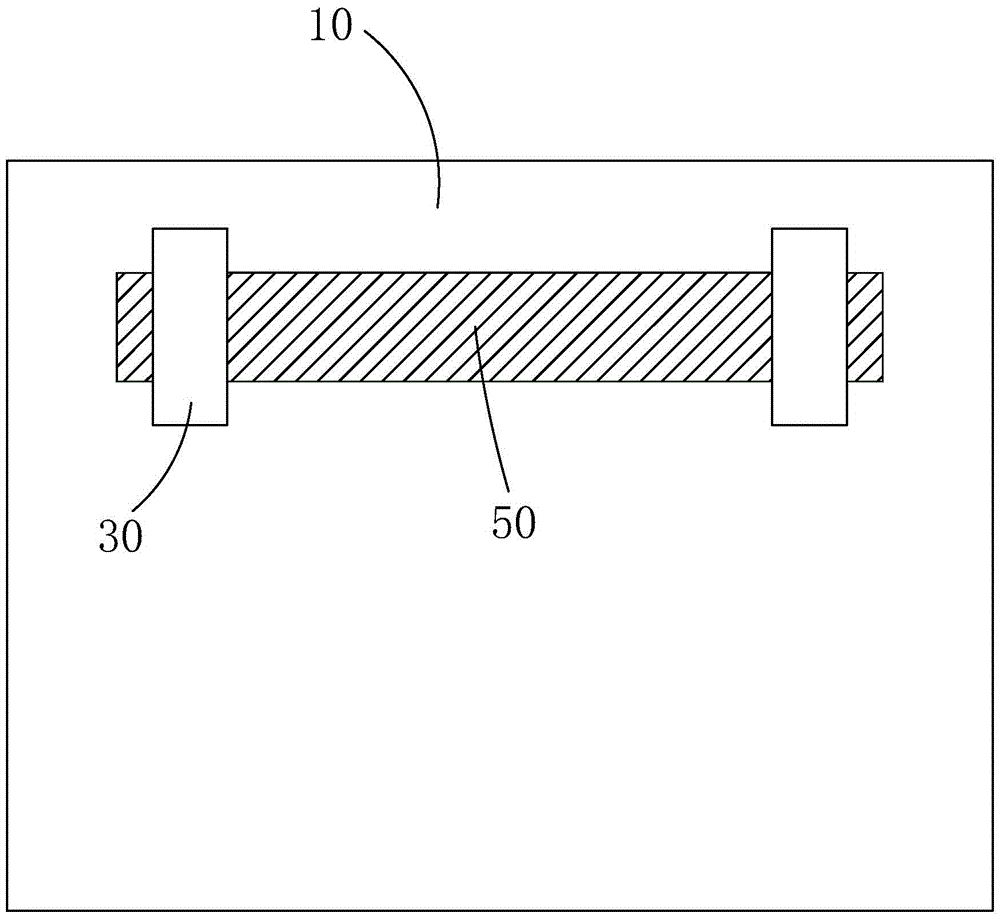

PCB fixing structure and liquid crystal display device

ActiveCN105592679AGood grounding effectGrounding SimplifiedPrinted circuit assemblingShielding materialsLiquid-crystal displayEngineering

The invention provides a PCB fixing structure and a liquid crystal display device. The PCB fixing structure fixes a PCB (50) on a back board (10) through annular conductive foam (30) and conductive glue (20), thereby improving contact performance between the PCB (50) and the back board (10), and improving grounding performance of the PCB. Then the annular conductive foam (30) is squeezed through a PCB housing (40). Enough compression ratio of the annular conductive foam for ensuring high electric conductivity is ensured, and grounding performance of the PCB is further improved, thereby conducting an ESD interference timely and effectively, preventing electrostatic injury, simplifying a PCB fixing process and saving working hour. The liquid crystal display device with the PCB fixing structure has advantages of simplifying the PCB fixing process in the liquid crystal display device, saving working hour, improving grounding performance of the PCB and preventing electrostatic injury.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

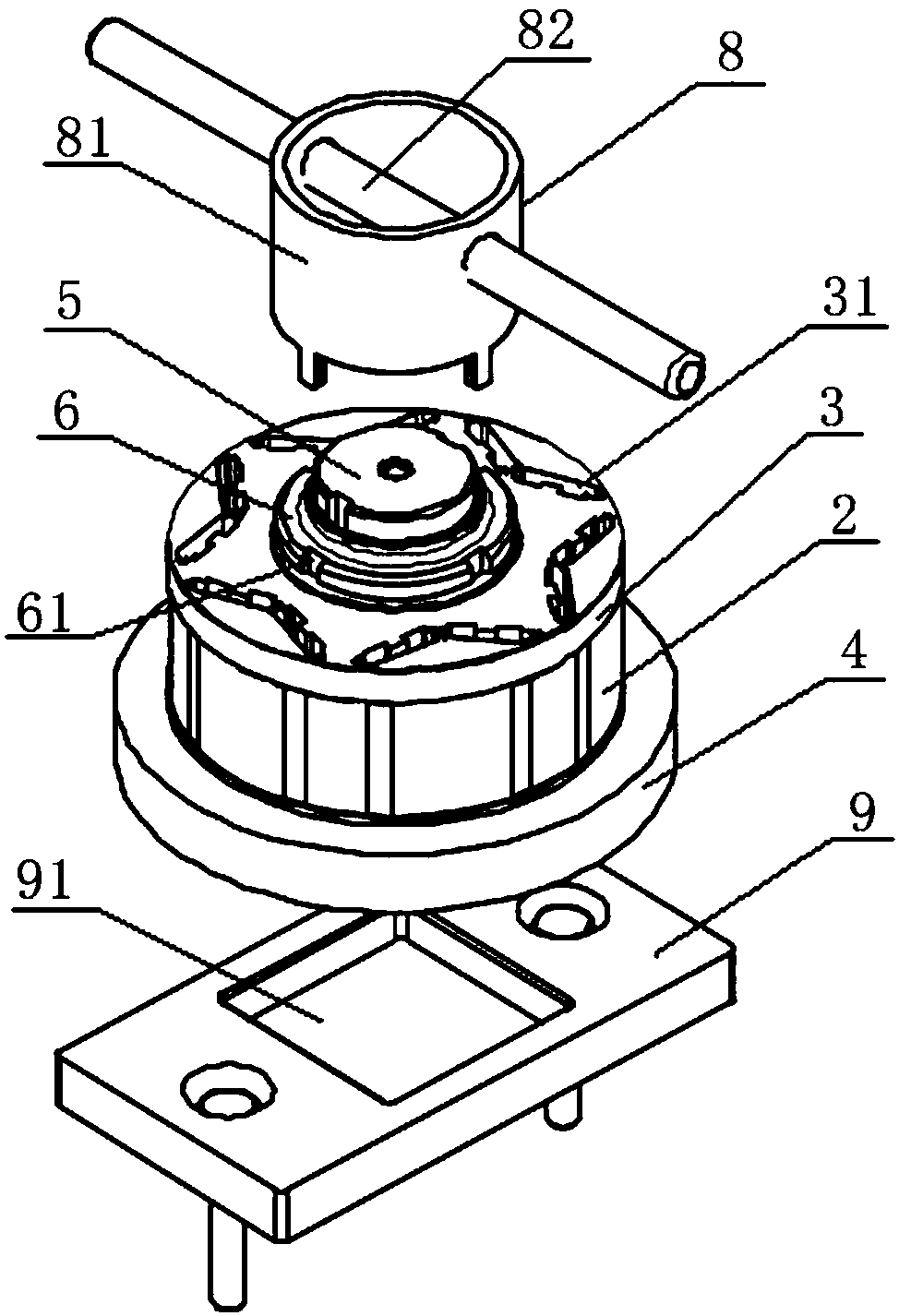

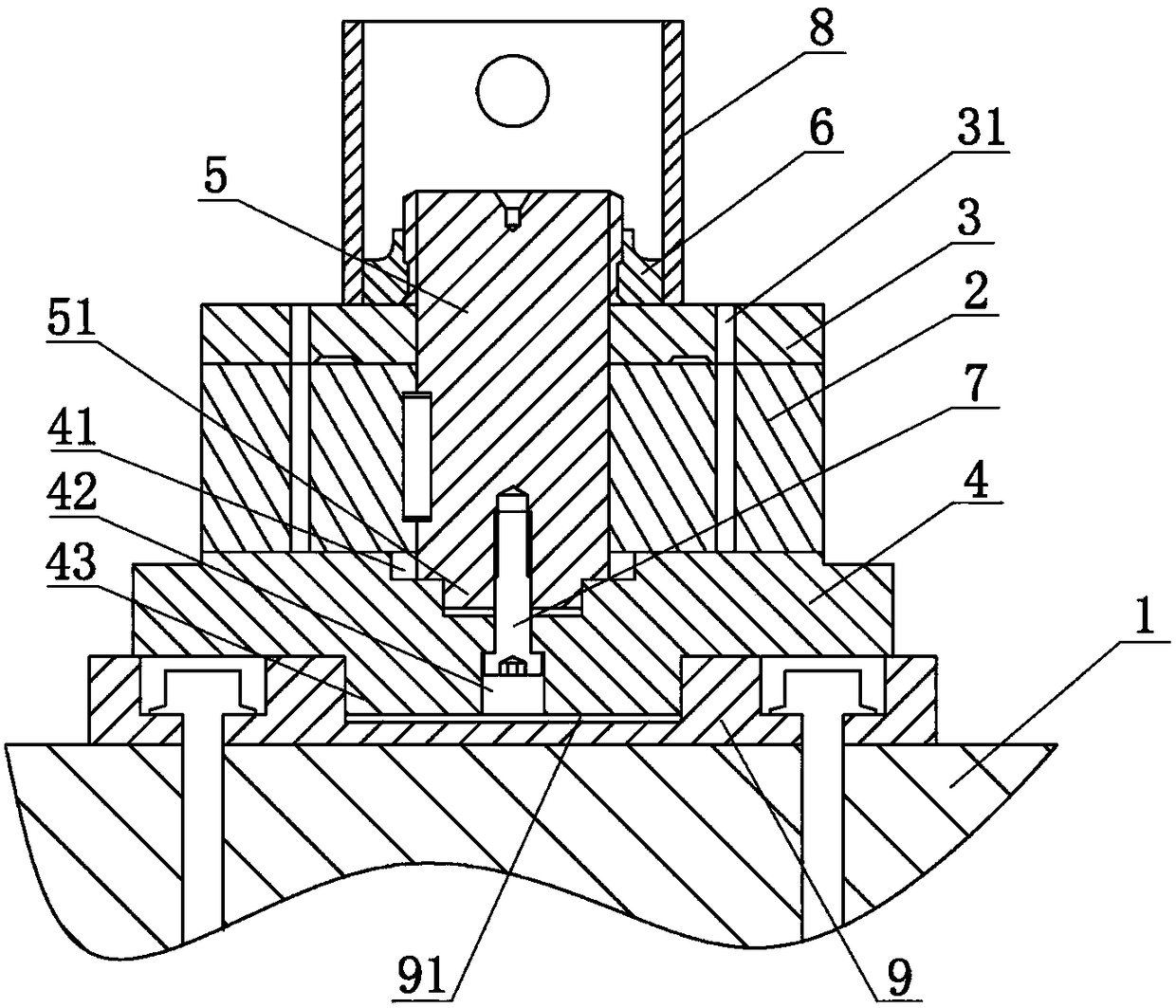

Motor rotor iron core potting lamination device and potting method

The invention relates to a motor rotor iron core potting lamination device and a potting method, and belongs to the technical field of a motor rotor. The lamination device is placed on an operation platform and comprises a cover board and a base which are respectively arranged on the upper and lower end faces of a rotor iron core, and a connection shaft which is positioned in the rotor iron core and locks and connects the cover board and the base; and an adhesive injection groove communicated with a magnetic steel groove of the rotor iron core is formed on the cover board. The potting method applying the lamination device comprises: installation of the potting lamination device, injection of a potting adhesive, curing of the potting adhesive and disassembling of a locking structure. The motor rotor iron core potting lamination device and the potting method have the beneficial effects that the potting lamination device is simple in structure, convenient and rapid to operate and convenient for integral assembling, locking and disassembling, and can effectively solve a problem that after the rotor iron core is injected with the adhesive, the adhesive permeates into a gap between punching sheets; use performance of the rotor iron core is improved; and working efficiency is improved.

Owner:江苏金坛绿能新能源科技有限公司 +1

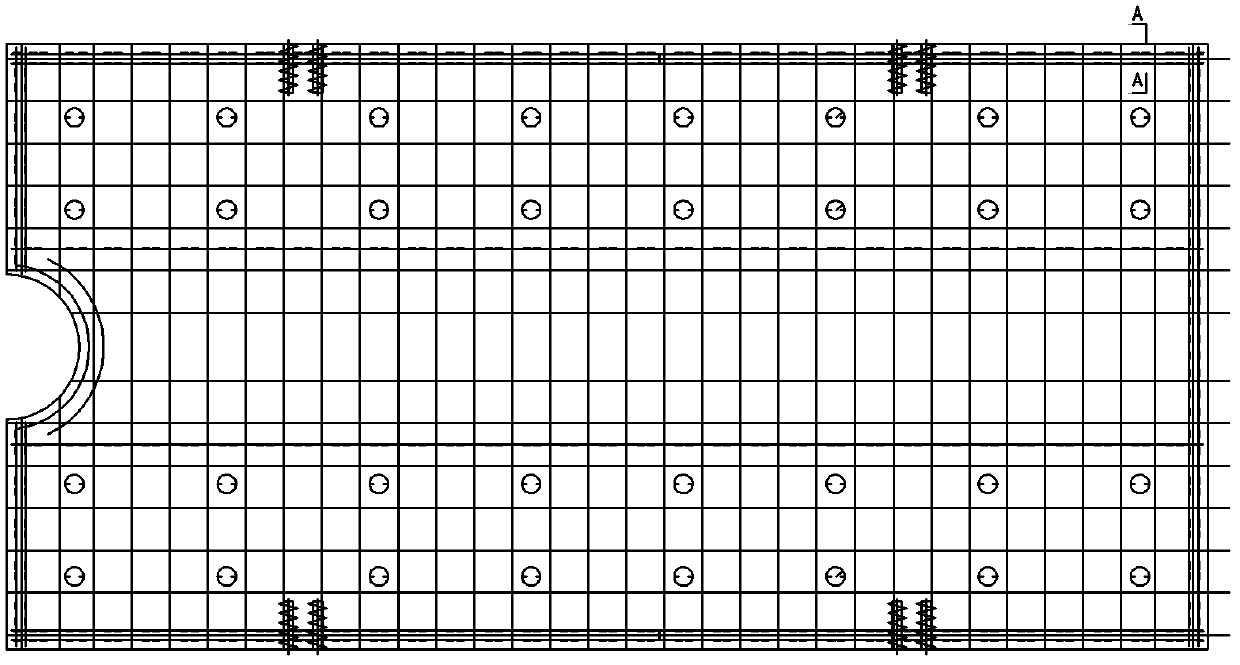

Double-layer bidirectional pre-tensioned track plate

The invention relates to a track plate, in particular to a double-layer bidirectional pre-tensioned track plate, which comprises a track plate, wherein the track plate is symmetrically provided with a layer of transverse pre-stressed reinforcement set and a layer of longitudinal pre-stressed reinforcement set on the two sides about the neutral axis respectively; the longitudinal pre-stressed reinforcement sets are distributed in the same horizontal plane of the track plate; the transverse pre-stressed reinforcement sets are distributed in the same horizontal plane of the track plate; the clear spacing between the longitudinal pre-stressed reinforcement set and the transverse pre-stressed reinforcement set on the same side of the track plate is not less than 6 mm; two vertical stirrups are arranged in a pre-stressed reinforcement anchoring region around the track plate respectively; the middle part of the track plate is also symmetrically provided with a vertical stirrup along the longitudinal direction of the track plate about the plate center; an insulating layer is arranged on the outer side of the vertical stirrups.

Owner:欧阳炎

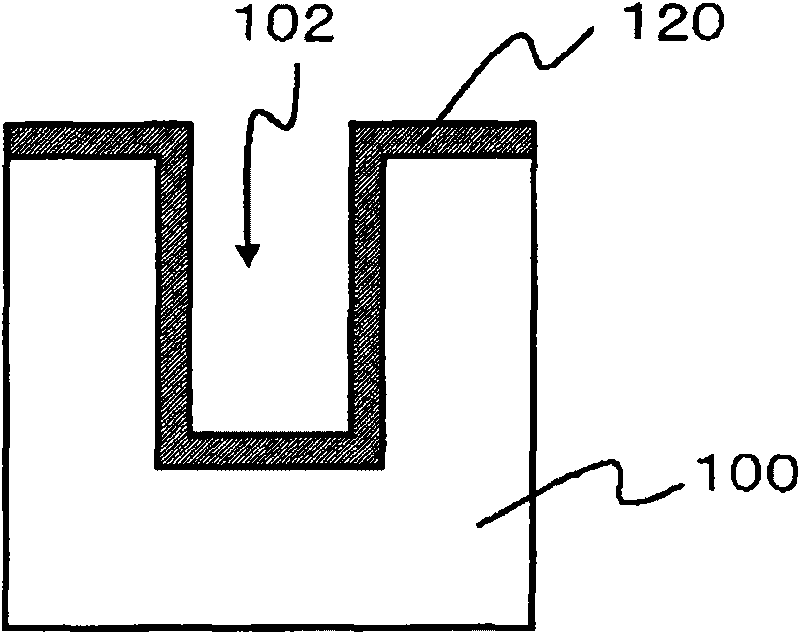

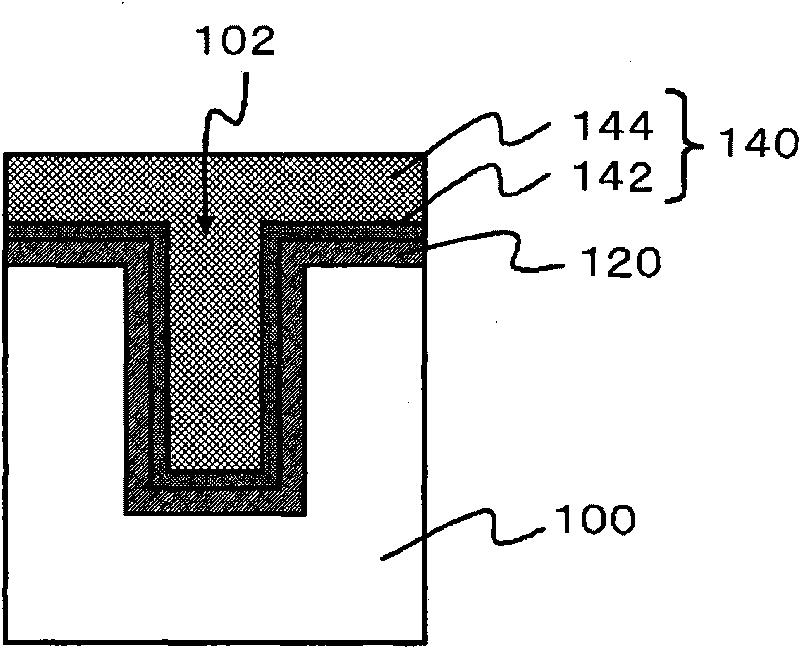

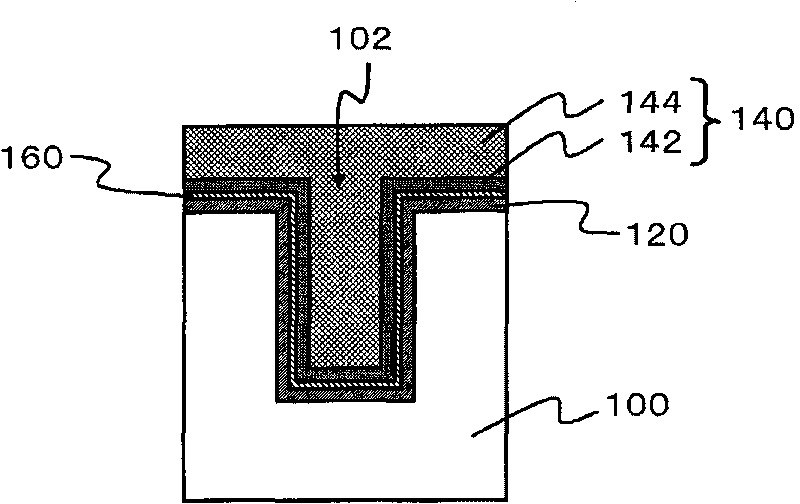

Semiconductor device and method of manufacturing the same

InactiveCN101714521AInhibition of Adhesive DeteriorationSuppresses degradation of resistance to electromigrationSemiconductor/solid-state device detailsSolid-state devicesAlloySemiconductor

The invention provides a semiconductor device and method of manufacturing the same. A metal barrier film which contains an additive element is formed on the side face and on the bottom of a trench formed in an insulating film; a seed film is formed over the metal barrier film; a plated layer (Cu film) is formed using the seed film as a seed so as to fill up the trench with a metal film; the metal barrier film and the metal film are annealed to thereby form therebetween an alloy layer which contains a metal composing the metal barrier film, the additive element, and a metal composing the metal film, and to thereby allow the additive element to diffuse into the metal film.

Owner:RENESAS ELECTRONICS CORP

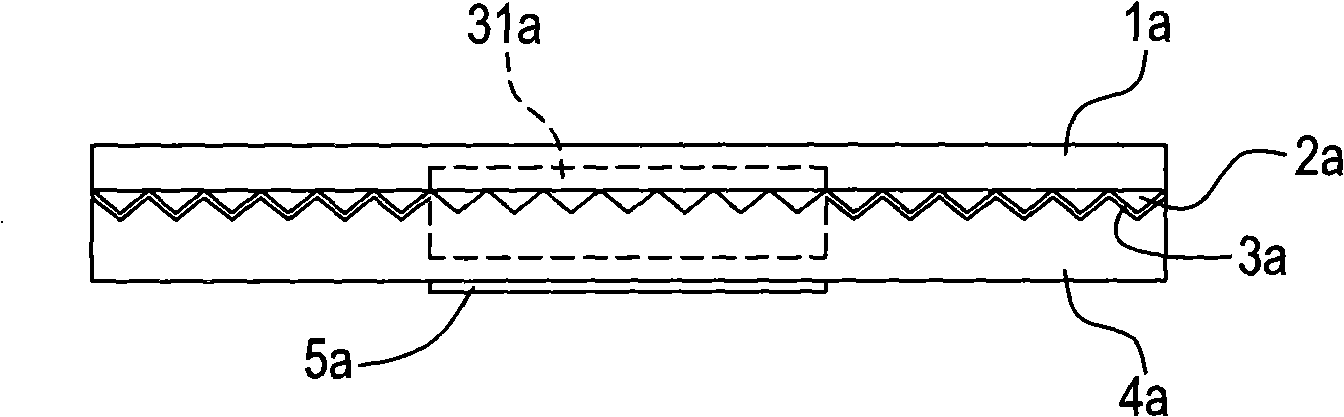

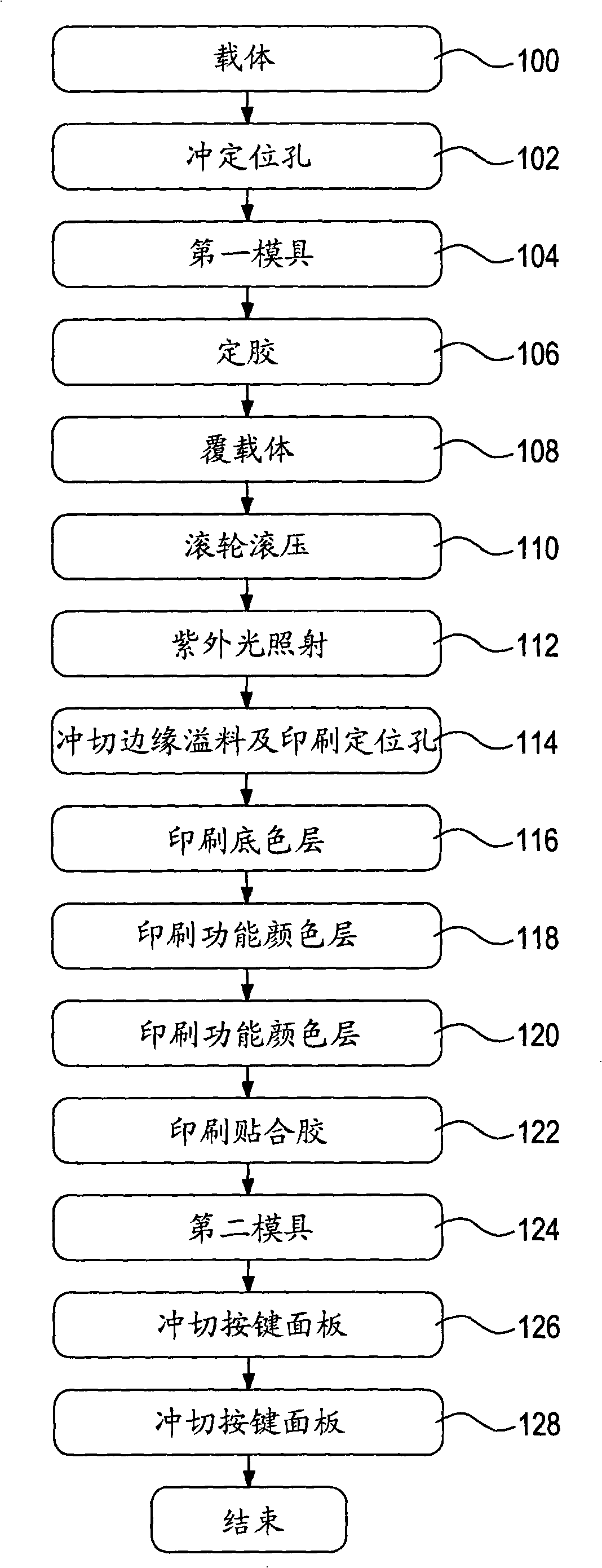

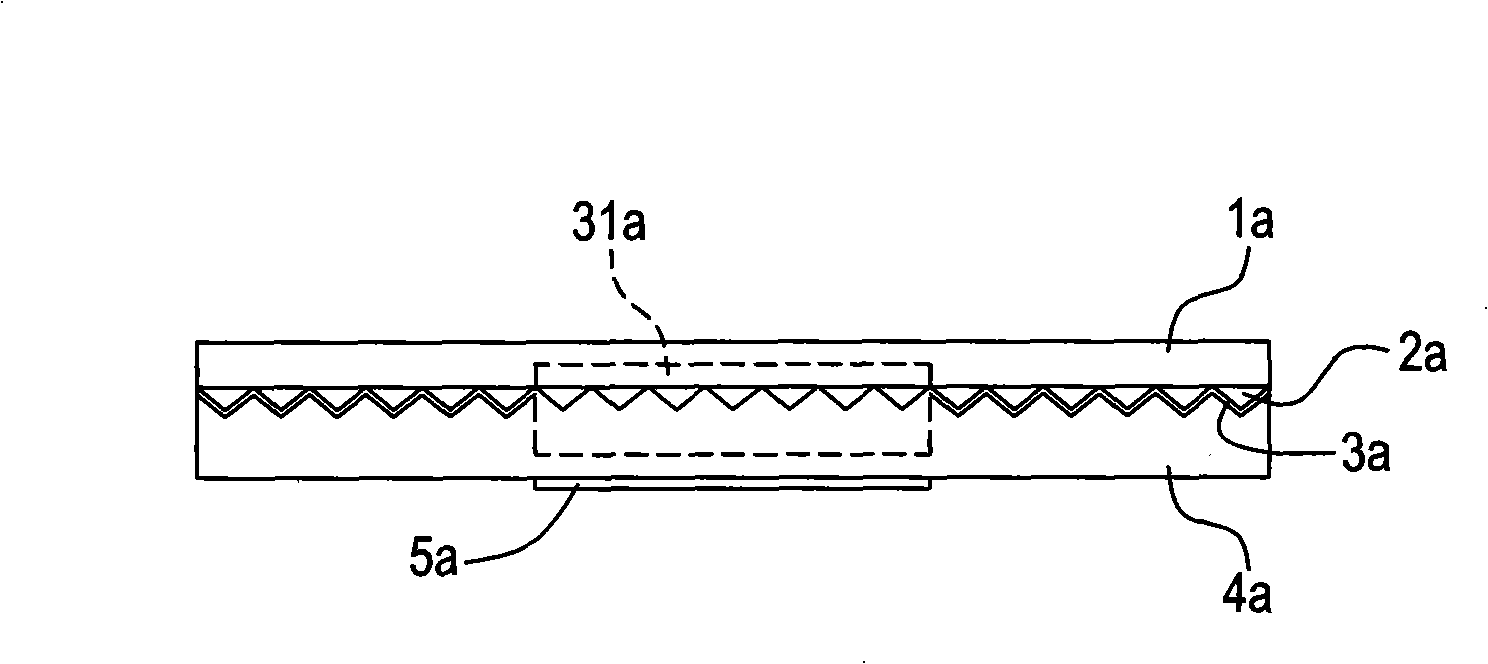

Method for preparing thin type press key panel

InactiveCN101276698AIncreasing the thicknessProduction process increaseElectric switchesUltraviolet lightsEngineering

A method for manufacturing a keystroke panel including a smooth surface, a misty surface or a grain layer is disclosed, comprising the steps of: at first, manufacturing a module whose inside bottom surface is coarse surface, smooth surface or grain surface, dropping colloid into the module and covering a carrier on the surface of the colloid, using idler wheels to roll and press on the surface of the carrier so that the carrier and the colloid are flat within the module; then irradiating with ultraviolet light in order that the colloid is hardened to form a keystroke layer attached to the carrier, afterwards, on the carrier, sequentially film-forming a bottom colour layer, functional colour layer and font colour layer as the background of the keystroke panel. Finally, hot-pressing the formed keystroke layer and the silica gel to combine both, namely, the manufacturing of keystroke panel is finished.

Owner:ICHIA TECH

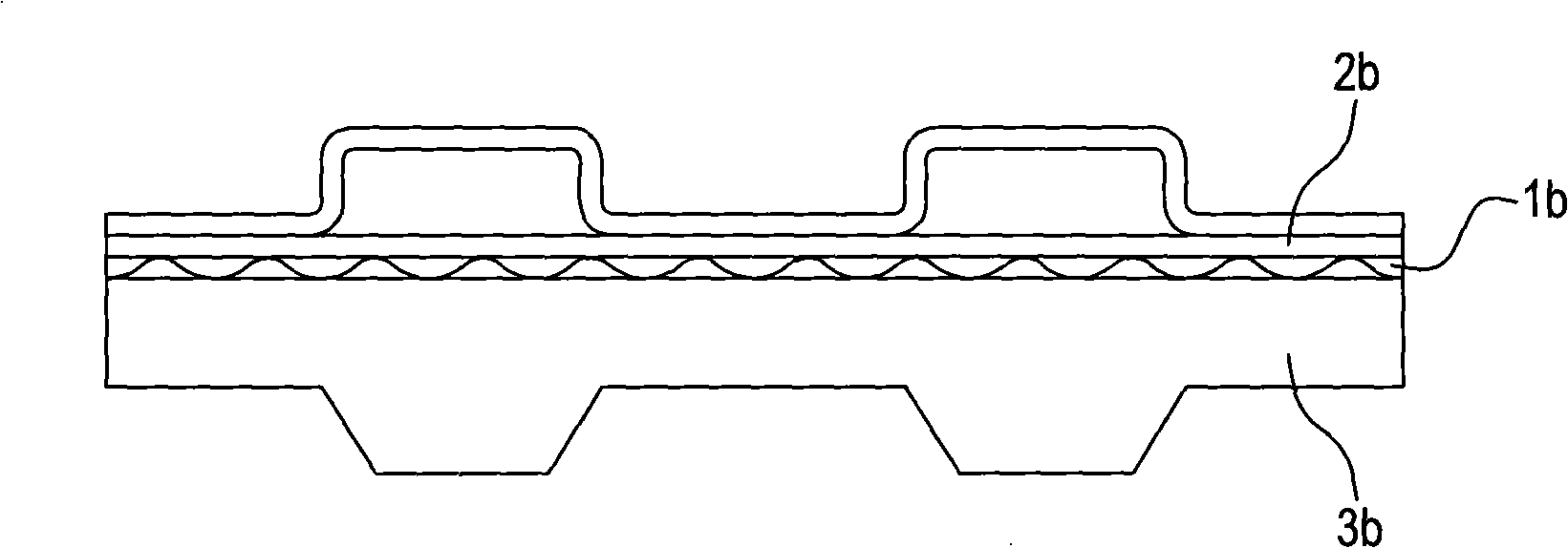

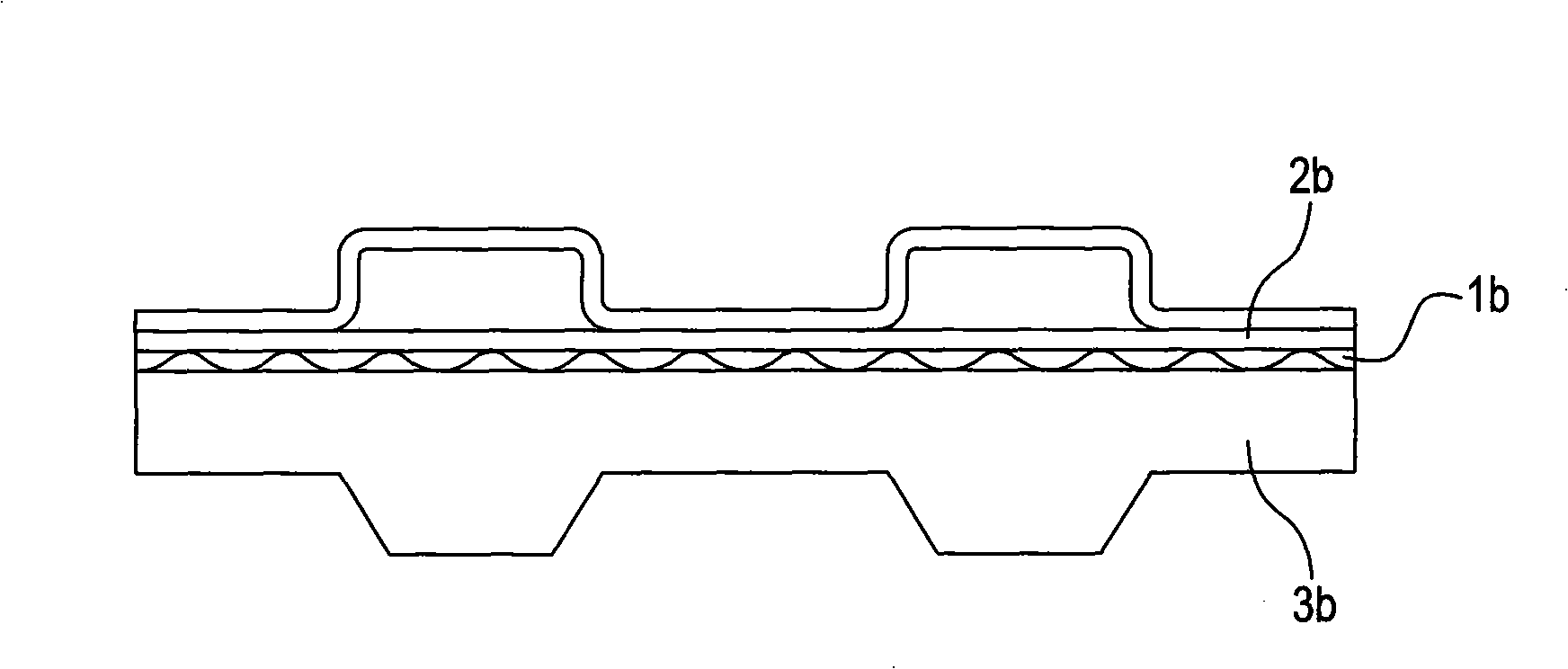

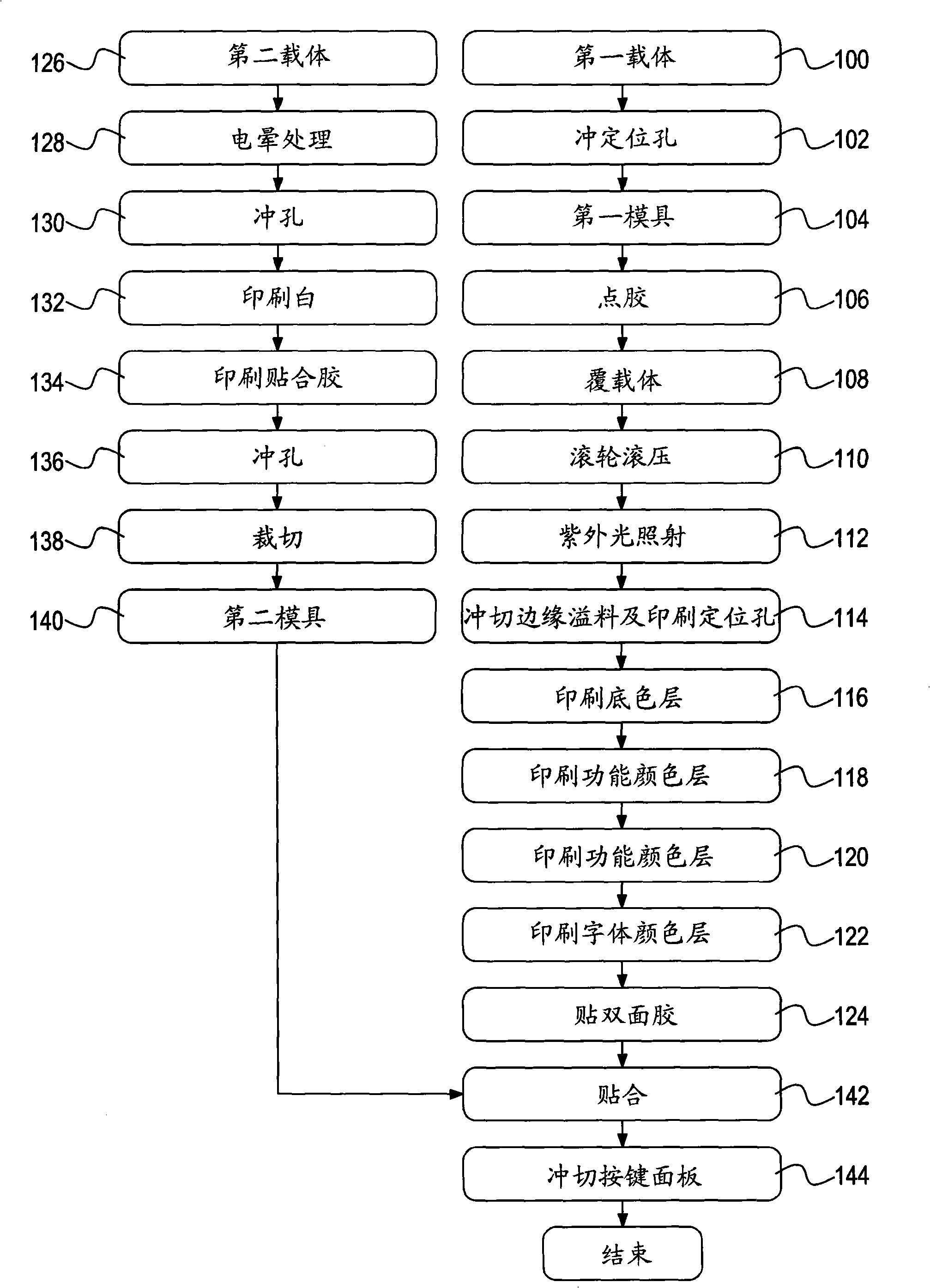

Method for preparing thin type press key panel

InactiveCN101276699AIncreasing the thicknessProduction process increaseElectric switchesUltraviolet lightsRoad surface

A method for manufacturing a thinning keystroke panel including a smooth surface, a misty surface or a grain layer is disclosed, comprising the steps of: at first, manufacturing a first module whose inside bottom surface is coarse surface, smooth surface or grain surface, dropping colloid into the first module and covering a first carrier on the surface of the colloid, using idler wheels to roll and press the first carrier and the colloid so as to be flat within the module; then irradiating with ultraviolet light in order that the colloid is hardened to form a keystroke layer attached to the first carrier, afterwards, on the carrier, sequentially film-forming a bottom colour layer, a functional colour layer and a font colour layer as the background of the keystroke panel; subsequently, manufacturing a second carrier, printing a reflecting layer on the surface of the second carrier, disposing the second carrier and the silicon gel into the second module to be hot-pressed to form an elastic elasticity layer, then bonding the elasticity layer with the keystroke layer to complete the manufacturing of the keystroke panel.

Owner:ICHIA TECH

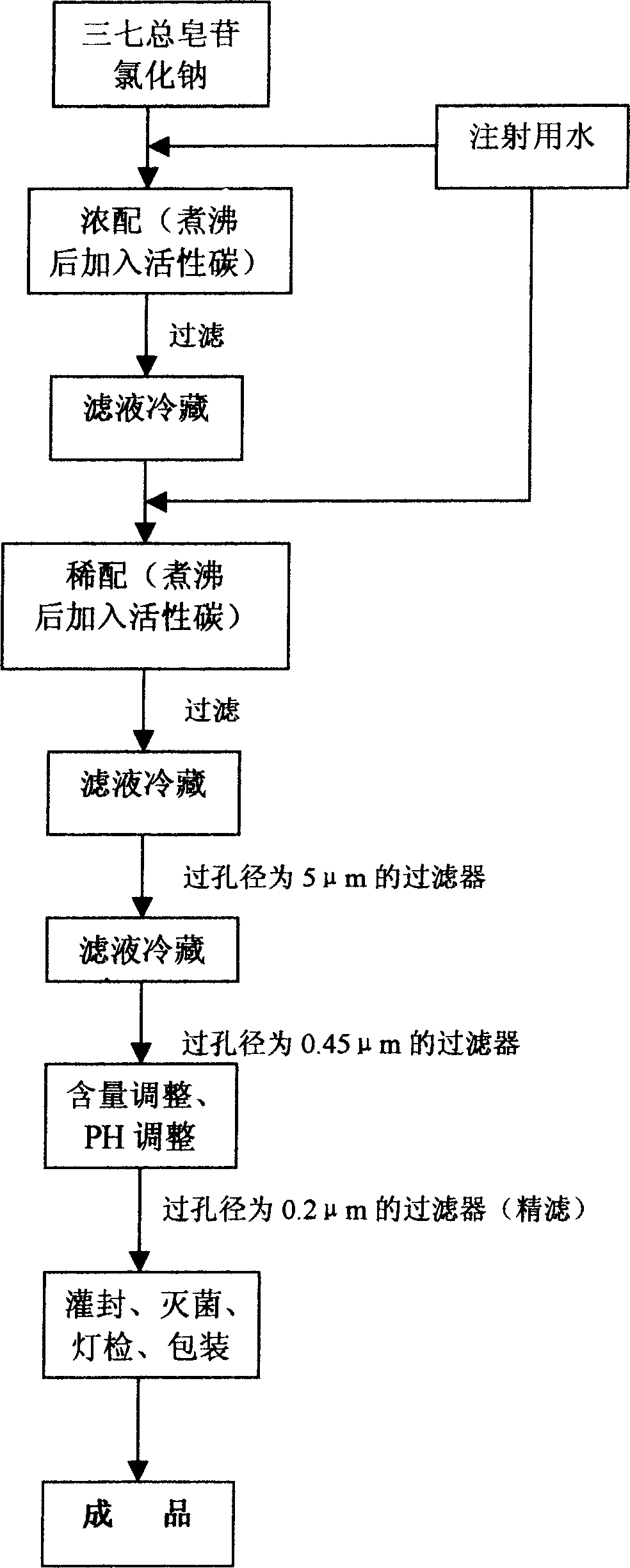

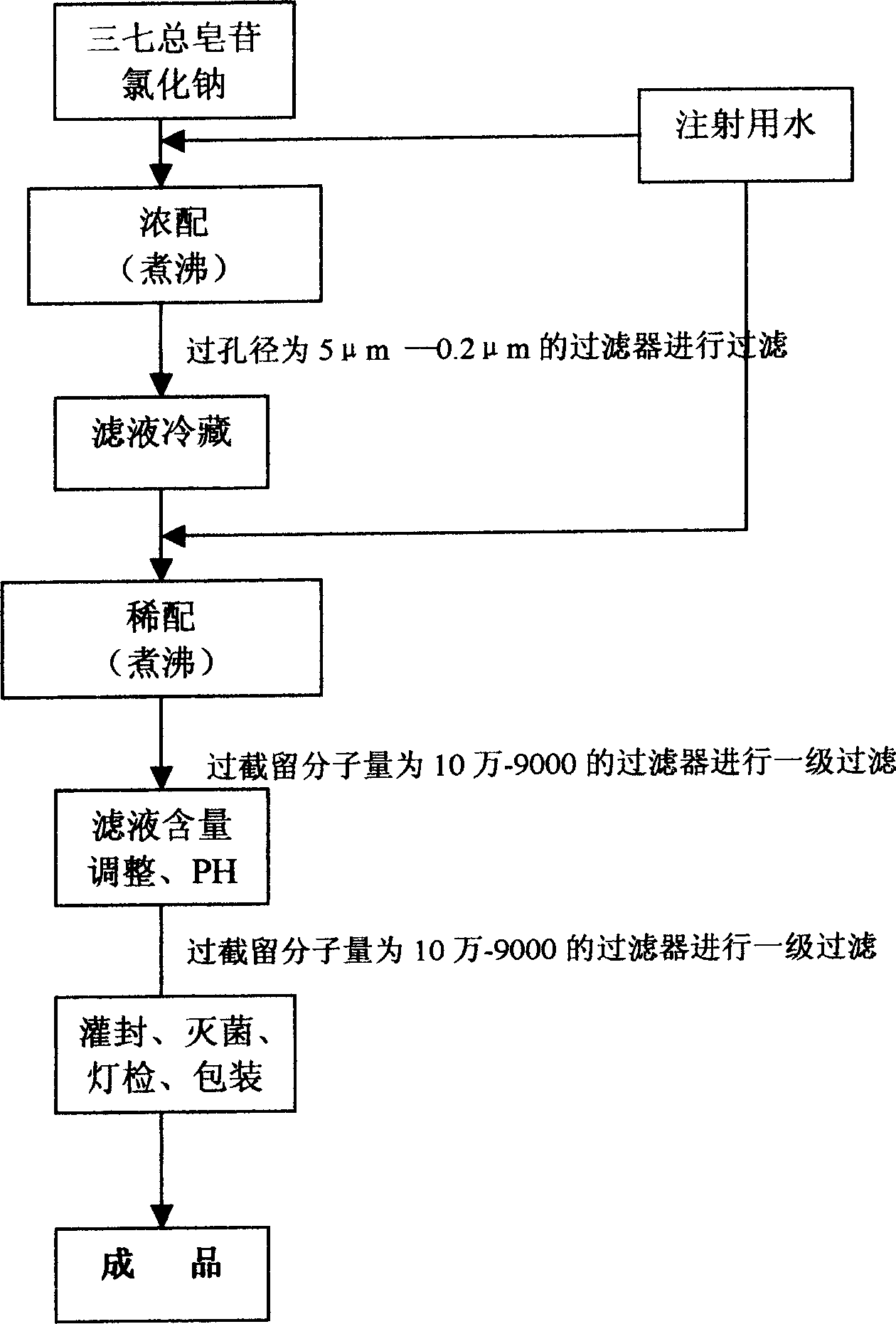

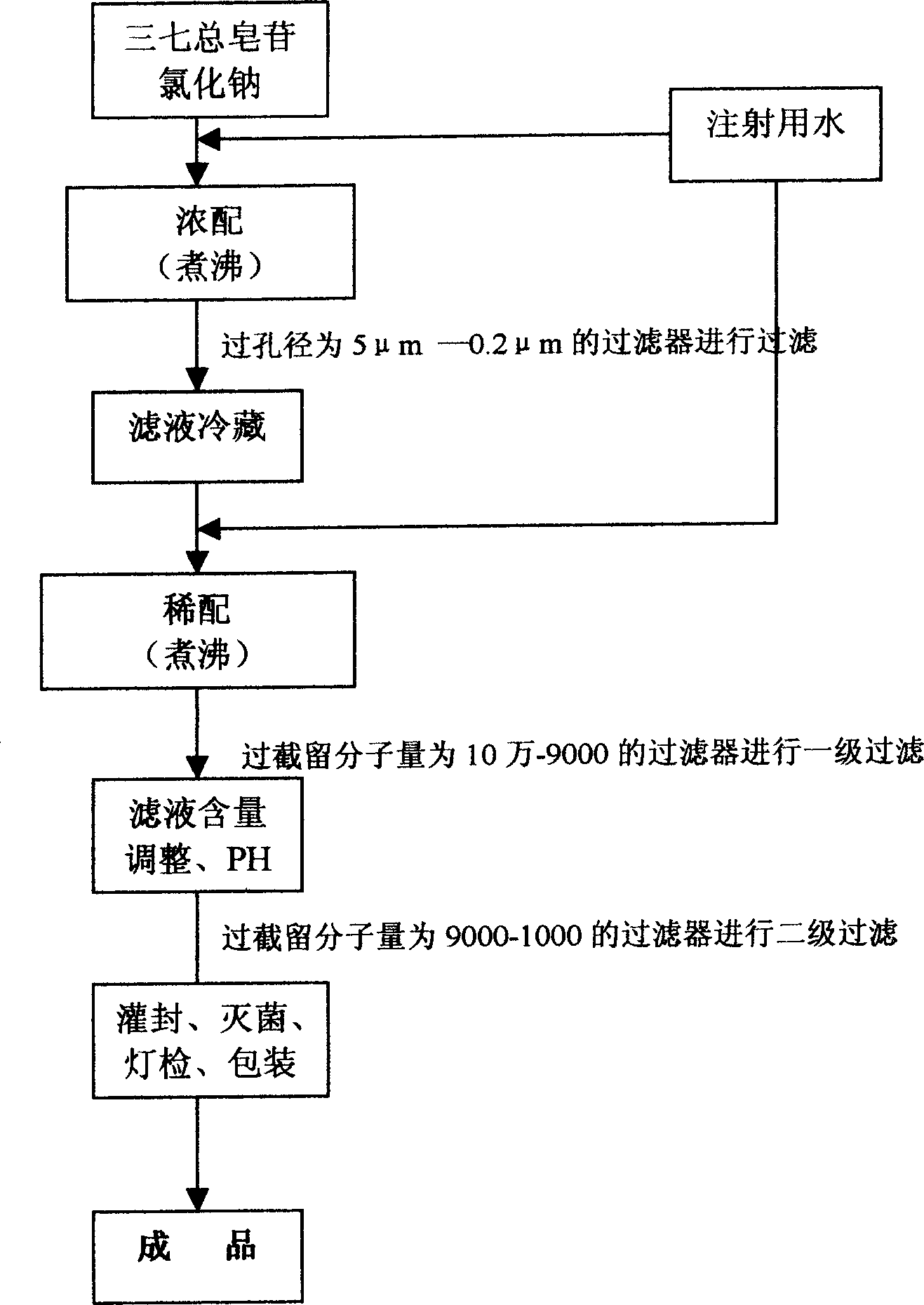

Preparation of Notoginsen triterpenes injection

InactiveCN1546047AImprove protectionAchieve removalOrganic active ingredientsPharmaceutical delivery mechanismMicroorganismTriterpene

The invention discloses a process for preparing Notoginsen triterpenes injection wherein membrane separation method or micro-filtration method are employed in the filtration procedure, based on the soup active ingredient, microorganism and particle diversity, membrane material with interception molecular weight between 1500 to 100000 can be selected to entrap the foreign substance and organism (ineffective composition and pyrogen substances) in the injection by their molecular weight in one or several times.

Owner:YUNNAN PHYTOPHARML

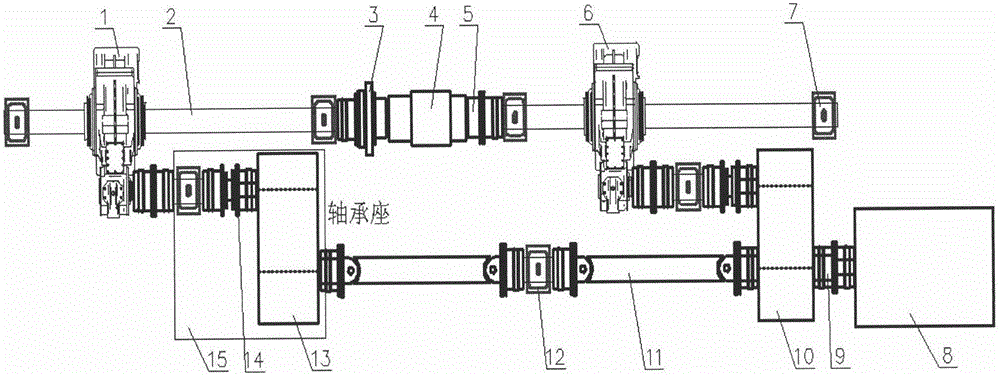

Cylindrical gearbox mechanical closed test bench suitable for any center distance

InactiveCN104535319AHigh reuse rateSolve the need to replace the gearbox with a different connectionMachine gearing/transmission testingDrive motorEngineering

Provided is a cylindrical gearbox mechanical closed test bench suitable for any center distance. If any of a model of a motor, operation speed and a wheel diameter of a gearbox is different from that of another gear box, the models or transmission ratios of the gearboxes are different and accordingly center distances of the gearboxes are different; different connection gearboxes are needed in order to test the gearboxes with different cylindrical gear center distances. The mechanical closed test bench of the novel structure is composed of two cylindrical gearboxes, two connection cylindrical gearboxes, a hydraulic torque loader, a drive motor, two torque meter, a bearing block, a coupler, a shaft, a universal shaft and the like, wherein the two cylindrical gearboxes are completely the same and used for tests and include the tested gearbox and the accompanying tested gearbox, and the two connection cylindrical gearboxes are completely the same. The cylindrical gearbox mechanical closed test bench has advantages of other mechanical closed load test benches, can be suitable for any change of the center distance of the tested gearbox automatically, and has the advantages of being easy and convenient to use, safe and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

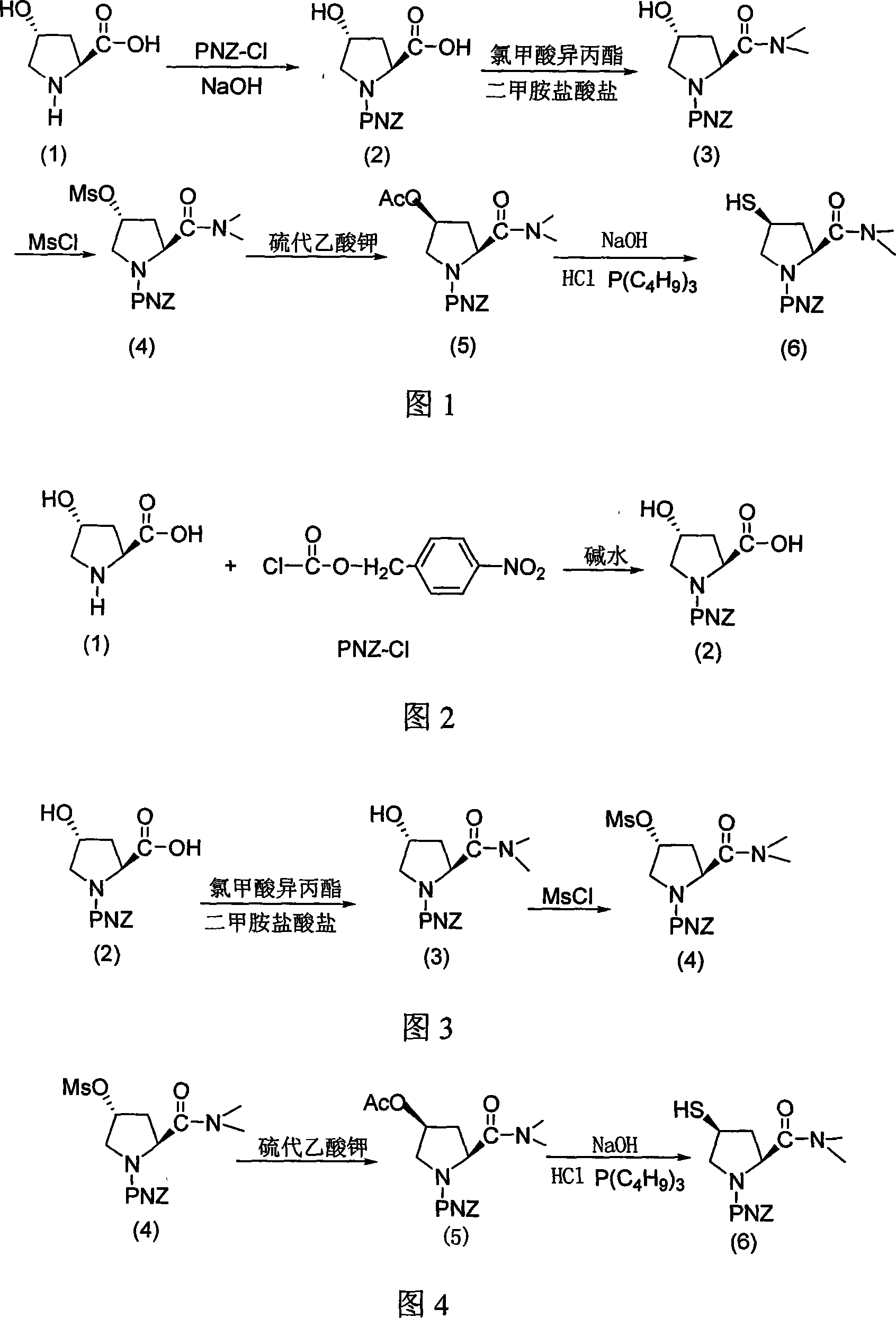

Method for synthesizing meropenem intermediate

InactiveCN101225069ASave man hoursReduce energy consumptionOrganic chemistrySide chainSynthesis methods

The invention provides a synthesis method of a side chain H of a meropenem, which is characterized in that a new radical is introduced respectively for three functional groups of 4R hydroxy L hydroxyproline and a certain spatial configuration is kept. The synthesis method for the side chain H of a meropenem has the advantages of moderate process conditions, stable product quality, and high yield, which is applicable to the industrial production on a large scale.

Owner:TIANJIN JINGYE FINE CHEM

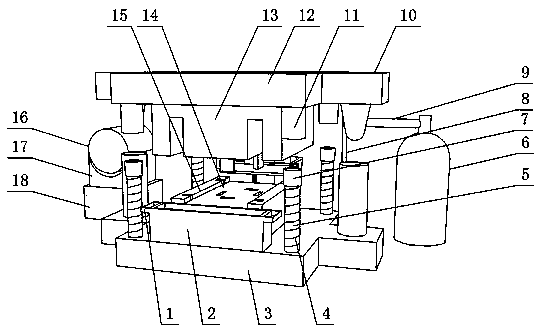

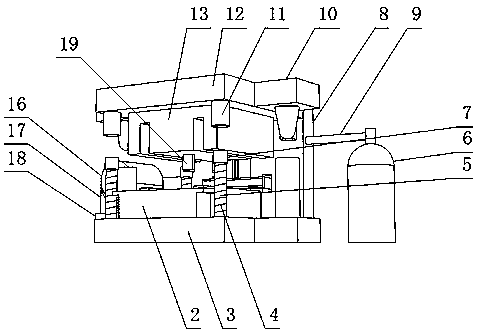

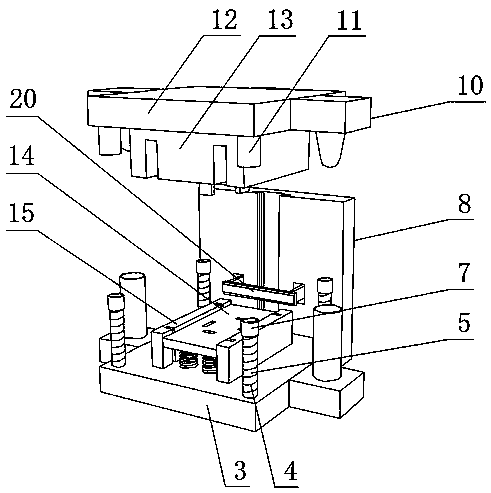

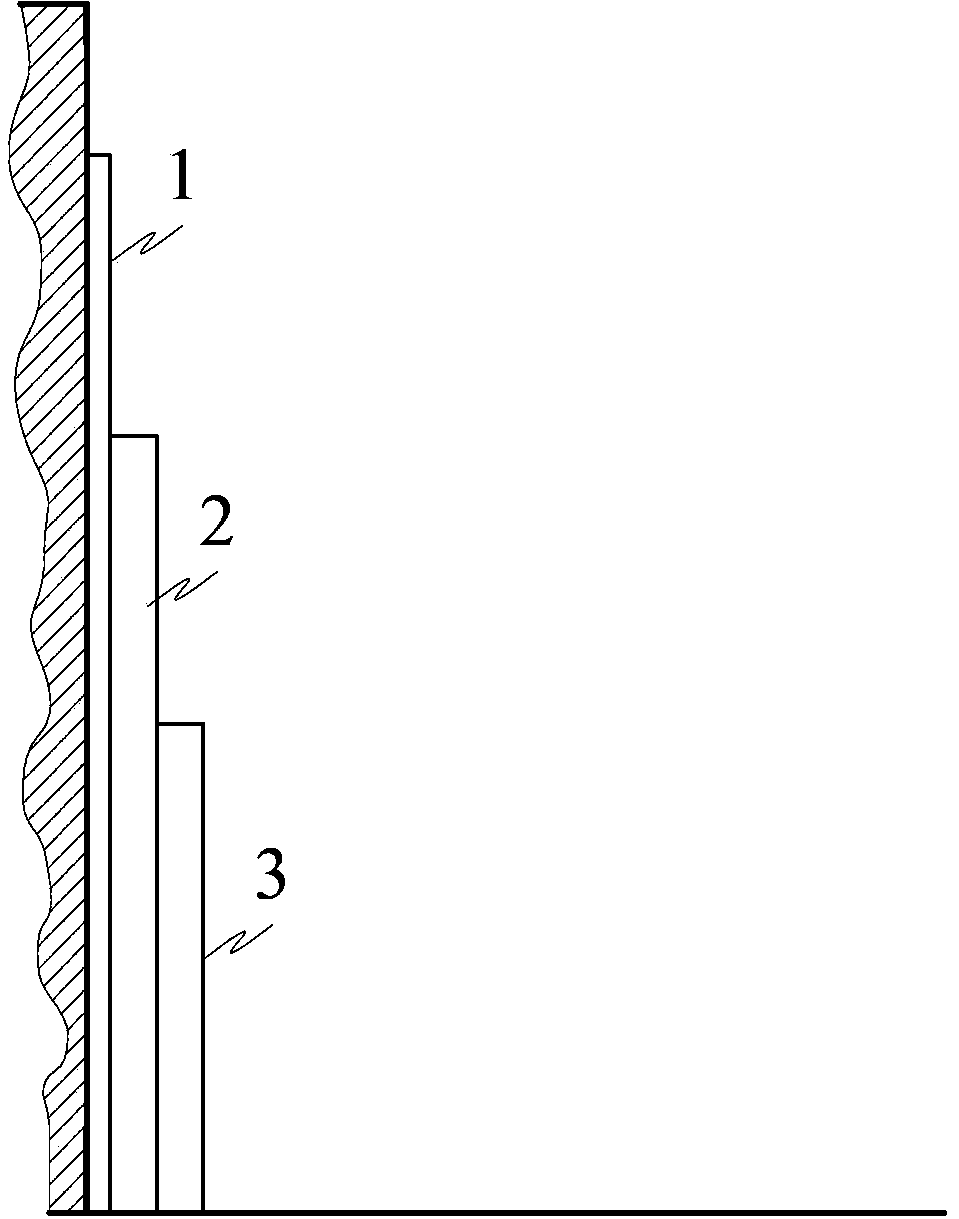

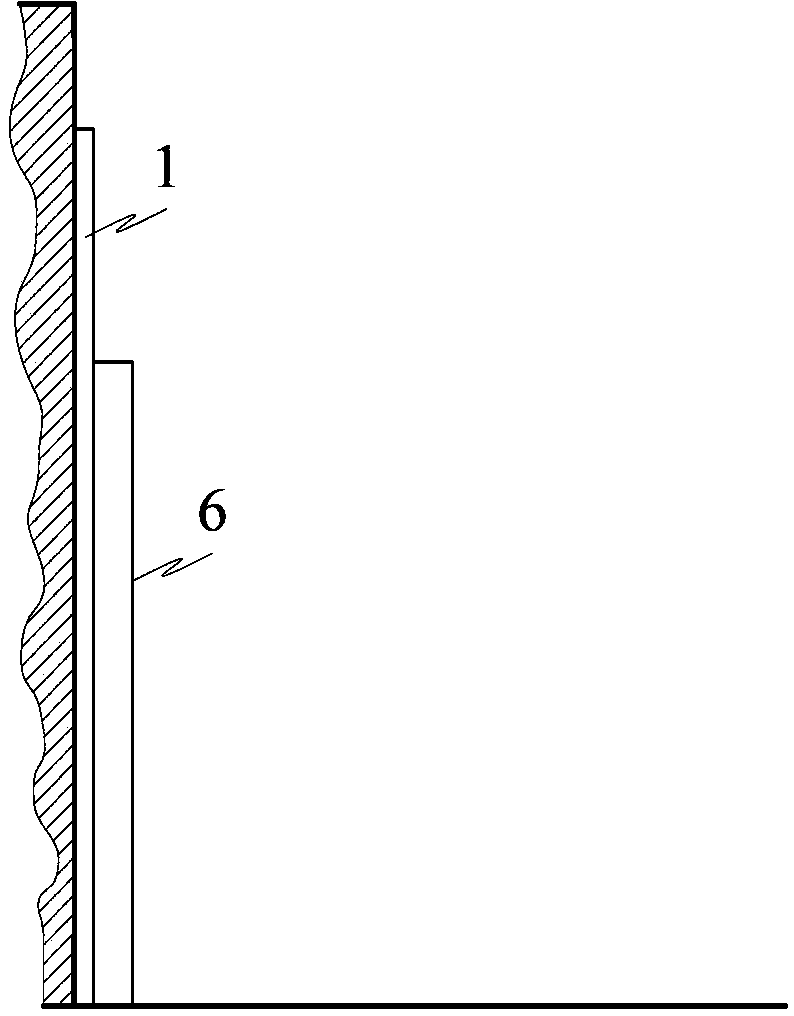

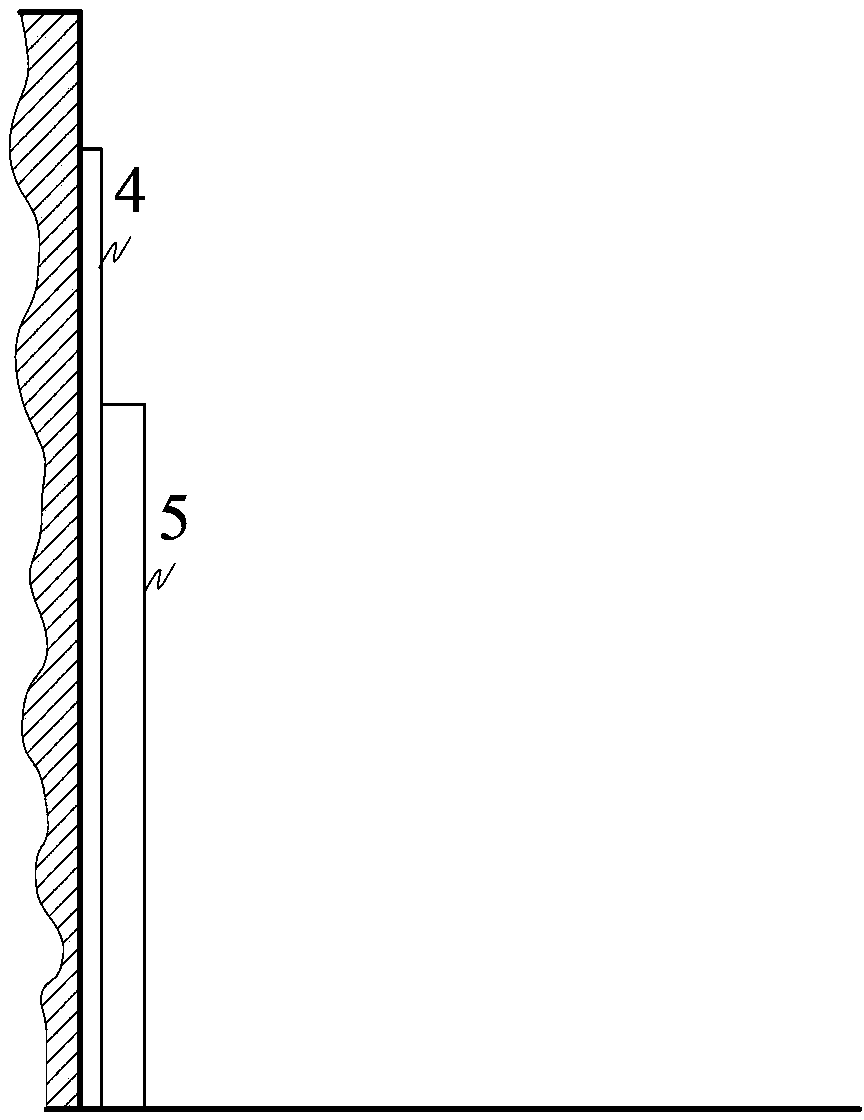

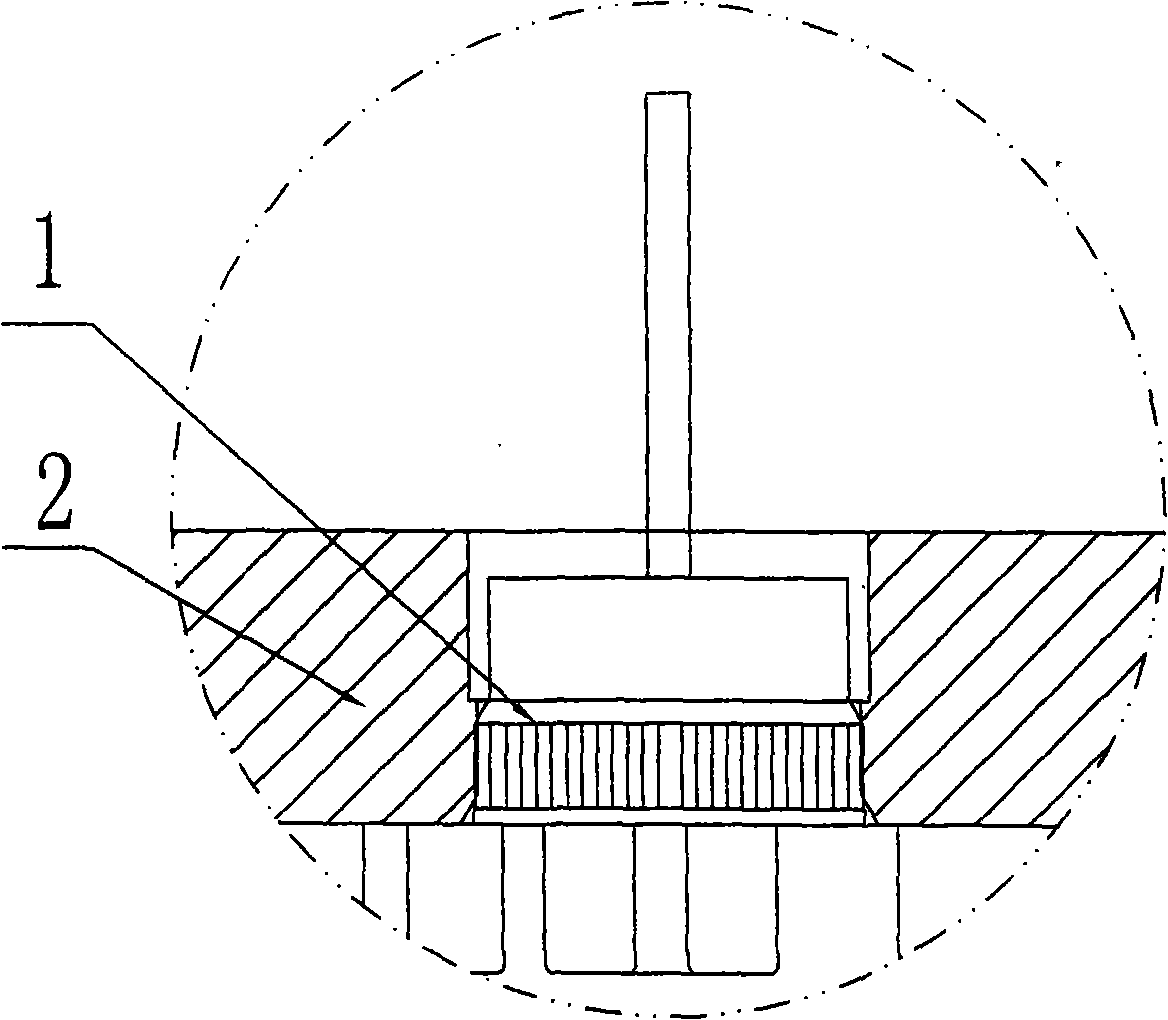

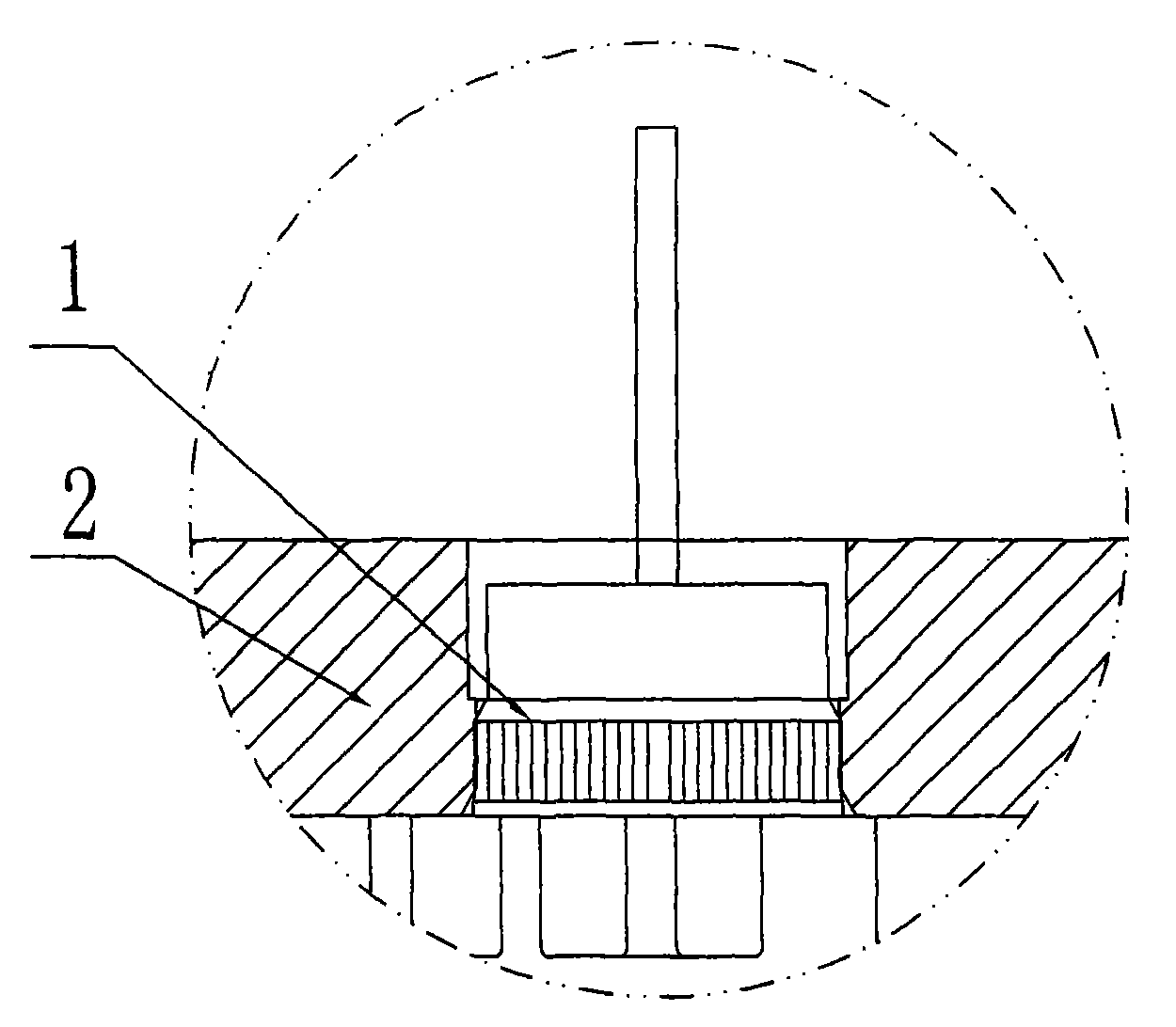

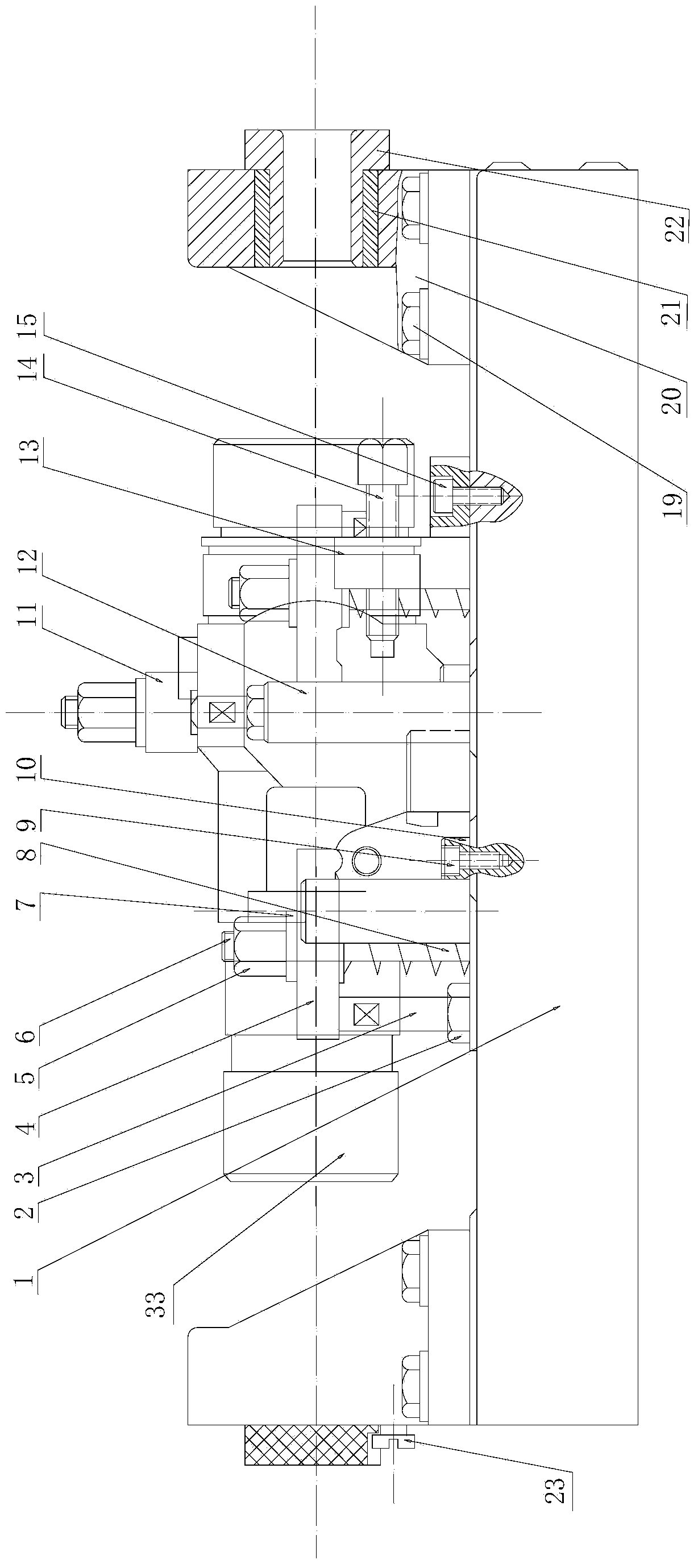

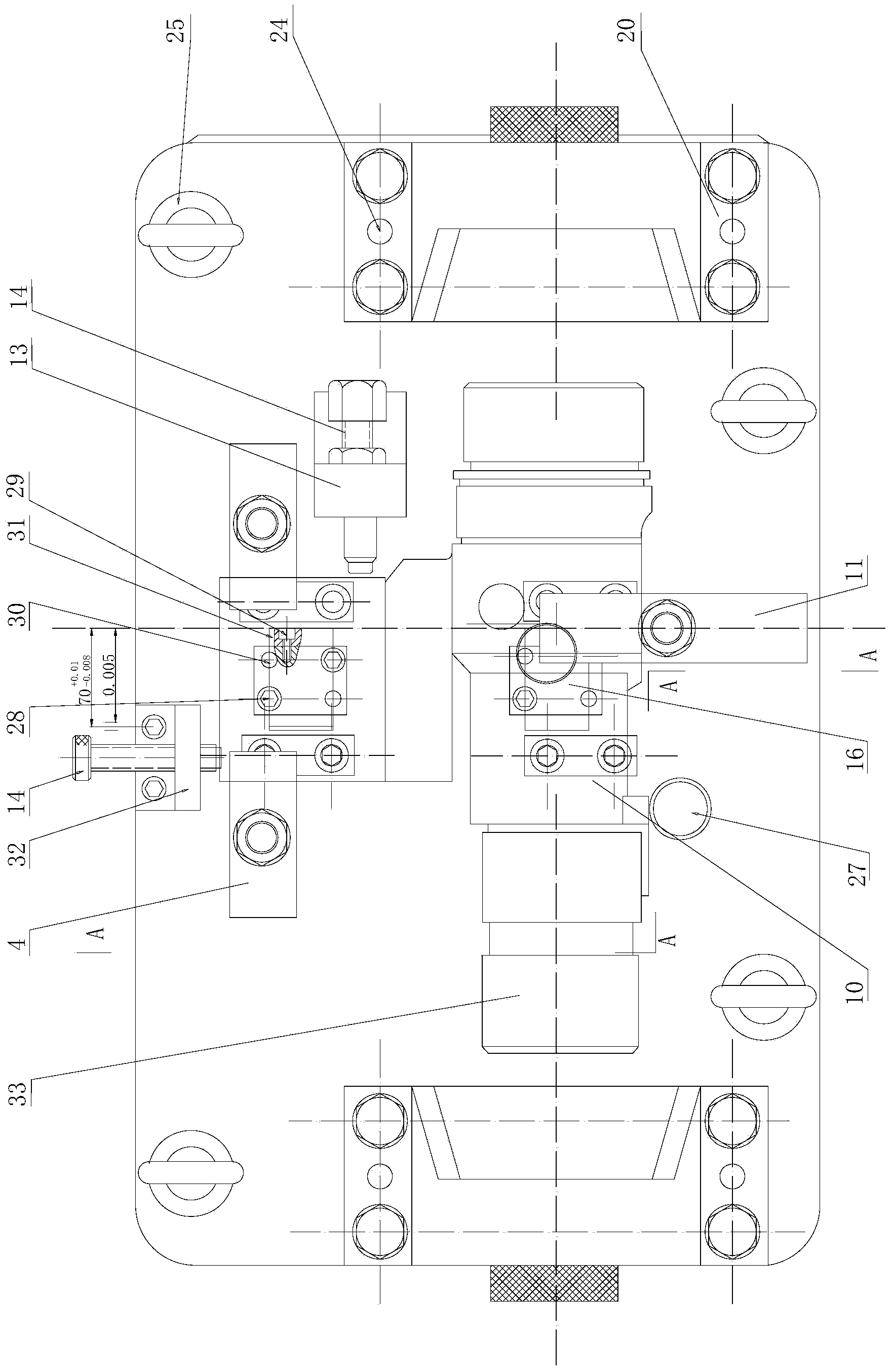

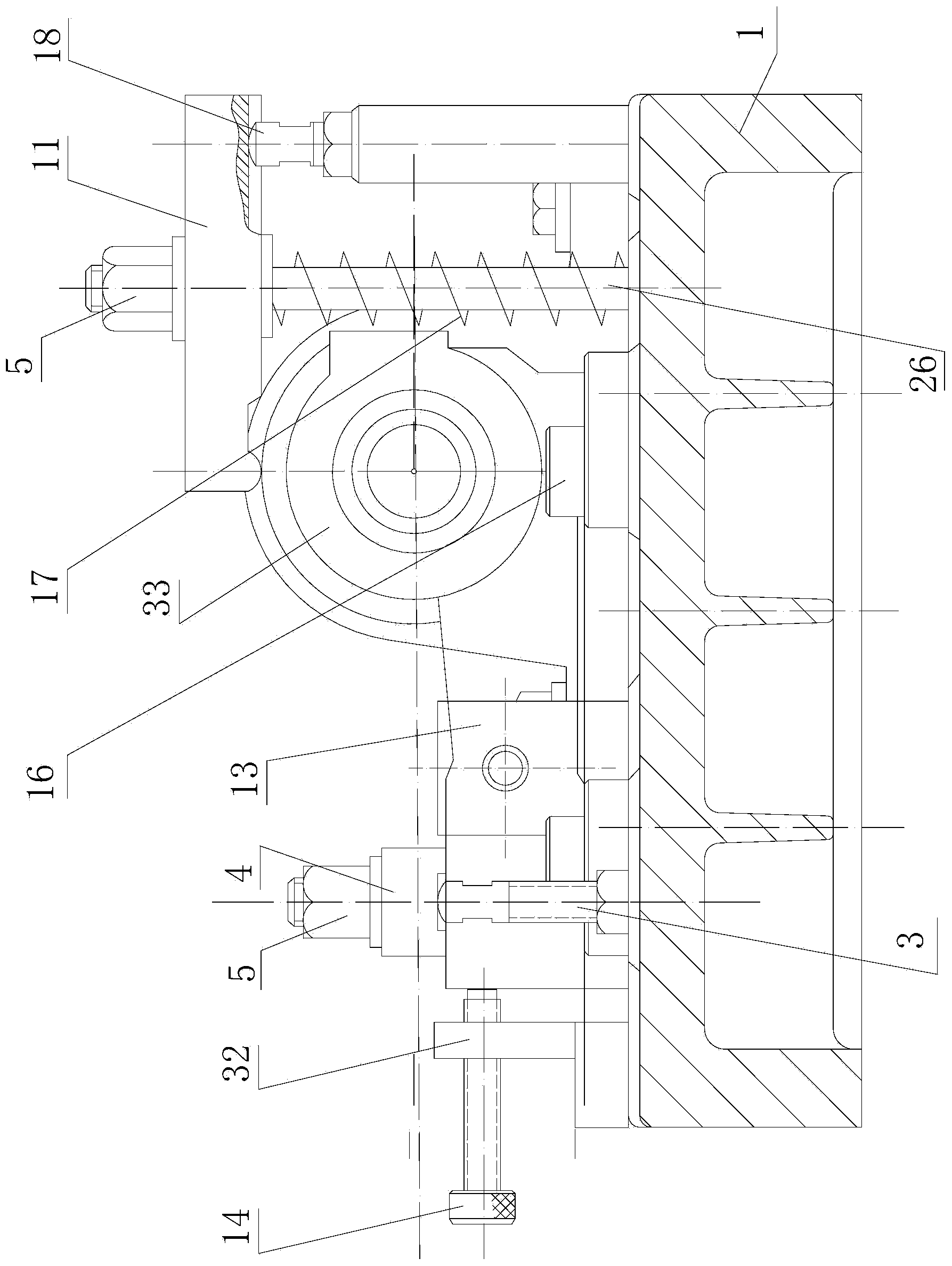

Multi-directional positioning stamping die

ActiveCN108787901APrecise positioningIncrease working hoursShaping toolsEjection devicesEngineeringMechanical engineering

The invention discloses a multi-directional positioning stamping die. The multi-directional positioning stamping die comprises a stamping die body. A die export mechanism is slidably connected to theinner portion of a lower stamping die. One ends of positioning columns are connected with positioning top caps in a sleeved mode, and the outer sides of the positioning columns are connected with first springs in a sleeved mode. One end of a hydraulic tube is connected with a hydraulic tank in a threaded mode. One side of a pushing mechanism is rotatably connected with a vibration motor. A base isarranged at the bottom of the vibration motor, and a base plate is connected to the bottom end of the base in a threaded mode. Through the combined use of a top block, a positioning cone, a positioning cone groove, a partition plate, a positioning cone shell, a second spring and a bottom block, positioning between an upper stamping die and the lower stamping die can be more precise, and the problems that dies after stamping do not meet the production requirements and need to be re-stamped, time and labor are wasted, and the labor hour of staff is increased due to the fact that positioning between the upper stamping die and the lower stamping die is not accurate are solved.

Owner:深圳市联华懿盛实业有限公司

Anticorrosive coating method for electric locomotive

ActiveCN104209257AImprove corrosion resistanceLong-lasting decorativeLiquid surface applicatorsCoatingsBogieLacquer

The invention provides an anticorrosive coating method for an electric locomotive. The method comprises the steps that mechanical pretreatment is performed to the whole surface of the locomotive, and the outer surface of a locomotive body, the outer surface of a cab, the surface of a base frame and the surface of a reversing frame are coated with a heavy anticorrosive coatingprimer; the inner surfaces of the cab and the locomotive body are coated with a heavy anticorrosive coating bottom surface unityprimer; the bottom surface unity primer on the inner surface of the cab is coated with a heavy anticorrosive coating flame retardant and sound insulation paint; primers on the surfaces of the base frame and the reversing frame are coated with a heavy anticorrosive coatingfinish paint; primers on the surfaces of thelocomotive body and the cab are coated with a heavy anticorrosive coatingintermediate paint; intermediate paints on the outer surfaces of the locomotive body and the cab are coated with a heavy anticorrosive coatingfinish paint. The locomotive coated with the method can operate for a long time in a severe corrosive environment, the discharge amount of a service environment volatile organic compound is lower, the coating application property is good, the construction time can be greatly shortened, the production efficiency is improved, the construction cost is reduced, and the paints are not prone to strip.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

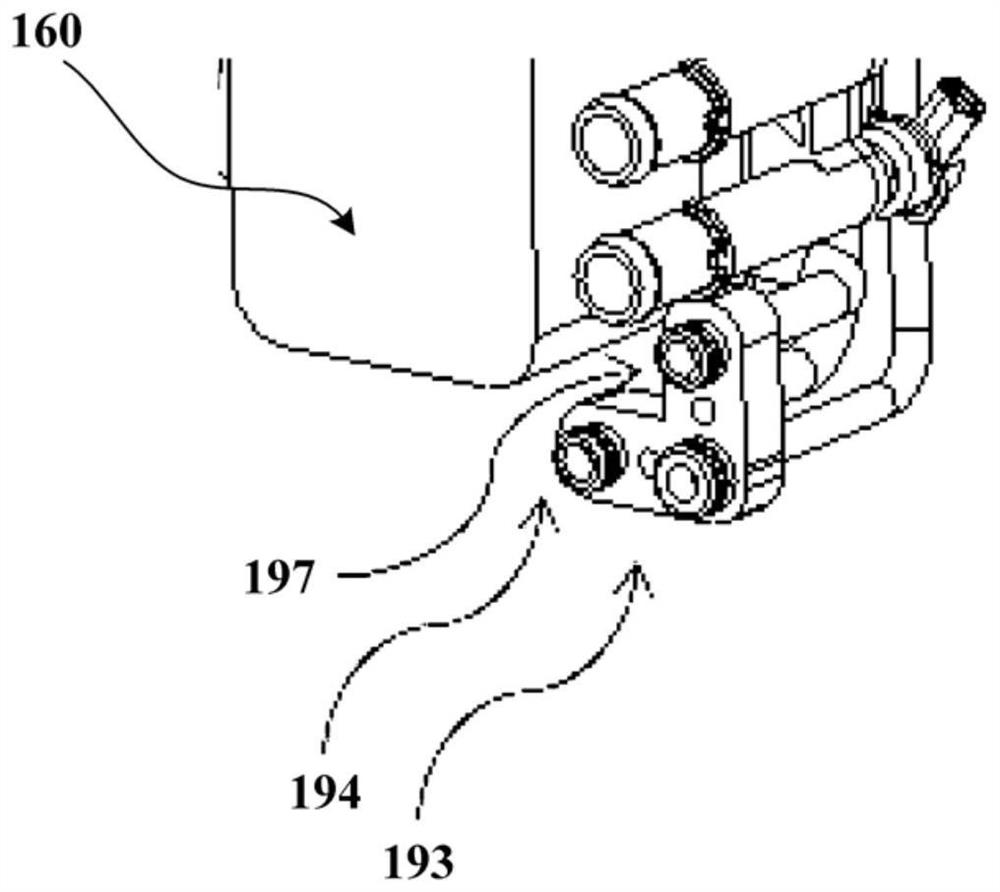

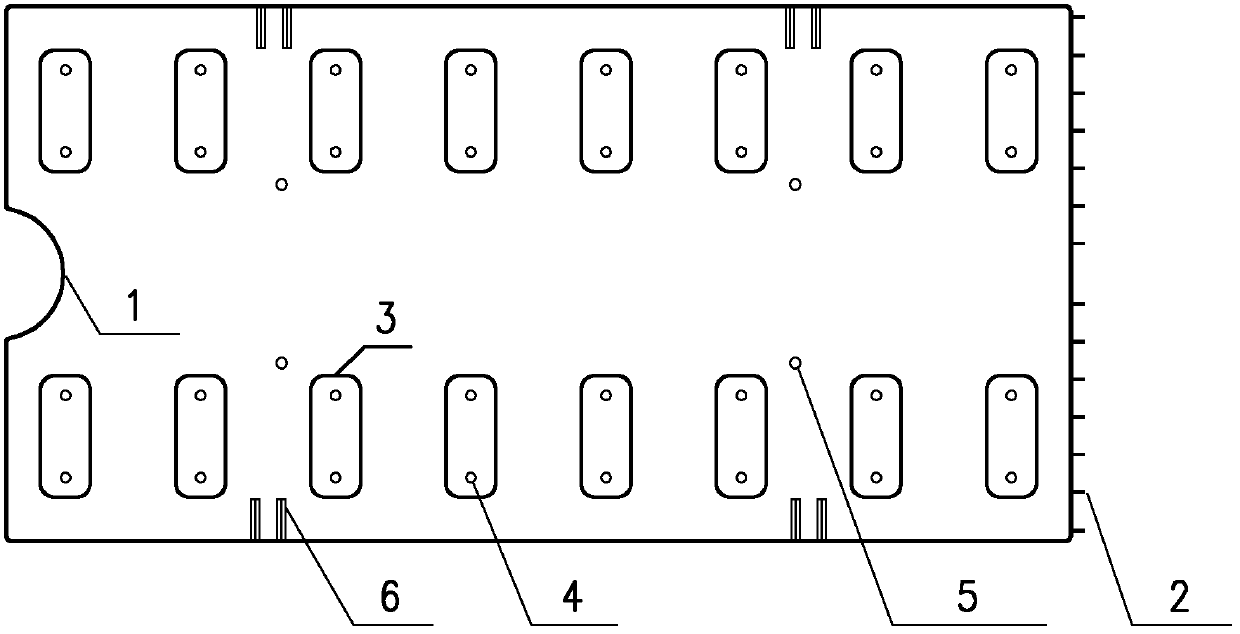

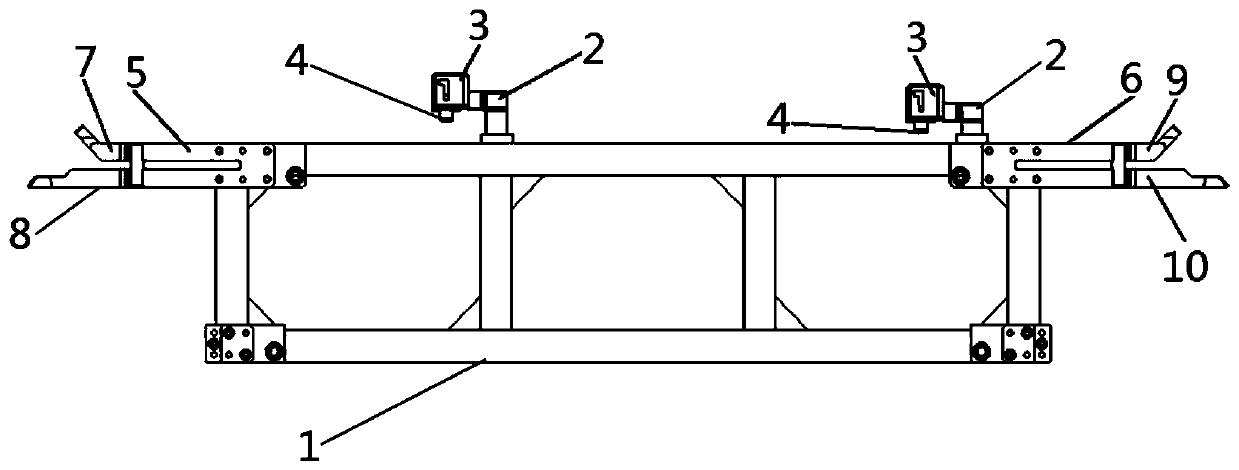

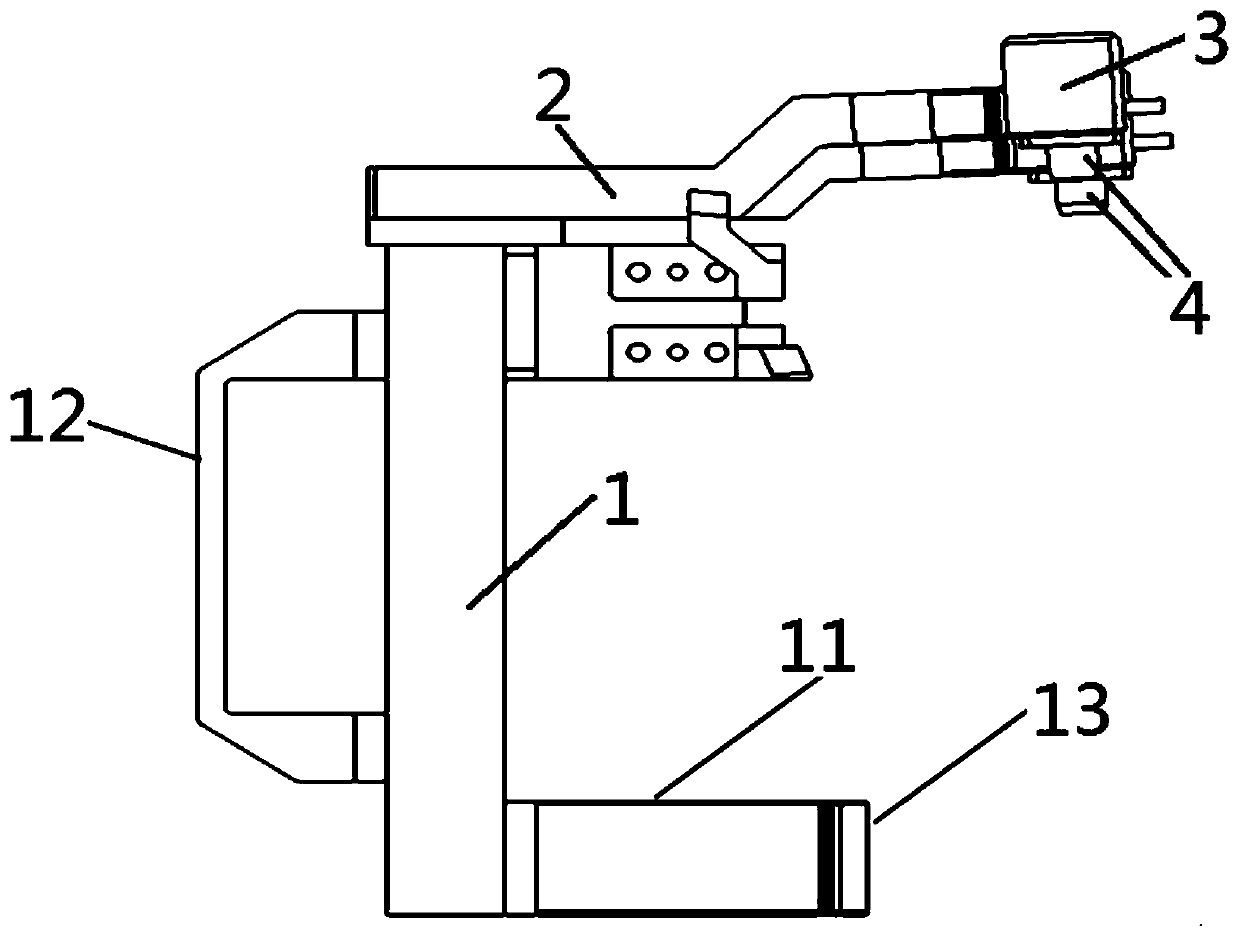

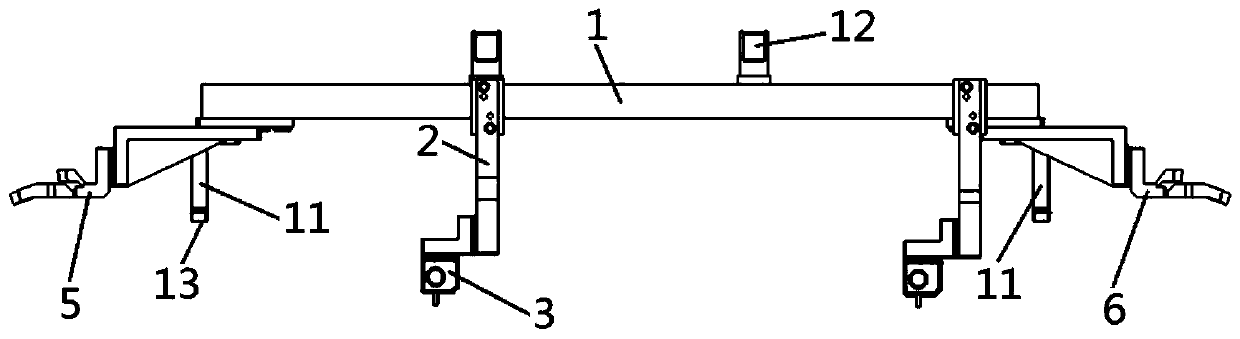

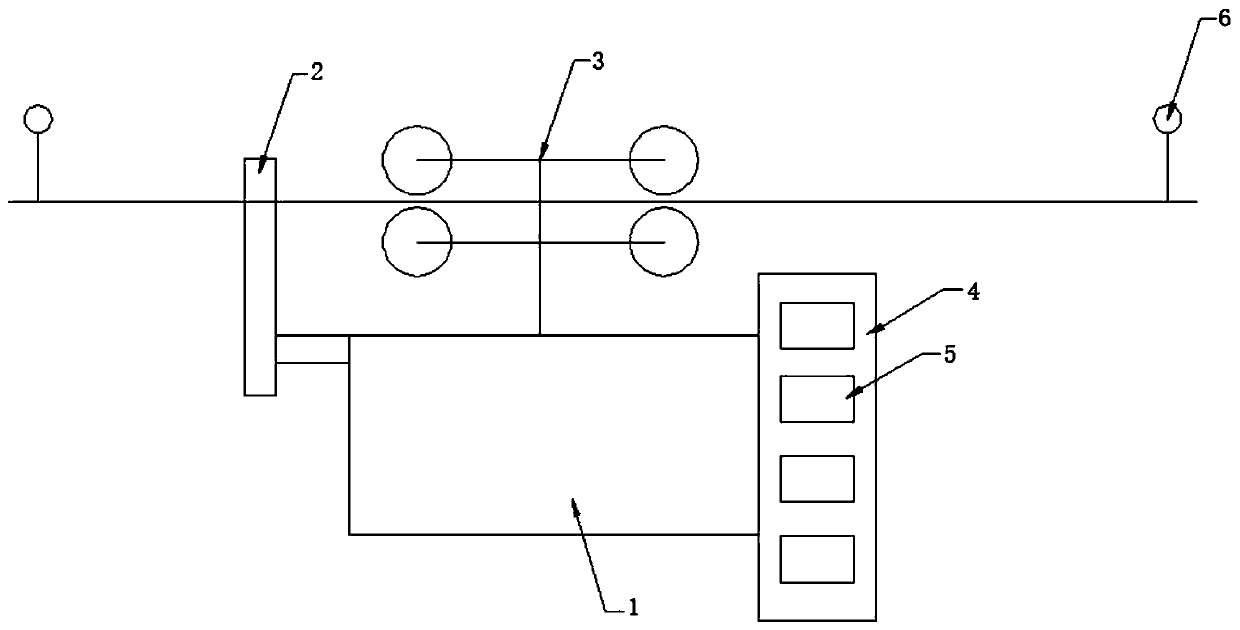

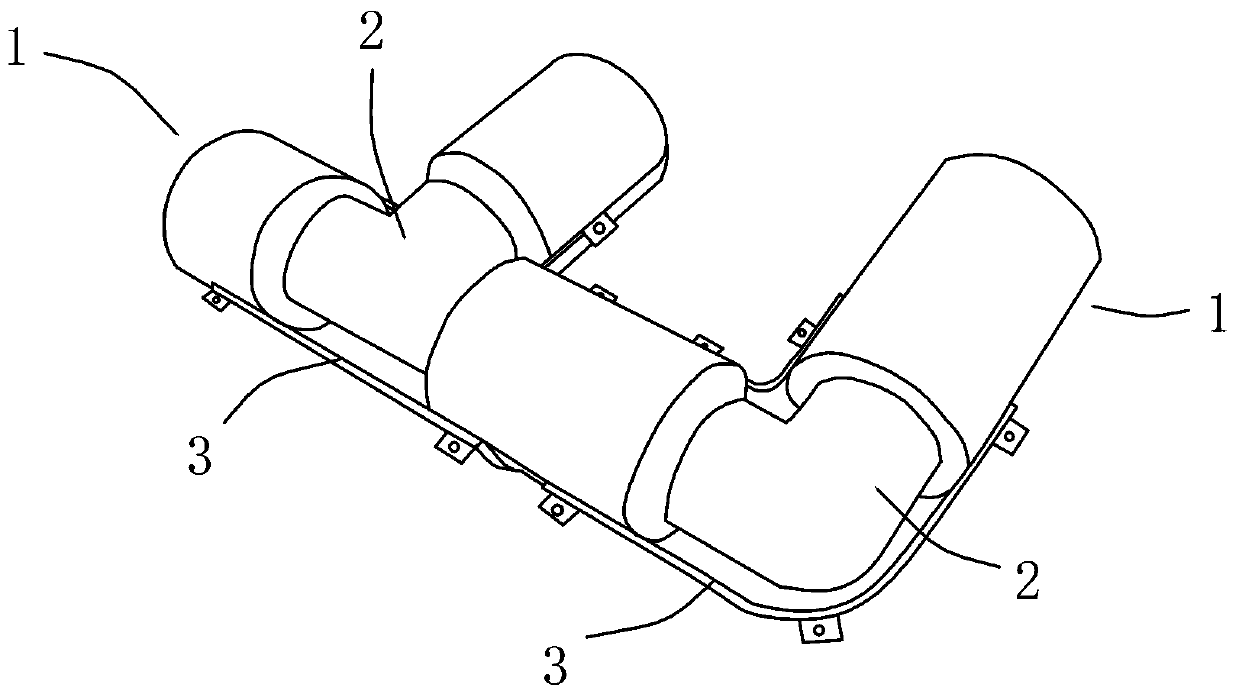

Car headlamp assembling and positioning tool

InactiveCN109823449AImprove assembly accuracyImprove Assembly ConsistencyVehiclesHeadlampEngineering

The invention provides a car headlamp assembling and positioning tool, and belongs to the technical field of car assembly auxiliary tools. Multiple connecting components (2) are arranged on the upperportion of a tool frame (1) of the car headlamp assembling and positioning tool, a car body positioning block (3) is arranged on each connecting component (2), a car body positioning pin (4) is arranged on the lower surface of each car body positioning block (3), a headlamp positioning block I (5) is arranged on one side of the tool frame (1), and a headlamp positioning block II (6) is arranged onthe other side of the tool frame (1). Car body positioning holes in one-to-one correspondence with the number and positions of the car body positioning pins (4) are arranged on the car body. The carheadlamp assembling and positioning tool is simple in structure and low in cost, and it is ensured that the space position of a car headlamp can be accurately positioned when the car headlamp is assembled, so that the assembly size consistency is good, and the labor hour is saved.

Owner:HANTENG AUTOMOBILE CO LTD

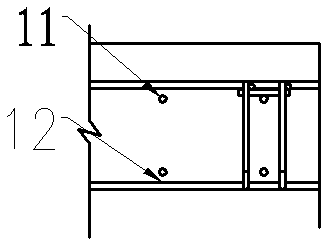

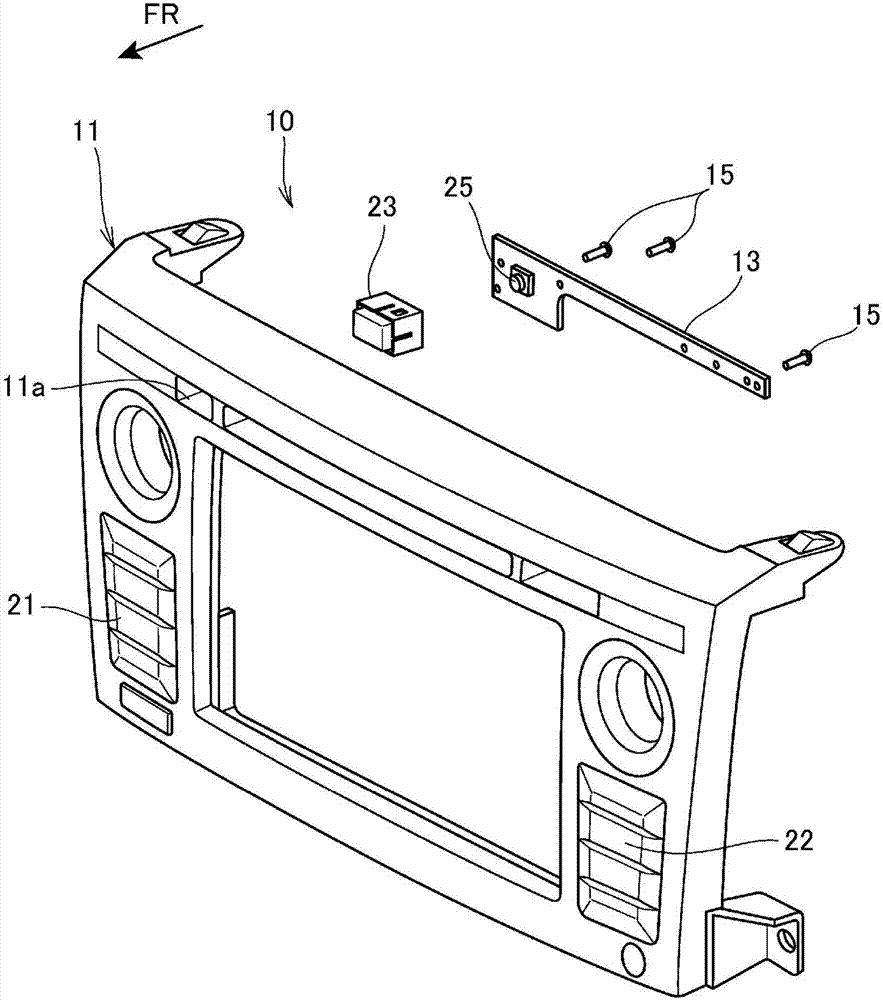

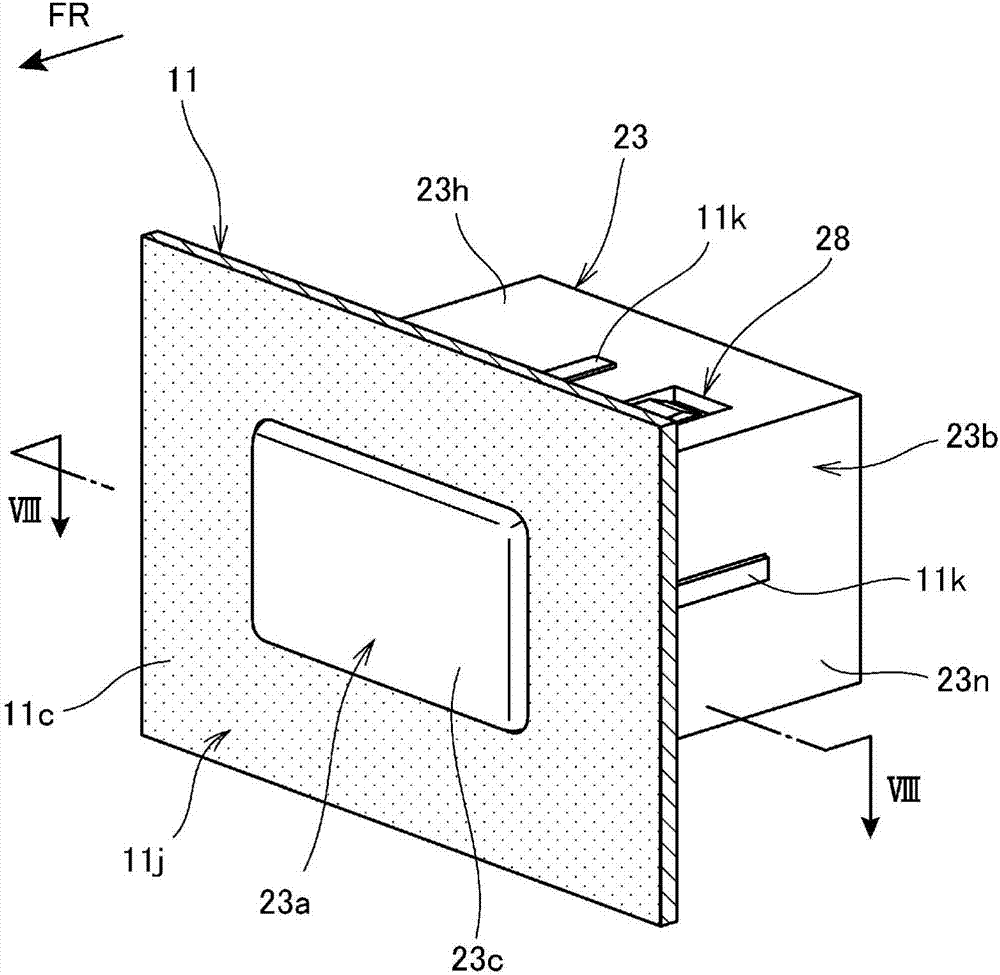

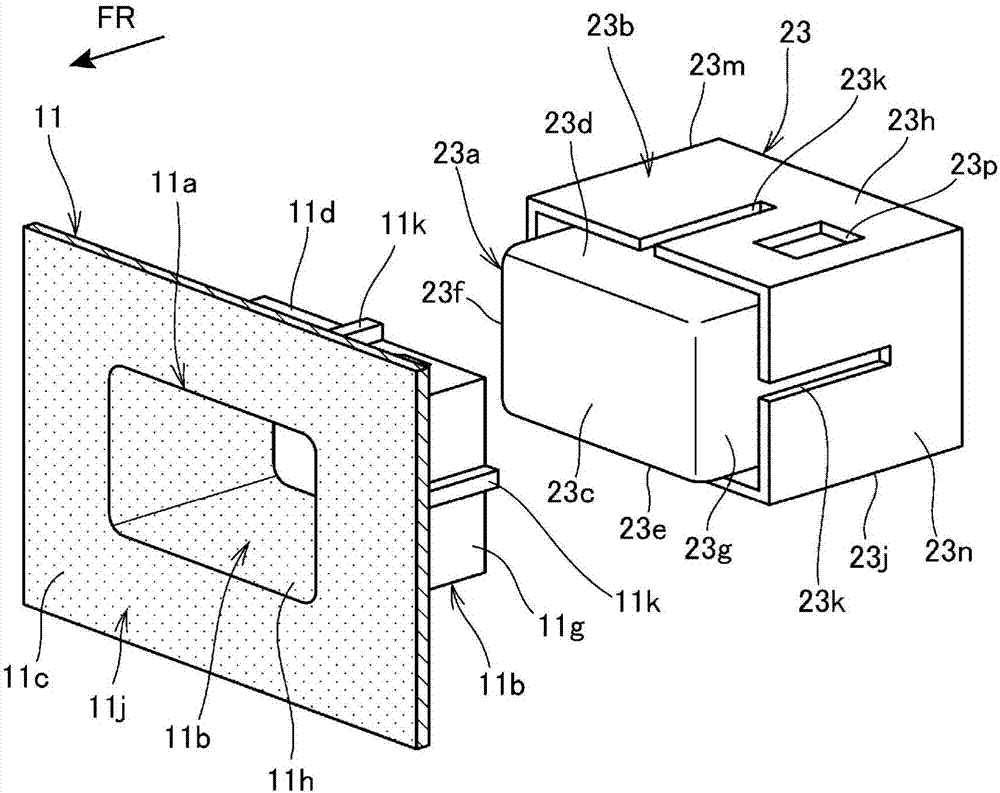

Button guide structure

ActiveCN107077984ALow costIncrease working hoursEmergency actuatorsElectric switchesEngineeringElectronic equipment

Provided is a button guide structure allowing for cost / man-hour reduction and quality improvement. In the button guide structure, a front panel (11) configured on the front side of electronic equipment, or the like, is provided with a push button (23) which is used to operate a switch and is slidable via a guide. The front panel (11) comprises a tube portion (11b) for inserting a portion of the push button (23). The push button (23) comprises a button main body portion (23a) to be inserted into the tube portion (11b), and an outer tube portion (23b) provided so as to surround this button main body portion (23a) while enclosing the tube portion (11b) when the button main body portion (23a) is inserted into the tube portion (11b). A guide portion comprising a rib (11k) and a slit (23k) is provided on the tube portion (11b) external surface (11w) and the outer tube portion (23b).

Owner:CLARION CO LTD

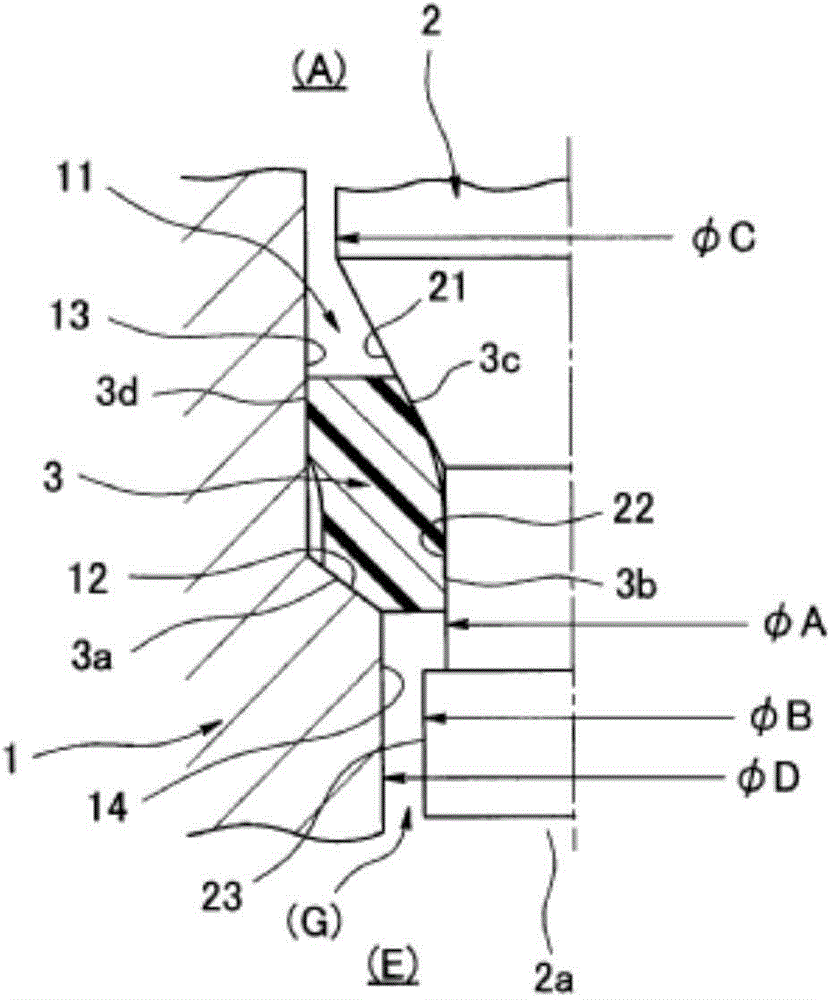

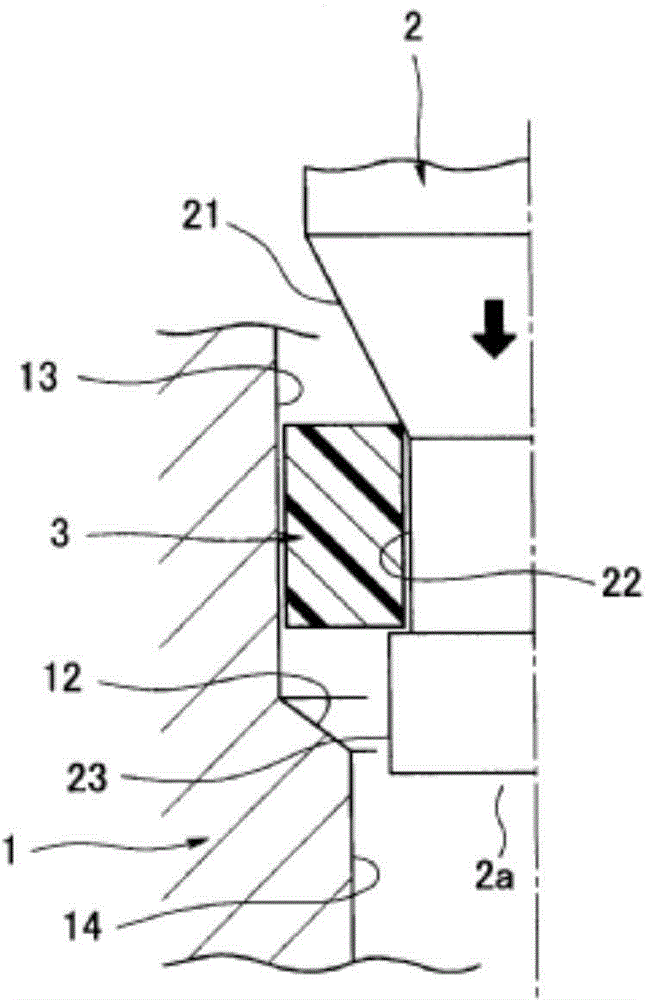

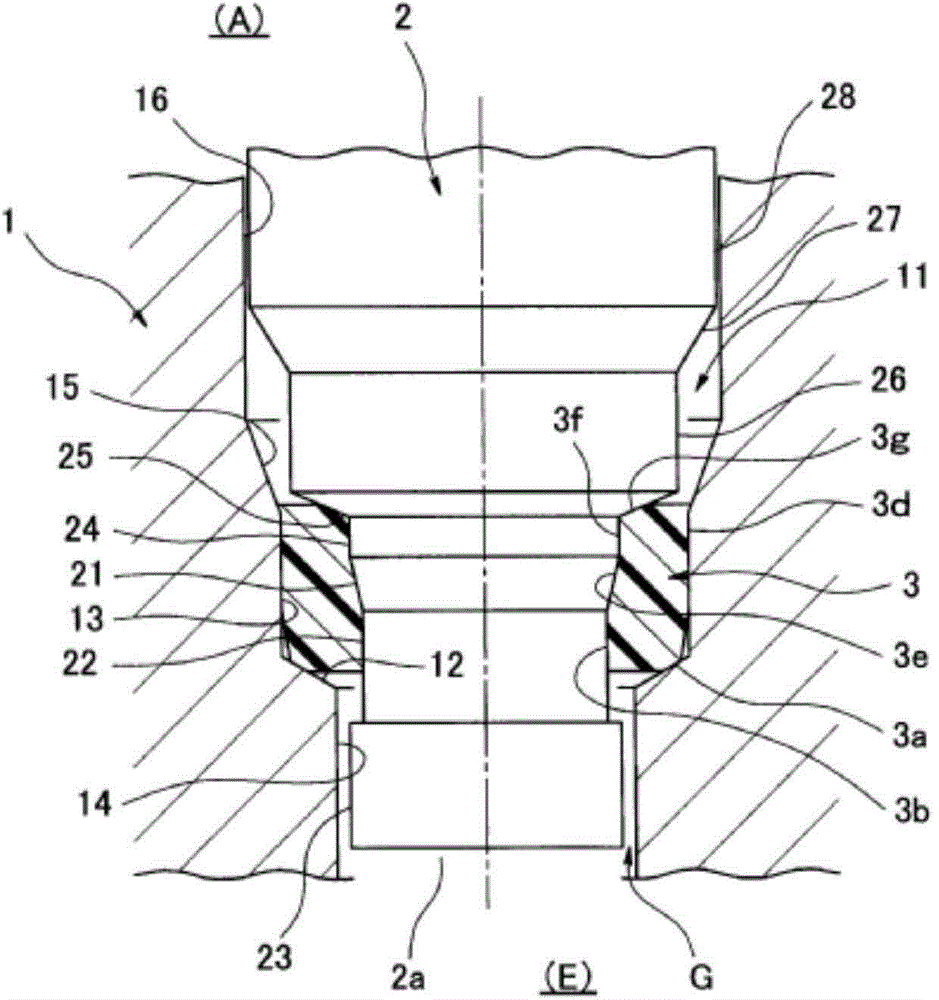

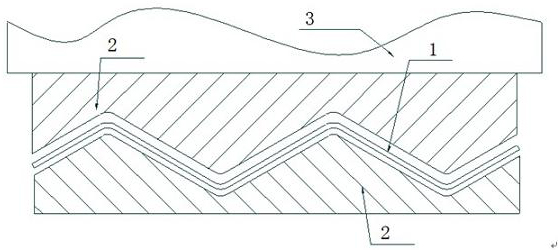

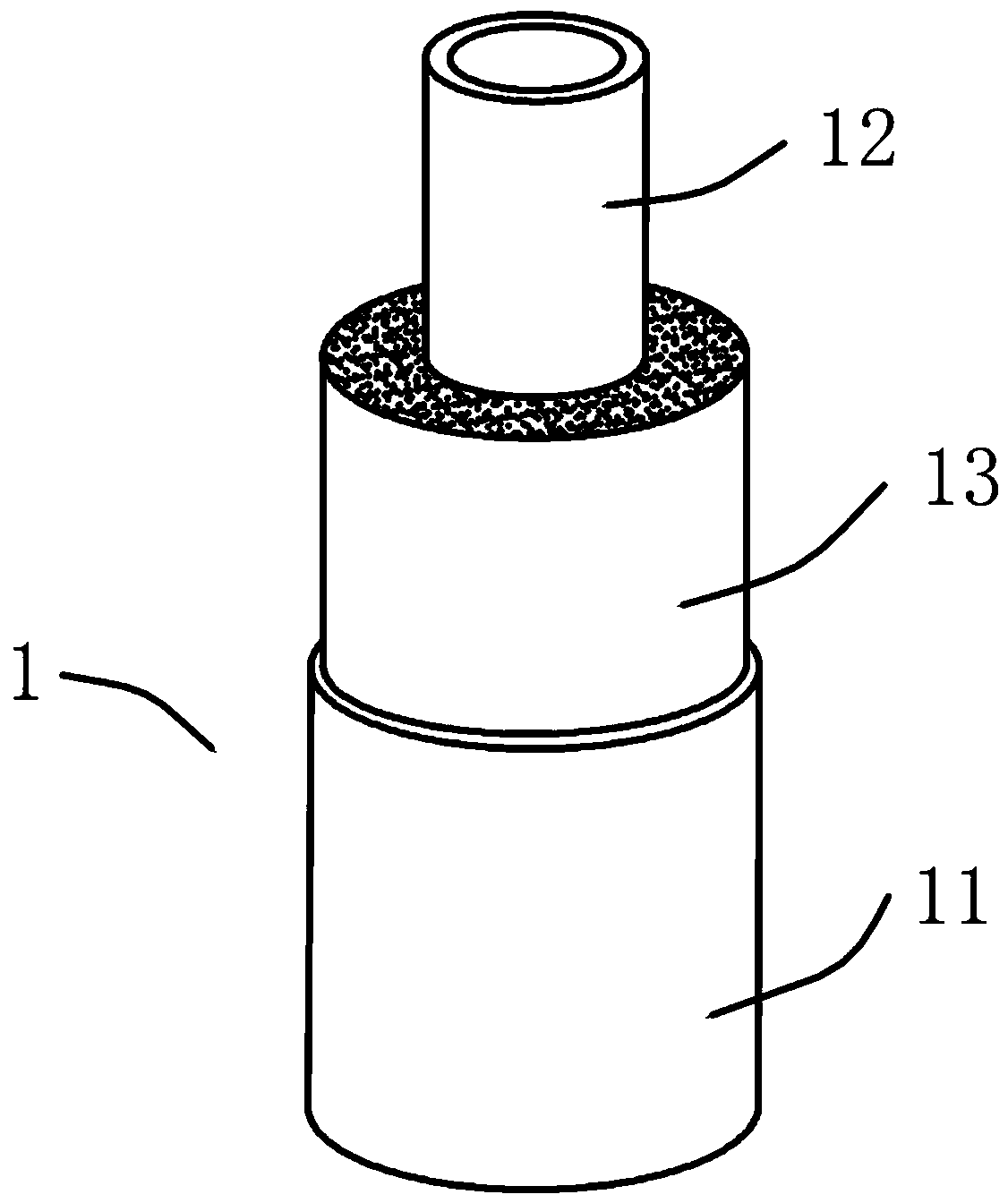

Sealing structure

ActiveCN104541092AImprove sealingIncrease working hoursSleeve/socket jointsEngine sealsMan-hourEngineering

The purpose of the present invention is to provide a sealing structure for which the man-hours for seal ring installation are not high and with which excellent sealing properties can be obtained. To achieve said purpose, a seal ring (3) is interposed between an outer member (1) and an inner member (2) fitted by being inserted in the outer member (1). On the outer circumferential surface of the inner member (2), a tapered outer circumferential surface (21), the diameter of which decreases in the direction of insertion of the inner member (2), and an installation section outer circumferential surface (22) that extends from the small diameter end in the insertion direction are formed. On the inner circumferential surface of the outer member (1), a stepped surface (12) located further in the insertion direction than the tapered outer circumferential surface (21) and facing the direction opposite to insertion and an installation section inner circumferential surface (13) extending from the outer diameter edge of the stepped surface (12) in the direction opposite to insertion are formed. The seal ring (3) is disposed in a compressed state between the tapered outer circumferential surface (21) and installation section outer circumferential surface (22) and the stepped surface (12) and installation section inner circumferential surface (13).

Owner:NOK CORP

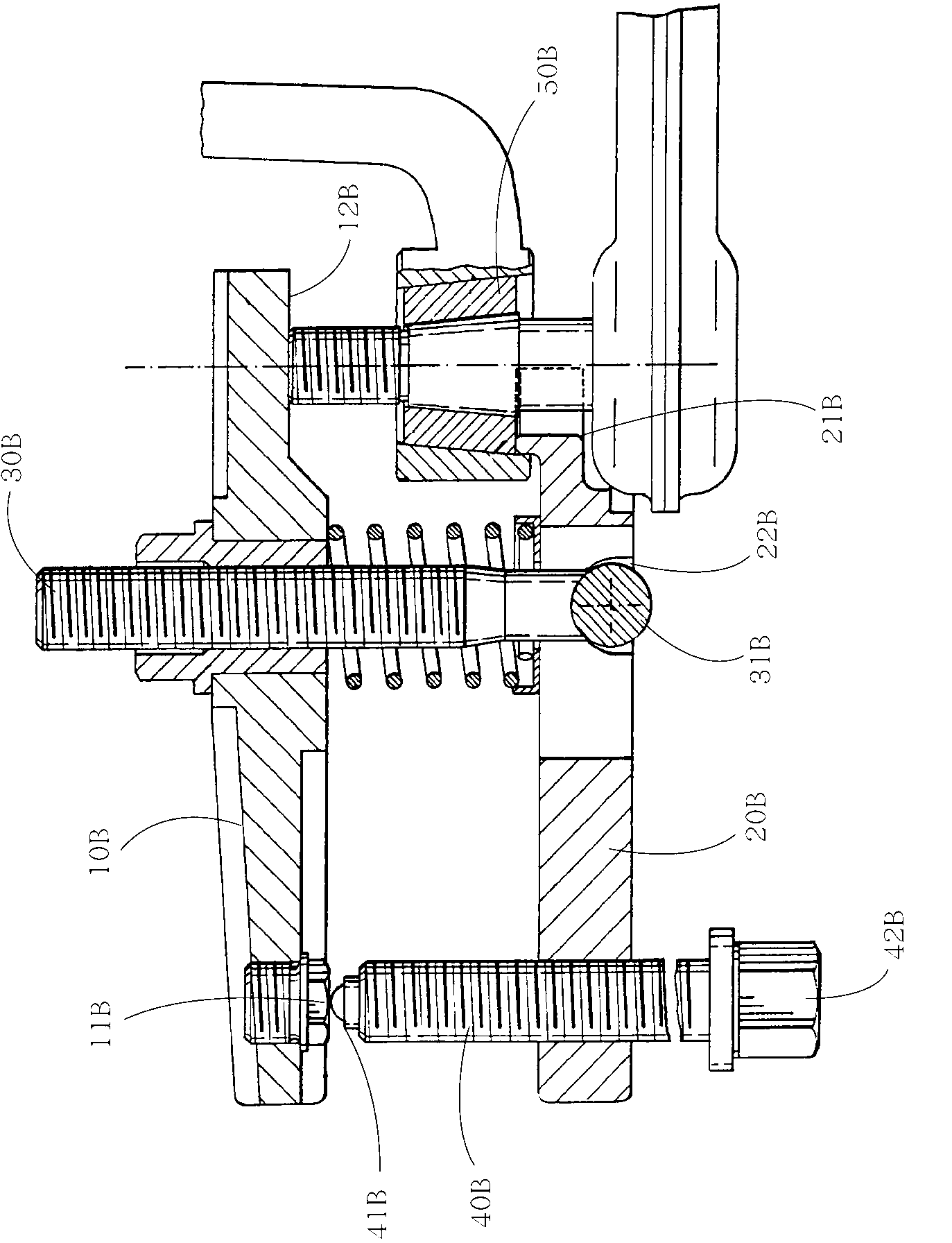

Replaceable removal tool structure

InactiveCN102729200AIncrease working hoursReduce work efficiency problemsMetal-working hand toolsMechanical engineeringEngineering

The invention provides a replaceable removal tool structure, mainly comprising a tool body, a rocker member, and an actively replaceable detent member. One side of the detent member is provided with an upper guide arc edge and a lower guide arc edge which can hang on an upper guide arc portion and a lower guide arc portion of the tool body. And the other side of the detent member which faces an abutting area of the rocker member is provided with a groove-shaped detent portion, and a detent edge is arranged in the detent portion. The detent member of the invention, which is creative in design, can actively combine the tool body on the basis of different specification changes of the detent portion, and can match forms with multiple sizes and specifications so as to enhance the practical use.

Owner:杨仁永

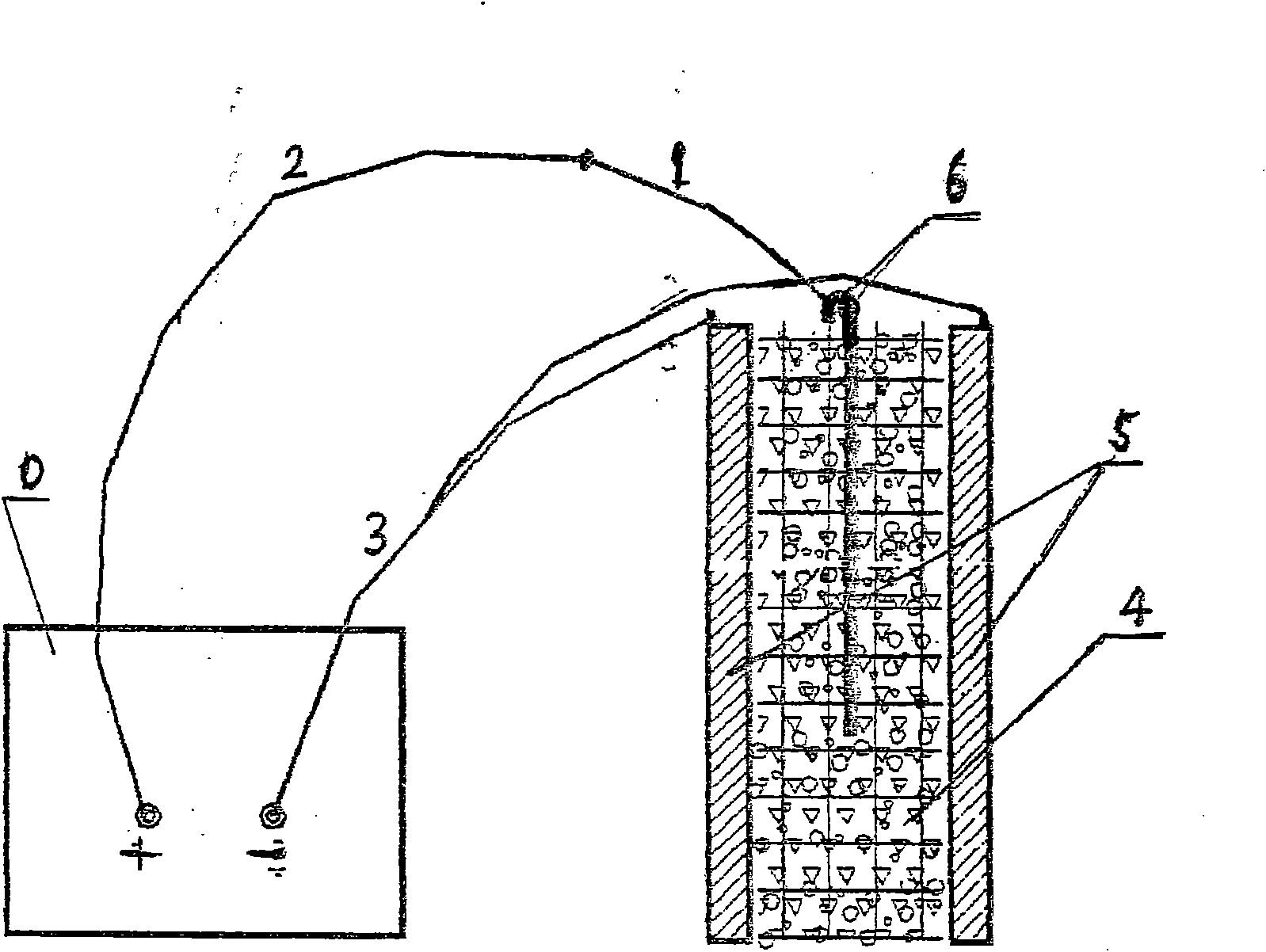

Demoulding method for metal template and cement product

InactiveCN101818569AGuarantee inherent strength and qualityHarm reductionForming/stuttering elementsForm treatmentElectrolysisWater vapor

The invention provides natural demoulding technology for realizing effective isolation of a metal template and the surface of a concrete material product, which comprises that: a conductive surface forming appliance for steel and aluminum metal templates and the like is utilized, metal electrode bars with insulating protective hooks in concrete materials such as newly cast hydrous cement and the like are inserted into a plate in rows, output positive and negative poles of a special power supply device are connected with a system consisting of the electrode bars and the metal templates by leads respectively, the electrolytic action is produced in the concrete material clamped by the electrode bar and the metal template when the concrete material is poured into the plate and the plate is powered on, and a water vapor mixing layer is produced between the metal template and the concrete material. Compared with a large amount of conventional harmful solvent type demoulding agent which only meets disposable use, the invention provides a simple, convenient, effectively, low-carbon and environmentally-friendly demoulding method with the advantages of simplified process, low cost, high work efficiency, no pollution, long efficiency and long service life or long-term use for performing construction by using the forming appliance for the templates and the like and producing the concrete material products such as cement and the like.

Owner:龚文跃

Assembling structure of diode of rectifier and heat-radiating plate for automotive

InactiveCN102064147AGuarantee working reliabilityIncrease contact areaAc-dc conversion without reversalSemiconductor/solid-state device detailsEngineeringCopper

The invention discloses an assembling structure of a diode of a rectifier and a heat-radiating plate for an automotive, comprising the diode and the heat-radiating plate. The assembling structure is characterized in that the heat-radiating plate is provided with a through hole needed by press mounting; the diode adopts a copper base structure with a circumferential surface provided with straight lines; and the diode and the heat-radiating plate are pressed and mounted together in an interference way through the through hole. The invention has the advantages of effectively simplifying the process, reducing the defective index, also enhancing the heat-radiating effect of products and enhancing the reliability of the products.

Owner:阚勇

Boring clamp for machining gear milling machine special-shaped oil cylinder and machining method

InactiveCN103522097AGuaranteed tightnessGuaranteed positionPositioning apparatusBoring/drilling componentsEngineeringMachining process

The invention relates to a boring clamp for machining a gear milling machine special-shaped oil cylinder and a machining method. The boring clamp is characterized in that the boring clamp comprises a clamp base, supporting plates arranged on the clamp base and a locating frame arranged between each set of supporting plates, wherein locating supporting plates matched with rectangular grooves in the bottom of the special-shaped oil cylinder are mounted on the locating frames; the boring clamp comprises a first screw frame and a second screw frame which are mounted on the upper end face of the clamp base, the first screw frame corresponds to one side face of the rectangular body of the special-shaped oil cylinder, the second screw frame corresponds to the other side face of the rectangular body of the special-shaped oil cylinder, and the first screw frame and the second screw frame are provided with first adjusting screws and boring rod supports, wherein the boring rod supports are symmetrically arranged on the two sides of the upper end face of the clamp base; the boring clamp further comprises locating pins, a pressing plate used for pressing the periphery of the special-shaped oil cylinder and a rectangular body upper end face pressing plate. The boring clamp has the advantages that machining precision and production efficiency of holes of the special-shaped oil cylinder can be greatly improved, and operation is simple, aligning only needs to be conducted at one time when the boring clamp is used for machining a batch of workpieces, and the boring clamp is especially suitable for production of batches of special-shaped oil cylinders; the special-shaped oil cylinder can be prevented from being deformed in the hole machining process, and geometric dimensioning precision of the machined special-shaped oil cylinder can be guaranteed.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

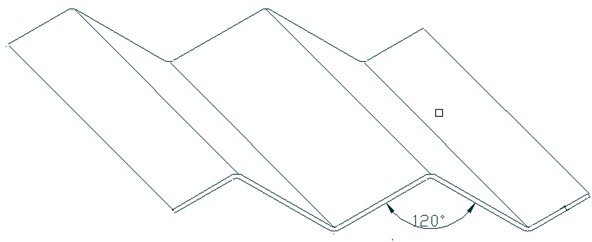

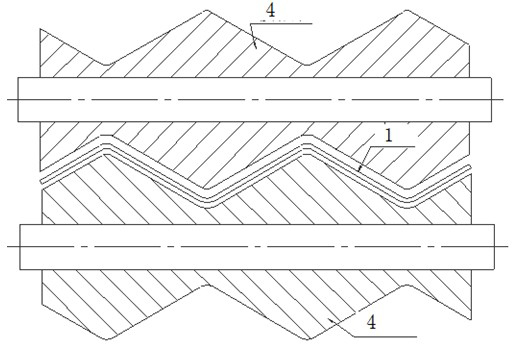

Manufacturing device and manufacturing method of wavy sheet for steel structure of heat exchange system

InactiveCN102319830AEasy to produceIncrease productivityHeat exchange apparatusProcess engineeringIndustrial engineering

The invention provides a manufacturing device and a manufacturing method of a wavy sheet for a steel structure of a heat exchange system, and the device is structurally characterized in that an upper row and a lower row of wavy wheels in the same shape with the wavy sheet, two groups of positioning wheels, one group of leveling wheels, one group of shaping wheels and an adjusting frame are arranged, wherein the shape of each wavy wheel is gradually changed from a cylinder to the shape of the wavy sheet; the two groups of positioning wheels and the one group of leveling wheels are arranged at the front ends of the wavy wheels so as to ensure the correct relative positions of a wavy sheet material and the wavy wheels; and the one group of shaping wheels and the adjusting frame are arranged at the tail ends of the wavy wheels so as to ensure the correct shaping of the wavy sheet. By adopting the manufacturing device and the manufacturing method, the traditional processing mode is thoroughly changed, the complex die manufacturing is abandoned, the stability of the product quality is improved, and the shaping wheels and the adjusting frame can be suitable for different materials so as to enable the product quality to be stable and reliable. The cost is greatly reduced, and a strip-shaped steel coil of the preset fixed size is adopted for replacing the cutting of a steel plate in the traditional process, thereby avoiding the waste of working time and the waste of remnants caused by cutting of the plate.

Owner:JIANGSU HAIXUN IND GROUP SHARE

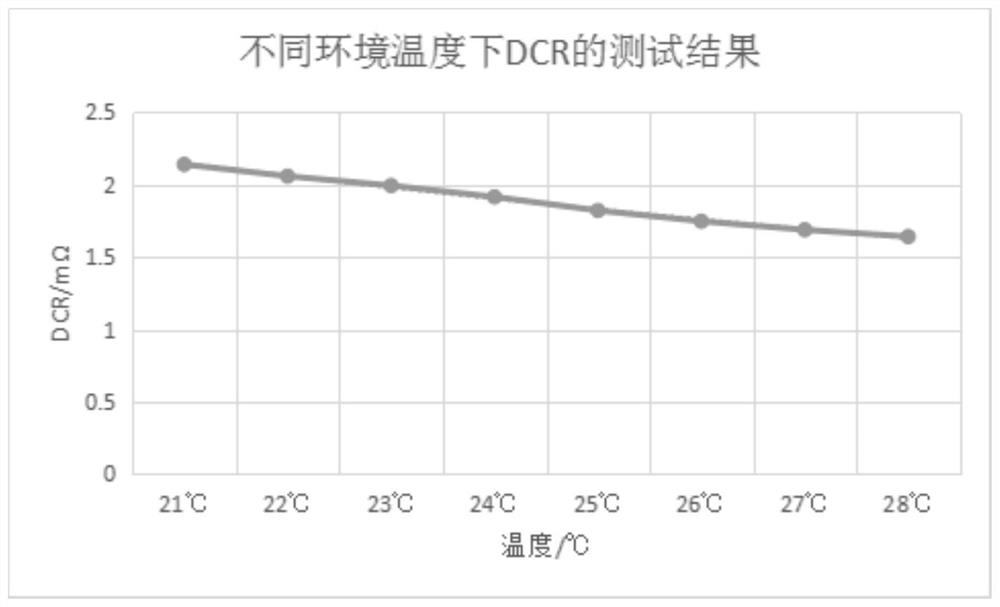

Lithium ion battery DCR test result correction method

ActiveCN112816889AEliminate the influence of temperature factorsAccurate DCR ResultsElectrical testingData processing systemTest battery

The invention discloses a lithium ion battery DCR test result correction method, which comprises the following steps of: adjusting the temperature of a constant temperature box, and placing batteries in it for the same time; acquiring a temperature value of each adjustment, a last voltage value before the corresponding DCR test, a test tail end voltage value and a charge and discharge current value data of each tested battery, and calculating to obtain the 'temperature and DCR' data of all groups, wherein a linear relation of fitting the DCR and the temperature is DCR correction=DCR actual*(a+bT-cT2); and collecting the temperature of the cell bodies before the DCR test and uploading the temperature to an upper computer program of the DCR by means of a sensor to obtain the corrected DCR. According to the lithium ion battery DCR test result correction method, the linear relation of fitting the DCR and the temperature is obtained through a design experiment, the temperature of the cell bodies is detected through the high-precision infrared temperature sensor, and the detected temperature data and the obtained fitting relation are combined with a data processing system of DCR test equipment, so that the DCR is corrected, and the accuracy is improved.

Owner:捷威动力工业江苏有限公司

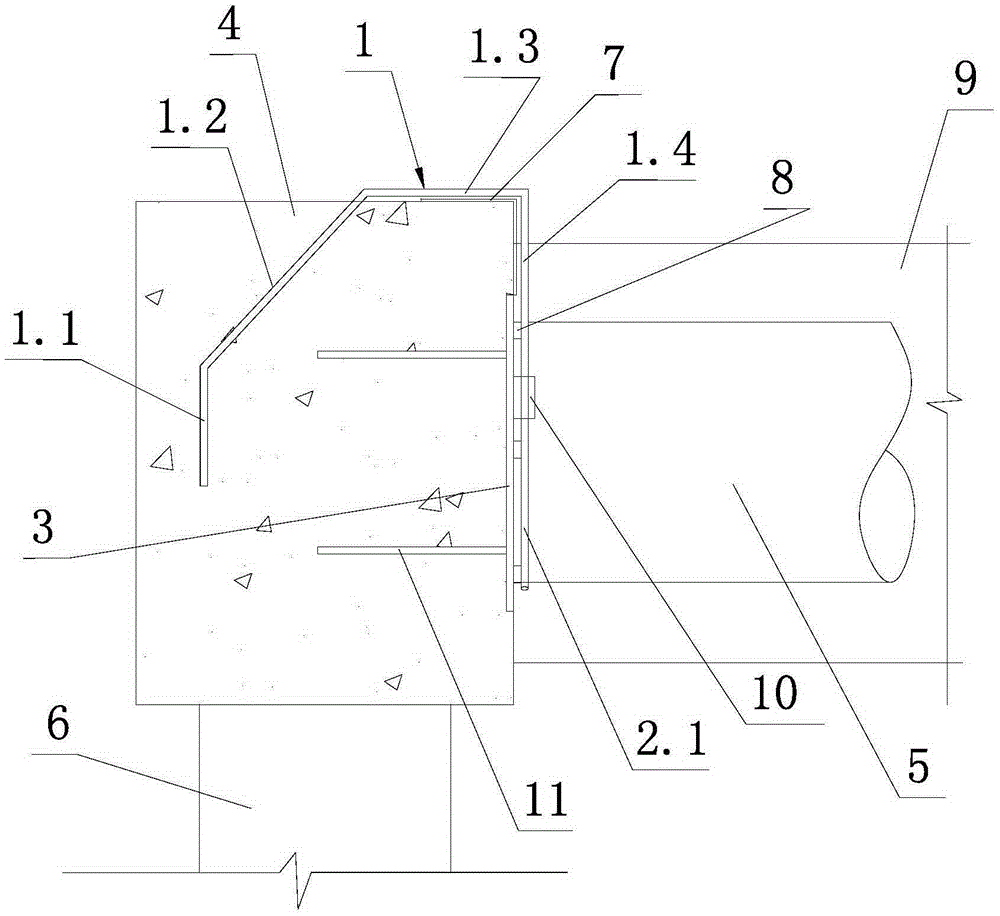

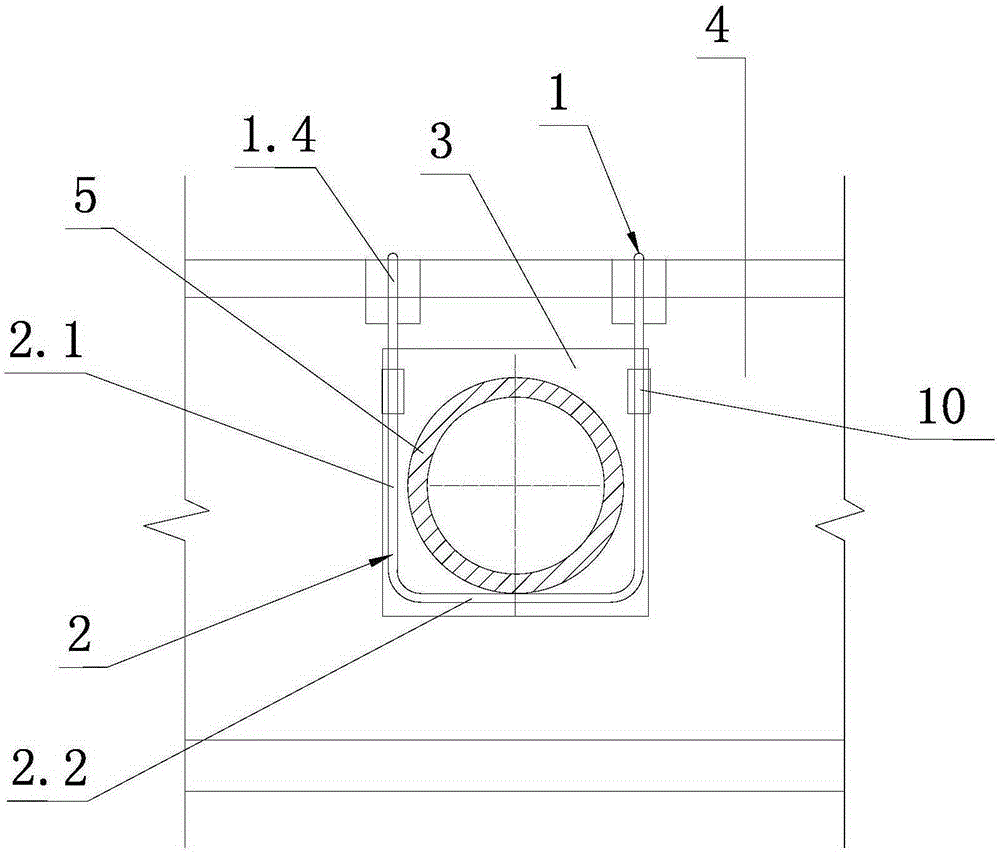

Rib type brackets and method for constructing top way steel pipe support and top plate through brackets

The invention discloses rib type brackets and a method for constructing a top way steel pipe support and a top plate through brackets. Each bracket comprises an anchoring steel rib (1), a U-shaped supporting rib and an embedded steel plate (3), wherein an anchoring vertical rib body (1) and an anchoring inclined rib body (1.2) of the anchoring steel rib (1) are located in a capping beam (4), and a vertical section (2.1) of the U-shaped supporting rib is fixed to the lower end of the anchoring steel rib (1). The method is characterized in that the two ends of the top way steel pipe support (5) are placed on the two rib type brackets, and the top way steel pipe support (5) is welded and fixed to embedded steel plate (3) of the rib type brackets. According to the brackets and the method, connection between ribs of the basement top plate (9) and a guard post wall (6) is not blocked, and the requirement for placement of the top way steel pipe support (5) can also be met.

Owner:ZHEJIANG XINJIE CONSTR +1

Inspection robot for highway tunnel

PendingCN109968321AImprove the quality of inspection processIncrease working hoursProgramme-controlled manipulatorElectricityEngineering

The invention relates to an inspection robot for a highway tunnel, and belongs to the field of robots. The inspection robot comprises a movable inspection platform mechanism, wherein an electricity supplying device is arranged at one end of the movable inspection platform mechanism, and a virus measuring device is arranged at the other end of the movable inspection platform mechanism; an infraredsensor is arranged in the virus measuring device; a driving device is mounted on the movable inspection platform mechanism; and travel switches are respectively arranged at two ends of the movable inspection platform mechanism. According to the inspection robot for the highway tunnel, a conventional detecting manner of manually detecting the tunnel is changed, and through the adoption of the robot, the automatic detection effect can be achieved; the working time is greatly reduced, the working efficiency is greatly improved, a large amount of human resource cost and a large amount of materialresource cost are saved, the detecting technology quality of the tunnel is improved, the phenomenon of omission is avoided, and the problem of potential safety hazards is effectively reduced.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

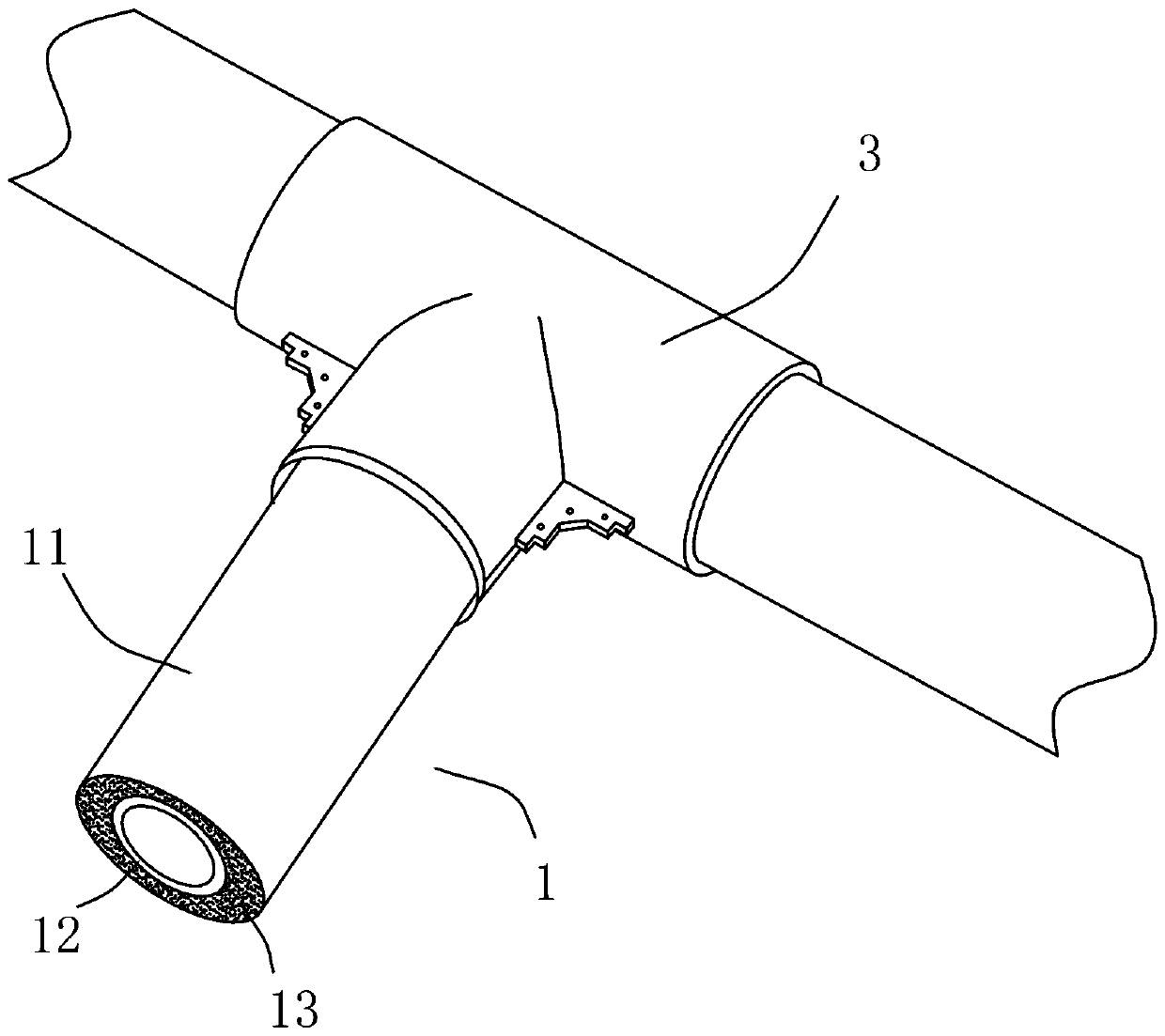

Construction method for heating power water feeding system with PPR polyurethane foaming heat preservation pipe

InactiveCN111022780ALow thermal conductivityImprove insulation effectThermal insulationPipe protection by thermal insulationInsulation layerPipe fitting

The invention relates to the field of water feeding systems and discloses a construction method for a heating power water feeding system with a PPR polyurethane foaming heat preservation pipe. The method comprises the following steps of (a) designing a construction drawing; (b) prefabricating the pipe; (c) arranging a pipe support in advance; (d) mounting the pipe; (e) performing pressure testingon the pipe; (f) washing the pipe; (g) sweeping and blowing the pipe; (h) performing foaming of a pipe fitting. According to the construction method, a polyurethane heat preservation layer is of a full-hole-closed foaming structure and is low in heat conductivity coefficient, good in heat preservation performance and low in thermal loss, the energy is saved, a PVC outer pipe is used as an outer protection shell and is good in waterproof performance, and the whole thermal loss of the hot water pipe is greatly reduced. The pipe is good in anti-corrosion and insulation performance and long in service life. The construction method is simple, the heat preservation pipe is convenient to install, cut and weld, operation is easily and quickly performed, and the work time is shortened. The materialcost and mounting cost are low.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

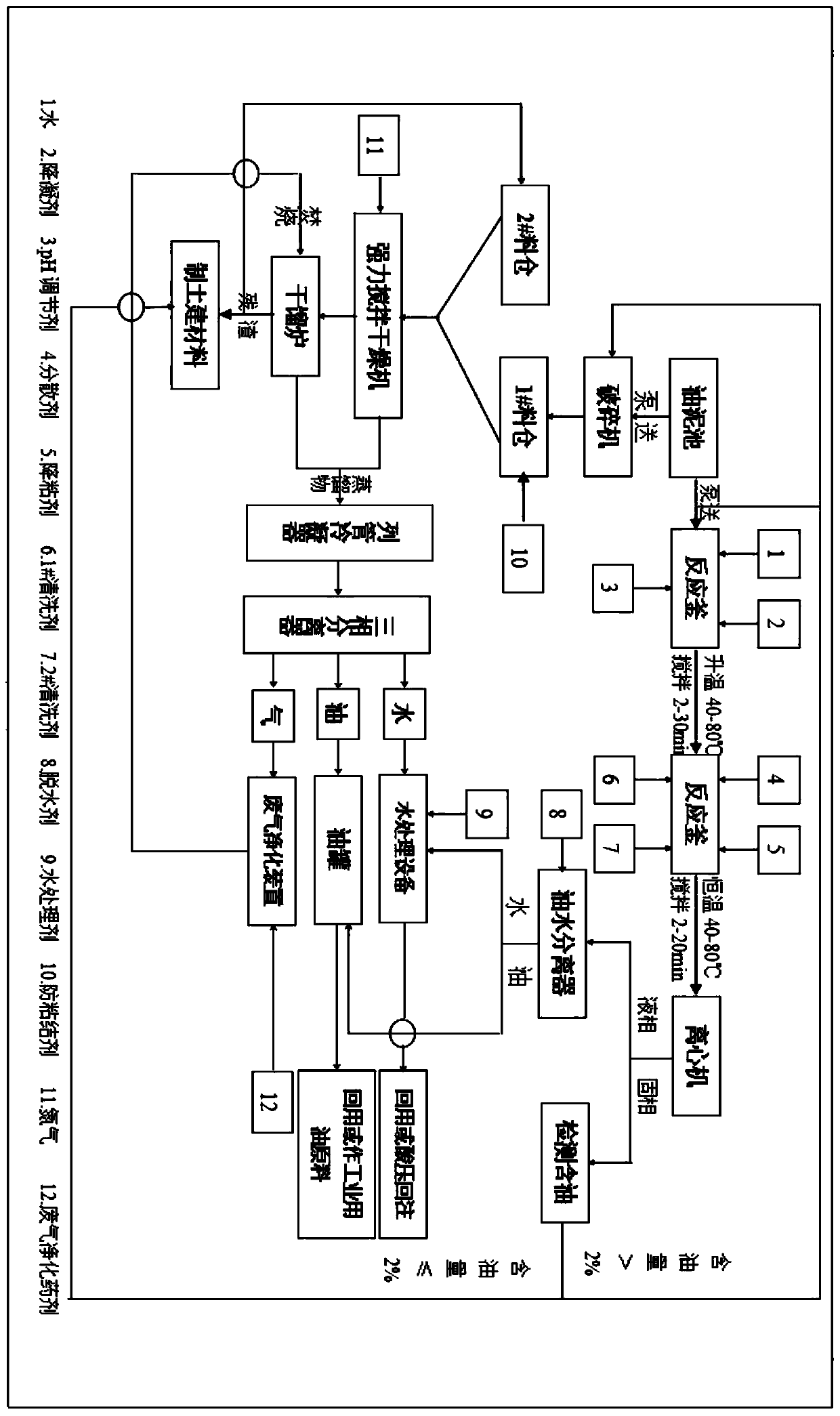

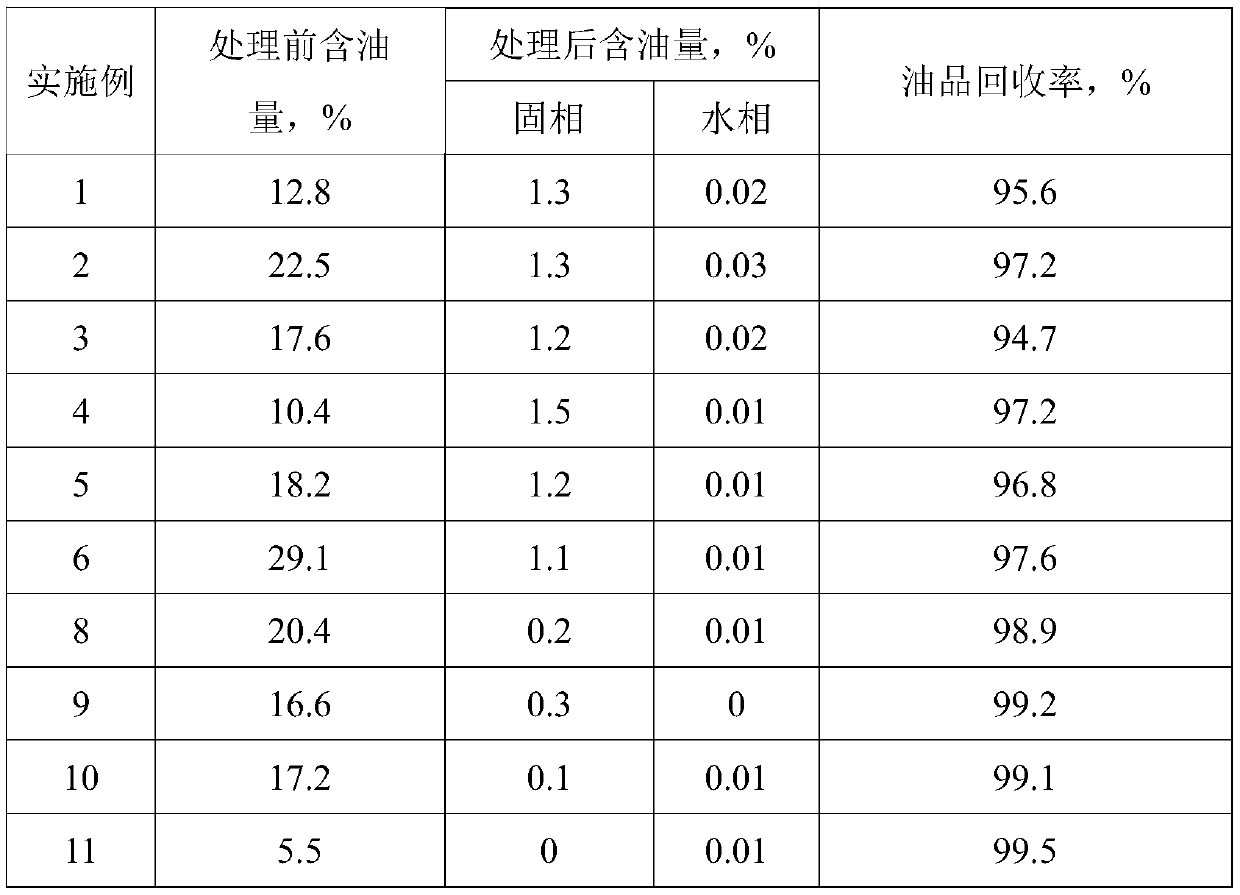

Oilfield solid waste treatment medicament and resourceful treatment process

ActiveCN109848177ALow priceWide variety of sourcesSolid waste disposalSludge treatment by pyrolysisCombustion chamberOil phase

The invention discloses an oilfield solid waste treatment medicament. The oilfield solid waste treatment medicament is characterized by comprising the following components of, a pour point depressant,a pH regulator, a dispersing agent, a viscosity reducer, a cleaning agent A, a cleaning agent B, a dehydrating agent, a photocatalyst, a zeolite molecular sieve, activated carbon, a ceramic ring, ananti-adhesive agent and a desulfurizing agent. The oilfield solid waste treatment method comprises the following steps of performing thermal chemical washing operation and dry distillation carbonization operation, according to the characteristics of oilfield solid waste generated by different stratums or working conditions, the thermal chemical washing operation or the dry distillation carbonization operation is independently adopted, or the thermal chemical washing operation is carried out firstly, and then the carbonization operation is carried out. The oilfield solid waste recycling treatment process is simple and feasible, and the application range is wide; the treated solid phase, oil, water and gas can be recycled, and the standard solid phase is used as a civil engineering raw material; the oil phase is recycled to an oilfield or used as an industrial oil raw material; the water phase is recycled to a cooling device or can be used in the thermochemical cleaning operation; and the non-condensable gas enters a combustion chamber of a dry distillation furnace for combustion and heat supply, so that the environment-friendly requirement is met.

Owner:中城投第十一集团生态环境有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com