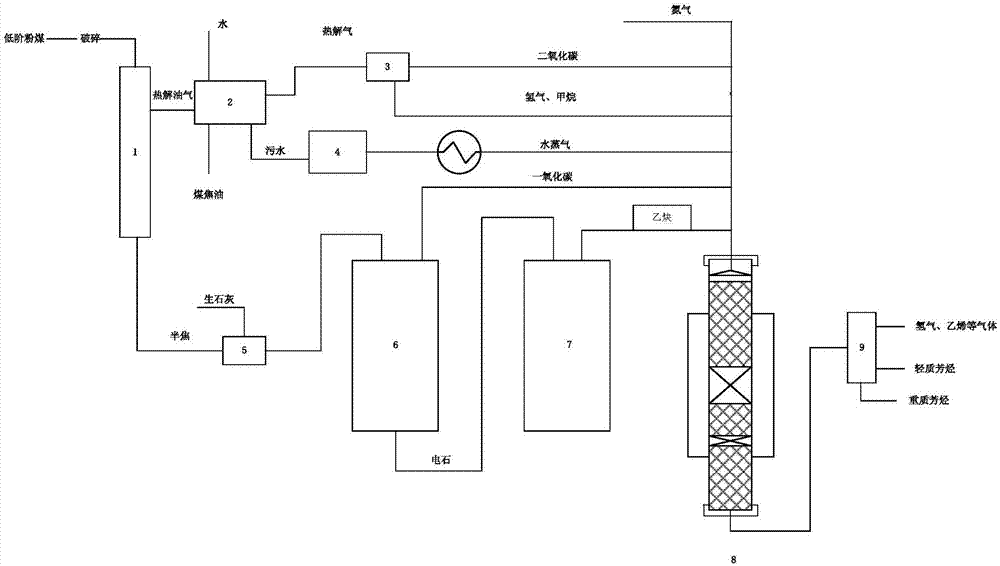

System used for preparing light aromatic hydrocarbon from pulverized coal and having wastewater reuse function and method

A technology for aromatics and sewage, which is applied in the field of producing light aromatics and can solve problems such as increasing demand for aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

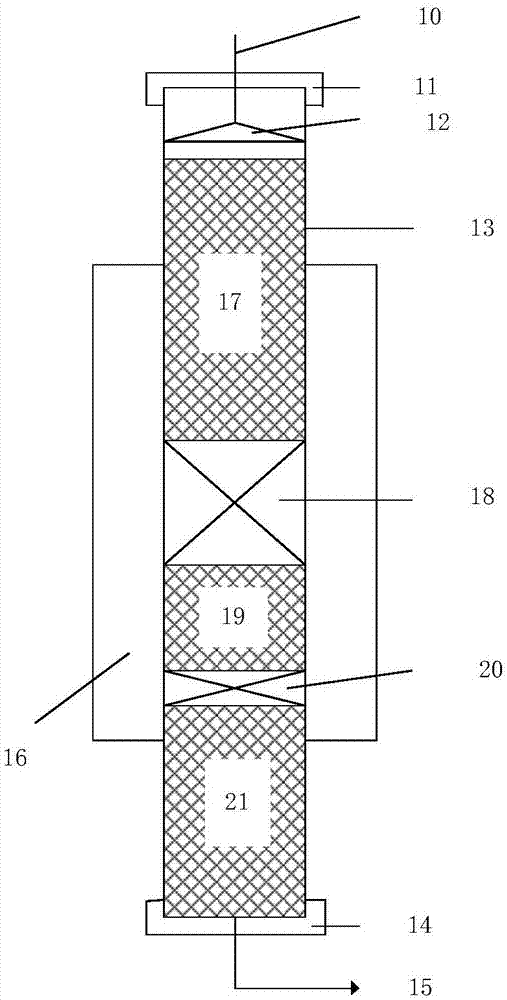

[0149] Screen the pulverized coal with a particle size of less than 3mm, send the pulverized coal to the top of the fast pyrolysis device 1 through the conveyor belt, enter the fast pyrolysis device 1 for pyrolysis, the pyrolysis temperature is 800°C, and the pyrolysis time is 2s to generate semi-coke, gas and coal tar. Mix quicklime and semi-coke at a mass ratio of 3:2, add an appropriate amount of binder, and press balls to control the diameter of the pellets to 10-40mm. The ball is sent into calcium carbide furnace 6 to produce calcium carbide. The calcium carbide produced is cooled and pulverized, the particle size of the calcium carbide is controlled between 50-80mm, and it enters the acetylene generator 7 to react to obtain acetylene.

[0150]In the reactor for preparing aromatics from acetylene in this embodiment, the stainless steel reaction sleeve used is a reaction sleeve lined with ceramics, and the inner diameter of the reaction sleeve: the length of the reaction ...

Embodiment 2

[0153] Screen the pulverized coal with a particle size of less than 3mm, send the pulverized coal to the top of the fast pyrolysis device 1 through the conveyor belt, enter the fast pyrolysis device 1 for pyrolysis, the pyrolysis temperature is 500°C, and the pyrolysis time is 30s to generate semi-coke, gas and coal tar. Mix quicklime and semi-coke at a mass ratio of 2:1, add an appropriate amount of binder, and press balls to control the diameter of the pellets to 10-40mm. The ball is sent into calcium carbide furnace 6 to produce calcium carbide. The calcium carbide produced is cooled and pulverized, the particle size of the calcium carbide is controlled between 50-80mm, and it enters the acetylene generator 7 to react to obtain acetylene.

[0154] In the reactor for preparing aromatics from acetylene in this embodiment, the stainless steel reaction sleeve used is a reaction sleeve lined with ceramics, and the inner diameter of the reaction sleeve: the length of the reactio...

Embodiment 3

[0157] Screen the pulverized coal with a particle size of less than 3mm, and send the pulverized coal to the top of the fast pyrolysis device 1 through the conveyor belt, and then enter the fast pyrolysis device 1 for pyrolysis. The pyrolysis temperature is 700°C, and the pyrolysis time is 15s. gas and coal tar. Mix quicklime and semi-coke at a mass ratio of 1:1, add an appropriate amount of binder, and press balls to control the diameter of the pellets to 10-40mm. The ball is sent into calcium carbide furnace 6 to produce calcium carbide. The calcium carbide produced is cooled and pulverized, the particle size of the calcium carbide is controlled between 50-80mm, and it enters the acetylene generator 7 to react to obtain acetylene.

[0158] In the reactor for preparing aromatics from acetylene in this embodiment, the stainless steel reaction sleeve used is a reaction sleeve lined with ceramics, and the inner diameter of the reaction sleeve: the length of the reaction sleeve:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com