Preparation method for L-hydroxyproline

A technology of hydroxyproline and glutamic acid, which is applied in the field of preparation of L-hydroxyproline, can solve the problems of high production cost and slow production efficiency, and achieve low production cost, extended application range, yield and purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

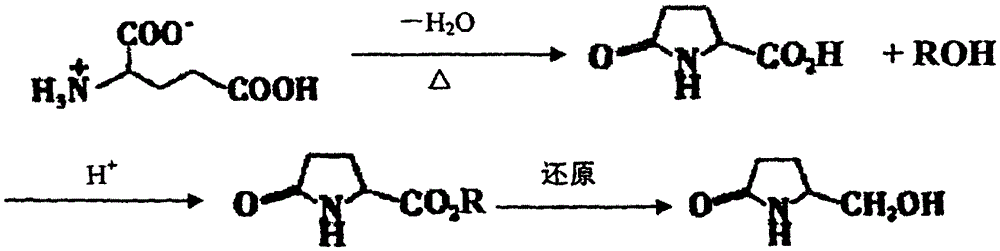

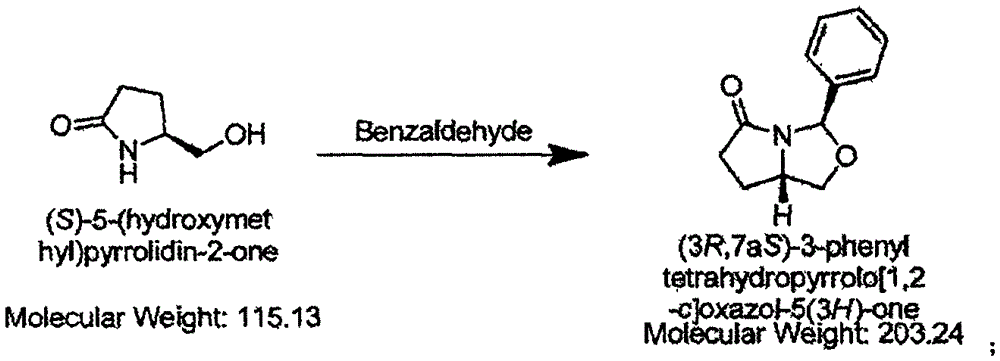

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to a preparation method of L-hydroxyproline, specifically comprising the following steps:

[0038] Add 60kg of glutamic acid into a 200L electric heating stainless steel reaction tank, carry out oil bath dehydration reaction at 220-290°C, keep it at 140°C for 55min, and put it into 10L of water;

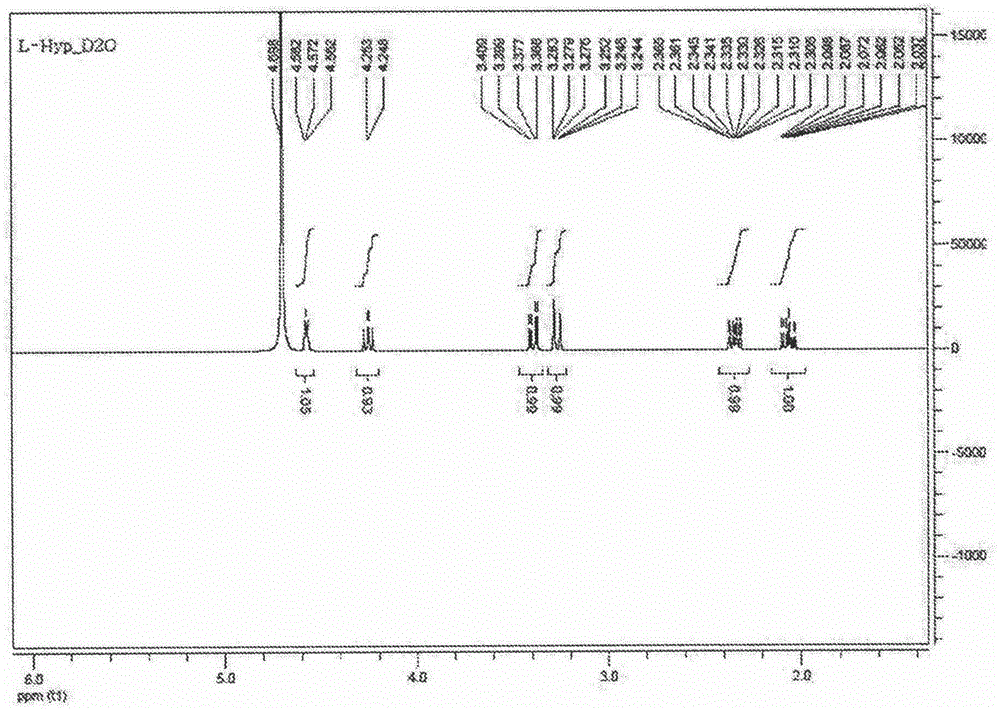

[0039] Stir and cool, centrifuge to obtain crude pyroglutamic acid, add water to the crude pyroglutamic acid at 65°C to saturation, centrifugally filter, cool to 35°C for crystallization, centrifuge the crystals, wash and dry to obtain pyroglutamic acid Fine product 28kg, yield 54% (based on glutamic acid feeding theoretical yield), melting point is 159~161 ℃, [a] 20 =-11.6 (C=2, H 2 O);

[0040] According to the feed ratio of pyroglutamic acid, absolute ethanol, and thionyl chloride as 1mol: 100ml: (0.06~1.2) mol, add 10L of absolute ethanol to a dry three-necked flask, cool to - Below 5°C, add 300ml of thionyl chloride dropwise, add 1000g of pyrogl...

Embodiment 2

[0048] This embodiment relates to a preparation method of L-hydroxyproline, specifically comprising the following steps:

[0049] Add 80kg of glutamic acid into a 200L electric heating stainless steel reaction tank, carry out dehydration reaction in oil bath at 250-270°C, keep it at 160°C for 50min, then put it into 10L of water;

[0050] Stir and cool, centrifuge to obtain the crude pyroglutamic acid, add water to the crude pyroglutamic acid at 50°C to saturation, centrifugally filter, cool to 30°C for crystallization, centrifuge the crystal, wash and dry to obtain pyroglutamic acid Fine product 37kg, yield 53.8% (based on glutamic acid feeding theoretical yield), melting point is 158.5 ~ 161 ° C, [a] 20 =-11.5 (C=2, H 2 O);

[0051] According to the feed ratio of pyroglutamic acid, absolute ethanol and concentrated sulfuric acid is 1mol: 100ml: (0.06 ~ 1.2) mol, add 10L of absolute ethanol to a dry three-necked flask, and cool down to -5°C with ice salt water Next, add 25...

Embodiment 3

[0059] This embodiment relates to a preparation method of L-hydroxyproline, specifically comprising the following steps:

[0060] Add 60kg of glutamic acid to a 200L electric heating stainless steel reaction tank, carry out oil bath dehydration reaction at 220-250°C, keep it at 140°C for 55min, and then put it into 10L of water;

[0061] Stir and cool, centrifuge to obtain crude pyroglutamic acid, add water to the crude pyroglutamic acid at 65°C to saturation, centrifugally filter, cool to 35°C for crystallization, centrifuge the crystals, wash and dry to obtain pyroglutamic acid Fine product 28kg, yield 54% (based on glutamic acid feeding theoretical yield), melting point is 158.5~161 ℃, [a] 20 =-11.5 (C=2, H 2 O);

[0062] According to the feed ratio of pyroglutamic acid, absolute ethanol, and hydrochloric acid is 1mol: 100ml: (0.06 ~ 1.2) mol, add 1L of absolute ethanol to a dry three-necked flask, and cool down to below -5°C with ice salt water , add 150g of hydrochlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com