Patents

Literature

80 results about "L-Hydroxyproline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroxyproine, L-hydroxyproline or C5H9O3N, is a major componet of protein collagen.

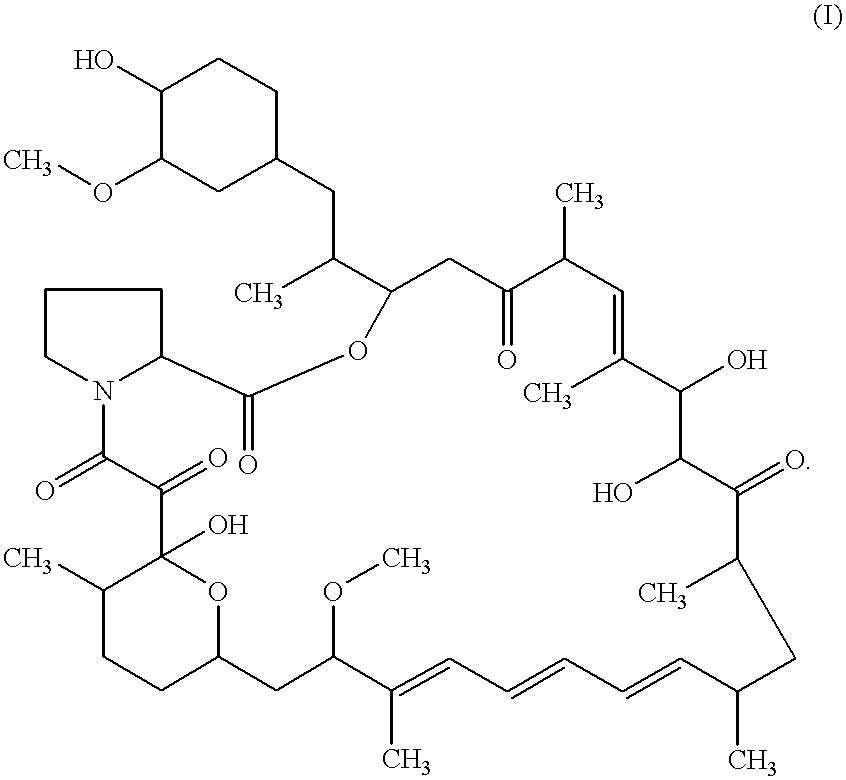

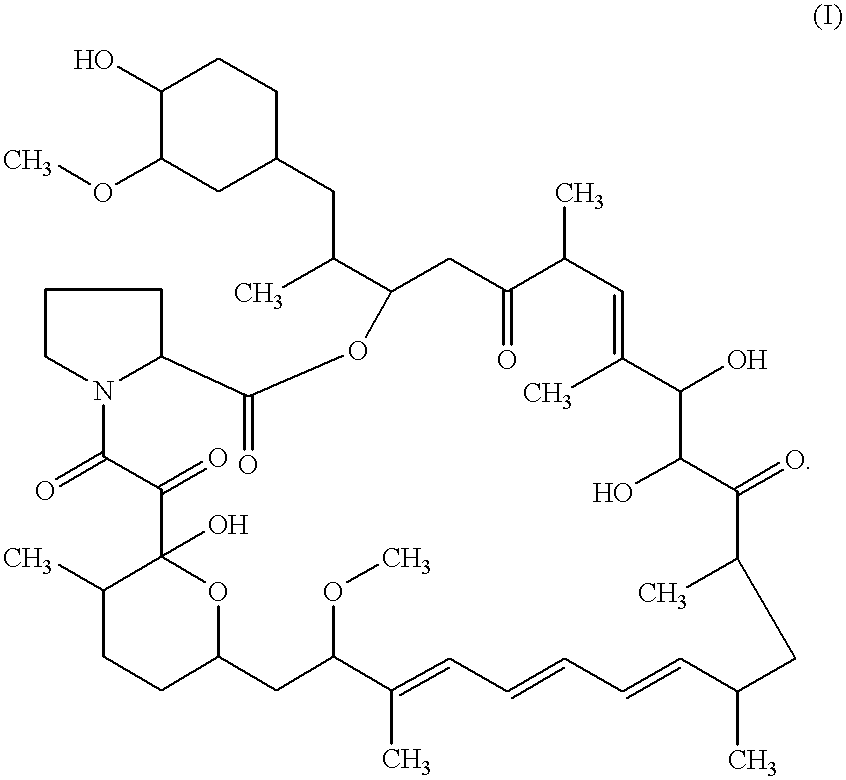

Macrocyclic lactone compounds and their production process

InactiveUS6187568B1Antibacterial agentsMicroorganism based processesMacrocyclic lactoneActinoplanes sp.

This invention provides a process for producing a macrocyclic lactone compound, which comprises cultivating Actinoplanes sp. FERM BP-3832, in the presence of L-proline, L-hydroxyproline or L-nipecotic acid, and then isolating a macrocylic lactone compound from the fermentation broth. The compounds produced by this process include a compound of the following formula:The present invention also relates to a pharmaceutical composition comprising the same, which is useful as immunosuppressive, antimycotic, antitumor agent or the like.

Owner:PFIZER INC

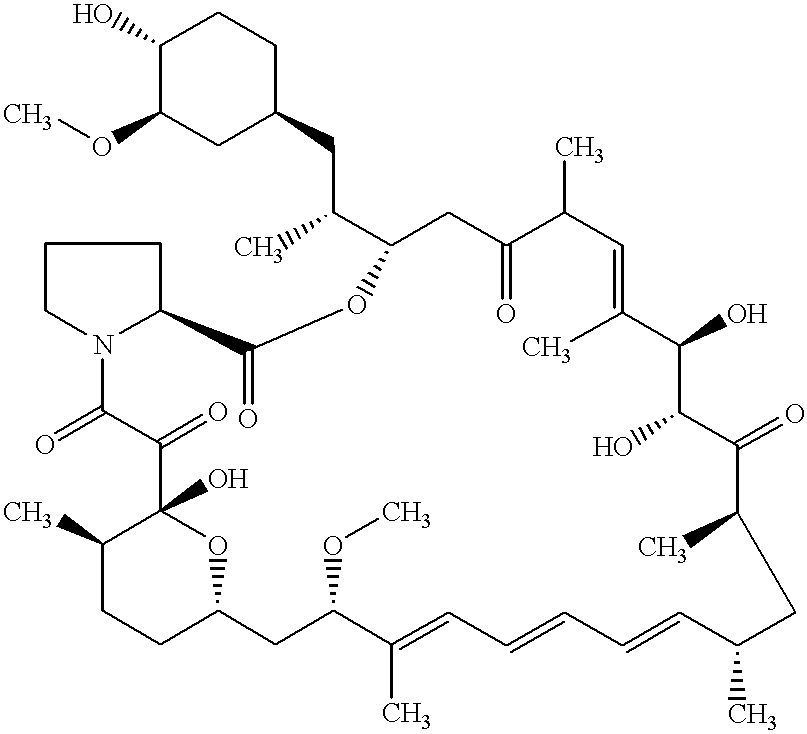

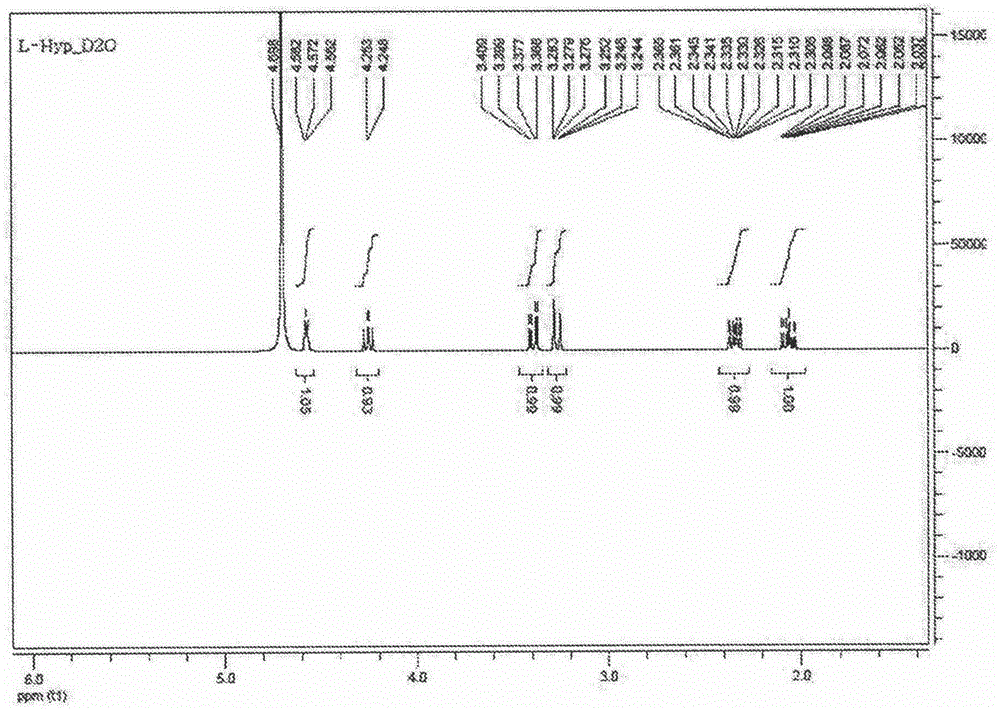

Method for extracting L-hydroxyproline from L-hydroxyproline fermentation liquor

ActiveCN105777603AAvoid pollutionHigh purityOrganic chemistryAccessory food factorsWastewaterMicrofiltration

The invention discloses a method for extracting L-hydroxyproline from L-hydroxyproline fermentation liquor. The method comprises the following steps: performing microfiltration on L-hydroxyproline fermentation liquor, adjusting the pH value of a microfiltration solution to be neutral, then performing cationic and anionic resin adsorption, performing nanofiltration to obtain a nanofiltration clear solution, and performing primary concentration crystallization after decolorization to obtain a final product. According to the method, a primary mother solution is delivered back to the process of cationic and anionic resin adsorption for recycling, the mode of direct adsorption of amino acid of the conventional ion adsorption exchange process is changed into a mode of adsorption of impurities, and then primary crystallization is performed after nanofiltration impurity removal to obtain a product, so that the purity, content, yield and separation efficiency of the L-hydroxyproline can be greatly improved, the wastewater quantity is reduced, and the generated wastes are used for preparing feeds to avoid environmental pollution.

Owner:TIANJIN JINGYE FINE CHEM

Joint detection kit for sialic acid and hydroxyproline

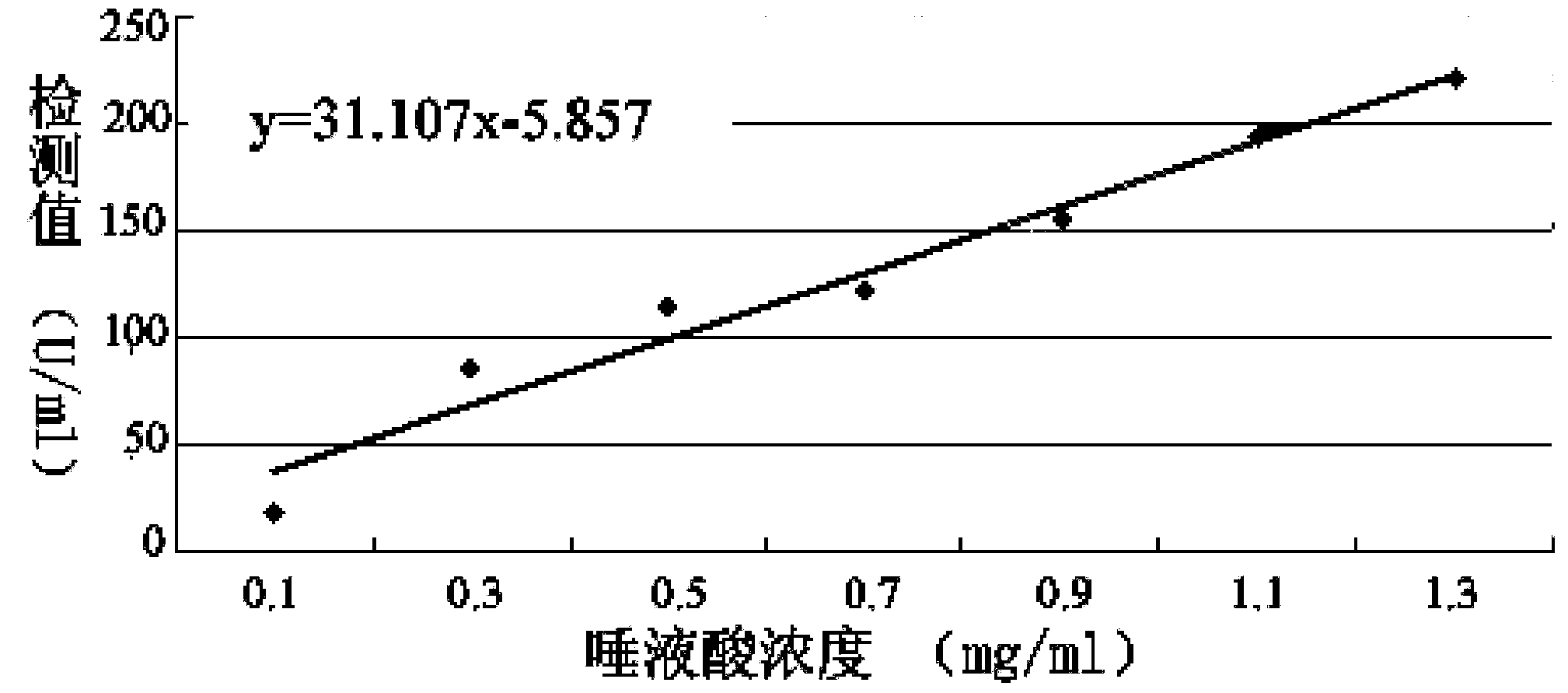

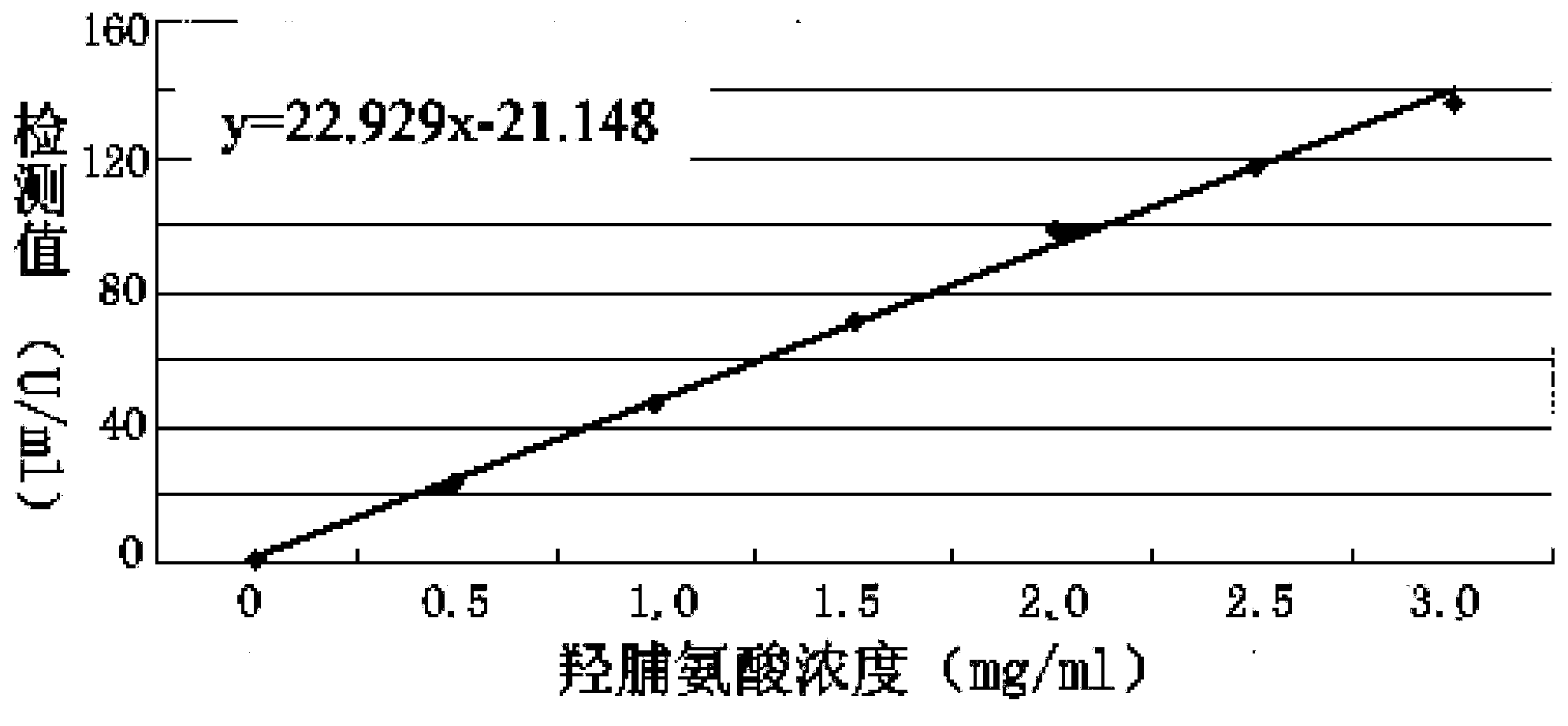

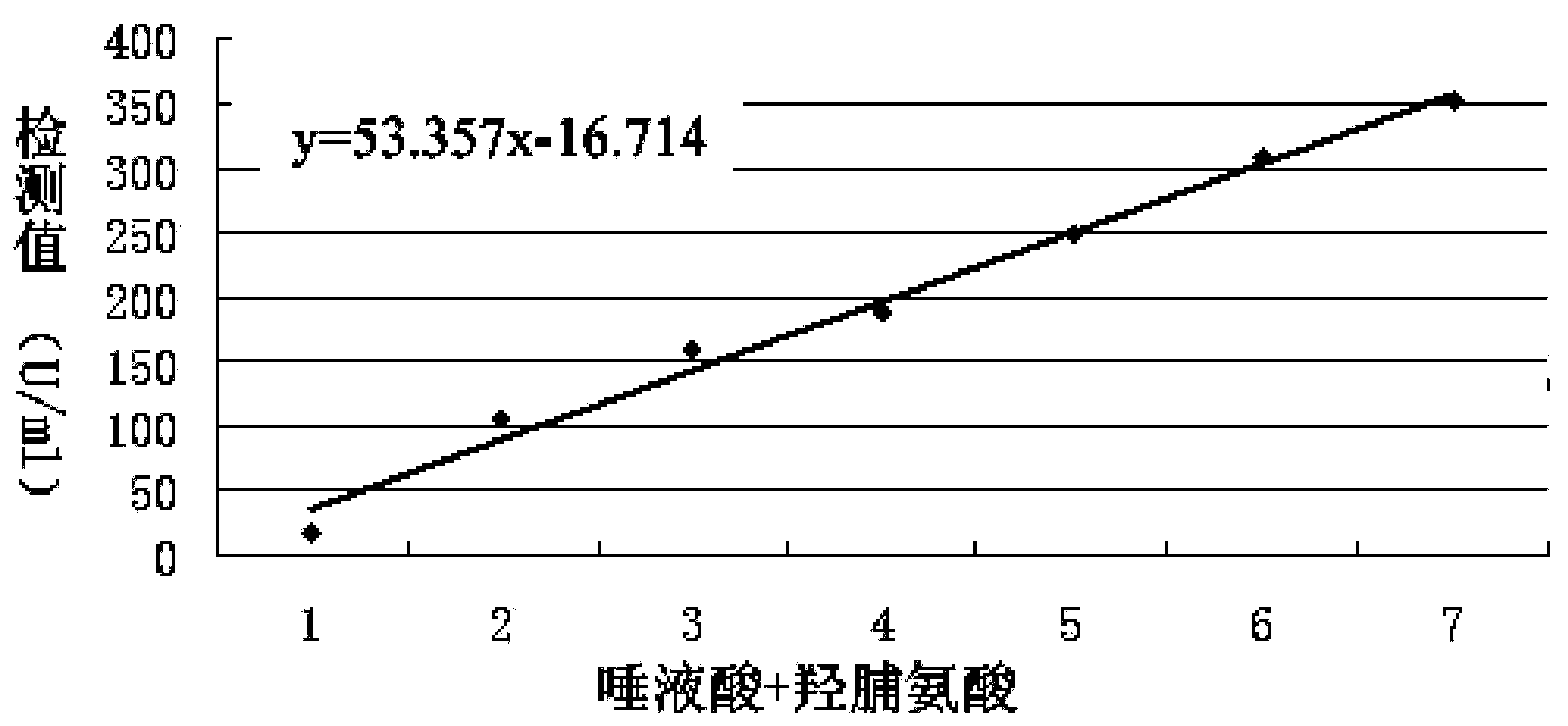

ActiveCN103512880AHigh sensitivitySimple and fast operationMaterial analysis by observing effect on chemical indicatorEthyl acetateEthyl fumarate

The invention discloses a joint detection kit for sialic acid and hydroxyproline. The kit comprises a color developing agent and a reference solution. The color developing agent is made from diethyl phthalate, ethyl acetate, 2,4-dinitrophenylhydrazine, hydrogen peroxide, hydrochloric acid and water, wherein the concentrations of the components are as follows: 0.35 mol / L of diethyl phthalate, 0.46 mol / L of ethyl acetate, 0.07 mol / L of 2,4-dinitrophenylhydrazine, 0.006 mol / L of hydrogen peroxide, and 0.62 mol / L of hydrochloric acid (hydrogen chloride). The reference solution is made from sialic acid, L-hydroxyproline and water, wherein the concentrations of the components are as follows: 0.3 g / L of sialic acid, and 0.25 g / L of L-hydroxyproline. With a specific color-developing analysis technology, in the same detection system, through primary reaction, multiple tumor markers can be reacted to develop colors. As the developed colors are superposed, the sensitivity of detection is improved. The joint detection kit complies with the trend of joint detection for tumor markers, is convenient and simple to operate, and is easy to promote and apply since the kit is operated without valuable equipment.

Owner:SHANDONG UNIV QILU HOSPITAL

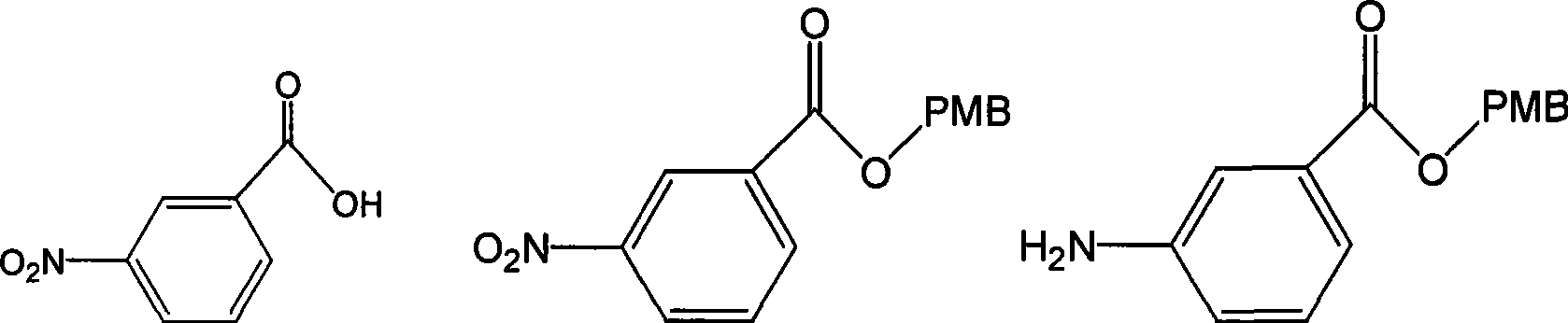

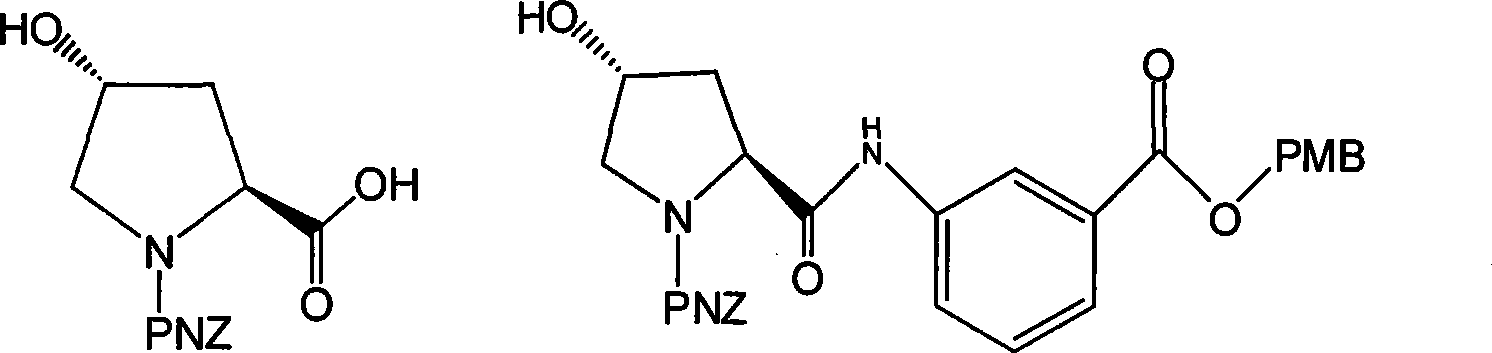

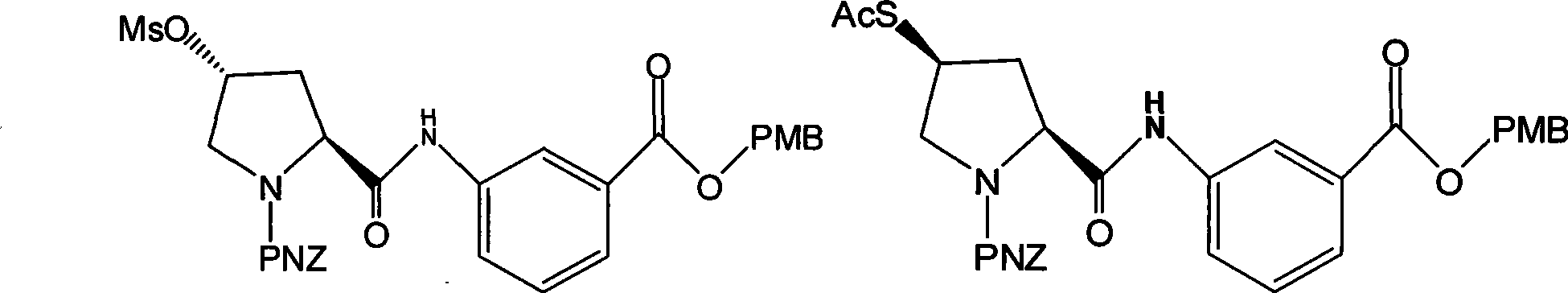

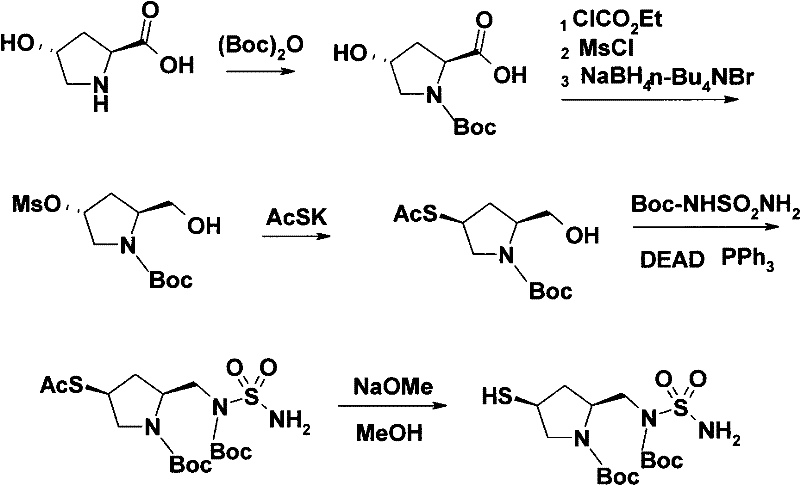

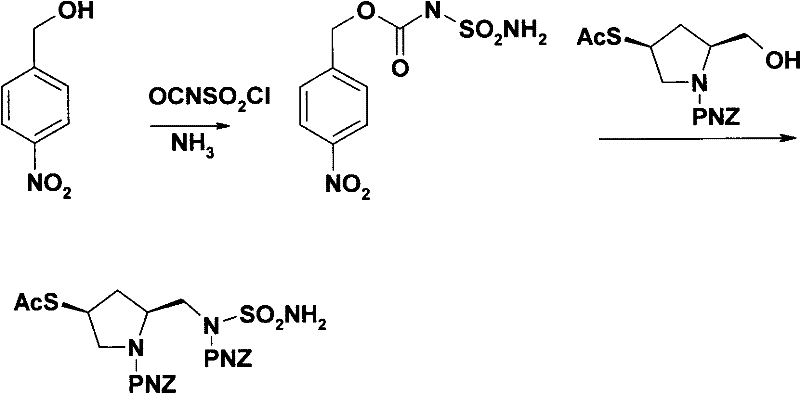

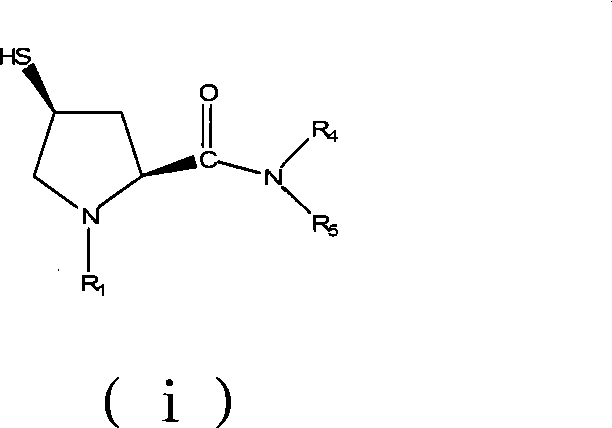

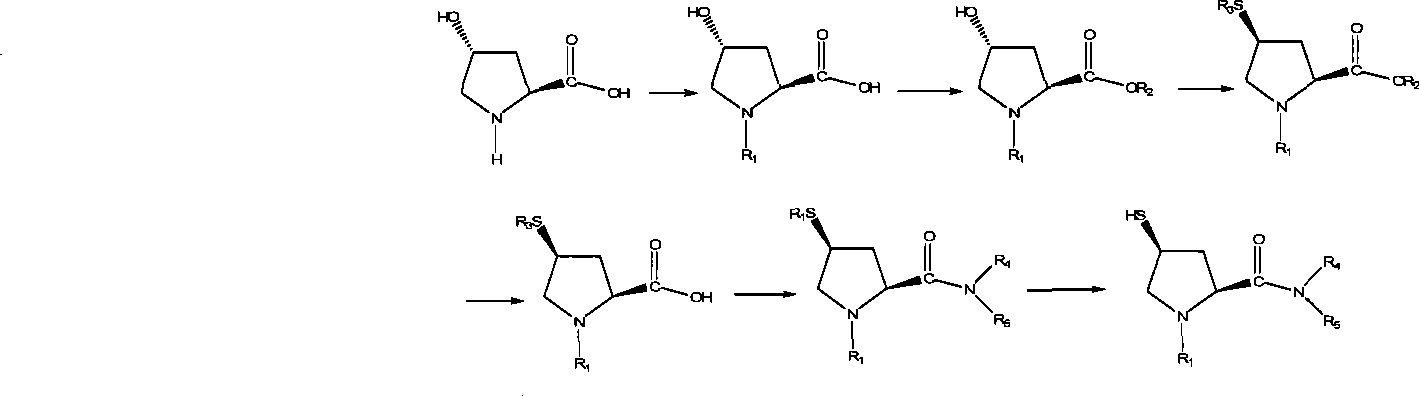

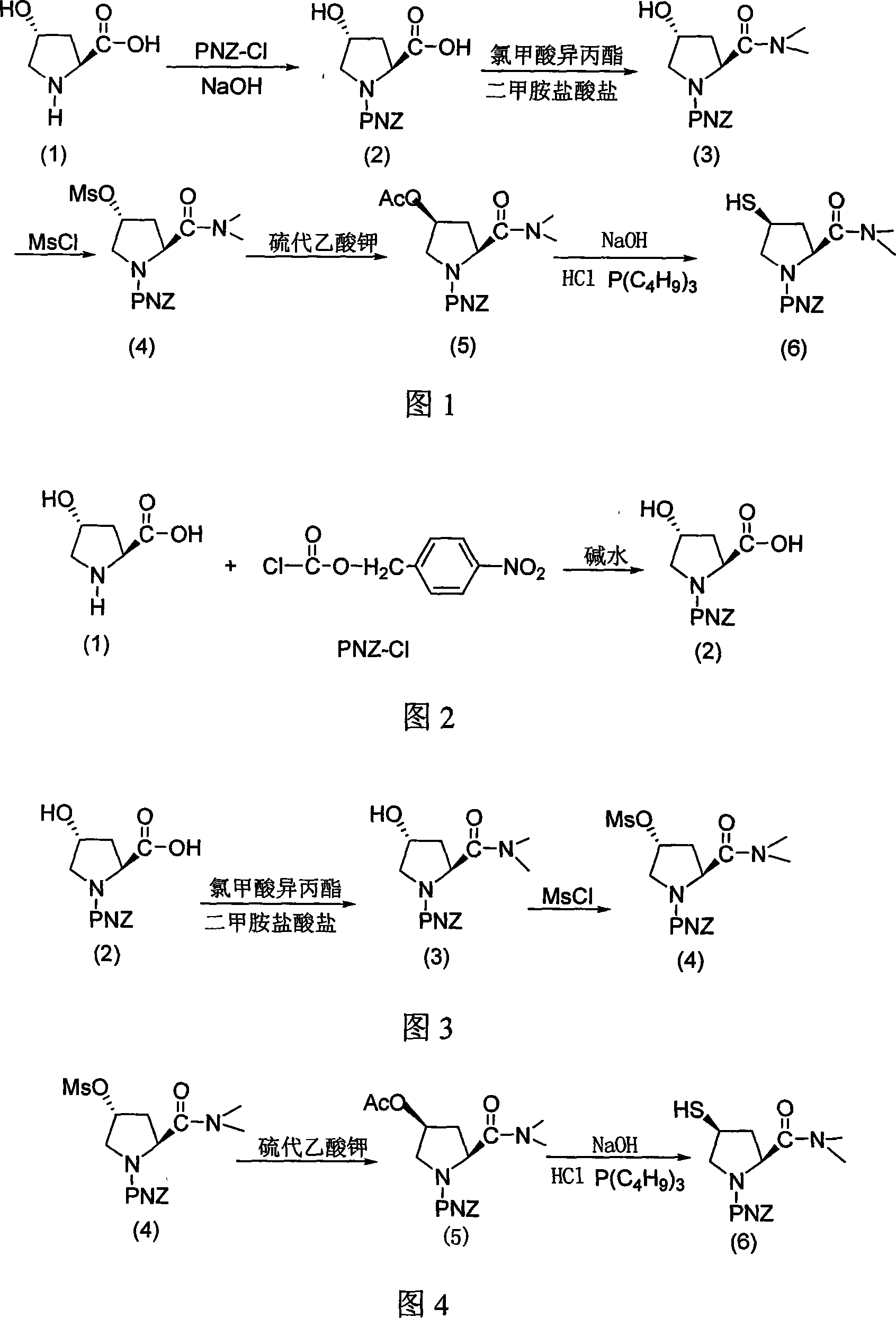

Preparation of carbapenem penicillin ertapenem intermediate

The invention discloses a preparation method of an intermediate for synthesizing carbapenems penicillin etapenem having the formula of VII. The preparation method comprises the following steps: allowing a compound having the formula of I and 4-methoxybenzyl chloride to react to obtain a product; reacting under the action of stannous chloride dehydrate, and regulating pH to 7; performing condensation reaction of above product and activated ester of PNZ L-hydroxyproline; reacting with methylsulfonyl chloride; reacting with potassium thioacetate; and hydrolyzing in acidic or alkaline condition, wherein PMB is shown in figure (1), PNZ is shown in figure (2), Ms is mesyl, and Ac is acetyl. The preparation method can be carried out at the room temperature, with the advantages of mild reaction condition, low cost, and easily realized industrial production.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

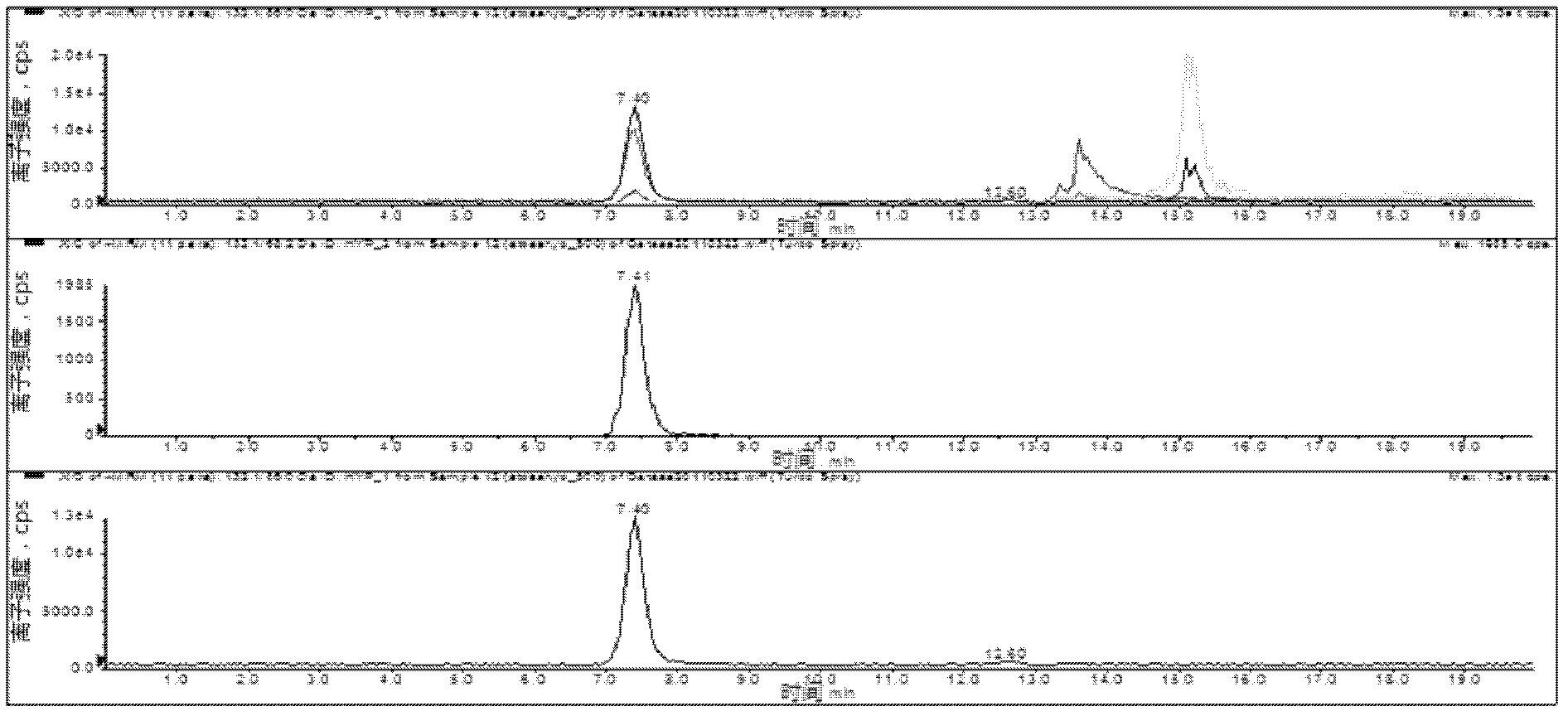

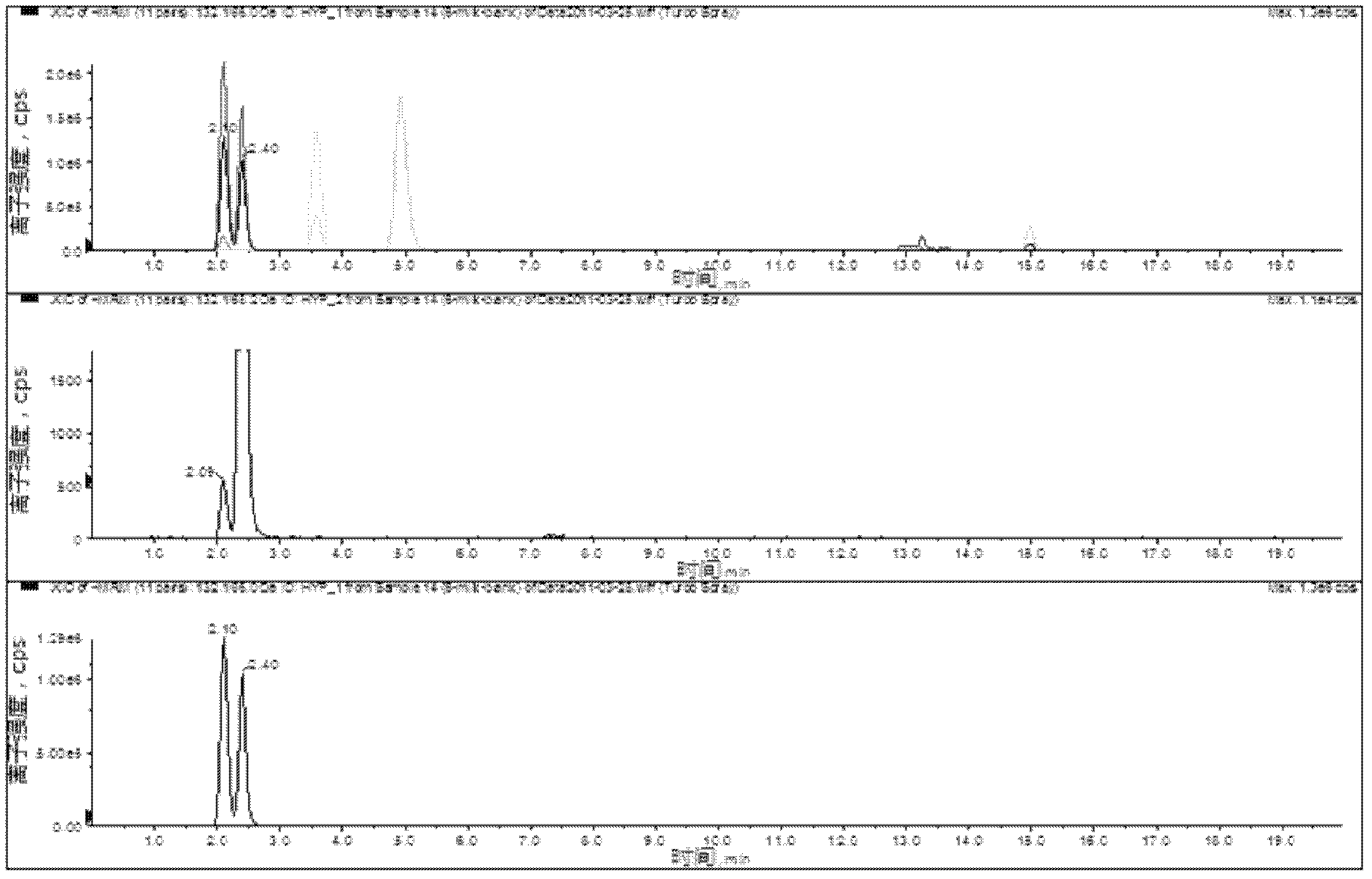

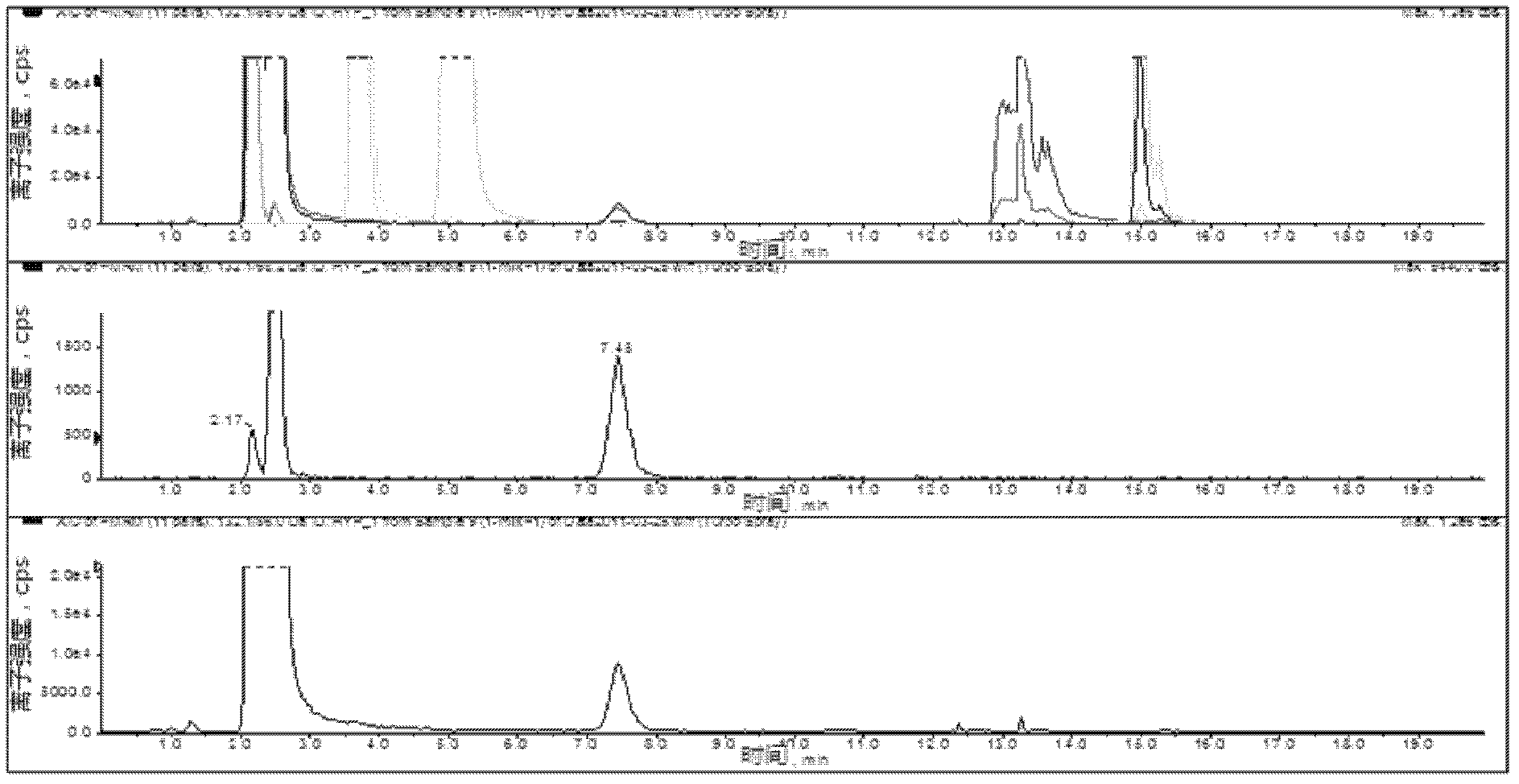

Method for detecting content of L-hydroxyproline in dairy product

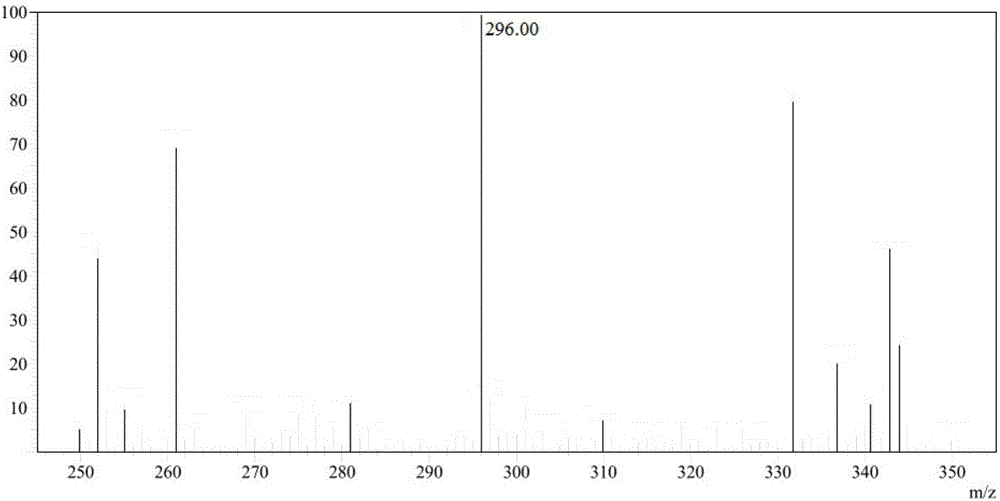

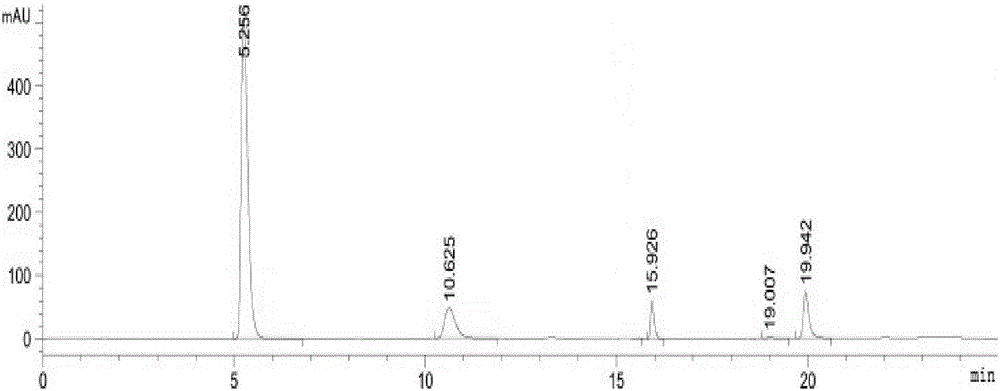

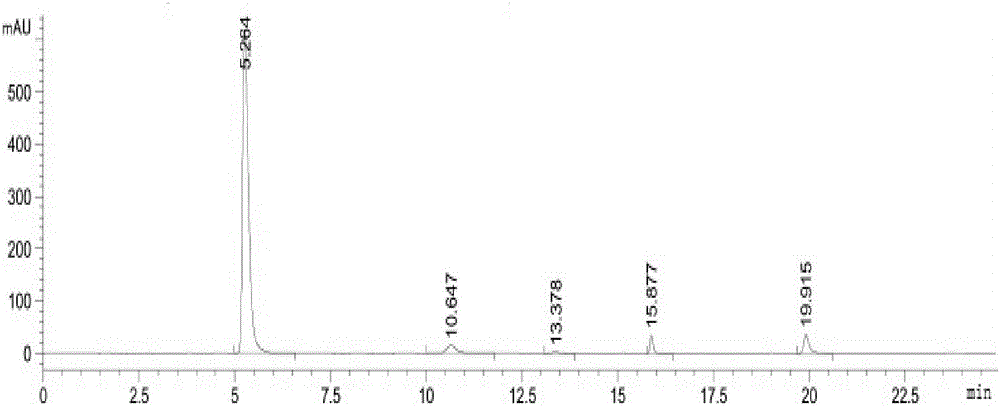

InactiveCN102590420AOvercoming poor specificityRich structural informationComponent separationChromatography columnTandem mass spectrometry

The invention discloses a method for detecting the content of L-hydroxyproline in a dairy product. The method comprises the following steps of: 1) pre-treating a sample, namely adding acid into the diary product and hydrolyzing to obtain test liquid; 2) analyzing the content of L-hydroxyproline by liquid chromatogram-tandem mass spectrometry, wherein hydrophilic interaction chromatography (HILIC) is adopted, a flowing phase is a mixed solution a flowing phase A and a flowing phase B, and the flowing phase A is a 10mM ammonium acetate aqueous solution of which the pH is 5.6; and the flowing phase B is acetonitrile, and the mass spectrometry condition is that: an electrospray ion source is adopted, a scanning mode is a positive ion scanning mode, a detection mode is a multi-reaction detection mode, electrospray voltage is 5,500V, the temperature of the ion source is 600 DEG C, the pressure force of a gas curtain is 20Psi, the atomization pressure force is 50Psi, and auxiliary pressure force is 30Psi. By the method, the detection accuracy and sensitivity can be improved obviously, and the content of the L-hydroxyproline in the dairy product can be determined easily, conveniently and quickly.

Owner:上海德诺产品检测有限公司

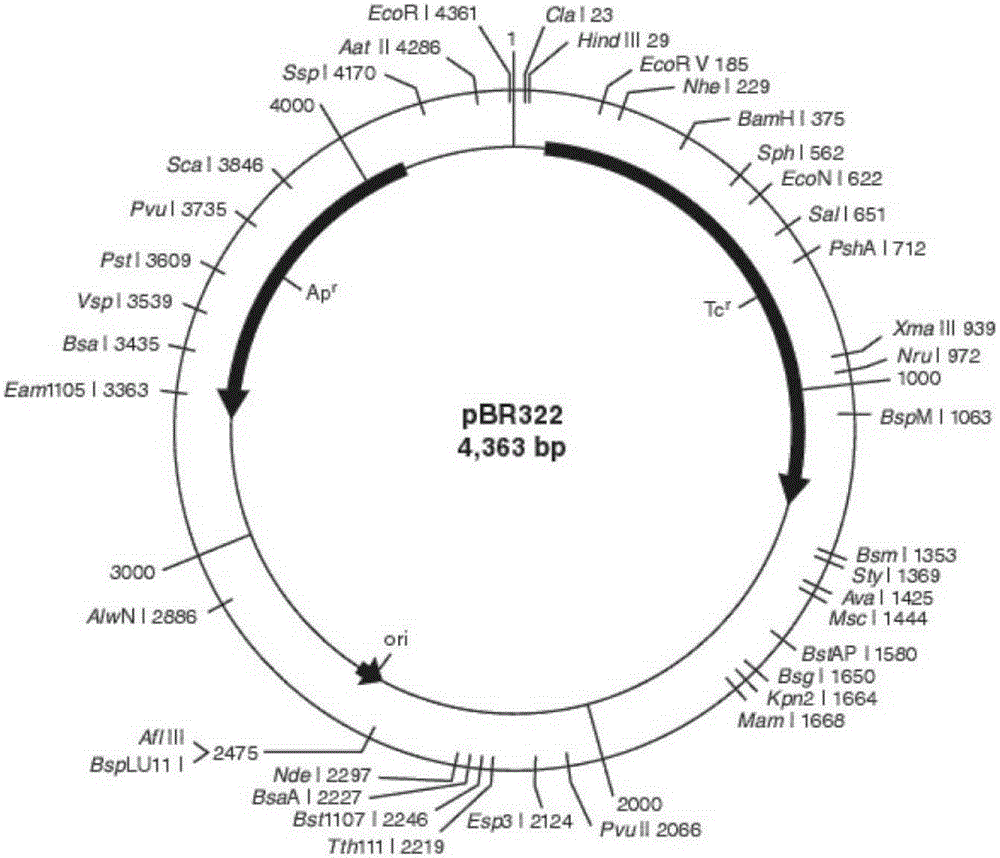

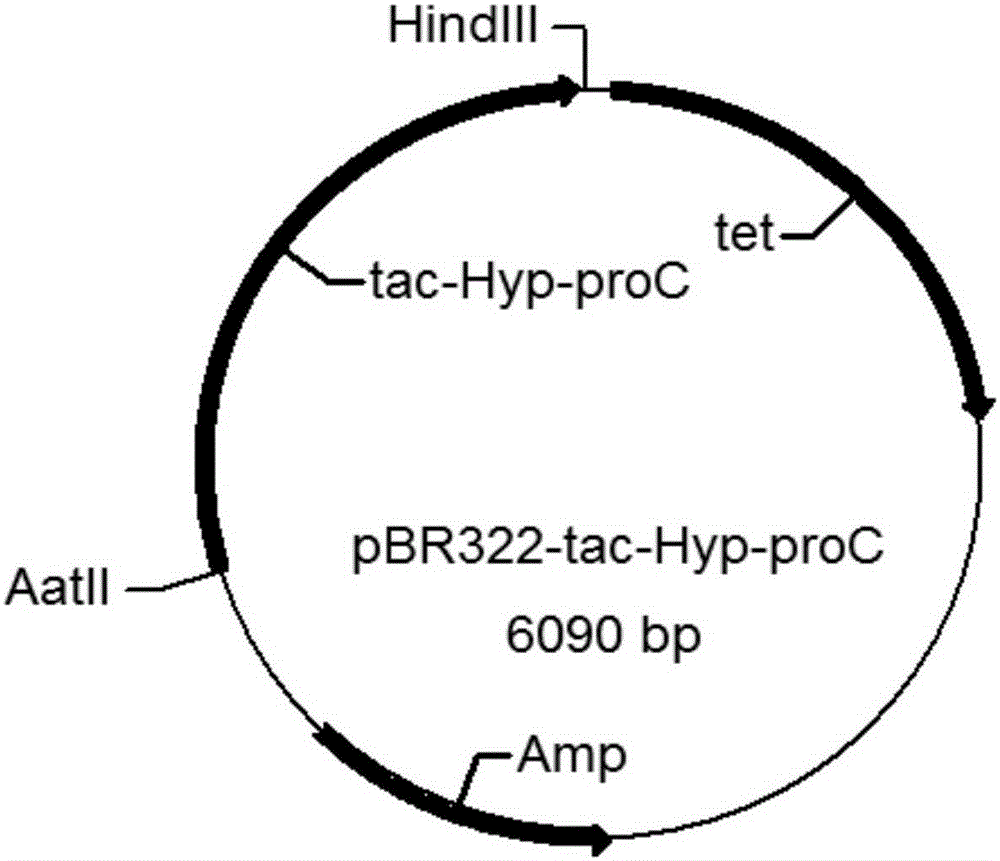

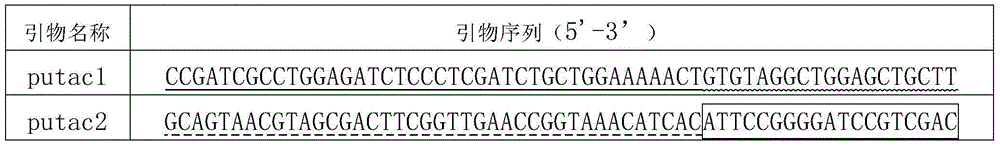

Bacteria for L-hydroxyproline production and application of bacteria for L-hydroxyproline production

ActiveCN105238708AHigh expressionImprove conversion rateBacteriaMicroorganism based processesEscherichia coliBacteroides

The invention discloses a strain of bacteria for L-hydroxyproline production and application of the bacteria for L-hydroxyproline production and provides Escherichia coli.HYP035 with a preservation number being CCTCC NO:M 2015401 in China Center For Type Culture Collection. According to experiments, the Escherichia coli.HYP035 can be used for L-hydroxyproline production, yield of L-hydroxyproline in fermentation broth is 45g / L, the proline conversion rate is 85%, a fermentation period is 40h, and high production value is achieved.

Owner:FUJIAN MINDONG REJUVENATION PHARMA

Fermentation technology for industrially producing L-hydroxyproline through fermentation method

InactiveCN105506017ARaise the level of fermentationReduce manufacturing costFermentationMicrobiologyFermentation

Provided is a fermentation technology for industrially producing L-hydroxyproline through a fermentation method. The fermentation technology comprises the following steps that 1, a strain is cultured in a liquid culture medium, and a mature seed is obtained; 2, the mature seed is moved into the fermentation culture medium in a fermentation tank for fermentation and metabolism, and the L-hydroxyproline is produced. The fermentation technology is applied to production of the L-hydroxyproline through microbial fermentation, the fermentation level is improved, the production cost is reduced, and three-waste pollution is avoided.

Owner:TIANJIN JINGYE FINE CHEM

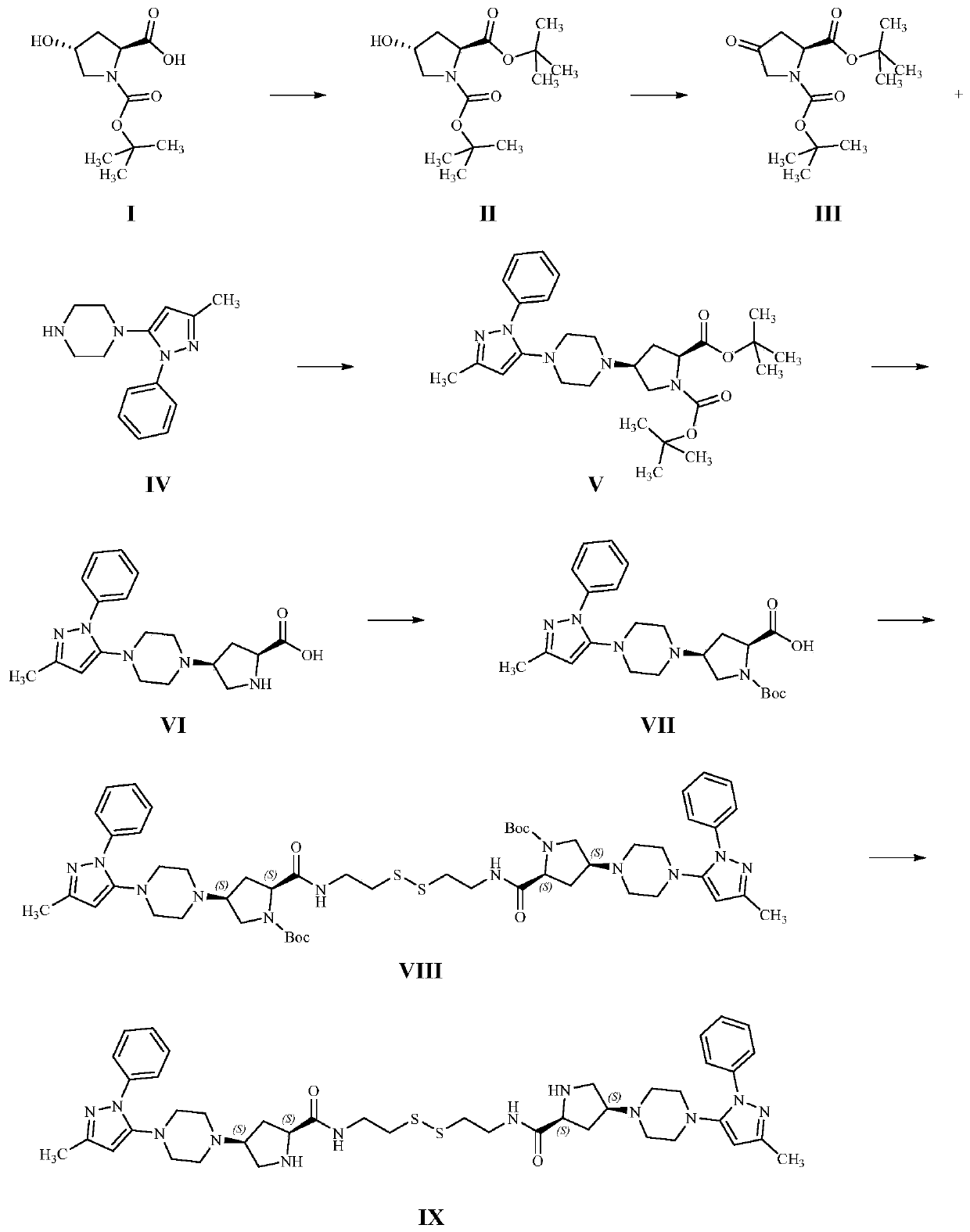

Method for preparing hydrobromic acid teneligliptin

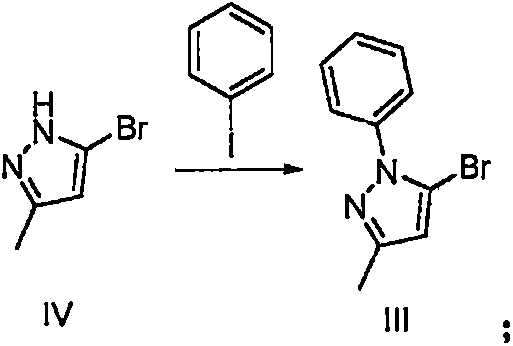

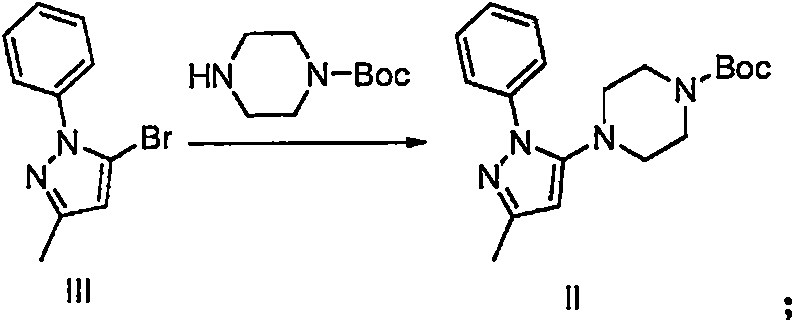

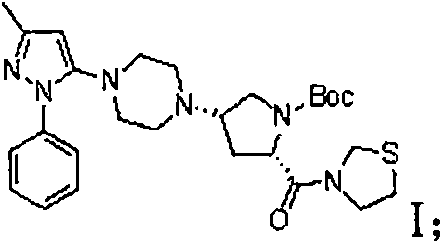

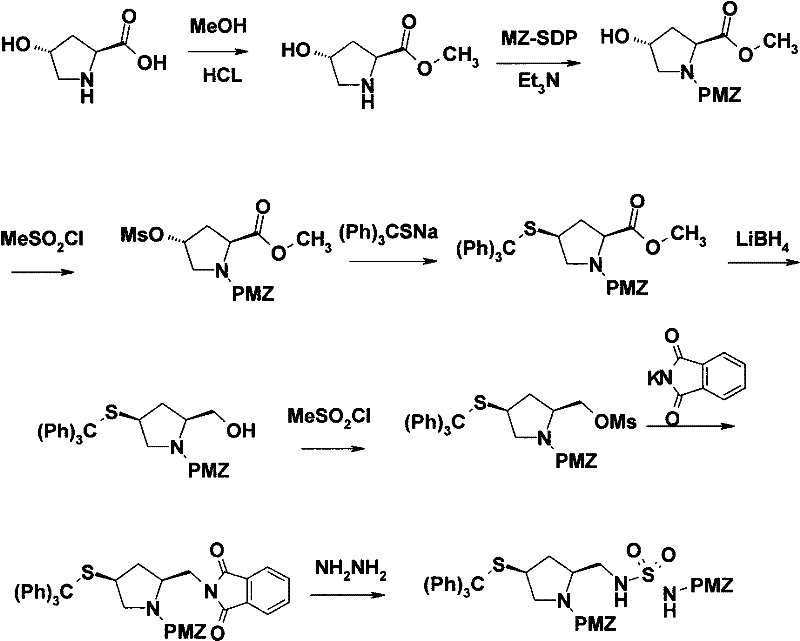

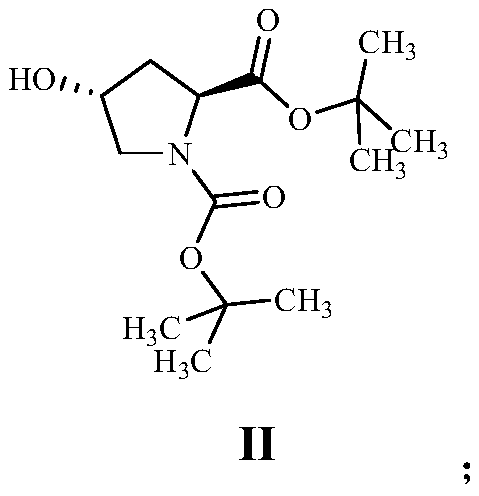

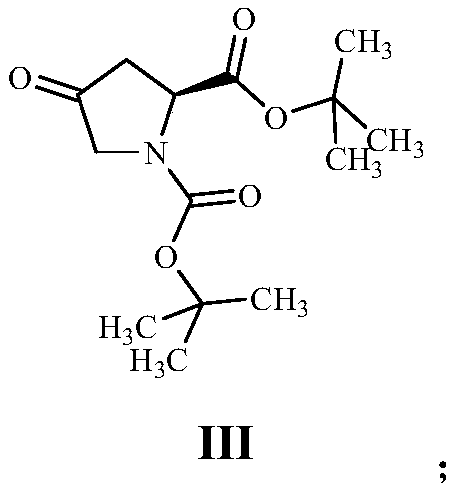

InactiveCN106349237ALow costHigh yieldOrganic chemistryBulk chemical productionSodium bicarbonateTert-Butyloxycarbonyl protecting group

The invention provides a method for preparing hydrobromic acid teneligliptin. The method includes steps of preparing L-hydroxyproline; mixing the L-hydroxyproline and sodium bicarbonate with each other to obtain mixtures, dissolving the mixtures in water, adding acetone into the water, dropping di-tert-butyl dicarbonate into the water, carrying out room-temperature reaction overnight and then treating reaction products to obtain t-butyloxycarboryl-N-hydroxyproline; preparing t-butyloxycarboryl-N-4-oxo-proline from the t-butyloxycarboryl-N-hydroxyproline; preparing (2S)-4-oxo-2-(3-thiazolidine carbonyl)-1-pyrrolidine carboxylic acid tert-butyl ester from the t-butyloxycarboryl-N-4-oxo-proline; preparing compounds III from compounds IV; preparing compounds II from the compounds III; preparing compounds 1-(3-methyl-1-phenyl-1H-pyrazole-5-base) piperazine from the compounds II; preparing intermediates I; preparing the hydrobromic acid teneligliptin from the intermediates I. The method has the advantages that the method is low in cost, and the cost of the method is only two-thirds of the cost of an existing method in the prior art; the yield of the hydrobromic acid teneligliptin is higher than 95%, and the purity of the hydrobromic acid teneligliptin is higher than 98%.

Owner:南通普悦生物医药有限公司

Method for decoloring L-hydroxyproline fermentation broth by utilizing active carbon

InactiveCN104276990ALarge specific surface areaStrong ability to adsorb pigmentIon-exchange process apparatusOrganic chemistryActivated carbonRoom temperature

The invention relates to a method for decoloring an L-hydroxyproline fermentation broth by utilizing active carbon. The method comprises pretreatment of active carbon, pretreatment of the fermentation broth, continuous decoloring of the L-hydroxyproline fermentation broth, regeneration of active carbon and other steps. According to the method, continuous decoloring is performed on the L-hydroxyproline fermentation broth by filling a chromatography column with powdered active carbon, and compared with a process of using powdered active carbon for decoloring in batches, active carbon can be repeatedly used for multiple times, column filling does not need repeatedly performing, regeneration can be directly performed after decoloring, the labor intensity is reduced, and the cost of purchasing active carbon is reduced. Additionally, the whole process is performed at room temperature, decoloring on a large scale is relatively easy to operate, high-temperature danger is avoided, energy is saved and cost is reduced. The method is mainly applied to removal of pigments in the L-hydroxyproline fermentation broth and is suitable for industrial application.

Owner:JIANGNAN UNIV

Method for industrially producing L-hydroxyproline through fermentation method

InactiveCN105506019ARaise the fermentation unitHigh yieldOrganic chemistryMicroorganism based processesFermentationPollution

Provided is a method for industrially producing L-hydroxyproline through a fermentation method. The method comprises the steps of strain solid culture, fermentation culture, fermentation liquor extraction and purification. According to the method for industrially producing the L-hydroxyproline through the fermentation method, the L-hydroxyproline is industrially produced through a direct glucose fermentation method, the fermentation unit, yield and quality of the L-hydroxyproline is improved, the production cost is reduced, and three-waste pollution is avoided.

Owner:TIANJIN JINGYE FINE CHEM

Process for synthesizing doripenem lateral chain

InactiveCN102249970ABlocking will notUniform crystal particlesOrganic chemistryVulcanizationBiological activation

The invention discloses a process for synthesizing a doripenem lateral chain. According to the process disclosed by the invention, L-hydroxyproline is taken as a starting raw material, and the doripenem lateral chain is obtained through the following steps of: amino protection, carboxyl protection, hydroxyl activation, reduction reaction, acetyl vulcanization reaction and condensation reaction. The process provided by the invention has the advantages of simple and easily-obtained raw materials, no high-temperature and high-pressure reactions and no super-low-temperature reactions; the 'three wastes' generated in the production process mainly comprise waste liquid and the wastewater in the waste liquid is neutralized by appropriate acid and alkali and then is discharged after achieving the discharging standard; and the organic solvents in the waste liquid comprises dichloromethane, dichloromethane and alcohols and can be recycled to be reutilized so that the pollution on the environment is small.

Owner:HUANGSHAN SHEXIAN HONGHUI CHEM

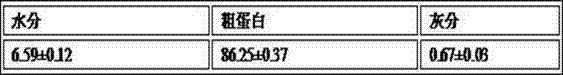

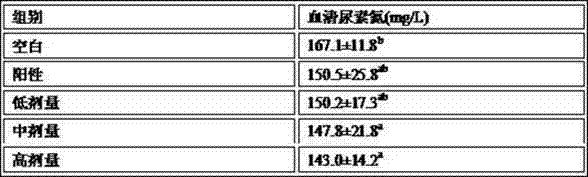

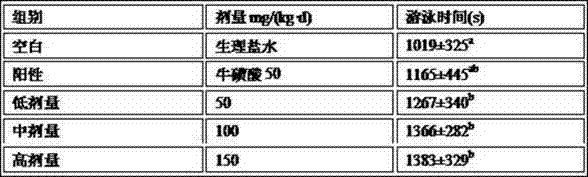

Fish skin and fish scale protein enzymolysis powder with function of relieving fatigue

The invention discloses fish skin and fish scale protein enzymolysis powder with a function of relieving fatigue. Every 100g of fish skin and fish scale protein enzymolysis powder comprises the following components by weight: 80g-85g of protein, 3g-4g of glycogen and 10g of L-hydroxyproline. The preparation method for the fish skin and fish scale protein enzymolysis powder comprises the following steps of: removing fishy smell and color of enzymatic hydrolysate by utilizing active carbon after carrying out enzymolysis of the fish skin and the fish scales; and carrying out vacuum concentration and vacuum drying to obtain protein enzymolysis powder. The fish skin and fish scale protein enzymolysis powder prepared by the preparation method can be used for supplementing a lot of substances such as amino acid consumed by the human body after being eaten, and used for reliving a lot of accumulated fatigue factors such as lactic acid, uric acid, urea and oxygen radical in the human body to quickly relieve the fatigue.

Owner:GUANGDONG OCEAN UNIVERSITY

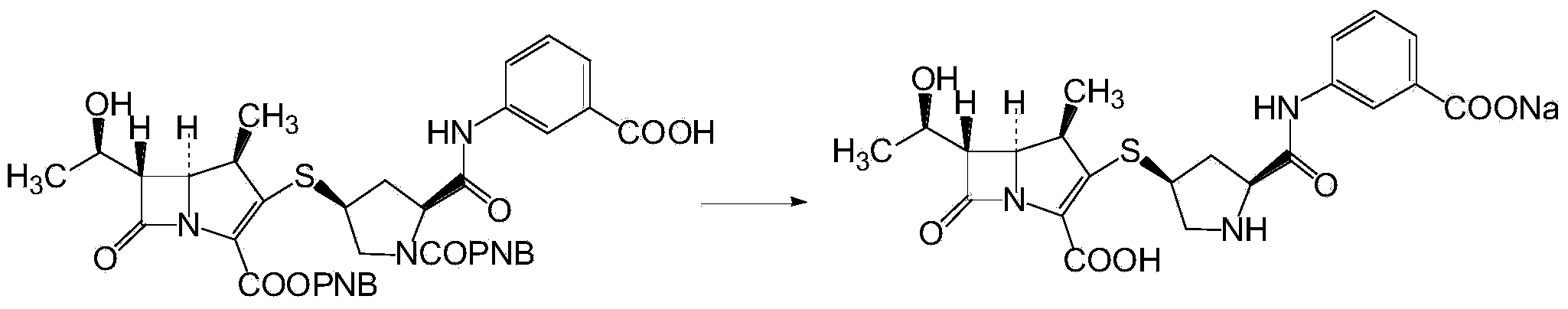

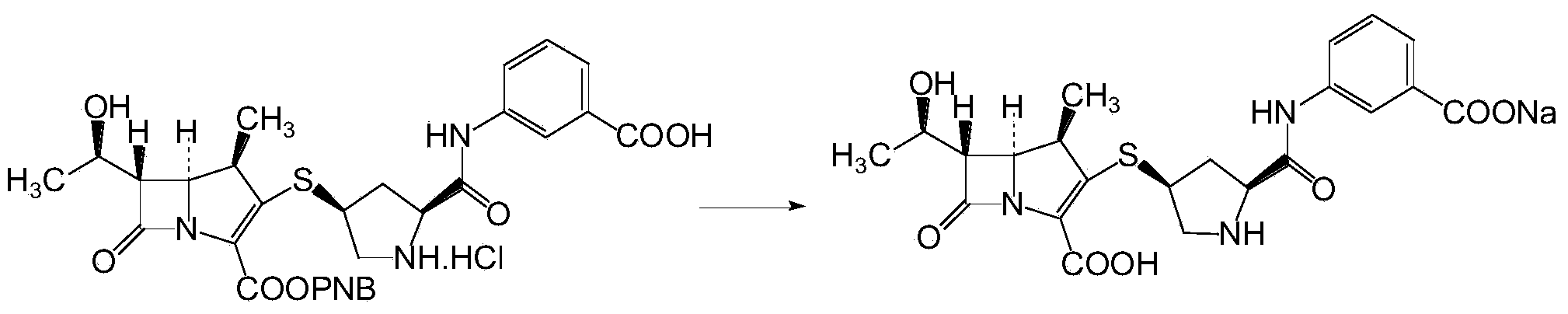

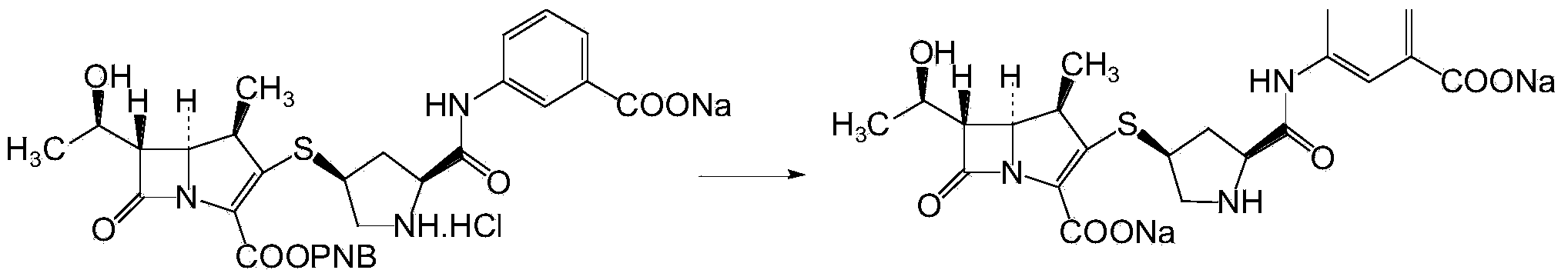

Ertapenem and ertapenem side chain, as well as preparation methods of ertapenem and ertapenem side chains

The invention discloses ertapenem and ertapenem side chains, as well as preparation methods of ertapenem and ertapenem side chains. L-hydroxyproline is protected by p-nitrobenzyl ester to obtain (2S,4R)-4-hydroxyl-1-(((4-Nitrobenzformyl)-oxyl)caboyl)pyrrolidine-2-carboxylic acid; then 4-nitro(1S,4S)-3-oxo-2-thia-5-azabicyclo[2.2.1]heptan-5-carboxylic anhydride can be obtained, and reacts with m-aminobenzoic acid p-nitrobenzyl ester to obtain ertapenem side chain III; and the ertapenem can be synthesized through two-step chemical reaction of condensation and deprotection to the ertapenem side chain III and a raw material MAP. An ertapenem side chain I (10), an ertapenem side chain II (13) and the ertapenem side chain III (2) which are prevailing in the market can be synthesized through simple steps, without the need of ultralow temperature, industrialization is easy, and the product purity is high, and the operation is simple and convenient.

Owner:HUNAN CHEMAPI BIOLOGICAL TECH

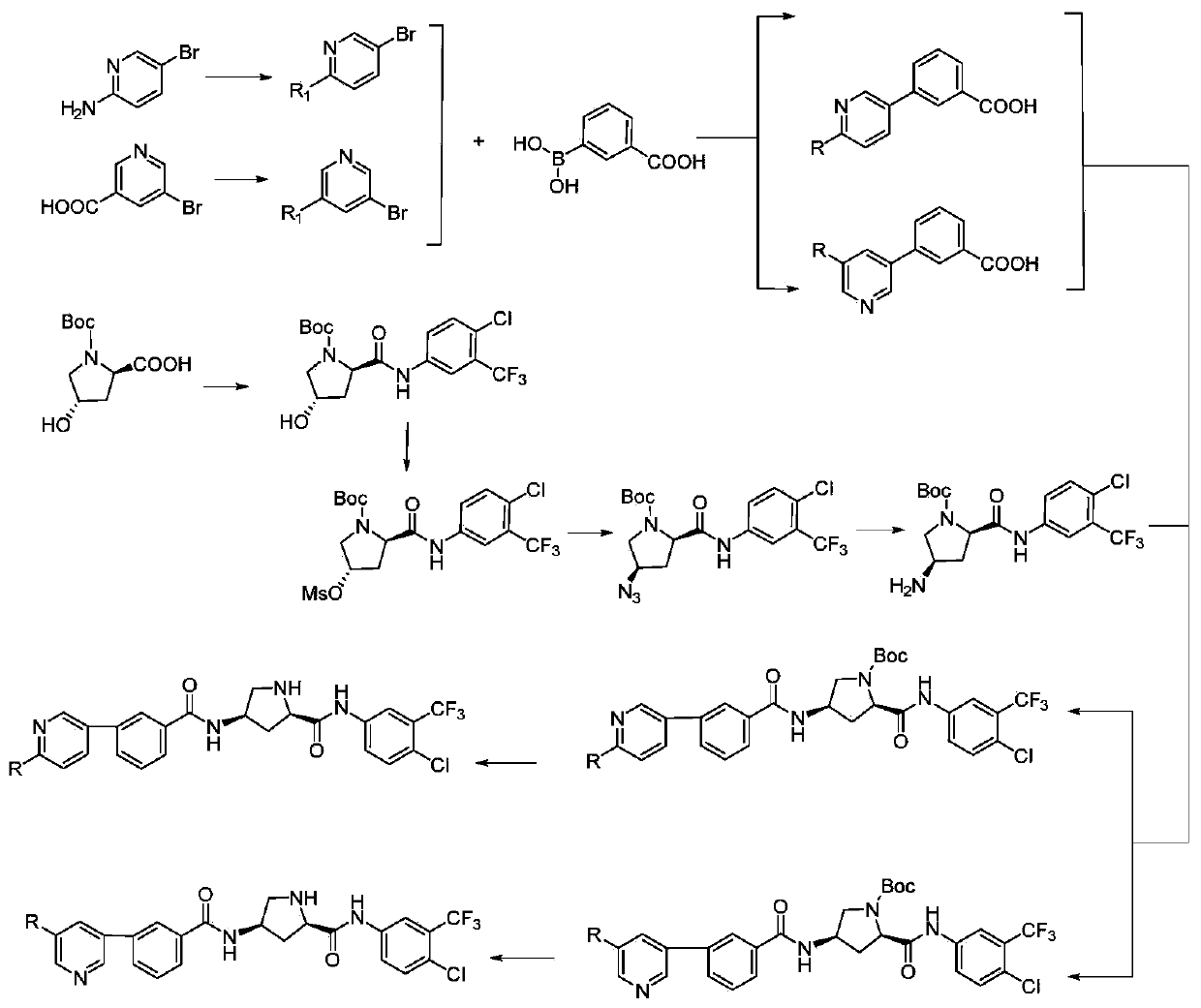

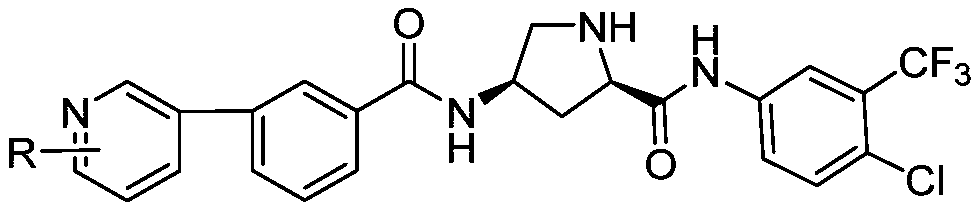

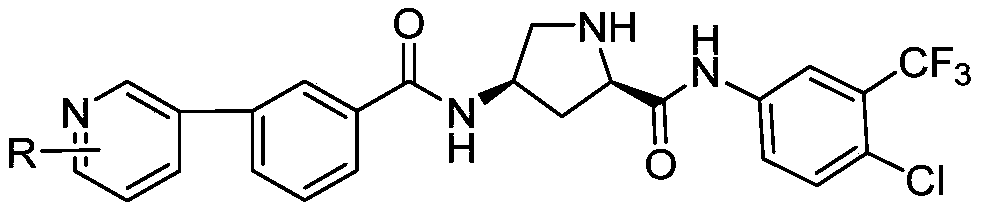

Hydroxyproline peptoid derivative and preparation method and application thereof

InactiveCN109796439AHas inhibitory activityStrong inhibitory activityOrganic chemistryAntineoplastic agentsBcr-Abl tyrosine-kinase inhibitorBcr abl kinase

Disclosed are a hydroxyproline peptoid derivative and a preparation method and application thereof. With biphenyl pyridine as a hinge region binding fragment, by adopting a design strategy of a fragment drug and introducing L-hydroxyproline as a flexible Linker, a peptoid micromolecule-like compound library with kinase inhibition activity is constructed, and through screening of ADP-Glo and otheractivity tests, a peptoid tyrosine-like kinase inhibitor which has Bcr-Abl kinase inhibition activity and prevents the proliferation of tumor cells is found. The compound can be used for preparing anti-tumor drugs and has the activity of inhibiting Bcr-Abl and Bcr-AblT315I kinases and activity of inhibiting the cell proliferation of K562 cells. By introducing the L-hydroxyproline, the structural diversity of the Bcr-Abl inhibitor is expanded, the activity result shows that the introduction of proline has a certain effect on the inhibition activity of the compound, and the proline can serve asa novel pharmacological-effect fragment of the Bcr-Abl tyrosine kinase inhibitor.

Owner:XIAN CENT HOSPITAL

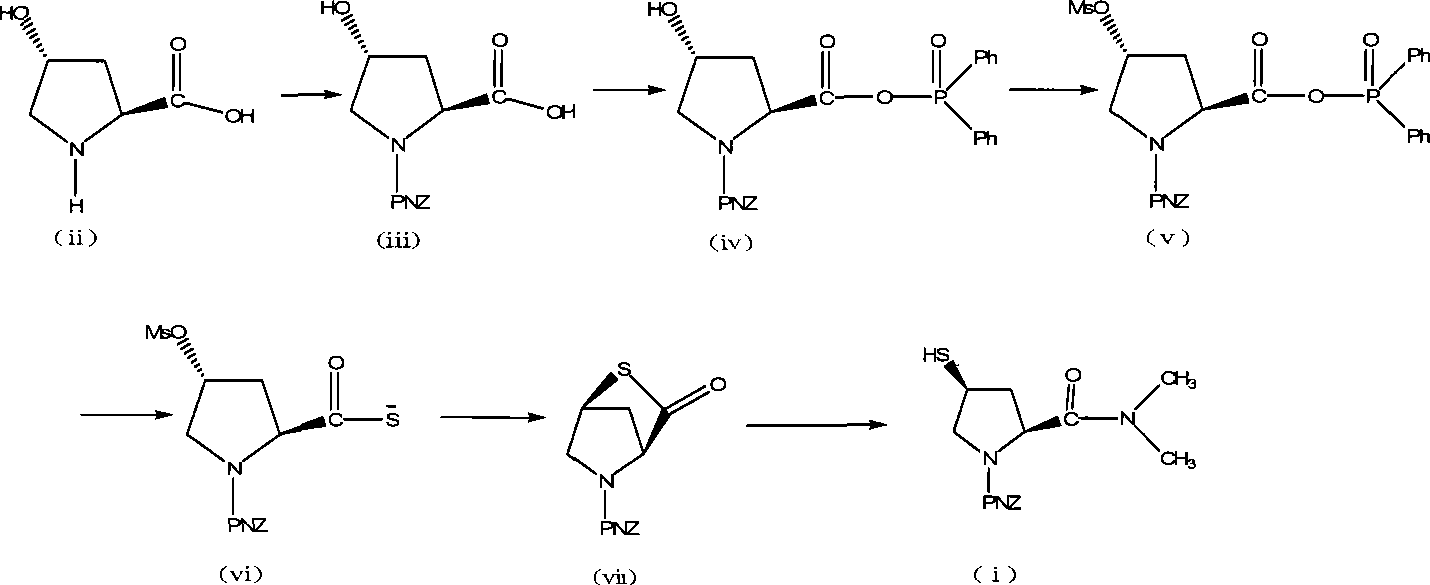

Preparation of carbapenem antibiotic side chain

ActiveCN101481346AEasy to purifyEasy to operateOrganic chemistrySide chainSODIUM SULFIDE NONAHYDRATE

The invention discloses a method for preparing side chains of carbapenems antibiotics, comprising the following steps: A) L-hydroxyproline (ii) reacts with 4-nitrobenzyl chloroformate and then is separated and crystallized to obtain a compound (iii); B) the compound (iii) reacts with diphenylphosphinyl chloride to obtain a compound (iv); the compound (iv) reacts with methanesulfonyl chloride to obtain a compound (v); the compound (v) reacts with sodium sulfide nonahydrate and is heated to 15-35 DEG C to react for 0.5-6h to obtain a compound (vii); C) the compound (vii) reacts with dimethyl amine hydrochloride and then is separated and crystallized to obtain a compound (i). The method simplifies the operation, ensures easy industrial production, reduces the production cost and leads the products to be easily purified; therefore, the obtained products have high purity and yield.

Owner:ZHEJIANG HISOAR CHUANNAN PHARMA +1

Method for synthesizing meropenem intermediate

InactiveCN101225069ASave man hoursReduce energy consumptionOrganic chemistrySide chainSynthesis methods

The invention provides a synthesis method of a side chain H of a meropenem, which is characterized in that a new radical is introduced respectively for three functional groups of 4R hydroxy L hydroxyproline and a certain spatial configuration is kept. The synthesis method for the side chain H of a meropenem has the advantages of moderate process conditions, stable product quality, and high yield, which is applicable to the industrial production on a large scale.

Owner:TIANJIN JINGYE FINE CHEM

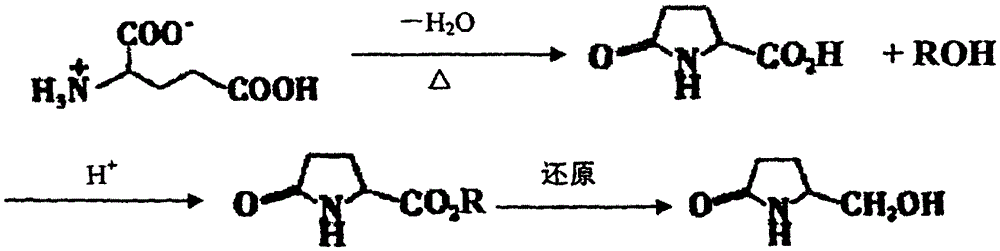

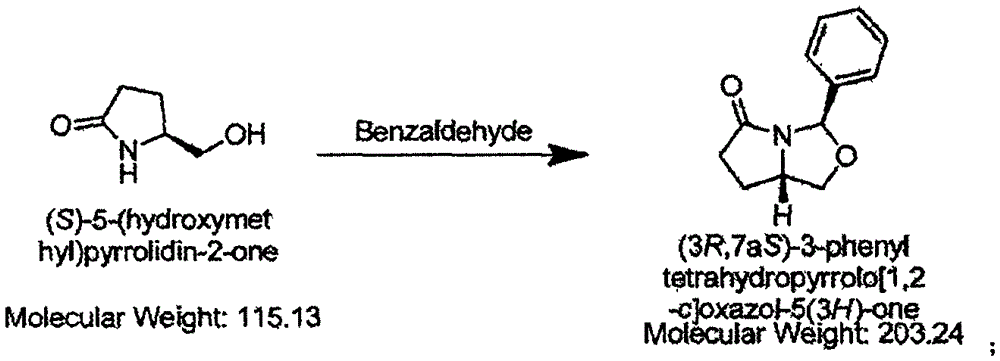

Preparation method for L-hydroxyproline

InactiveCN105837486ASolve the problem of production constraintsWork around limitationsOrganic chemistryAlcoholL-Pyroglutamic Acid

The invention provides a preparation method for L-hydroxyproline. The preparation method comprises the following steps: preparing pyroglutamic acid; preparing pyroglutamate; preparing pyroglutamic acid alcohol; preparing (3R,7aS)-3-phenyltetrahydropyrrolo[1,2]oxazole-5(3H)-one; and preparing L-hydroxyproline. Compared with the prior art, the invention has the following beneficial effects: the method overcomes the problems that a traditional manner of extraction of L-hydroxyproline from an animal donor has potential safety hazards and that production of L-hydroxyproline is limited as biological raw materials are utilized, and can synthesize L-hydroxyproline under the condition of shortage of biological raw materials; synthetic methods for L-hydroxyproline are enriched; the added value of L-hydroxyproline is increased; the application scope of L-hydroxyproline can be further broadened; prepared L-hydroxyproline is high in yield and purity, so the synthesis purity of atazanavir is indirectly improved; and common raw materials can be selected in preparation of L-hydroxyproline, so production cost is low.

Owner:南通普悦生物医药有限公司

Human skin cell growth solution

InactiveCN106726686APromote new lifePromote hyperplasiaCosmetic preparationsToilet preparationsSodium bicarbonateArginine

The invention discloses a human skin cell growth solution. The human skin cell growth solution is prepared from the following components of L-arginine, L-asparagine, L-aspartate, L-cystine dihydrochloride, L-glutamic acid, glycine, L-histidine, L-hydroxyproline, L-leucine, L-lysine hydrochloride, L-methionine, L-phenylalanine, L-proline, L-serine, L-threonine, L-tryptophan, L-tyrosine, L-valine, L-glutamine, succinic acid, sodium pyruvate, para aminobenzoic acid, calcium nitrate, potassium nitrate, ammonium nitrate, anhydrous magnesium sulfate, anhydrous sodium dihydrogen phosphate, sodium bicarbonate, potassium chloride, sodium chloride and magnesium chloride. The human skin cell growth solution has the advantages that the nutrients required by growth of cells of basal layers are provided, the newborning of surface cells is promoted, and the skin moisturizing, nourishing and compactness effects are realized; the proliferation of collagen is promoted, the dermis is thickened, the skin elasticity is restored, the aging is delayed, the market prospect is broad, and the human skin cell growth solution is suitable for being greatly popularized.

Owner:弎西艾斯(苏州)生物科技有限公司

Snake gall neck essence

InactiveCN106265441AGood skin carePromote absorptionCosmetic preparationsToilet preparationsPolyethylene glycolGlycerol

The invention discloses snake gall neck essence. The snake gall neck essence comprises the following components: snake gall extract, L-ascorbic acid 2-glucoside, benzethonium, L-hydroxyproline, butanediol, trehalose, propylene glycol, glycerol, ethanol, hydroxyethyl cellulose, polydimethylsiloxane, potassium sorbate, sorbic acid, ethylhexylglycerol, hyaluronic acid, polyethylene glycol-8, glycerol glucoside, ascorbic phosphatidic acid, citric acid, perfume, and a solvent. Substances such as the snake gall extract, the L-ascorbic acid 2-glucoside and the L-hydroxyproline are added, irrigation is low, good skin protecting effect of moisturizing and moistening the skin can be achieved, and absorption of the skin to the snake gall neck essence can be promoted.

Owner:南京禾宇化工有限公司

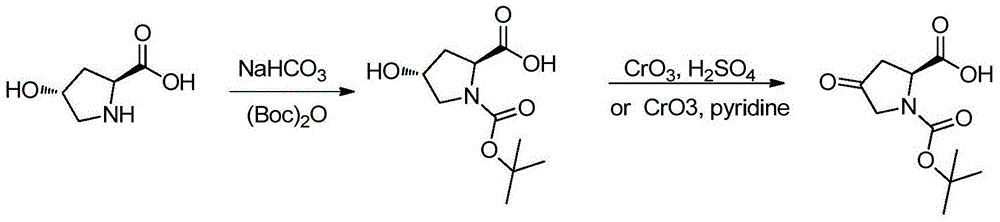

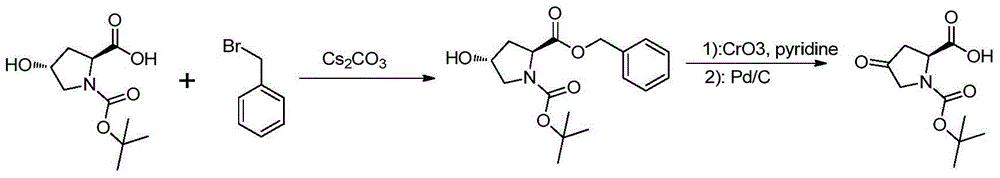

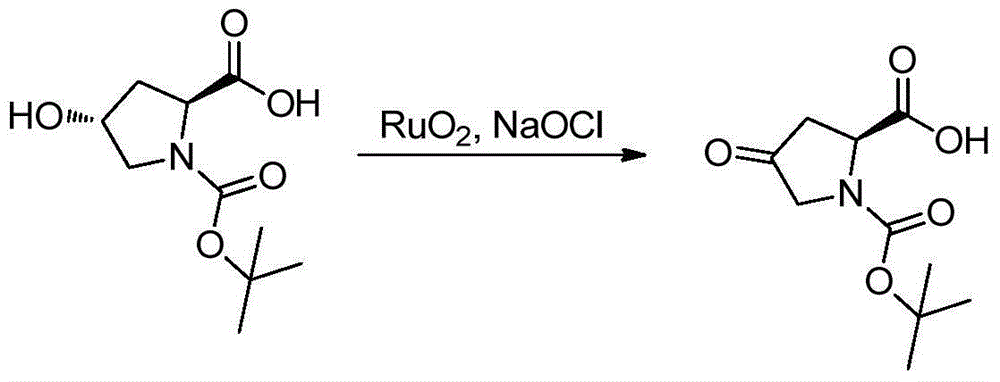

Method for synthesizing 4-oxo-L-proline derivative

The invention relates to the field of preparation methods of chemical drug intermediates, in particular to a method for synthesizing a 4-oxo-L-proline derivative. The method comprises steps as follows: L-hydroxyproline and an oxidant are mixed, and a mixture is obtained and reacts to produce an intermediate product; after an amino-group protective agent is added to a solution containing the intermediate product, the mixture reacts continuously; then, the mixture has a quenching reaction and is subjected to acidification, extraction, separation, drying and purification, and the 4-oxo-L-proline derivative is obtained. According to the method for synthesizing the 4-oxo-L-proline derivative, the primary raw material L-hydroxyproline is low in cost and easy to obtain; the whole synthesizing steps are convenient, simple and easy to operate; poisonous reagents such as heavy metals and the like are not used in the production process, and the 4-oxo-L-proline derivative is environment-friendly, low in cost and suitable for industrial production.

Owner:SICHUAN TONGSHENG AMINO ACID CO LTD

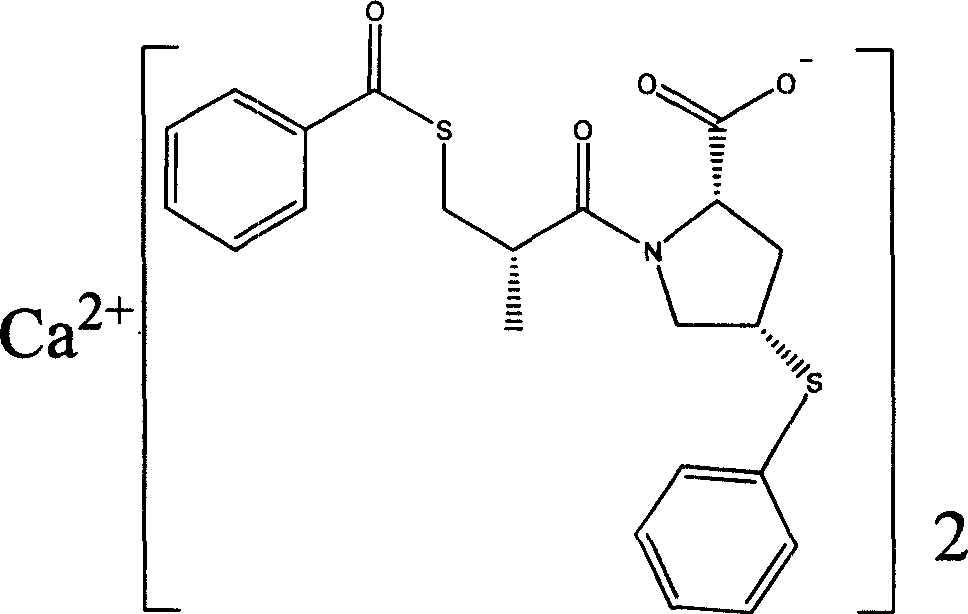

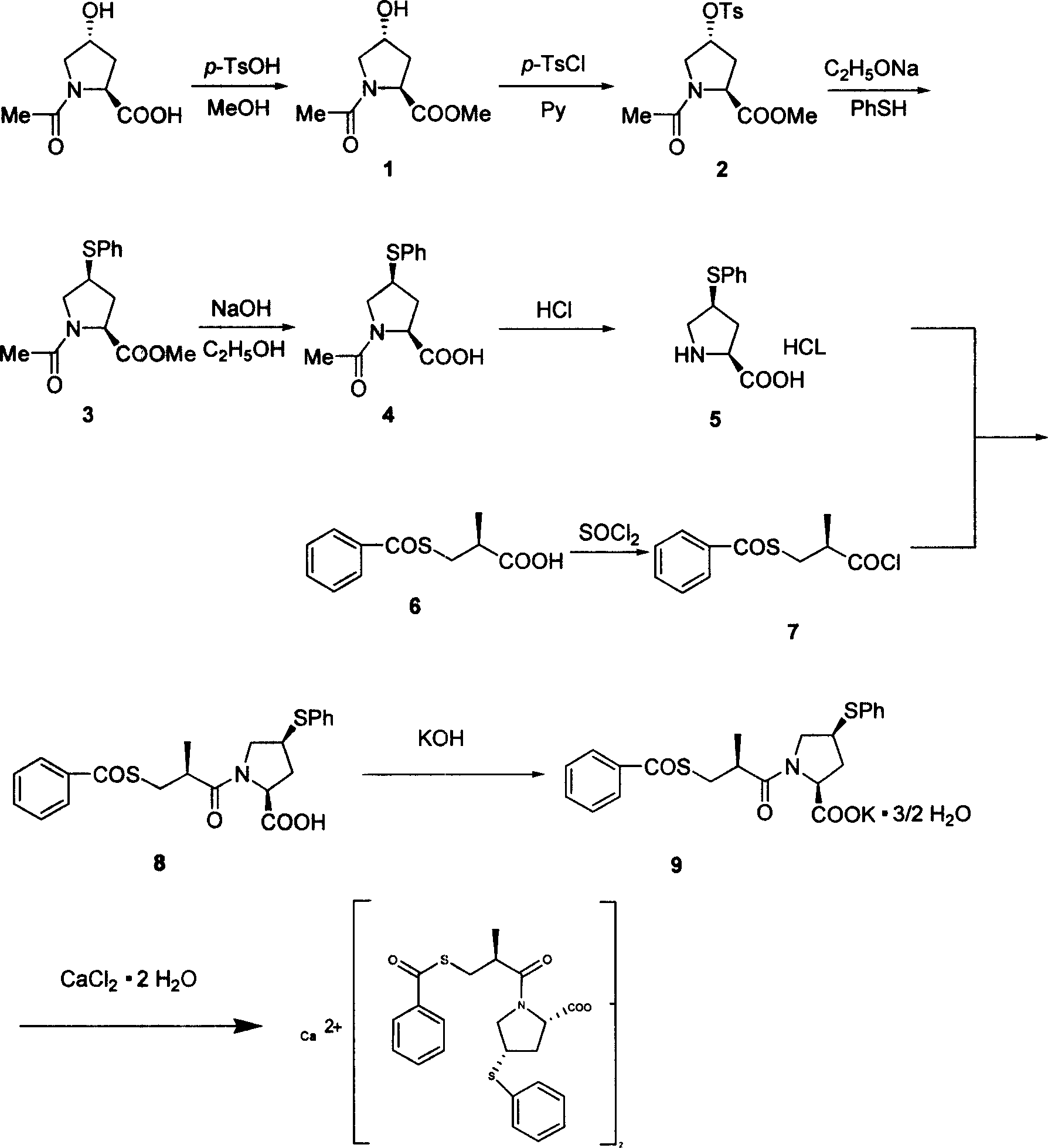

Method of preparing zofenopril calcium

The invention discloses a making method of zonfenpuli calcium, which comprises the following steps: adopting N-aceto-L-hydroxyproline as raw material; esterifying with carbinol; sulfonating through p-toluene sulfonyl chloride; substituting by benzene sulfenyl; hydrolyzing through alkaline; reacting to generate salt; obtaining cis-4-benzene sulfenyl-L-proline hydrochlorate; reacting with (s)-3-(benzoyl sulfuric group)-2-methyl propionyl chloride; obtaining the product.

Owner:GUANGDONG BANGMIN PHARMA

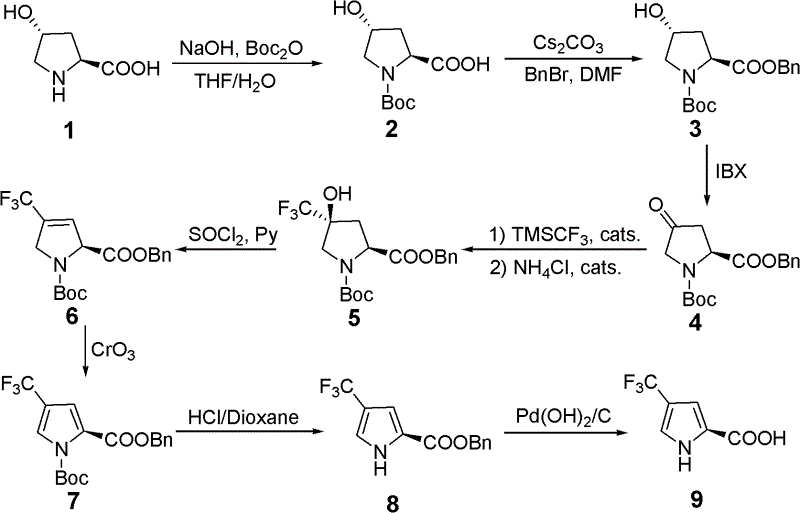

Synthetic method for 4- trifluoromethyl-2- trifluoromethyl

ActiveCN102617438AMild reaction conditionsSave raw materialsOrganic chemistryBulk chemical productionChromium trioxideTert-Butyloxycarbonyl protecting group

The invention discloses a synthetic method for 4-trifluoromethyl-2-trifluoromethyl. The method includes choosing L-hydroxyproline as a starting material, using Boc and Bn for protecting imidogen and carboxyl respectively, generating an intermediate (2S, 4R)-N-Boc-4-hydroxyproline benzyl ester; obtaining an intermediate (2S)-N-Boc-4-pidolic acid benzyl ester through 2-IBX oxidative hydroxyl; reacting TMSCF3 with the (2S)-N-Boc-4-pidolic acid benzyl ester and introducing trifluoromethyl; obtaining an intermediate N-Boc-4-trifluoromethyl-2-pyrrole carboxylic acid benzyl ester through thionyl chloride dehydration and chromium trioxide oxidation; and obtaining the 4-trifluoromethyl-2-trifluoromethyl through removing of a protecting group by hydrogen chloride and palladium hydroxide on activated carbon.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

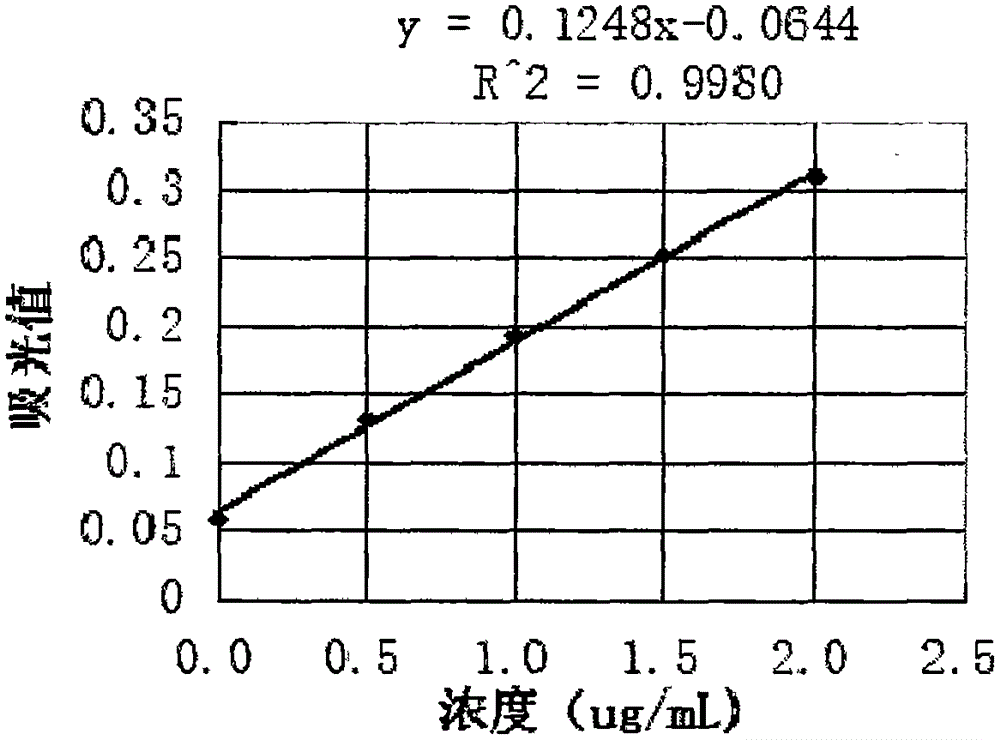

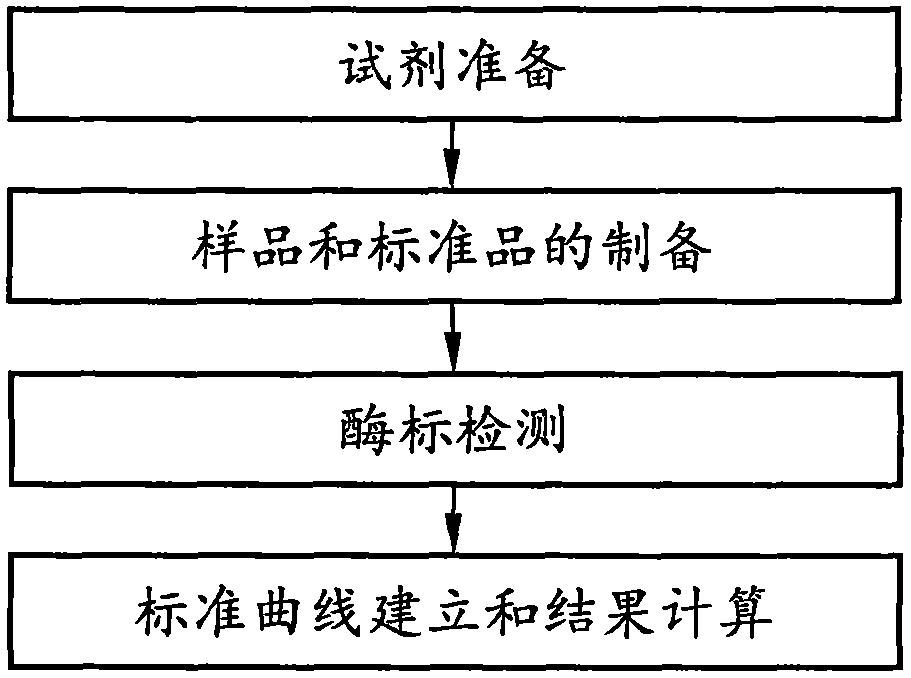

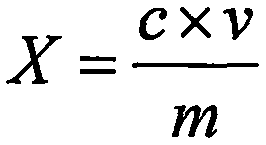

Rapid ELISA (enzyme-linked immunosorbent assay) method for leather hydrolyzed protein L-hydroxyproline in raw milk

InactiveCN105651716AReduce pollutionQuick checkMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationElisa methodStandard Preparations

The invention discloses a rapid ELISA (enzyme-linked immunosorbent assay) method for leather hydrolyzed protein L-hydroxyproline in raw milk. The method comprises the following steps: 1, reagent preparation; 2, sample and standard preparation; 3, ELISA; 4, establishment of a standard curve and result calculation. The ELISA method has high sensitivity, good reproducibility and high detection speed and is applicable to rapid screening of the leather hydrolyzed protein in the raw milk. Further, time consumed by the detection method is shortened by more than two thirds while compared with time consumed by a method assigned by the Ministry of Health, and the reagent dose is almost 3% of the reagent dose of the assigned method, so that the method has the advantages of rapid detection, low cost and little environmental pollution.

Owner:WEINAN HUALONG ANIMAL HUSBANDRY CO LTD

Fast detection method of leather-hydrolyzed protein L-hydroxyproline

InactiveCN105203478AReduce usageSimple processPreparing sample for investigationColor/spectral properties measurementsWater bathsProtein insertion

The invention discloses a fast detection method of leather-hydrolyzed protein L-hydroxyproline, in particular to a fast detection method of leather-hydrolyzed protein L-hydroxyproline illegally added into milk. The fast detection method of the leather-hydrolyzed protein L-hydroxyproline illegally added into the milk is convenient to use, fast, simple and convenient to operate and high in sensitivity and is characterized in that a reagent is added into the milk or a dairy product to be detected and is heated in water bath to conduct precipitation treatment on protein in the milk or the dairy product, and standing is performed for layering; an oxidizing agent and a color developing agent are added into supernatant collected in the step 1, reaction is performed for a period of time, and then a colorimetric method is adopted to determine the L-hydroxyproline so as to obtain related results.

Owner:SHAANXI INST FOR FOOD & DRUG CONTROL +1

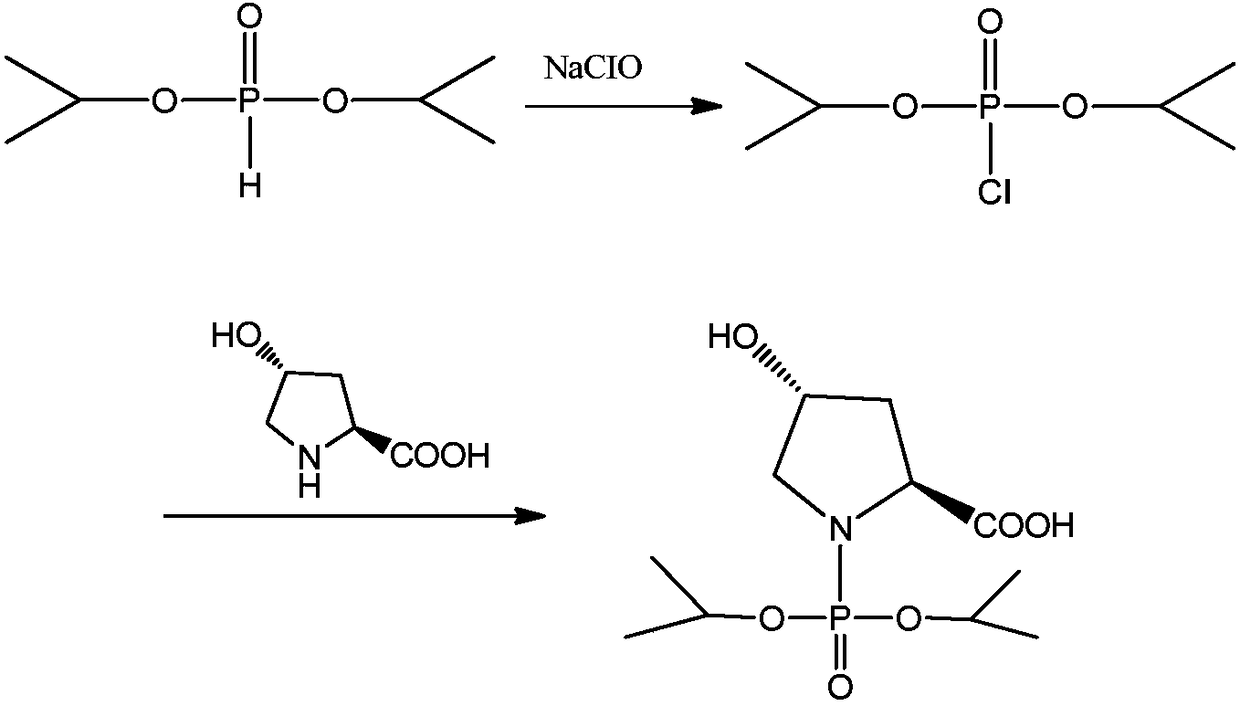

Preparation method of N-(O, O-diisopropylphosphoryl)-trans-4-hydroxy-L-proline

InactiveCN109096333AAvoid the hassle of post-processingStay out of troubleGroup 5/15 element organic compoundsOrganic chemistry methodsFiltrationGas phase

The invention belongs to the technical field of medical intermediates and specifically relates to a preparation method of N-(O, O-diisopropylphosphoryl)-trans-4-hydroxy-L-proline. The preparation method of the N-(O, O-diisopropylphosphoryl)-trans-4-hydroxy-L-proline comprises the steps of adding L-hydroxyproline to purified water; cooling an obtained mixture; beginning to drip 25% sodium hydroxidesolution into the obtained mixture while stirring the obtained mixture; regulating pH value of a mixture to 9.0-10; stirring the mixture to a clarified state for future use; dripping sodium hypochlorite into diisopropyl phosphite at a low temperature; rapidly stirring an obtained mixture and preserving the heat of the obtained mixture for reaction; after it is detected in gas phase that DIPP reaction is completely finished, adding sodium hydrogen sulfite to a reaction product; adding prepared L-hydroxyproline solution to the reaction product; controlling the pH value of a reaction system so that the reaction system is kept to be alkaline; heating and preserving the heat of the reaction system till the pH value of a reaction liquid is not changed; using halogenated hydrocarbon to wash thereaction system and layering the reaction system; regulating an aqueous phase to be acidic by using hydrochloric acid; adding an ester organic solvent to extract the aqueous phase; decompressing and concentrating an organic phase; carrying out cooling and suction filtration on the decompressed and concentrated organic phase; and drying the cooled and sucked-filtered organic phase at 40 degrees centigrade to obtain white powder solids. The preparation method of the N-(O, O-diisopropylphosphoryl)-trans-4-hydroxy-L-proline, provided by the invention, has the advantages of less side reaction, highyield, high purity and mild reaction condition.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

Bioconversion method of L-hydroxyproline

InactiveCN107435056AHigh selectivityMild reaction conditionsMicroorganism based processesFermentationChemical reactionPollution

The present invention discloses a bioconversion method of L-hydroxyproline. According to the bioconversion method, a surfactant and an additive are added to establish a bioconversion system by using L-proline and alpha-ketoglutaric acid as substrates and using the whole cell of engineering bacteria containing proline-4-hydroxylase as a catalyst, and a conversion reaction is performed to obtain the conversion liquid containing L-hydroxyproline. According to the present invention, the bioconversion method has advantages of strong stereoselectivity, mild reaction conditions, easy operation, low cost, less pollution and less catalyst consumption, and can complete the reactions difficultly performed in chemical reactions, wherein the space time yield is more than 62.36 g / d / L, the yield is more than 90%, the crystal purity is more than 98%, and the optical purity is more than 99%.

Owner:绍兴百茵生物技术有限公司

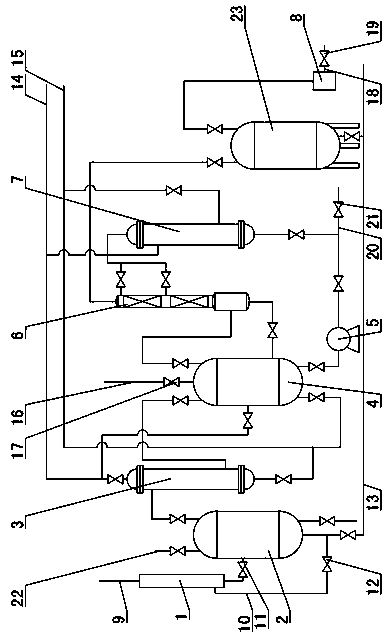

Apparatus to recycle waste ammonia water from L-hydroxyproline production and treatment method of apparatus

PendingCN109354099AAchieve reuseReduce solubilityWater contaminantsNature of treatment waterPurified waterAmmonia gas

The invention belongs to the technical field of waste ammonia water recycling and relates to an apparatus to recycle waste ammonia water from L-hydroxyproline production and a treatment method of theapparatus. The apparatus and the treatment method are characterized in that the apparatus comprises blow-off tank (2) and a cyclic adsorbing device, waste ammonia water incoming pipe (22) is connectedto the top of the blow-off tank (2) and is provided with a waste ammonia water incoming valve, a discharge port of the blow-off tank (2) is communicated with the cyclic adsorbing device, a dischargeport of the cyclic adsorbing device is connected with ammonia water outgoing pipe (20), blow-down pipe (13) is connected to the bottom of the blow-off tank (2), a blow-off tank blow-down valve is arranged between the blow-off tank (2) and the blow-down pipe (13), and the cyclic adsorbing device is connected with purified water incoming pipe (16). The apparatus herein helps solve the problem that direct emission of waste ammonia water causes environmental pollution and reduce the production cost for enterprises; the treatment method helps recycle ammonia gas, thereby avoiding the environmentalpollution due to direct emission of waste ammonia water.

Owner:SHANDONG JINYANG PHARMA

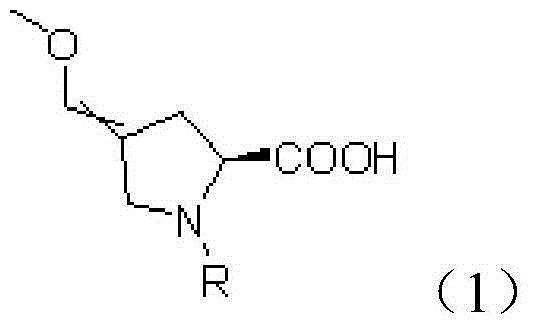

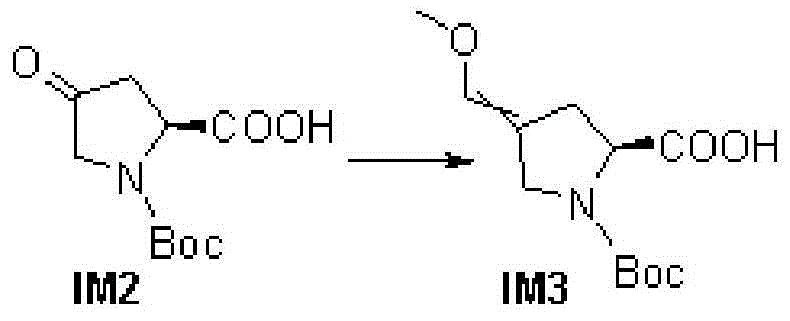

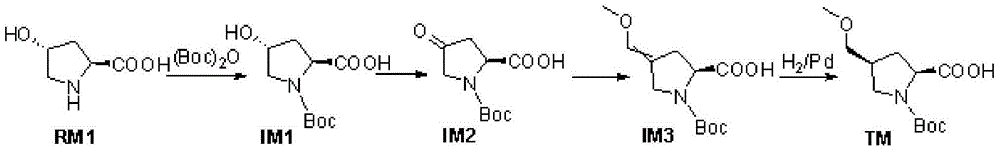

(4S)-N-Boc-4-methoxymethyl-L-proline synthesis method

The invention discloses a (4S)-N-Boc-4-methoxymethyl-L-proline synthesis method. The method comprises that 1, L-hydroxyproline as an initial raw material is subjected to Boc protection so that N-Boc-L-hydroxyproline is produced, 2, the N-Boc-L-hydroxyproline is dissolved in a solvent, the solution and 2, 2, 6, 6-tetramethyl-1-piperidinyloxy (TEMPO) undergo an oxidation reaction to produce (2S)-N-Boc-4-oxopyrrolidine-2-carboxylic acid, 3, the (2S)-N-Boc-4-oxopyrrolidine-2-carboxylic acid and (methoxymethyl)triphenylphosphonium chloride are dissolved in a solvent and undergo a wittig reaction to produce (2S)-N-Boc-4-methoxymethylenepyrrolidine-2-carboxylic acid, and 4, the (2S)-N-Boc-4-methoxymethylenepyrrolidine-2-carboxylic acid and tert-butylamine are dissolved in water and undergo a hydrogenation reaction to produce (4S)-N-Boc-4-methoxymethyl-L-proline. The method shortens reaction processes, is free of severe-toxicity cyanides, improves safety, reduces environmental protection pressure, improves atom economy, reduces waste discharge and greatly reduces a raw material cost.

Owner:PORTON FINE CHEM

Synthesis method of teneligliptin-related impurity

InactiveCN110028496AImprove protectionReasonable process designOrganic chemistrySynthesis methodsQuality control

The invention discloses a synthesis method of a teneligliptin-related impurity, optimal reaction steps and reaction conditions are screened out through a large number of experiments, the whole processis reasonable in design, high in operability, mild in reaction condition and high in yield, and industrial production can be realized. According to the invention, Boc-L-hydroxyproline and 1-(3-methyl-1-phenyl-5-pyrazolyl)piperazine are taken as raw materials, and the raw materials are subjected to seven-step reaction to synthesize the teneligliptin-related impurity, and the prepared teneligliptin-related impurity is high in purity, can provide a basis for quality control, safety and efficiency evaluation of teneligliptin, and has important application values.

Owner:TLC NANJING PHARMA RANDD CO LTD

Method for producing L-hydroxyproline by microbial fermentation method

InactiveCN110016486AGuaranteed yieldGuaranteed qualityOrganic chemistryMicroorganism based processesEscherichia coliEvaporation

The invention discloses a method for producing L-hydroxyproline by a microbial fermentation method. The method comprises the steps of inoculating fermentation culture mediums with escherichia coli, adding a carbon source and a nitrogen source to the fermentation culture mediums, in the presence of the carbon source, enabling the carbon source in aqueous mediums to be converted into L-hydroxyproline, and performing extraction on the aqueous medium so as to obtain the produced L-hydroxyproline; performing filtration on L-hydroxyproline fermentation liquid through a ceramic membrane to obtain trapped substances and a filtered clear solution, conveying the filtered clear solution into a nanofiltration membrane, performing impurity removal clarification to obtain a nano filtered clear solutionand a nano filtered trapped solution, and performing filtration and concentration on the nano filtered clear solution through a reverse osmosis membrane so as to obtain a concentrated solution; and decoloring the concentrated solution through activated carbon so as to obtain a L-hydroxyproline solution, conveying the L-hydroxyproline solution into an evaporator, and performing evaporation and crystallization so as to obtain white L-hydroxyproline crystals. Multi-stage membranes are combined with filtration and concentration, and the L-hydroxyproline is separated and extracted; on the base of guaranteeing the yield and the quality of L-proline by the technology, zero discharge of waste water is also realized; and in the fermentation culture mediums, sugar, glycol or organic acid is used asthe carbon source, and a large quantity of L-hydroxyproline is directly obtained.

Owner:南通普悦生物医药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com