Guide valve type electromagnetic valve

A solenoid valve and pilot valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of increasing the number of parts, man-hours and costs, being adsorbed on the blocking surface, and unable to be separated, etc., to achieve low cost, The effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the pilot type solenoid valve of the present invention will be described with reference to the drawings.

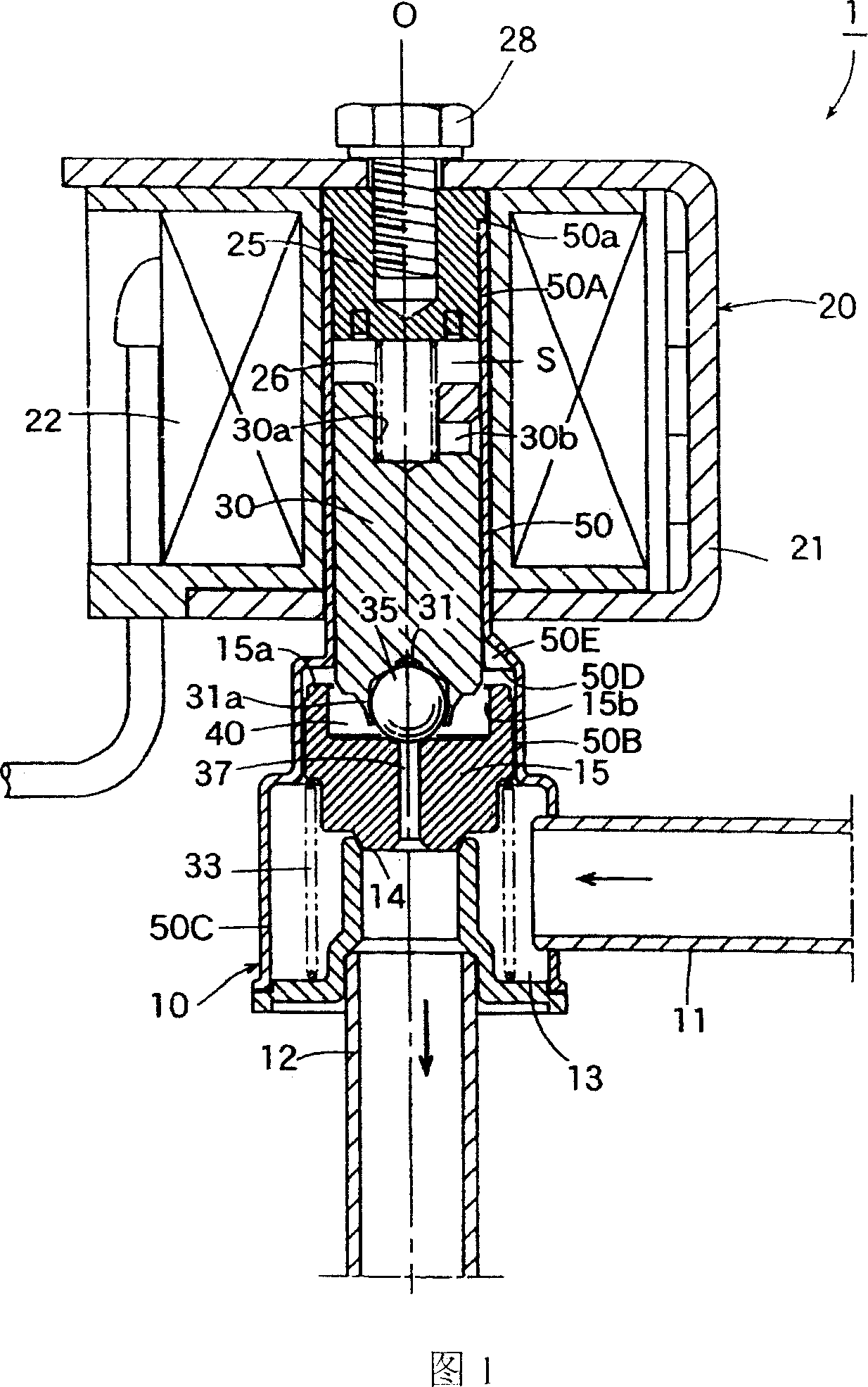

[0028] Fig. 1 is a longitudinal sectional view showing an embodiment of a pilot type solenoid valve of the present invention.

[0029] In the pilot solenoid valve 1 of the illustrated embodiment, the parts having the same structure or function as those of the pilot solenoid valve 1' of the conventional example shown in FIG. 4 above are given the same reference numerals. Repeated explanations are omitted, and the differences are highlighted below.

[0030] The pilot solenoid valve 1 of this embodiment is also used in refrigeration cycles such as air conditioners, and is different from the above-mentioned conventional example in the structure of the pilot pipe.

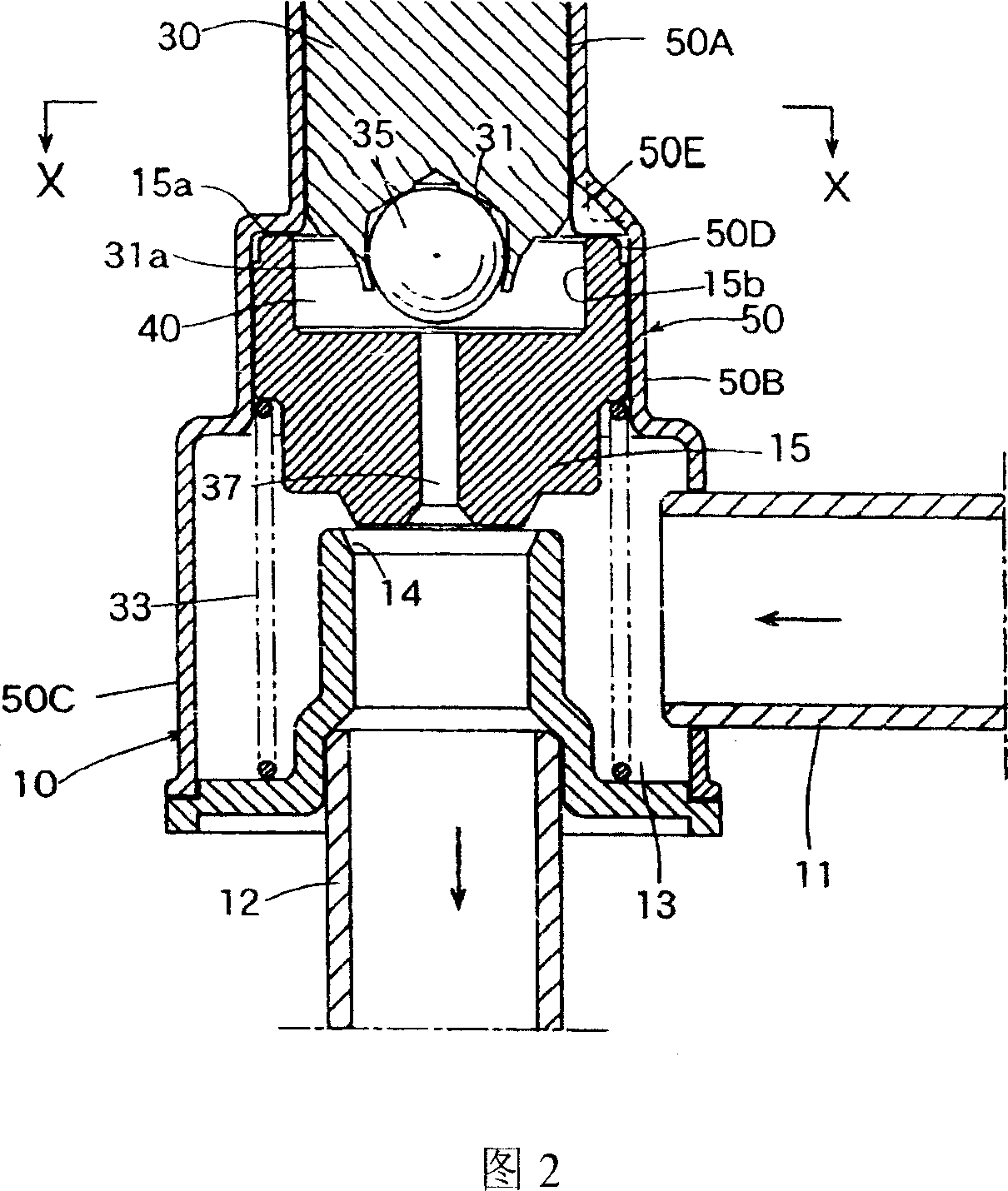

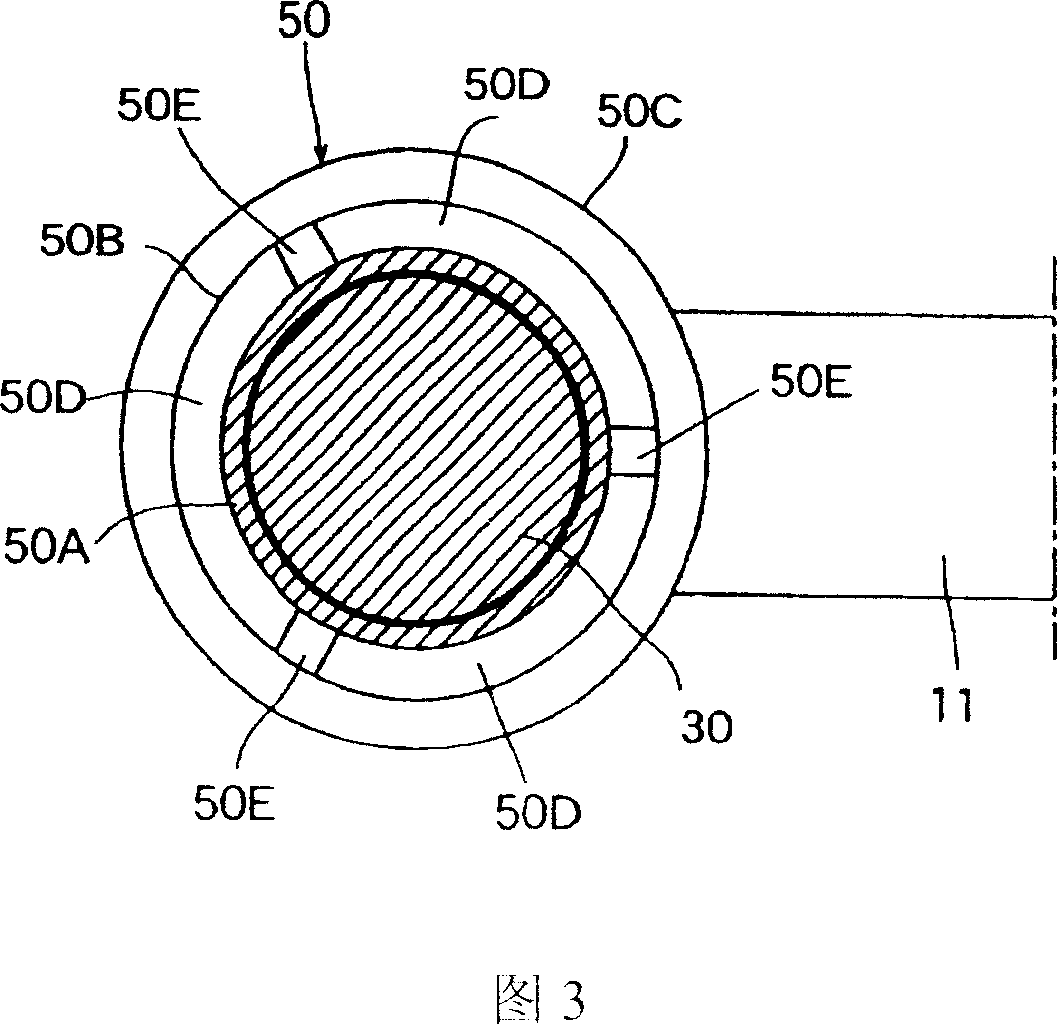

[0031] That is, as shown in FIGS. 2 and 3 , the guide pipe 50 of this embodiment includes: a small-diameter portion 50A slidably inserted into the plunger 30 ; a large-diameter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com