Patents

Literature

170 results about "PARA-AMINOBENZOIC ACID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

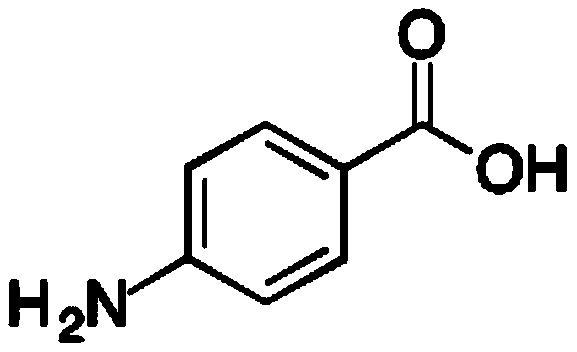

Para-aminobenzoic acid (PABA), also called aminobenzoic acid, a vitamin-like substance and a growth factor required by several types of microorganisms. In bacteria, PABA is used in the synthesis of the vitamin folic acid.

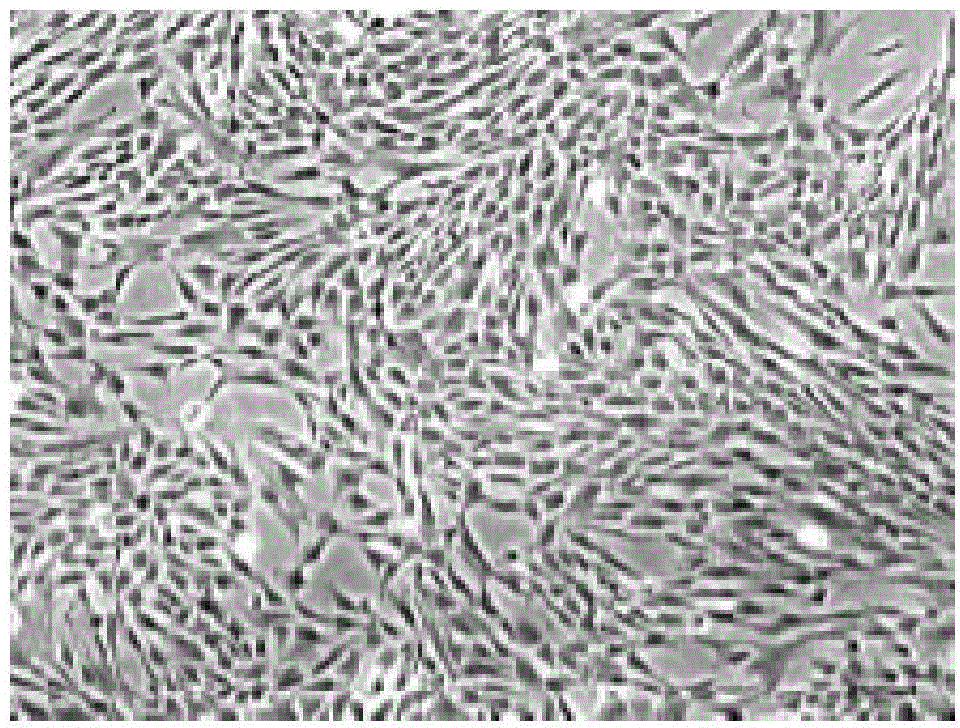

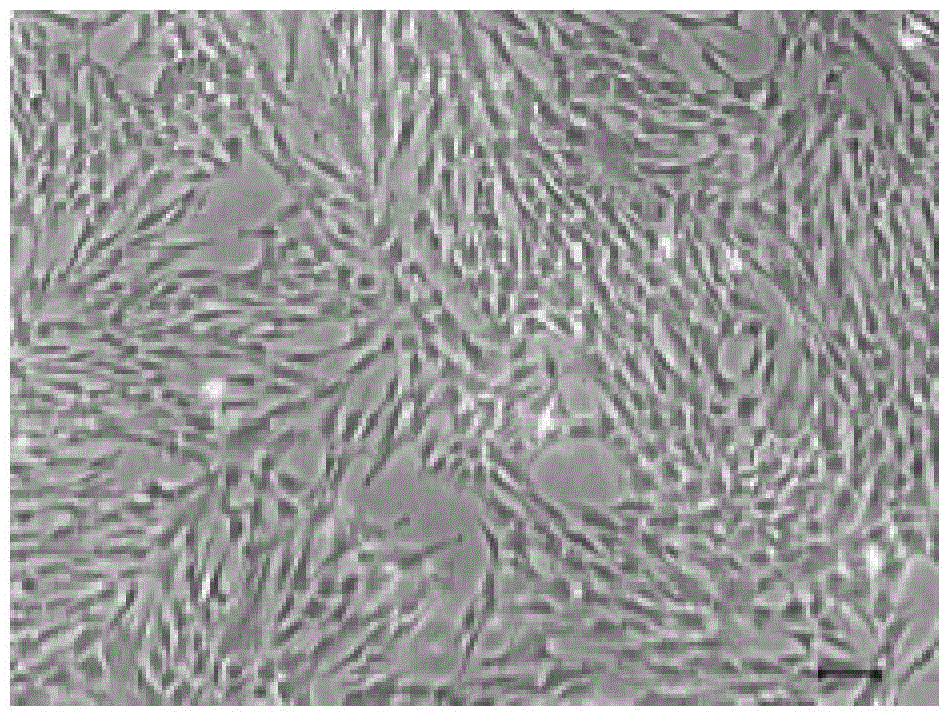

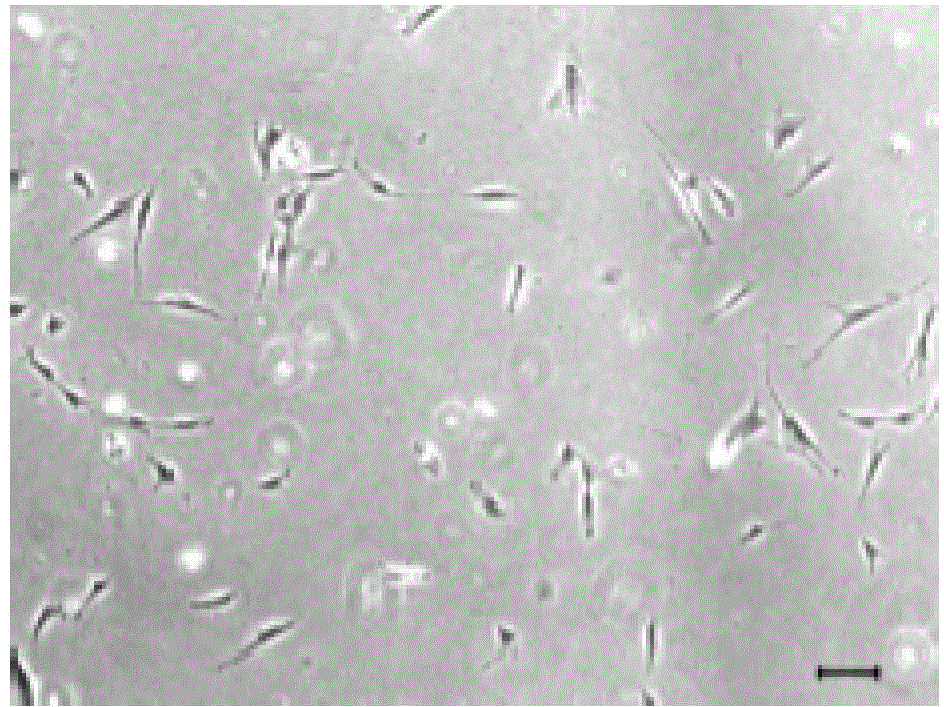

SFM (serum-free medium) for culturing MSCs (mesenchymal stem cells)

ActiveCN103555665AClear ingredientsAvoid heterogeneous contaminationSkeletal/connective tissue cellsSodium bicarbonateSerum free media

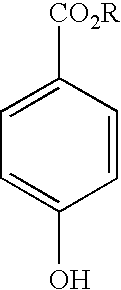

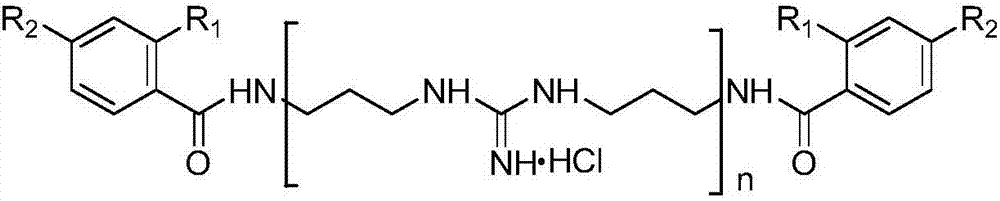

The invention relates to an SFM (serum-free medium) for culturing MSCs (mesenchymal stem cells). Based on volume, the SFM comprises the following components: 10.2 grams per liter of alpha-MEM (alpha-minimum essential medium), 2.4 grams per liter of sodium bicarbonate, 1 to 5 millimoles of L-glutamine, 50 to 300 milligrams per liter of poloxamer 188, 2 to 8 grams per liter of recombinant human albumin, 10 to 20 milligrams per liter of recombinant human transferrin, 2 to 10 milligrams per liter of recombinant human insulin, 1 to 5 millimoles per liter of Hepes, 50 nanomoles of beta-mercaptoethanol, 0.1 to 1 milligram per liter of lipid, 1 to 5 milligrams per liter of trace element, 0.1 to 5 milligrams per liter of glutathione, 0.5 to 5 milligrams per liter of para-aminobenzoic acid, 1 to 50 nanograms per milliliter of hydrocortisone, 20 to 50 milligrams per liter of vitamin PP, 5 to 50 milligrams per liter of vitamin C, 2 to 10mu M of compound shown in a formula I, 5 to 20mu M of compound shown in a formula II, 10 to 20 nanograms per milliliter of progestin, 1 to 10 milligrams per liter of putrescine, 1 to 10 international units per liter of heparin, 1 to 10 nanograms per milliliter of EGF (epidermal growth factor), 1 to 10 nanograms per milliliter of b-FGF (b-fibroblast growth factor), 1 to 10 nanograms per milliliter of HGF (hepatocyte growth factor) and 1 to 10 nanograms per milliliter of VEGF (vascular endothelial growth factor). The SFM for culturing the MSCs is a BPS-SFM which has determinate chemical components and is free of animal-derived substances.

Owner:BEIJING DONGFANG HUAHUI BIOMEDICAL TECH

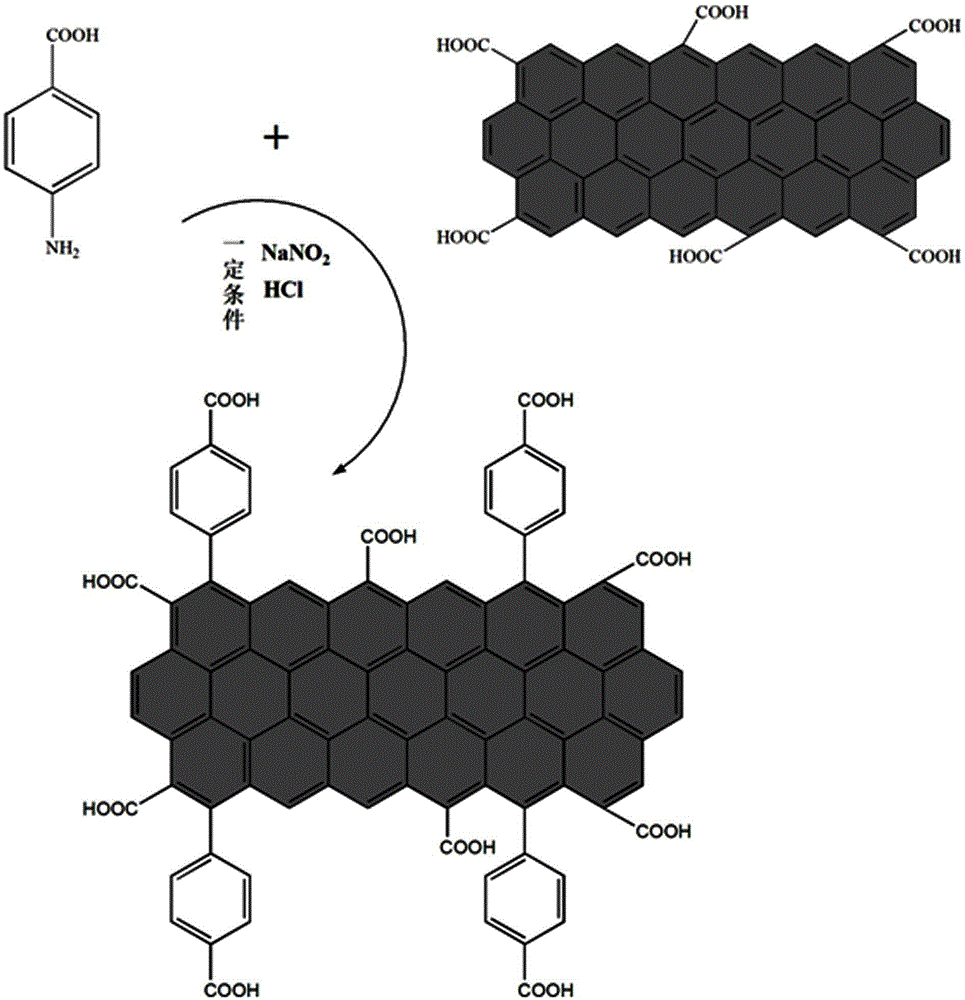

Steel structure fireproof anticorrosion function integrated coating and preparing method thereof

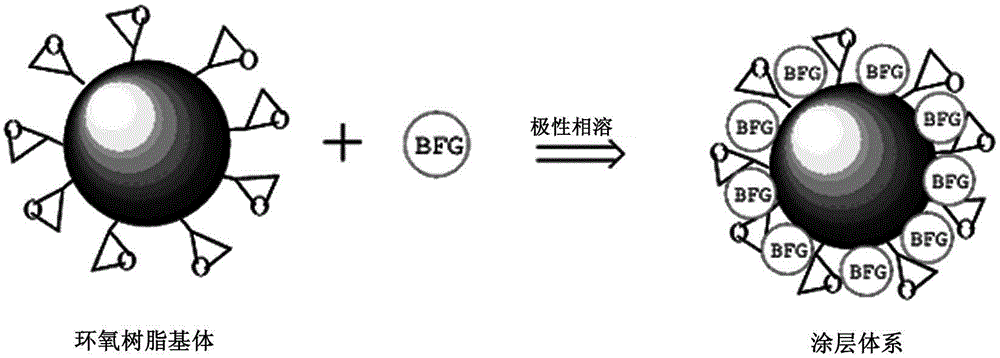

ActiveCN105385310ALarge specific surface areaImprove barrier propertiesFireproof paintsAnti-corrosive paintsBenzoic acidEpoxy

The invention provides steel structure fireproof anticorrosion function integrated coating and a preparing method thereof. The coating is prepared by compounding benzoic acid functionalized graphene, water-borne epoxy resin, a water-borne curing agent and water. The benzoic acid functionalized graphene is prepared from graphene and para aminobenzoic acid. The preparing method adopts a hydrothermal method to prepare the graphene and further functionalizes the graphene to generate the benzoic acid functionalized graphene as a nanofiller, and the benzoic acid functionalized graphene is compounded with the water-borne epoxy resin to form the steel structure fireproof anticorrosion function integrated coating, which has the characteristics of small filler use level, environment friendliness in a preparing process and low energy consumption. In the preparing method, the filler and the water-borne epoxy resin have better compatibility, and the crosslinking density of a coating is further increased, so that the thermal barrier property and corrosion resistance of the epoxy resin are furthest improved, more ideal flame-retardant and anticorrosion effects are achieved, the prevalent defects of poor barrier property and short anticorrosion period of the current water-borne anticorrosion coating are overcome, and better application prospect and practical significance are realized.

Owner:SHENYANG SHUNFENG IND GRP CO LTD

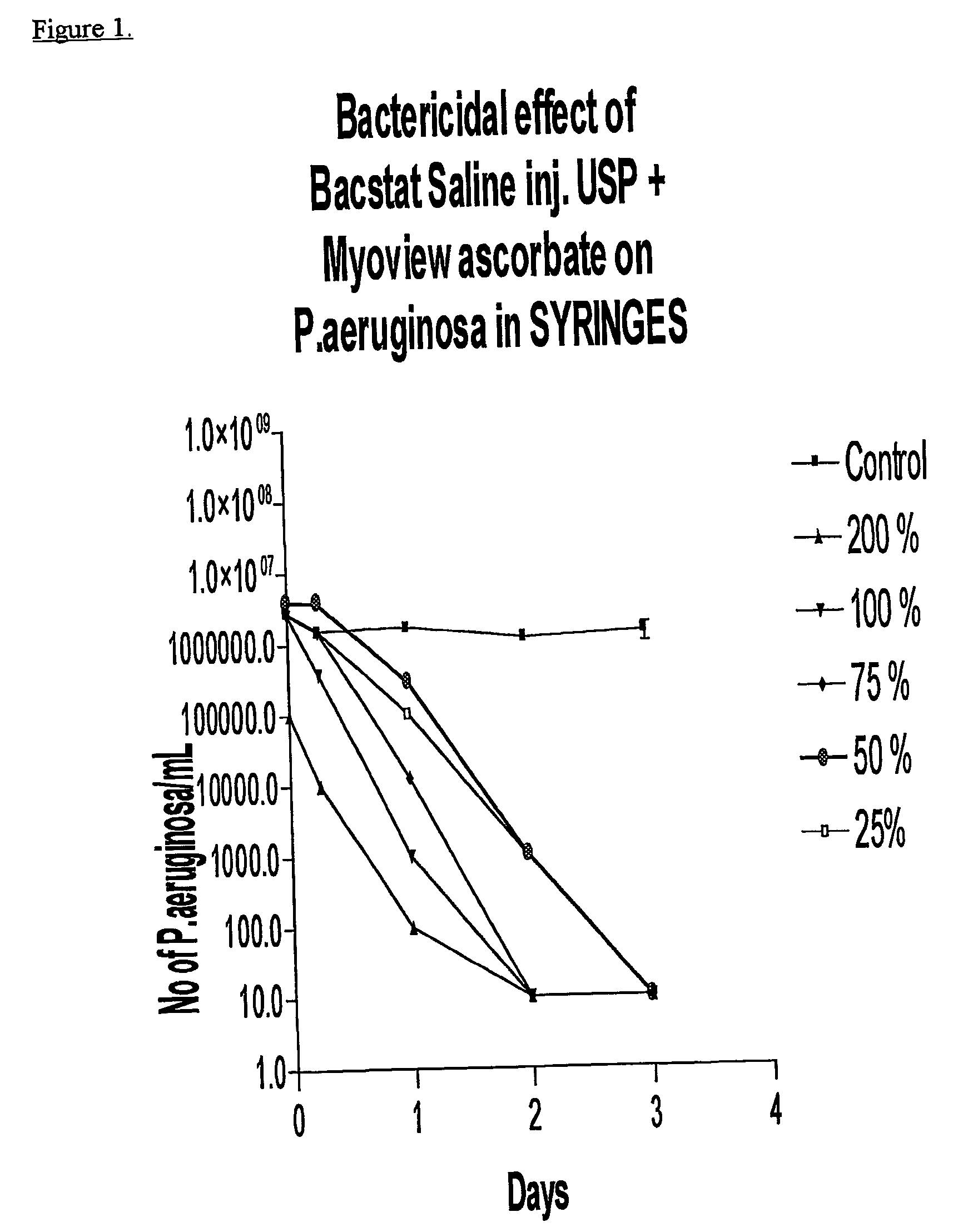

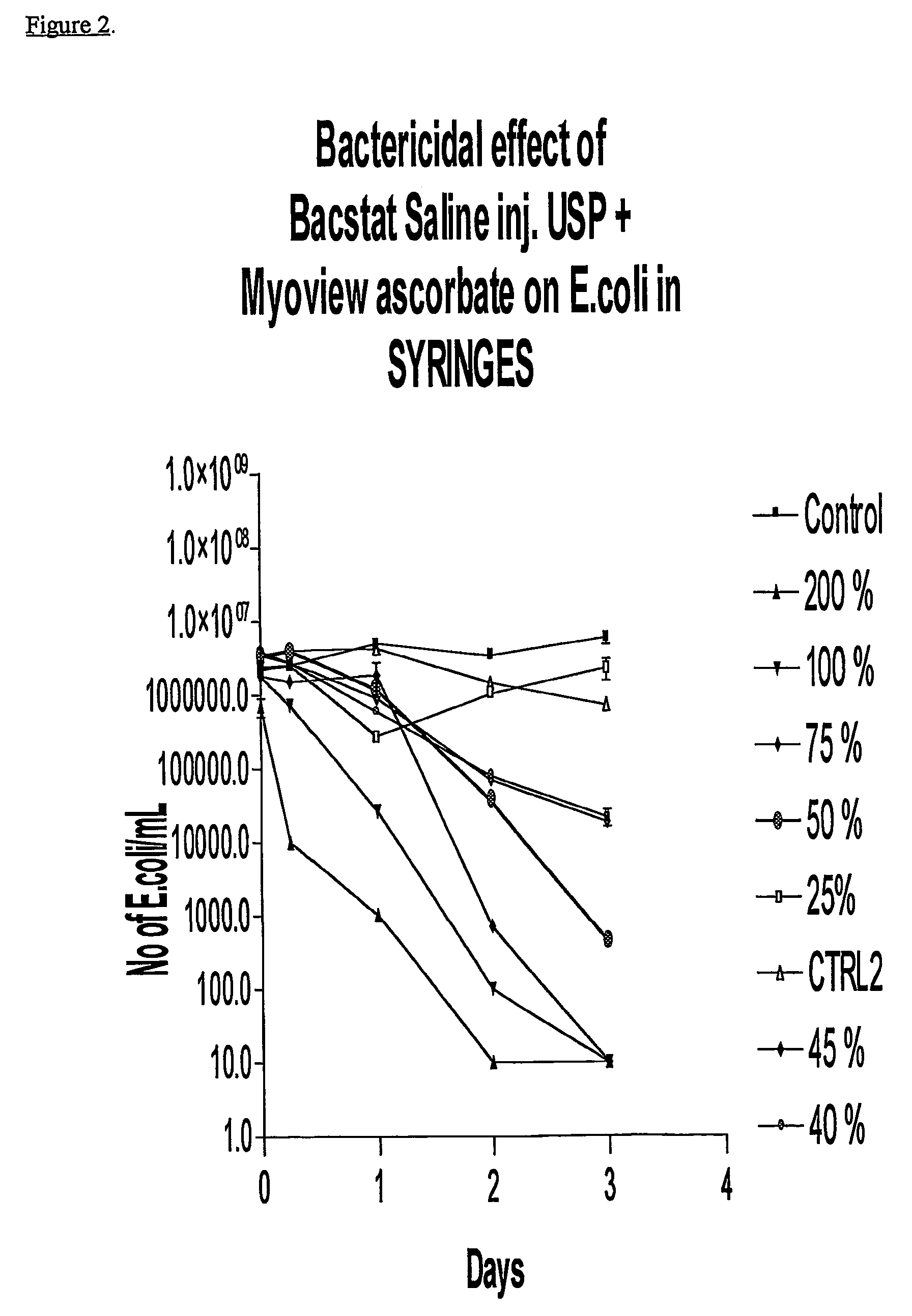

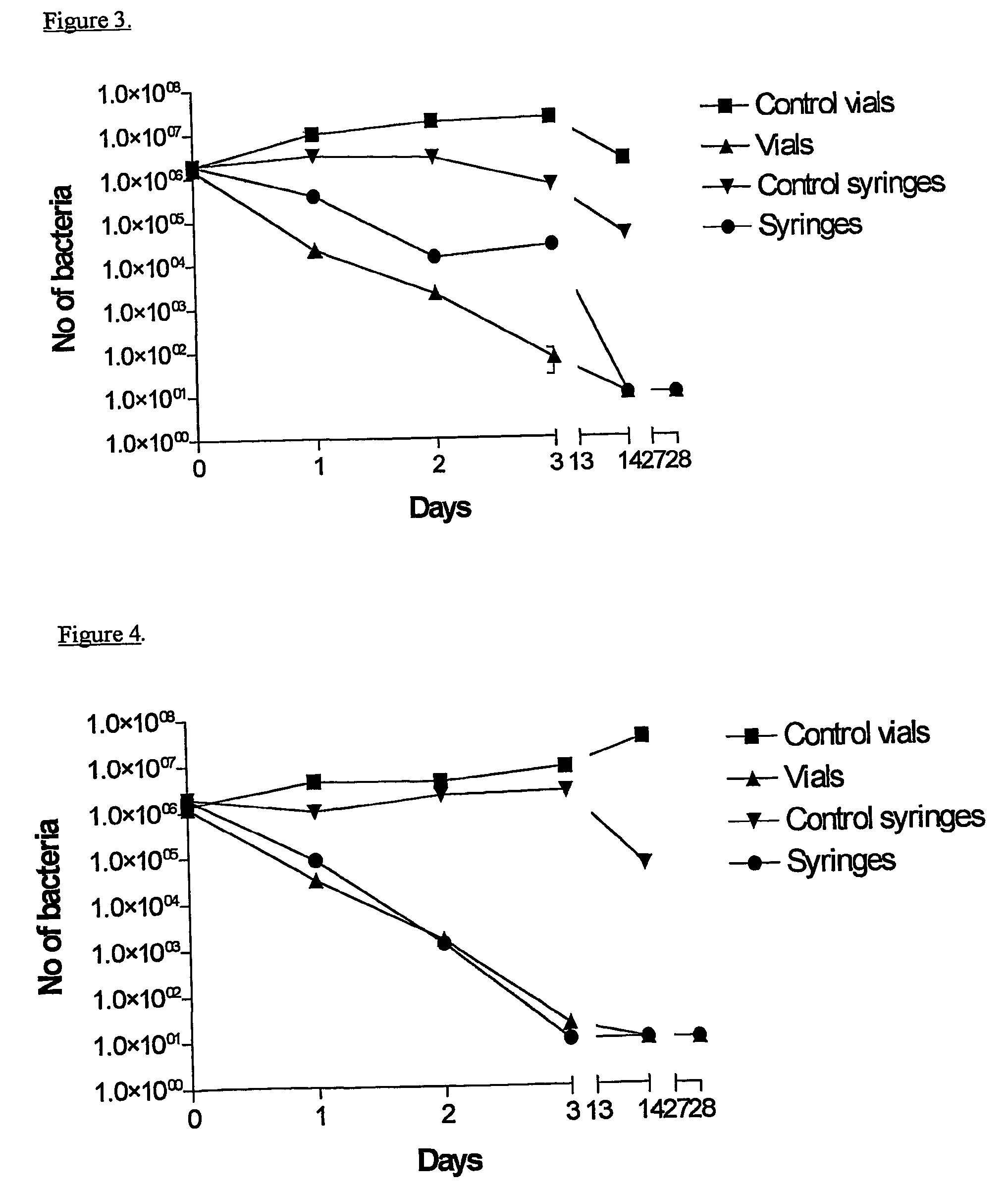

Stabilised radiopharmaceutical compositions

InactiveUS20040057899A1Good water solubilityMaintain good propertiesPowder deliverySolution deliveryImaging agentAscorbic acid

The present invention relates to stabilised <99m>Tc radiopharmaceutical compositions, which include both a radioprotectant and one or more antimicrobial preservative(s), and hence have an extended lifetime of use. The radioprotectant is ascorbic acid, para-aminobenzoic acid, gentisic acid or a salt thereof with a biocompatible cation, and the antimicrobial preservative is one or more compound from the paraben series of preservatives. The invention is particularly useful for cationic, lipophilic <99m>Tc heart imaging agents such as Myoview(TM).

Owner:GE HEALTHCARE LTD

Compositions and methods for an orally administered inhibitor of biting insects

InactiveUS20050008656A1Reduce inflammationReduce swellingBiocideAlgae medical ingredientsBenzoic acidPantothenic acid

The present disclosure concerns methods and compositions to inhibit insects from biting a subject. In preferred embodiments, the compositions may be administered orally, for example using a spray bottle to deliver to the mouth. In certain embodiments, the compositions and methods are effective to reduce swelling, itching, redness and / or inflammation of the local area of an insect bite. The compositions may include one or more herbs selected from the group consisting of rice bran, peppermint, barley grass, lobelia; chlorella, watercress, alfalfa and parsley and one or more vitamins selected from the group consisting of thiamin (B-1), riboflavin (B-2), niacin (B-3), pantothenic acid (B-5), pyridoxine (B-6), folic acid (B-9), cyanocobalamin (B-12), choline, inositol, d-biotin, para-aminobenzoic acid, and lecithin. Administration of effective amounts of the compositions is sufficient to inhibit insects from biting and / or treat insect affected areas of a subject.

Owner:MEREDITH SARAH

Dietary composition and method for promoting healthy hair growth and melanogenesis

InactiveUS20110287061A1Retarding and preventing and grayingRetarding and preventing and reversing grayingOrganic active ingredientsVitamin food ingredientsTyrosineCore component

A dietary composition for promoting melanogenesis in hair of a user comprising approximately 5,000 IU per day of catalase, a synergistic core component, 5-α-reductase inhibitors, an antioxidant component, and approximately 200 mg per day of L-tyrosine. Preferably, the synergistic core component comprises copper, vitamin B6, biotin, para-aminobenzoic acid, folic acid, zinc, and pantothenic acid. Further, 5-α-reductase inhibitors preferably comprise Saw palmetto, phytosterols, and nettle root extract. The antioxidant component preferably comprises horsetail, Fo-Ti, chlorophyll, and barley grass.

Owner:BEGGAN CATHY

Reaction-type halogen-free flame retardant bis-(p-aminocarboxyphenyl)phenylphosphine oxide and synthetic method thereof

InactiveCN104945658APollution is notReduce production stepsGroup 5/15 element organic compoundsBenzoic acidDichlorophenylphosphine

The invention relates to reaction-type halogen-free flame retardant bis-(p-aminocarboxyphenyl)phenylphosphine oxide and its synthetic method and application and belongs to the field of preparation of a flame retardant. The synthetic method comprises the following steps: using glacial acetic acid as a solvent, adding para amino benzoic acid into glacial acetic acid, slowly dropwise adding dichlorophenylphosphine oxide into an acetic acid solution of para aminobenzoic acid, continuously stirring and reacting at 85-95 DEG C for 4-6 h, and absorbing hydrogen chloride discharged by the reaction by the use of aqueous alkali; and cooling a reaction product after the end of the reaction, carrying out suction filtration, washing and drying to obtain white powdery bis-(p-aminocarboxyphenyl)phenylphosphine oxide. The bis-(p-aminocarboxyphenyl)phenylphosphine oxide flame retardant has advantages of low toxicity, low smoke, innocuousness, high efficiency and the like, is a reactive flame retardant integrating a carbon source, an acid source and a gas source, and is applied in inherent flame retarding of nylon or thermoplastic polyester copolymer.

Owner:NANJING LIHAN CHEM CO LTD

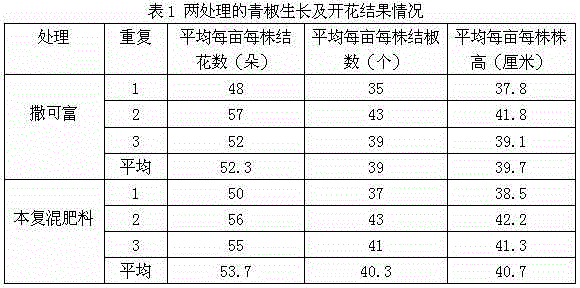

Humic acid type functional compound fertilizer and preparation method thereof

InactiveCN104447009APromote absorptionImprove disease resistanceSuperphosphatesMagnesium fertilisersVitamin B12Pantothenic acid

The invention discloses a humic acid type functional compound fertilizer and a preparation method thereof and relates to the technical field of compound fertilizers. The humic acid type functional compound fertilizer comprises a basic fertilizer nitrogen, phosphorus and potassium and auxiliary raw materials including humic acid, attapulgite powder, a granulating solution and granulating powder, wherein the granulating solution comprises the following ingredients in percentage by mass: 0.1-3 percent of an animal amino acid, 1-20 percent of urea, 0.3-3 percent of zinc sulfate, 0.1-2.5 percent of manganese sulfate, 0.1-0.8 percent of boric acid, 0.1-0.3 percent of sodium molybdate, 0.1-1 percent of magnesium sulfate, 0.1-0.3 percent of compound sodium nitrophenolate and the balance of water; the granulating powder comprises the following ingredients in parts by mass: 0.3-25 parts of ferrous sulfate, 0.1-0.5 part of copper sulfate, 0.1-0.3 part of vitamin B12, 0.1-0.3 part of para aminobenzoic acid, 0.1-0.3 part of cobalt chloride, 0.1-1 part of calcium pantothenate, 0.1-1 part of EDTA-2Na and 0.1-0.3 part of sodium selenite. The fertilizer disclosed by the invention is high in utilization rate and can be used for increasing the yield of crops.

Owner:王意强 +1

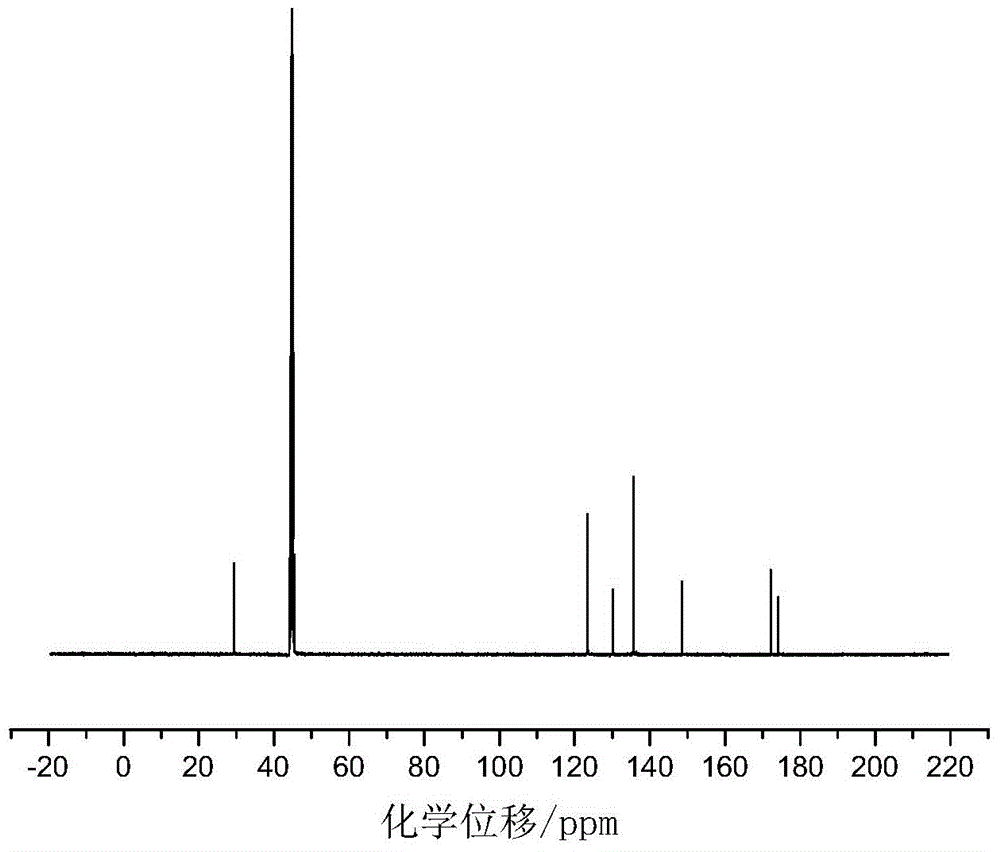

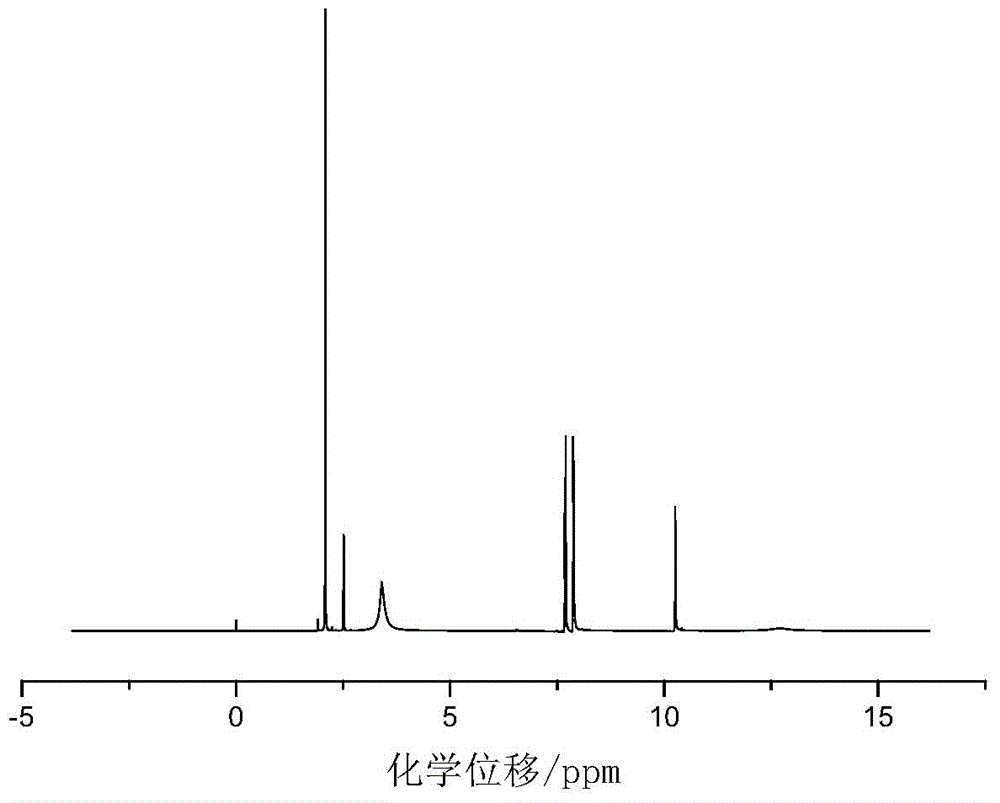

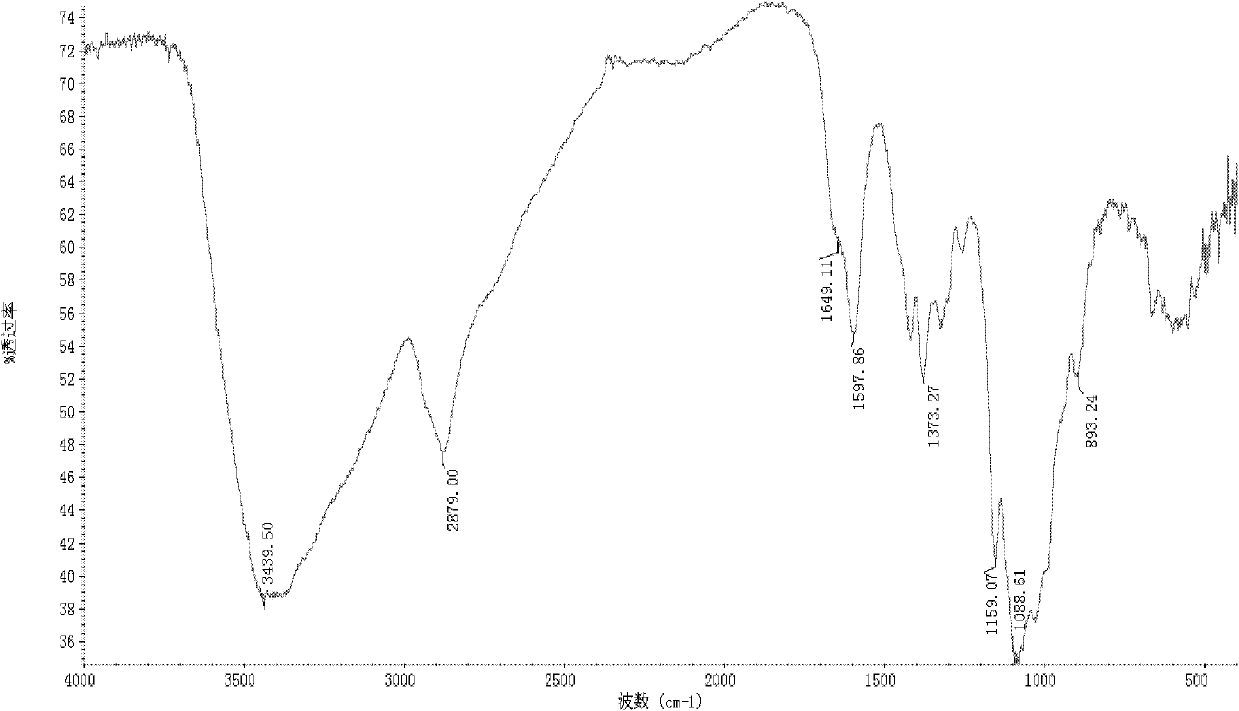

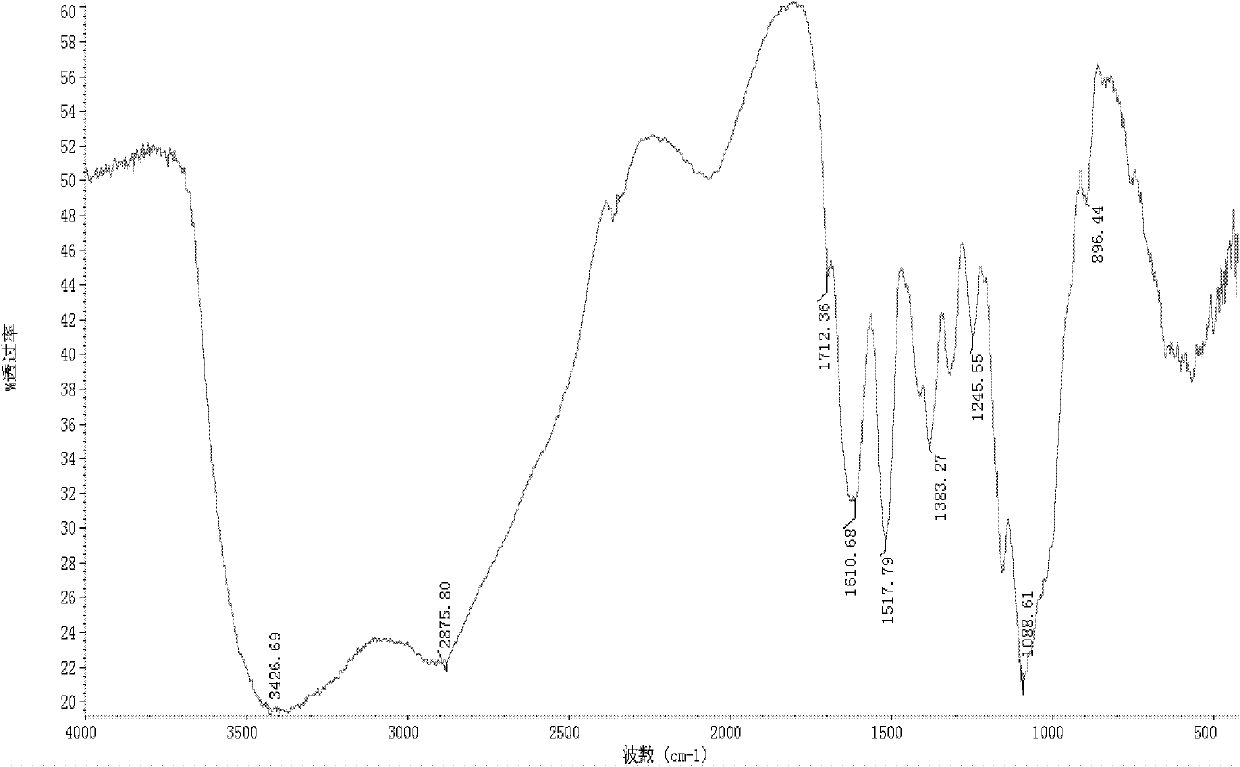

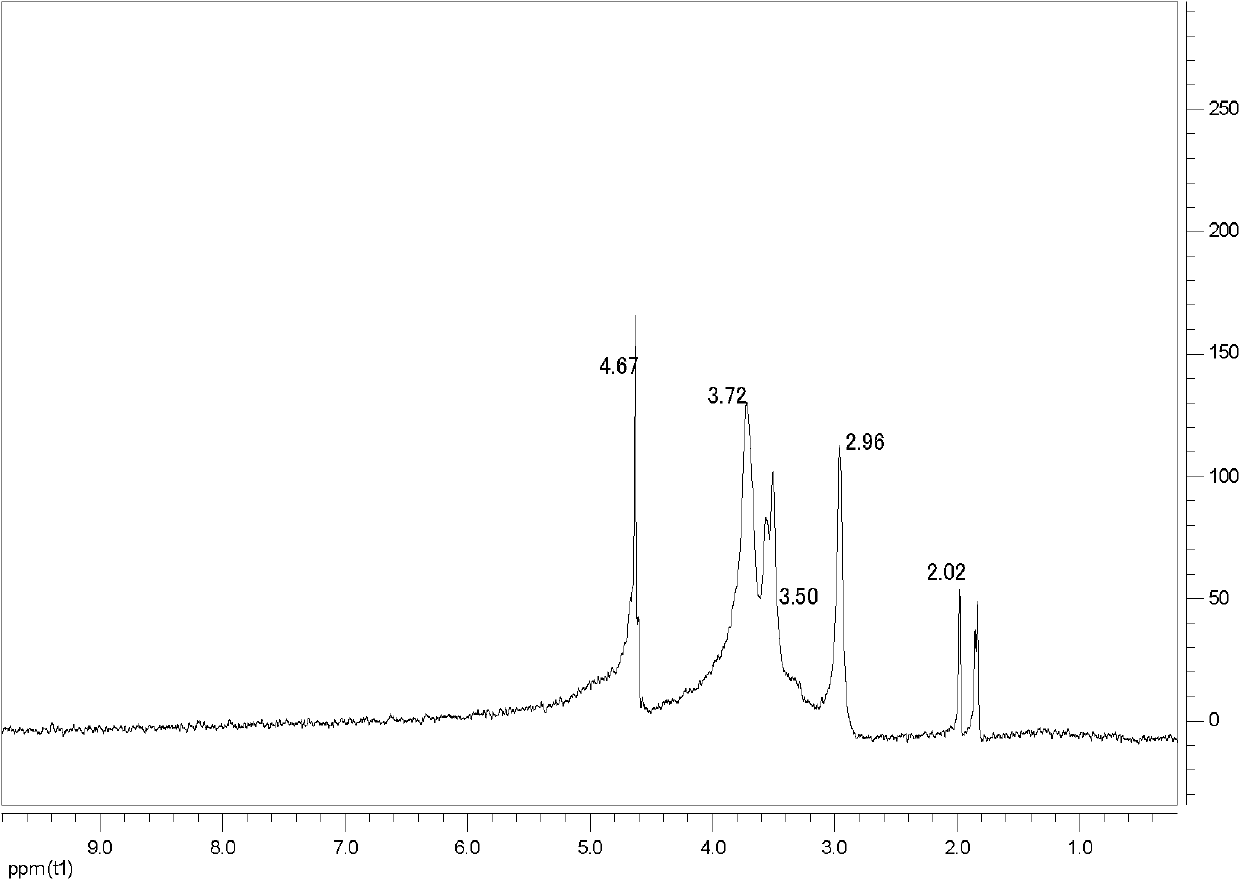

Chitosan ester p-aminobenzoate and preparation method thereof

InactiveCN102153674AExpand the range of antibacterialStrong antibacterial activityFood preservationBenzoic acidPhenacyl

The invention discloses chitosan ester p-aminobenzoate, which has a structure shown in the specifications, wherein X is between 0.65 and 0.95, and the molecular weight is between 70 and 80 kilodaltons. The materialization indexes of the compound are that: the chitosan ester p-aminobenzoate is a pale yellow powder solid, can be dissolved in water and is dissolved in ethanol and isopropanol slightly. After a p-animo-benzoyl structure is introduced into a chitosan molecular chain, the minimum inhibitory concentration of the compound on staphylococcus aureus and aspergillus niger is 0.1 percent and 0.25 percent respectively, so the chitosan ester p-aminobenzoate can be used as food antiseptic additives.

Owner:OCEAN UNIV OF CHINA

Stabilized radiopharmaceutical compositions

InactiveUS7052672B2Amenable to inclusionHigh activityPowder deliverySolution deliveryImaging agentAscorbic acid

Owner:GE HEALTHCARE LTD

Preparation method of fluorescence polyurethane resin

InactiveCN103102675ASimple processHigh fluorescence intensityInksLuminescent compositionsTernary complexUltimate tensile strength

The invention discloses a preparation method of fluorescence polyurethane resin. The preparation method comprises the steps of: 1) preparing europium-para aminobenzoic acid-oleic acid ternary complex powder; 2) preparing polyurethane resin; and 3) mixing the europium-para aminobenzoic acid-oleic acid ternary complex powder with the polyurethane resin to obtain the fluorescence polyurethane resin. The fluorescence polyurethane resin disclosed by the process is high in fluorescence intensity, good in anti-counterfeiting effect, not easy to be counterfeited, simple in cooling process, low in cost and easy to achieve industrialization when being applied to anti-forgery ink.

Owner:张家港威迪森化学有限公司

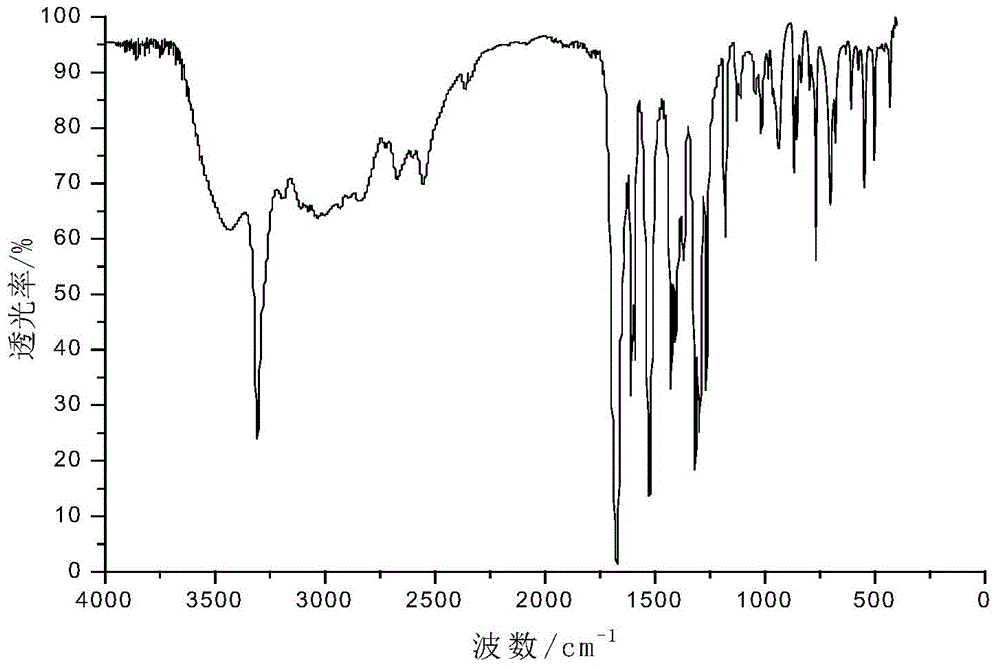

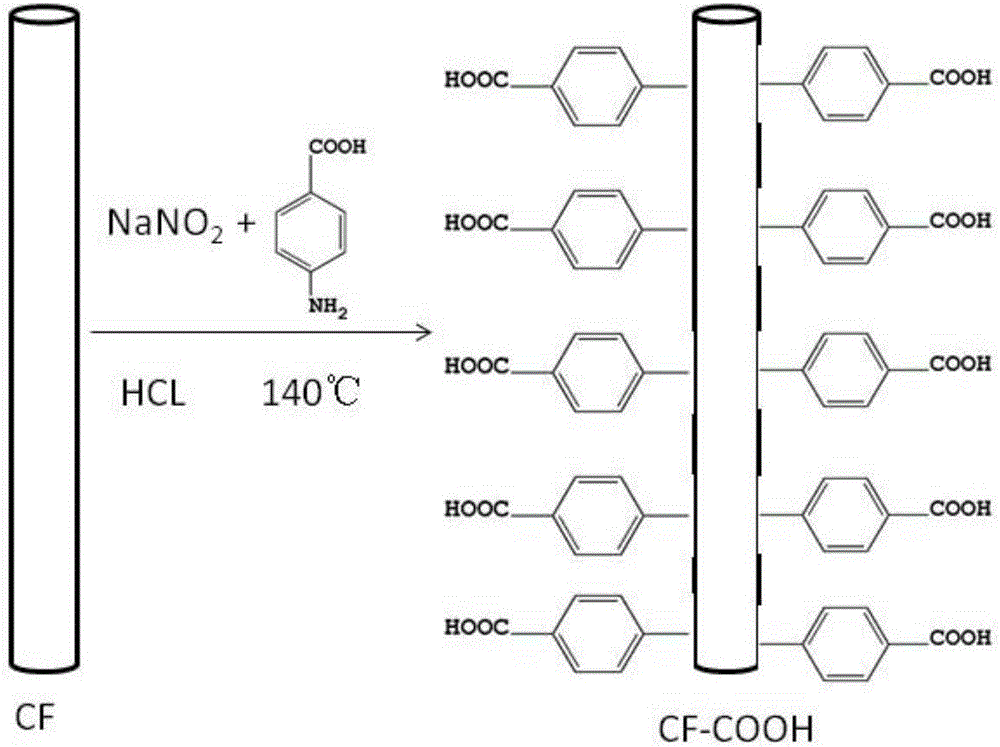

Preparation method for para aminobenzoic acid lossless modified carbon fiber enhanced paper base wet-type friction material

The invention discloses a preparation method for a para aminobenzoic acid lossless modified carbon fiber enhanced paper base wet-type friction material. Carbon fibers, para aminobenzoic acid and excessive hydrochloric acid are added to a three-neck flask, a certain quantity of sodium nitrite is slowly added after a reaction reaches certain temperature, a short-time diazo-reaction is conducted under the condition of a magnetic stirring oil bath, and carbon fibers with the surfaces grafted by benzoic acid are obtained. Then, the modified carbon fibers, aramid fibers, paper fibers, padding and resin are mixed to prepare friction material base paper, the friction material base paper is then hot-pressed and solidified, and the para aminobenzoic acid modified paper base wet-type friction material is obtained. A friction material sample is subjected to a frictional wear performance test, the dynamic friction coefficient of the sample reaches 0.12 to 0.15, the wear rate is 0.9*10<8>cm<3> / J to 1.2*10<8>cm<3> / J, the excellent frictional wear performance is shown, the technological process is simple, cost is low, and the preparation method is an efficient and environment-friendly graft modification treatment method and has the wide application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

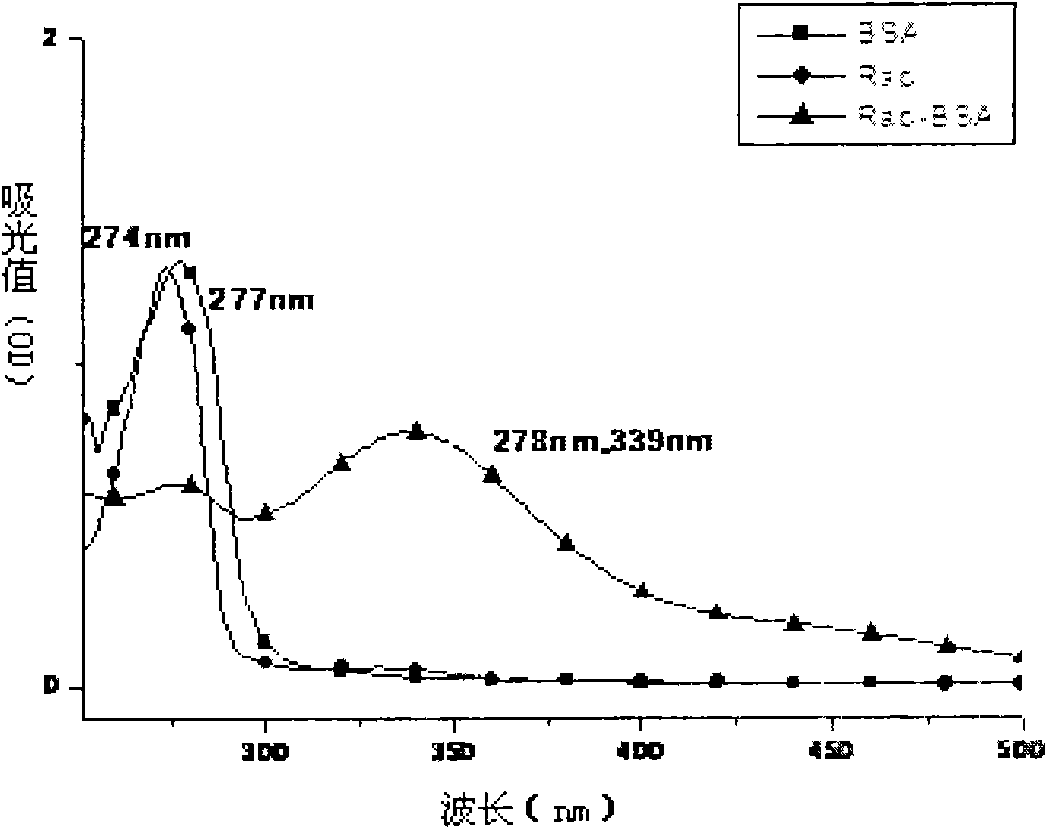

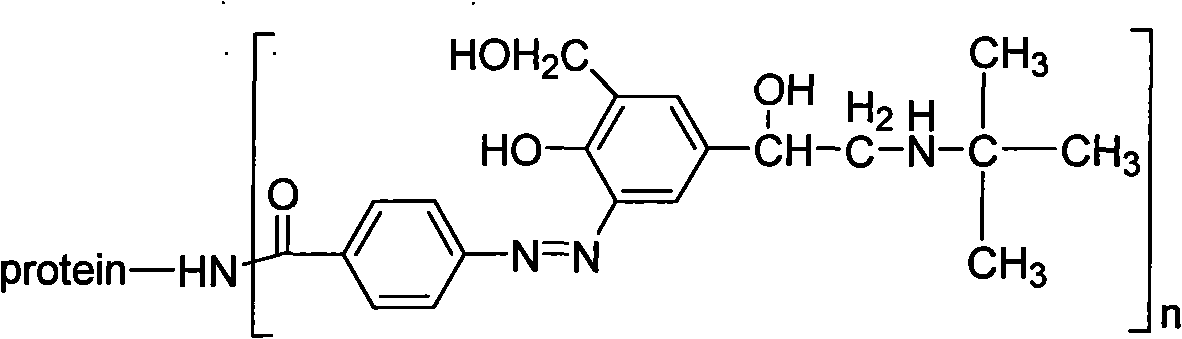

Synthesis method of ractopamine artificial antigen

A synthesis method of ractopamine artificial antigen is characterized by linking ractopamine with activated para aminobenzoic acid to prepare ractopamine active intermediate containing carboxyl, adopting ethyl[3-(dimethylamino)propyl]carbodiimide as crosslinker to couple the ractopamine active intermediate with the amino of carrier protein, and dialyzing and freeze drying the product to obtain ractopamine artificial antigen. In the synthesis method of the invention, ractopamine can be coupled with carrier protein successfully so that ractopamine artificial antigen-antibody absolute immunogen can be prepared which can prompt an immune response in animals.

Owner:QINGDAO VLAND BIOTECH INC

Method for preparing tetracaine

ActiveCN102731333ALow priceCheap price, effectively reduce production costOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidHydrogen

The invention relates to a method for preparing tetracaine, which comprises the following steps: dissolving para aminobenzoic acid and n-butanal in absolute methanol, preserving temperature and mixing; then concentrating to remove methanol to obtain 4-(n-butene amino) benzoic acid; adding the 4-(n-butene amino) benzoic acid, water and sodium hydroxide into a high pressure reaction kettle; then adding palladium carbon (10%), and introducing hydrogen to reduce so as to obtain 4-(n-butyl amino) benzoic acid; adding the 4-(n-butyl amino) benzoic acid into another reaction flask, adding toluene and then adding N,N-dimethylethanolamine; refluxing and dividing water; and then purifying and drying to obtain tetracaine. The method provided by the invention has the advantages of low cost of raw materials, high yield and high purity and the like.

Owner:山东诚汇双达药业有限公司

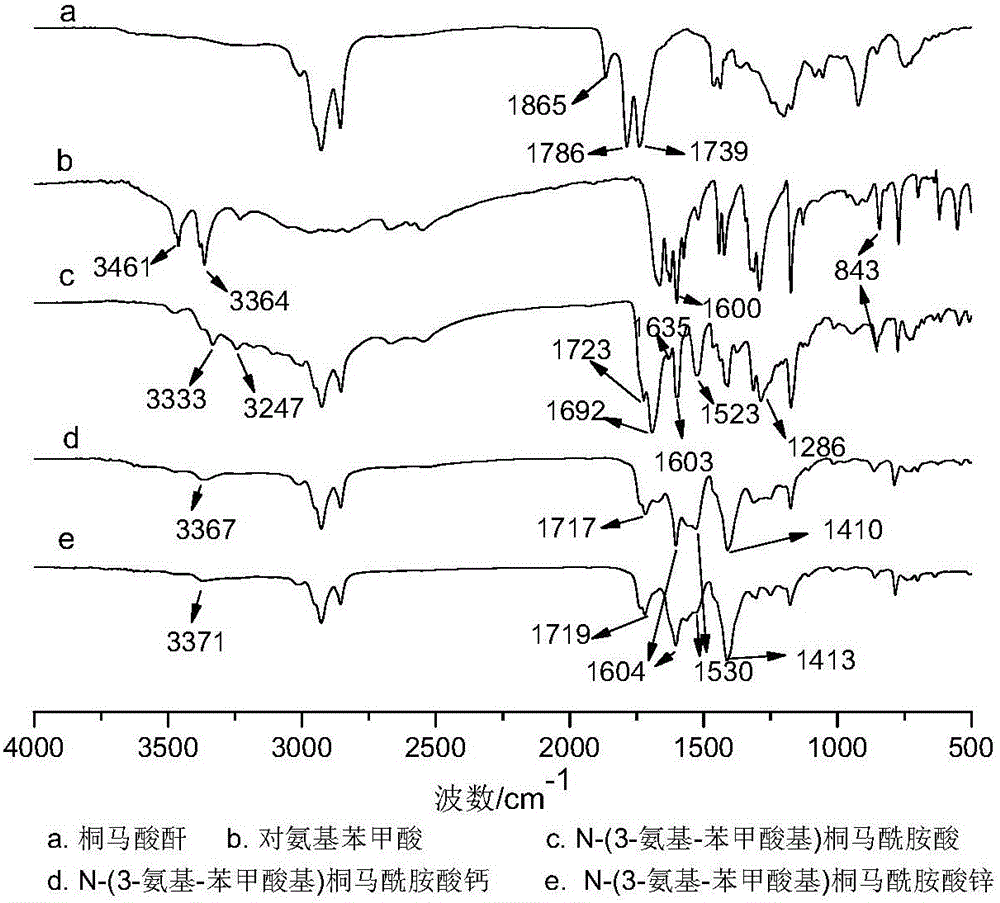

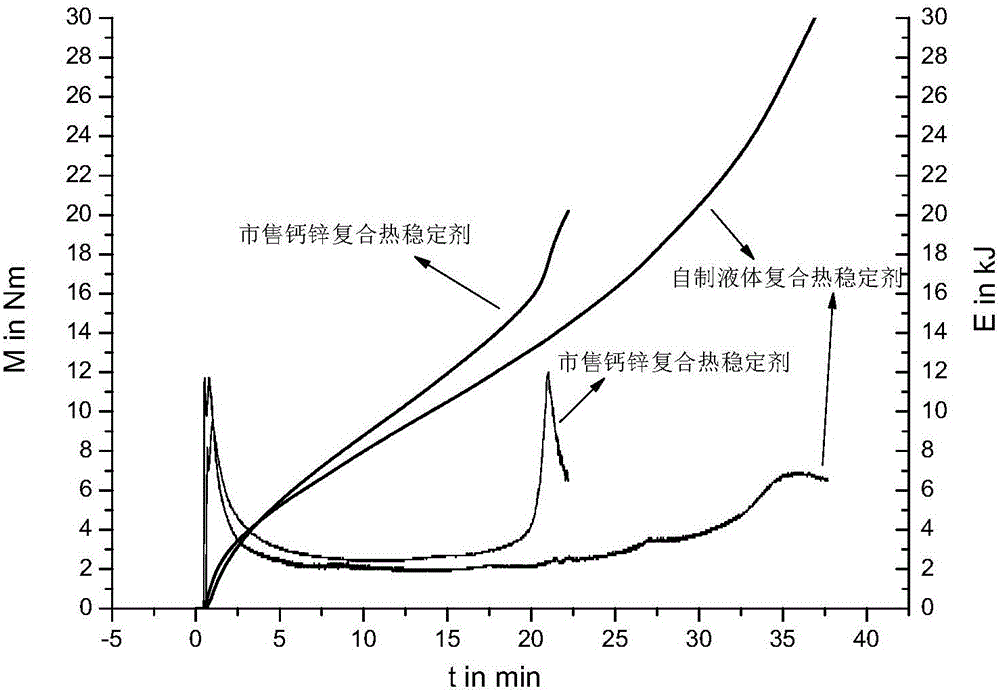

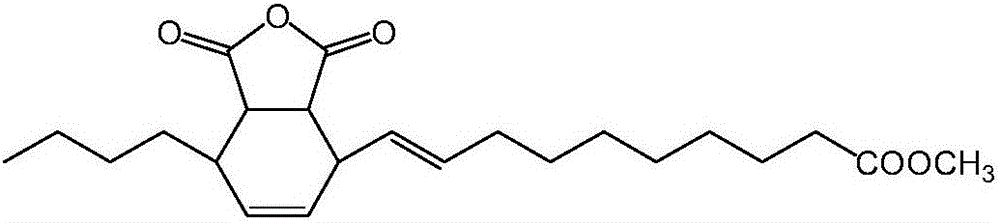

Heat stabilizer for PVC (polyvinyl chloride) and preparation method and application thereof

ActiveCN105949508ARich sourcesGet rid of dependenceOrganic compound preparationCarboxylic acid amides preparationPolyvinyl chlorideAminolysis

The invention discloses a heat stabilizer for PVC (polyvinyl chloride) and a preparation method and application thereof. The preparation method includes: subjecting tung maleic anhydride and para aminobenzoic acid to anhydride aminolysis reaction to obtain N-(3-amino-benzoyloxy) tung maleic amic acid; performing one-step reaction of the prepared N-(3-amino-benzoyloxy) tung maleic amic acid and metal oxides or metal hydroxides in solvent to prepare liquid N-(3-amino-benzoyloxy) tung maleic amic acid metal salt; compounding the prepared N-(3-amino-benzoyloxy) tung maleic amic acid calcium salt with zinc salt to obtain a liquid composite heat stabilizer. The prepared calcium-zinc liquid composite heat stabilizer has advantages of nontoxicity, freeness of heavy metals, environment friendliness and the like and endows PVC products with high heat stability and transparency. The preparation method is simple in process route and mild in condition, raw materials which are selected from natural environment-friendly renewable resources are rich in source and low in cost.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Process of preparing purified azadirachtin in powder form from neem seeds and storage stable aqueous composition containing azadirachtin

InactiveUS6193974B1Composition is stableGood bio-efficacyBiocideDead animal preservationSolventEmulsion

This invention relates to a process of preparing storage stable aqueous Azadirachtin containing Azadirachtin A to provide a predominant pesticidal composition which comprises the steps of diluting 50,000-100,000 ppm Azadirachtin with 25,000 to 50,000 Azadirachtin A weight / volume with ethanol water solvent in a ratio in the range 100-70:0-30 volume / volume to produce 2,000-40,000 ppm Azadirachtin containing 1,000-20,000 ppm of Azadirachtin A weight / volume. This is followed by emulsifying of the diluted Azadirachtin with non-ionic and non-toxic emulsifying agents in an amount ranging from 0.2 to 30% and neem oil 20-50% volume / volume. The pH of the emulsified diluted Azadirachtin is adjusted to 3.5 to 6.0 by adding an alkali solution. 1-2.5% of a sunscreen like p.aminobenzoic acid or its esters and 1-10% oleic acid volume / volume are added to create a micro-emulsion for stabilizing the composition with a good bio-efficacy.

Owner:DALMIA CENT FOR RES & DEV

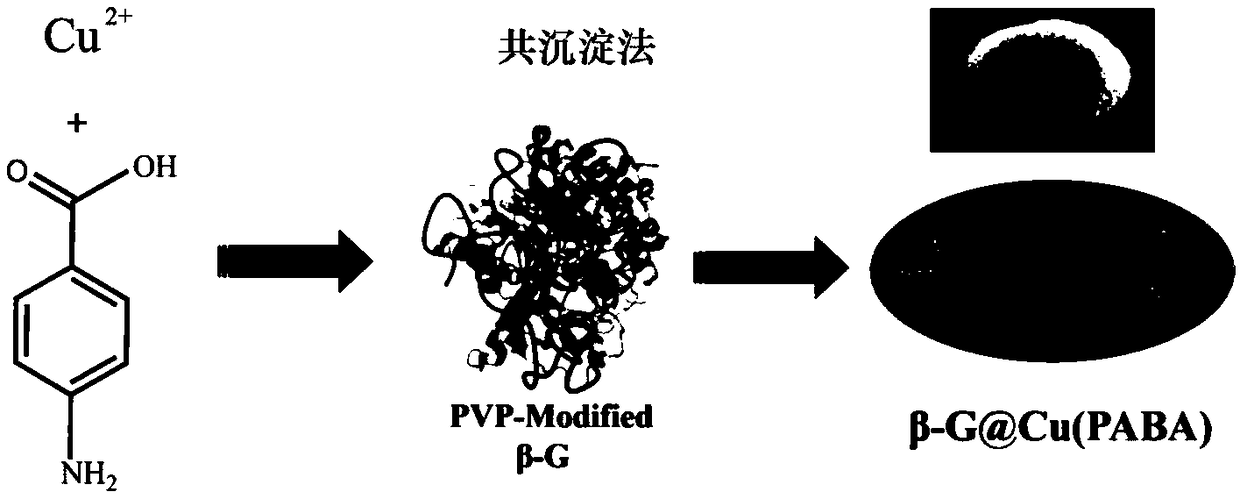

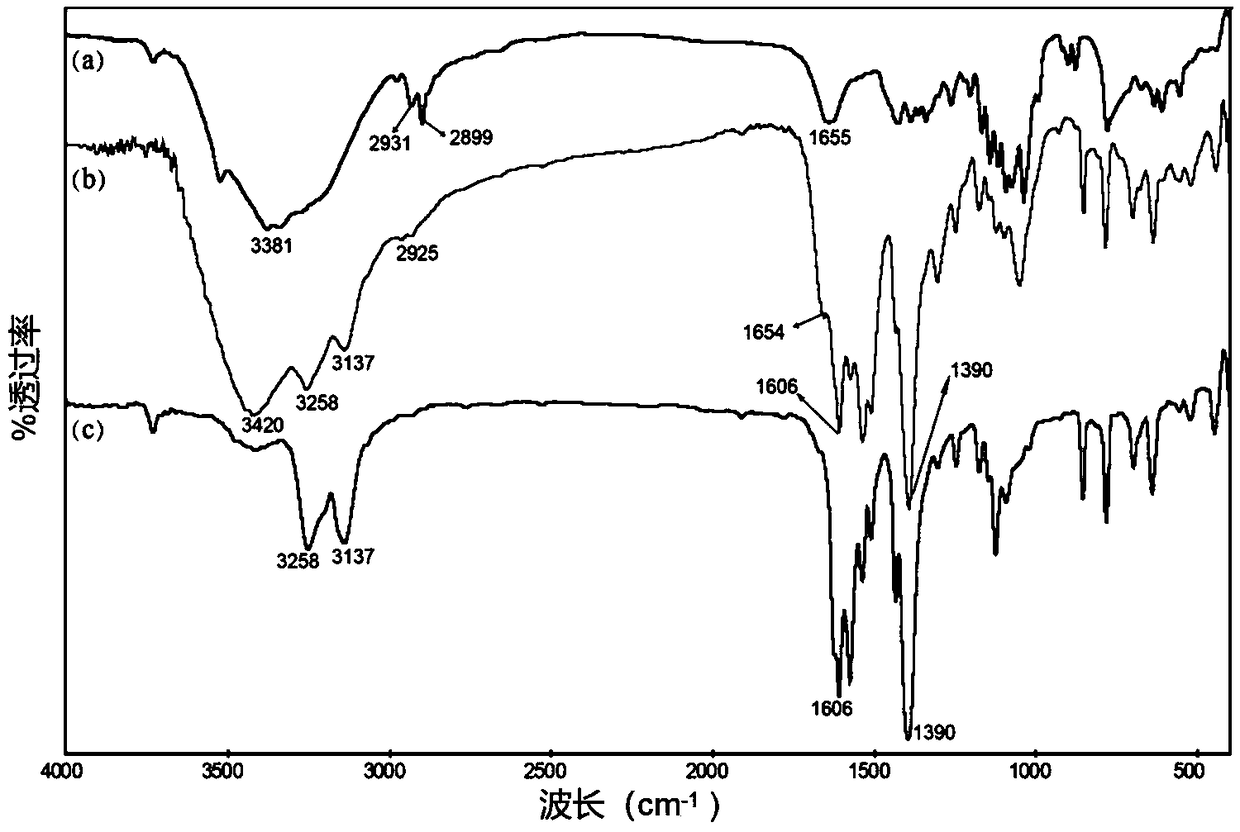

Metal organic frame material immobilized beta-glucosidase and preparation method and application thereof

ActiveCN109082420AIncrease lossPH suitableOn/in organic carrierFermentationMaterials preparationAlglucerase

The invention belongs to the technical field of material preparation and relates to a metal organic frame material immobilized beta-glucosidase and a preparation method and application thereof. By adoption of a co-precipitation method, beta-glucosidase is introduced into a porous structure of a metal organic frame material Cu (PABA) formed by metal copper ions and para-aminobenzoic acid to realizeenzyme immobilization. The metal organic frame material grows according to enzymes, namely enzyme immobilization and frame material preparation are carried out at the same time. By one-step completion of immobilizing material preparation and enzyme immobilization, enzyme stability and resistance to organic solvents and metal ions are improved, the recycling rate is remarkably increased, and cellulose hydrolysis efficiency of cellulase is improved.

Owner:JIANGSU UNIV

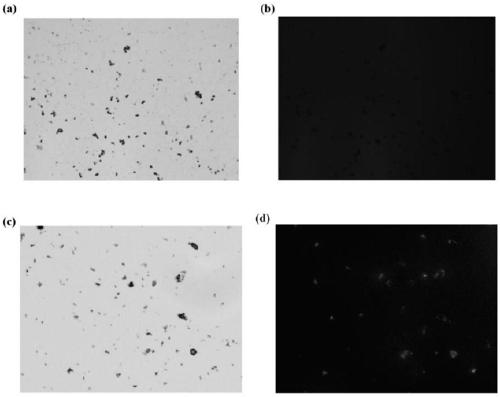

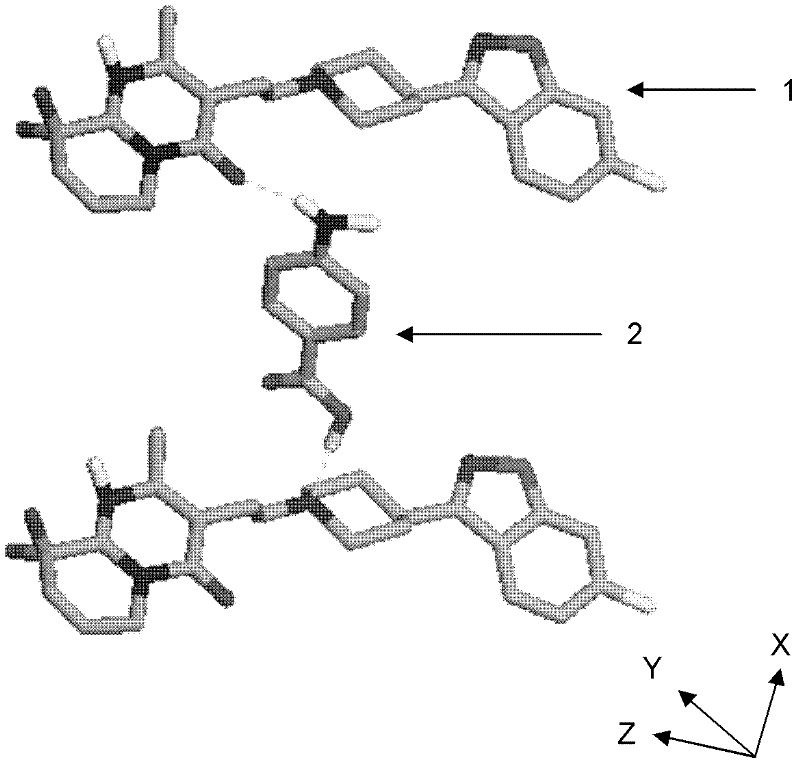

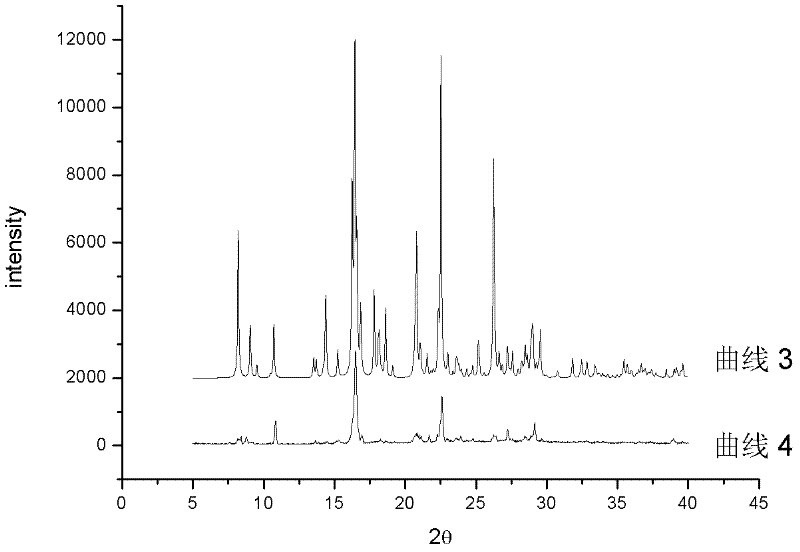

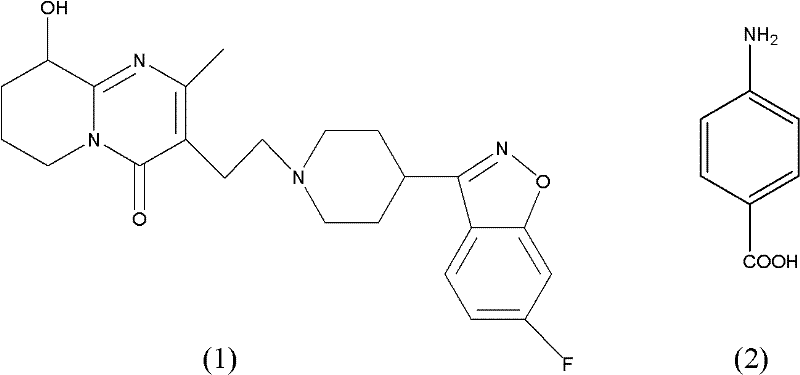

Novel paliperidone medicinal eutectic and preparation method thereof

The invention belongs to the technical field of medicinal eutectics, and particularly relates to a novel paliperidone medicinal eutectic and a preparation method thereof. According to the paliperidone medicinal eutectic, two paliperidone molecules and a para aminobenzoic acid molecule are bonded by two hydrogen bonds to form a basic structural unit of the paliperidone medicinal eutectic, an N atom on a piperidine ring in one paliperidone molecule, which serves as a hydrogen bond donor, and an H atom on carboxyl in the para aminobenzoic acid, which serves as a hydrogen bond receptor form a first hydrogen bond; and a hydrogen atom on amino of the para aminobenzoic acid, which serves as a hydrogen bond donor, and an oxygen atom on pyrimidine-4-keto-carbonyl of the other paliperidone molecule, which serves as a hydrogen bond receptor form a second hydrogen bond. According to the medicinal eutectic, the characteristic of the conventional Chinese herbal medicines in the treatment of dementia praecox is inherited, and the dissolubility, stability and bioavailability of the medicinal eutectic are improved obviously.

Owner:吉林三善恩科技开发有限公司

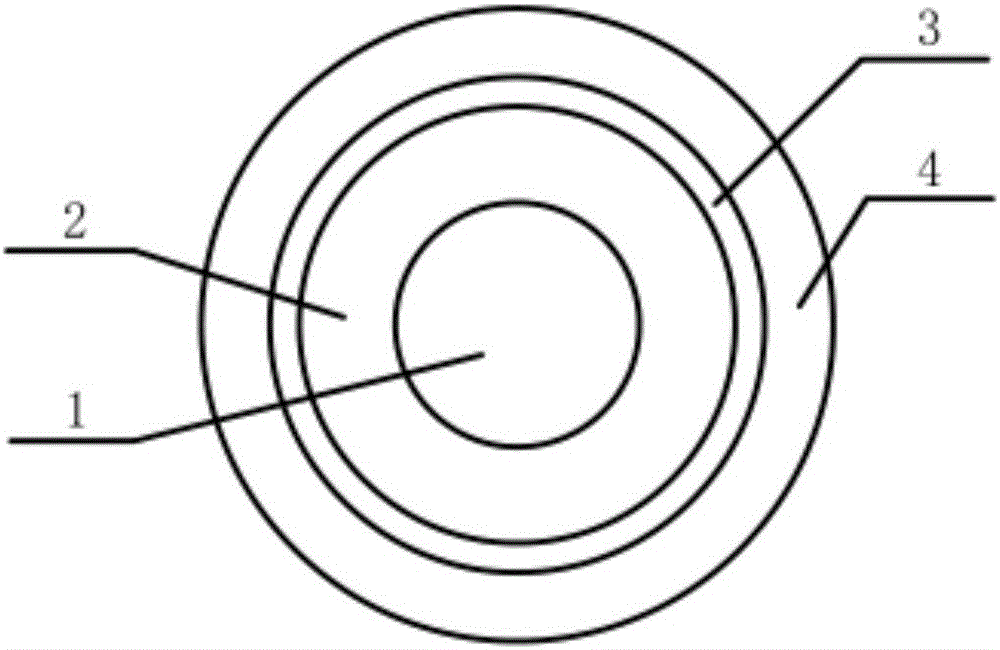

Anti-aging and anti-twisting wind power cable

InactiveCN105778469AGood flexibility at low temperatureHigh tensile strengthInsulated cablesPower cablesCopper conductorFiber

The invention discloses an anti-aging and anti-twisting wind power cable. The anti-aging and anti-twisting wind power cable comprises a copper conductor, wherein an insulation layer is coated at the exterior of the copper conductor, a winding layer is coated at the exterior of the insulation layer, and a protective sheath layer is coated at the exterior of the winding layer; the protective sheath layer is made of polyurethane composite material; the polyurethane composite material is prepared form the following raw materials in parts by weight: 50 to 80 parts of polyurethane, 20 to 35 parts of nylon, 10 to 20 parts of ABS (acrylonitrile-butadiene-styrene) resin, 3 to 12 parts of diphenyl-methane-diisocyanate, 2 to 10 parts of montmorillonoid, 3 to 12 parts of kaolin, 2 to 10 parts of talcum powder, 3 to 12 parts of zinc borate, 3 to 15 parts of aluminium hydroxide, 10 to 25 parts of carbon fiber, 2 to 4 parts of silane coupling agent, 0.5 to 2 parts of antioxidant, 5 to 15 parts of phosphorus-containing flame retardant, and 0.2 to 1.5 parts of lubricant; the phosphorus-containing flame retardant is formed by reacting para aminobenzoic acid and tetrakis hydroxymethyl phosphonium sulfate. The anti-aging and anti-twisting wind power cable has the advantage that the anti-aging, anti-twisting and flame-retardant properties are excellent.

Owner:王社兵

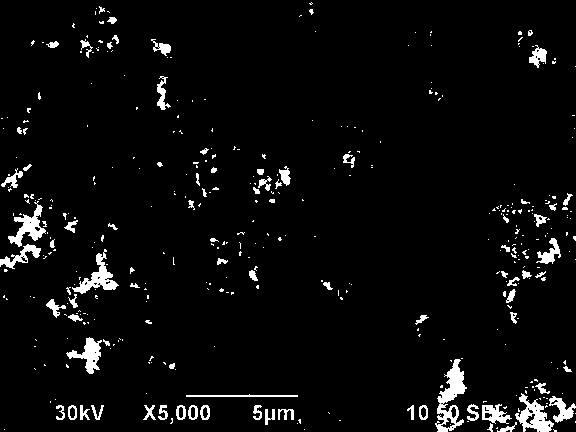

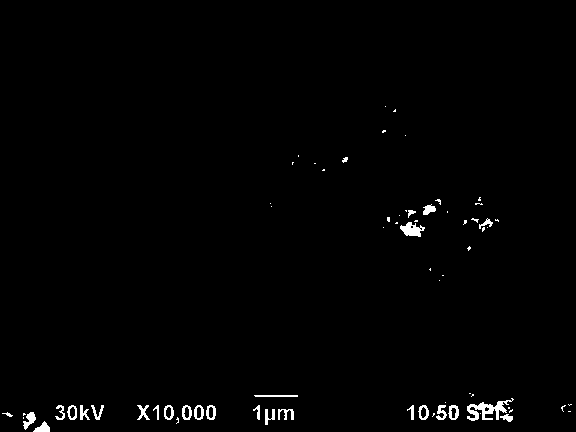

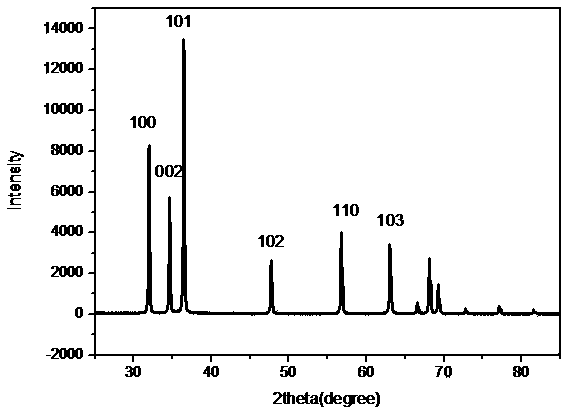

Nanometer zinc oxide photocatalyst and preparation method and application thereof

InactiveCN104028259AEffective catalytic degradationEasy to prepareWater/sewage treatment by irradiationWater contaminantsN dimethylformamideCalcination

The invention discloses a nanometer zinc oxide photocatalyst and a preparation method and an application thereof. According to the key point of the technical scheme, the nanometer zinc oxide photocatalyst is prepared by the following steps: reacting zinc salt with organic ligands in a N,N-dimethylformamide solvent at room temperature, so as to form a Zn(II) precursor and then performing calcination at the temperature of 400 to 800 DEG C, wherein the molar mass ratio of zinc salt (n) to organic ligands (n) is (0.5-2) to 1, the zinc salt is Zn(NO3)2.6H2O, and the organic ligands include at least one of 1,3,5-trimesic acid, terephthalic acid, isophthalic acid, phthalic acid, formic acid and 4,4',4''-s-triazine-1,3,5-three-para aminobenzoic acid. The invention further discloses the preparation method of the catalyst and the application of the catalyst to processing of organic waste water containing rhodamine B. The nanometer zinc oxide photocatalyst has the advantages of environmental friendliness, simple preparation process, strong innovativeness and practicability and the like.

Owner:HENAN NORMAL UNIV

High-temperature-resistant bearing lubricant additive

InactiveCN106047445AImprove high temperature resistanceHigh viscosityAdditivesCarboxylic saltTemperature resistance

The invention discloses a high-temperature-resistant bearing lubricant additive. The high-temperature-resistant bearing lubricant additive is prepared from, by weight, 6-12 parts of sodium dodecyl benzene sulfonate, 4-8 parts of fatty alcohol polyoxyethylene ether carboxylate, 5-9 parts of triphenyl phosphorothioate, 3-9 parts of zinc dialkyl dithiophosphate, 4-6 parts of para aminobenzoic acid, 6-9 parts of octyl phenol, 3-5 parts of calcium alkyl salicylate, 2-3 parts of a fluorinated surfactant, 2-5 parts of a fluorinated surfactant, 2-4 parts of cinnamyl alcohol, 5-12 parts of diisocyanate, 8-15 parts of dodecencylsuccinic acid, 3-6 parts of inositol hexaphosphoric acid, 4-8 parts of modified aluminium triphosphate, 4-8 parts of a viscosity index improver, 4-8 parts of an oxidation and corrosion inhibitor and 4-8 parts of an extreme pressure antiwear agent. Compared with the prior art, the lubricant additive has the advantages that the additive properties can be optimized through the compounding effect of multiple auxiliaries, the good lubricant property enhancing effect can be achieved through a little amount of the additive, the high temperature resistance, the viscosity property and the wear resistance of a lubricant can be promoted, and the quality of the lubricant is greatly promoted.

Owner:ANHUI QIANSHAN BEARING MFG

High temperature resisting modified polyhexamethylene guanidine, preparation method and application thereof

ActiveCN107099031AHigh melting pointHigh decomposition temperatureBiocideOrganic chemistryBenzoic acidPolymer science

The invention relates to a high temperature resisting modified polyhexamethylene guanidine, a preparation method and an application thereof and belongs to the technical field of disinfection. The high temperature resisting polyhexamethylene guanidine provided by the invention is suitable for application in high polymer materials, such as, plastics, rubber and synthetic fiber. The preparation method comprises the following steps: by taking polyhexamethylene guanidine as a raw material, adding phenyl compound (benzoic acid, benzoyl chloride, methyl benzoate, phthalic anhydride or para aminobenzoic acid), wherein the mass ratio of phenyl compound to polyhexamethylene guanidine is (0.001-0.01):1; performing grafting reaction under nitrogen protection under the reaction temperature of 120-180 DEG C; stirring under normal pressure and reacting for 1-5h, and then reducing the temperature to 80-100 DEG C; discharging, thereby acquiring the high temperature resisting modified polyhexamethylene guanidine. The high temperature resisting modified polyhexamethylene guanidine disclosed by the invention is longer in antibacterial time and better in antibacterial effect.

Owner:河北佩清科技有限公司

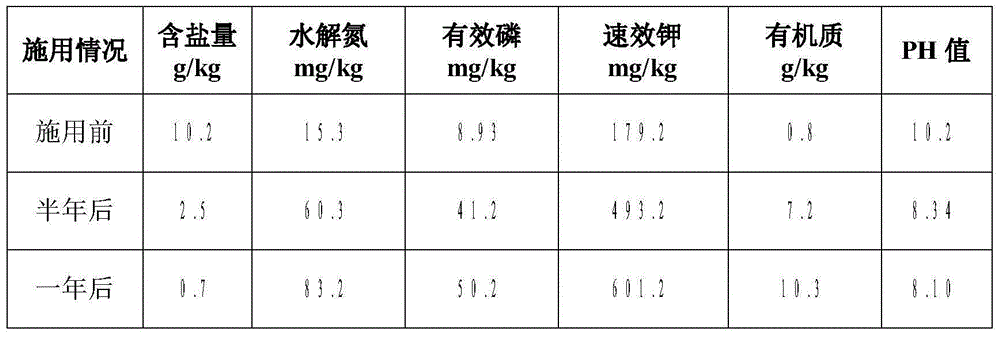

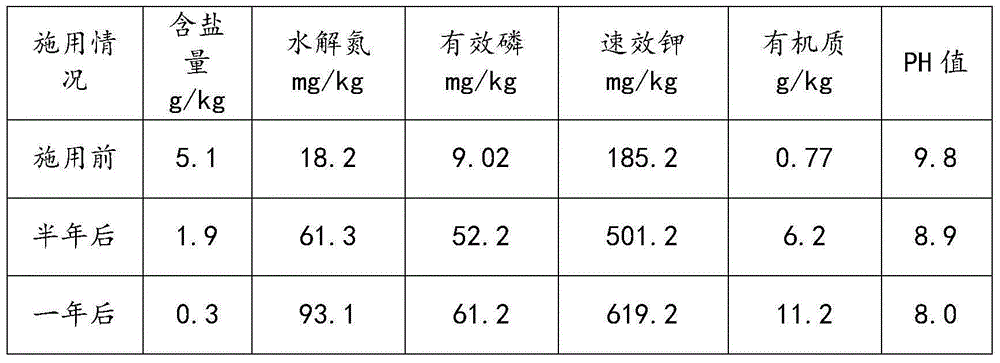

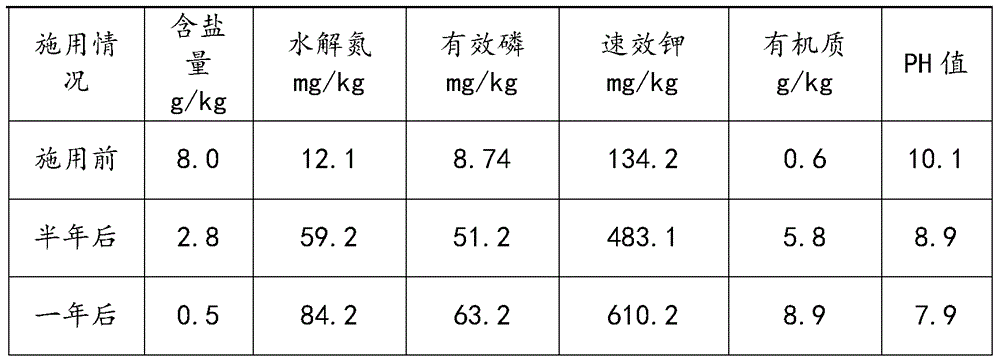

Novel improvement fertilizer for sandy saline and alkaline land and preparation and application method of novel improvement fertilizer

ActiveCN105175191AHigh organic contentIncrease the granular structureFertilising methodsFertilizer mixturesPeatMoisture

The invention discloses novel improvement fertilizer for a sandy saline and alkaline land and a preparation and application method of the novel improvement fertilizer. The novel improvement fertilizer is prepared from 20-30 parts of organic fertilizer, 20-30 parts of peat, 10-20 parts of humic acid, 5-10 parts of perlite, 5-10 parts of vermiculite, 17-30 parts of flue gas desulfurization gypsum, 10-20 parts of powdered pumice, 3-6 parts of compound fertilizer, 1-2 parts of amino acid, 2-3 parts of water-retaining agents, 1-2 parts of nicotinic acid, 2-3 parts of para aminobenzoic acid, 1-2 parts of inositol and 3-4 parts of serine. In the preparation process, organic fertilizer, peat and humus are dried till the moisture content is smaller than 10%, the mixture is then smashed together with other components and screened after being smashed, the final grain size is smaller than 3 mm, mixing is conducted, the application amount is determined according to the soil salt content in the application process, and the mixture is mechanically mixed with soil. By means of the novel improvement fertilizer, the organic matter content in soil of the sandy saline and alkaline land is increased, and the improvement of the granular structure of the soil is accelerated; the permeability, the water-retaining property and the nutrient preserving capacity of the soil are increased; floras of the soil are effectively activated, and beneficial bacteria in the soil are rapidly propagated; the soil acidity and alkalinity are effectively regulated; effective constituents such as nitrogen phosphorus and potassium and microelements of the soil are increased.

Owner:江苏垚源生态环境建设有限公司

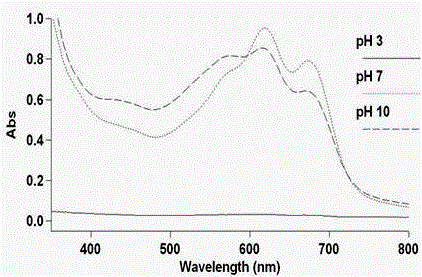

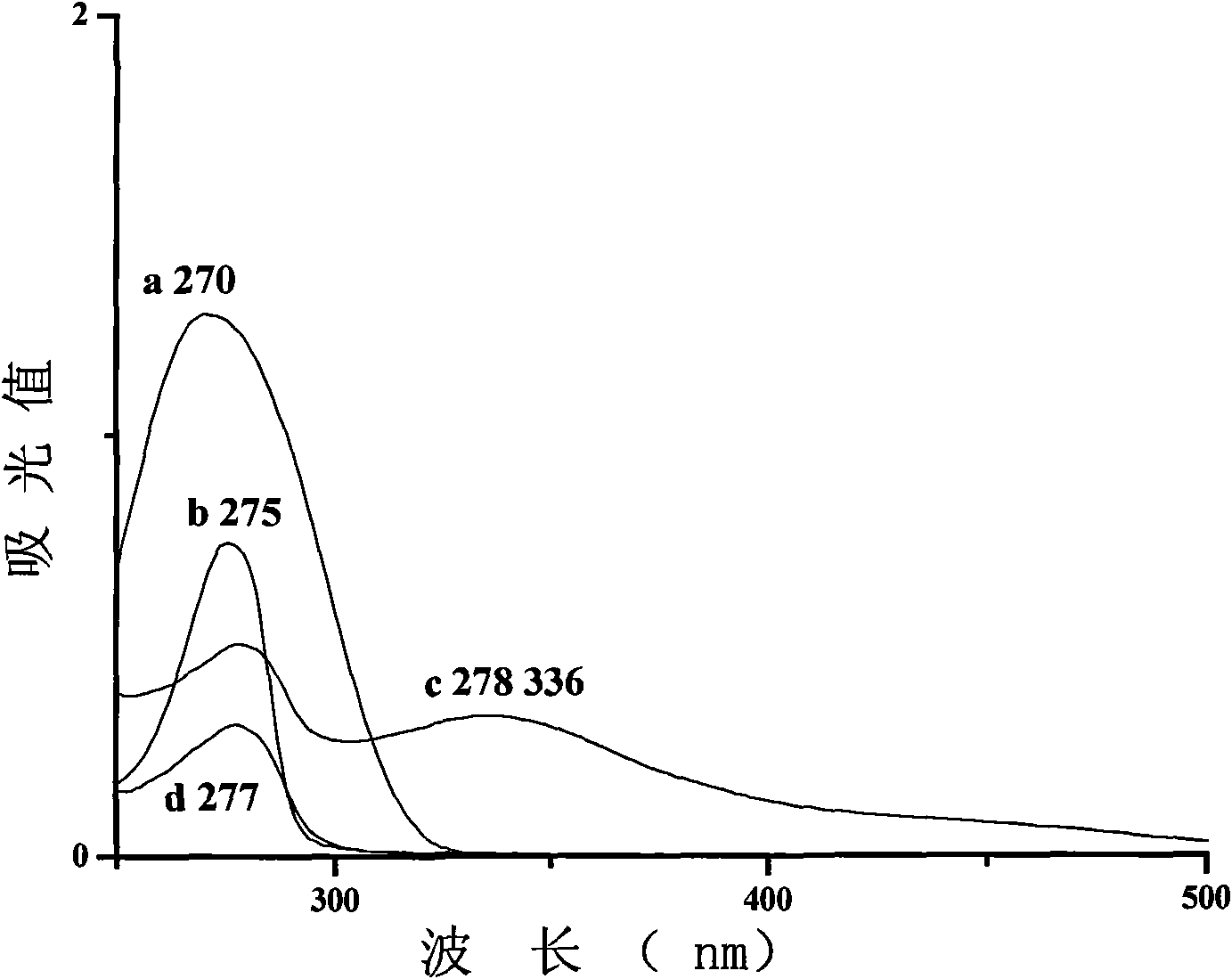

Pseudofusicoccum sp. F10 for producing indigo blue pigment and printing and dyeing application thereof

The invention relates to the field of light chemical engineering and aims at providing Pseudofusicoccum sp. F10 and printing and dyeing application thereof. The Pseudofusicoccum sp. F10 can produce an indigo blue pigment, the pigment is a compound with C-CH3 substituents and containing para-aminobenzoic acid, the biggest absorption peak of the pigment in a neutral and weakly-alkaline water solution is located at the position of 620 nm, the pigment precipitates in an acidic water solution and is not sensitive to oxidants, and a reducing agent sodium sulfite has the damage effect on the pigment. During dyeing and printing application, the pigment has the good printing and dyeing effect on cotton fabrics, and a mordant NaCl is conducive to the dyeing effect. The novel natural dye obtained by adopting the Pseudofusicoccum sp. F10 is safe, is environmentally friendly and is not limited by regions or environments, the fungal pigment has good reproducibility, the yield is increased remarkably by adopting a biological cultivation method, and industrialization is easier to achieved.

Owner:LUOHE MEDICAL COLLEGE

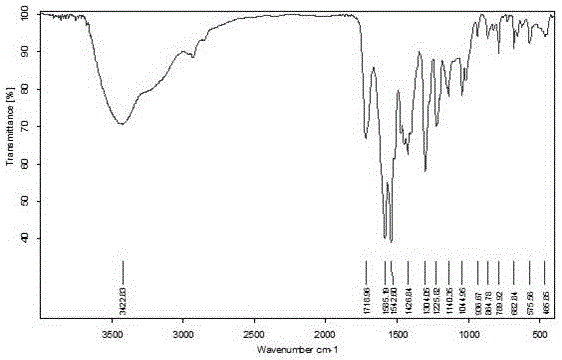

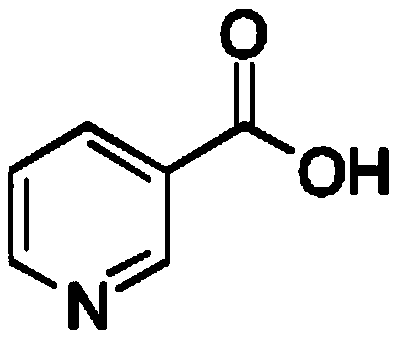

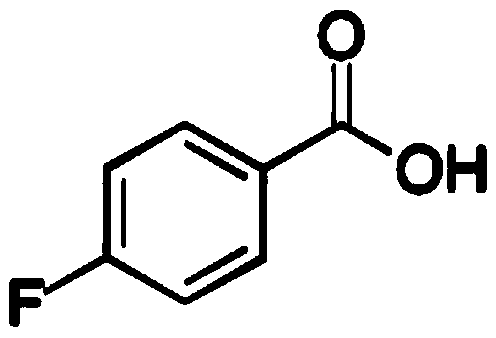

Electronic cigarette liquid, preparation method thereof and novel acid for preparing nicotine salt and electronic cigarette

The invention relates to an electronic cigarette liquid, a preparation method thereof and a novel acid for preparing a nicotine salt and an electronic cigarette. The electronic cigarette is prepared from the following raw materials in parts by weight: 1 to 5 parts of nicotine, 2 to 10 parts of organic acid and 50 to 300 parts of organic solvent, wherein the organic acid is any one or a mixture ofnicotinic acid, parafluorobenzoic acid and para aminobenzoic acid. The electronic cigarette is prepared through reaction of the nicotine and a specific type of organic acid in the organic solvent. Compared with other existing electronic cigarette liquids, the electronic cigarette liquid disclosed by the invention has the advantages of lower nicotine salt concentration (the content of the nicotineis lower than or equal to 20mg / mL), better smoking feel, unique atomizing effect and smoking feel, and certain health care function.

Owner:深圳多客技术有限公司

Compound for detecting leucine aminopeptidase, preparation method of compound and application of compound

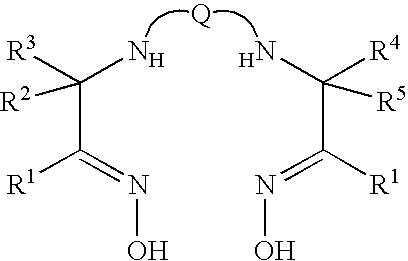

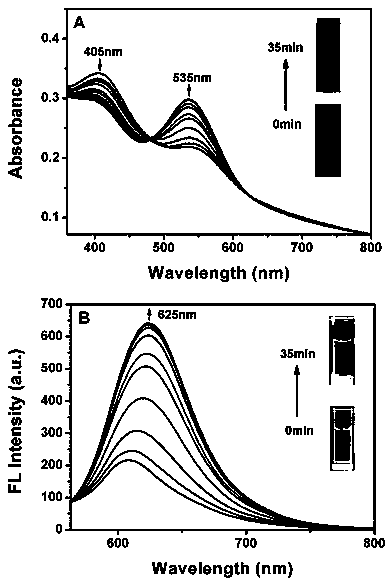

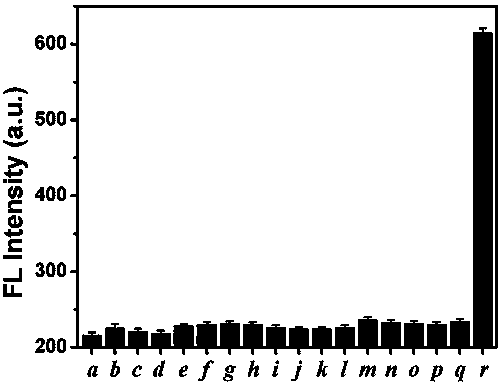

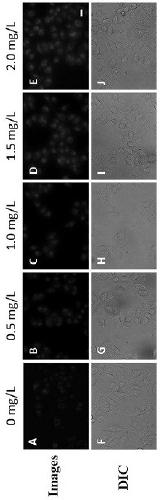

ActiveCN109438319AGood water solubilitySolve the short wavelength of fluorescence emissionOrganic chemistryFluorescence/phosphorescenceFluorescenceMolecular probe

The invention belongs to the field of biochemical engineering, and particularly relates to a preparation method and an application of a near-infrared fluorescent molecular probe NF-O-Leu for detectingleucine aminopeptidase (LAP). The structural general formula of the compound NF-O-Leu is as shown in the specification, R1, R2, R3, R4, R5 and R6 are introduced substituent groups and can be used foradjusting electronic effects of the fluorescent probe, so that fluorescence of the fluorescent probe is changed. According to the near-infrared fluorescent molecular probe NF-O-Leu, near-infrared fluorescent dyes NF-OH and LAP receptor units (leucine residues) are bridged together by para-aminobenzoic acid (PABA), the target near-infrared fluorescent molecular probe NF-O-Leu is synthesized and used for specifically monitoring LAP activity in vitro and in vivo, and trace LAP in living cells is successfully tracked and detected.

Owner:HUBEI UNIV

Salbutamol artificial antigen and preparation method and application thereof

The invention relates to a salbutamol artificial antigen and a preparation method and an application thereof. The preparation method comprises the following steps: linking salbutamol with activated para aminobenzoic acid to prepare salbutamol active intermediate containing carboxyl, adopting ethyl[3-(dimethylamino)propyl]carbodiimide as crosslinker to couple the methyloic salbutamol active intermediate with the amino of carrier protein, and dialyzing and freeze drying the product to obtain the antigen. The salbutamol artificial antigen can be used to prepare salbutamol polyclonal antibody. By the preparation method, the absolute immunogen of specific antibody which can prompt an immune response in animals can be prepared. The preparation method of the invention has the advantages of low cost of preparation method, simple operation and good repeatability.

Owner:QINGDAO VLAND BIOTECH INC

Tetracaine preparation method

ActiveCN105646261AHigh yieldThe synthesis steps are simpleOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidHydrochloride

The invention discloses a tetracaine preparation method, comprising the following steps in sequence: (1) performing a catalytic reduction reaction on para aminobenzoic acid and n-butanal to prepare N-butyl para aminobenzoic acid; (2) filtering reaction liquid obtained in step (1), then adding sodium hydroxide for mixing; (3) enabling the N-butyl para aminobenzoic acid treated by the sodium hydroxide to directly react with N,N-dimethyl chloroethylamine hydrochloride without refining and separation, thus obtaining tetracaine. According to the method, the steps are fewer, the operation is simple, more convenience and cleanness are realized, and the product yield is higher.

Owner:JINAN CHENGHUI SHUANGDA CHEM

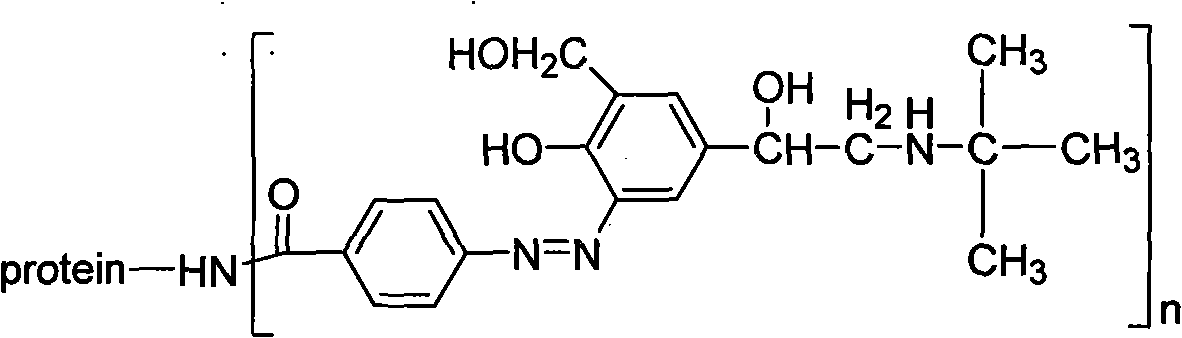

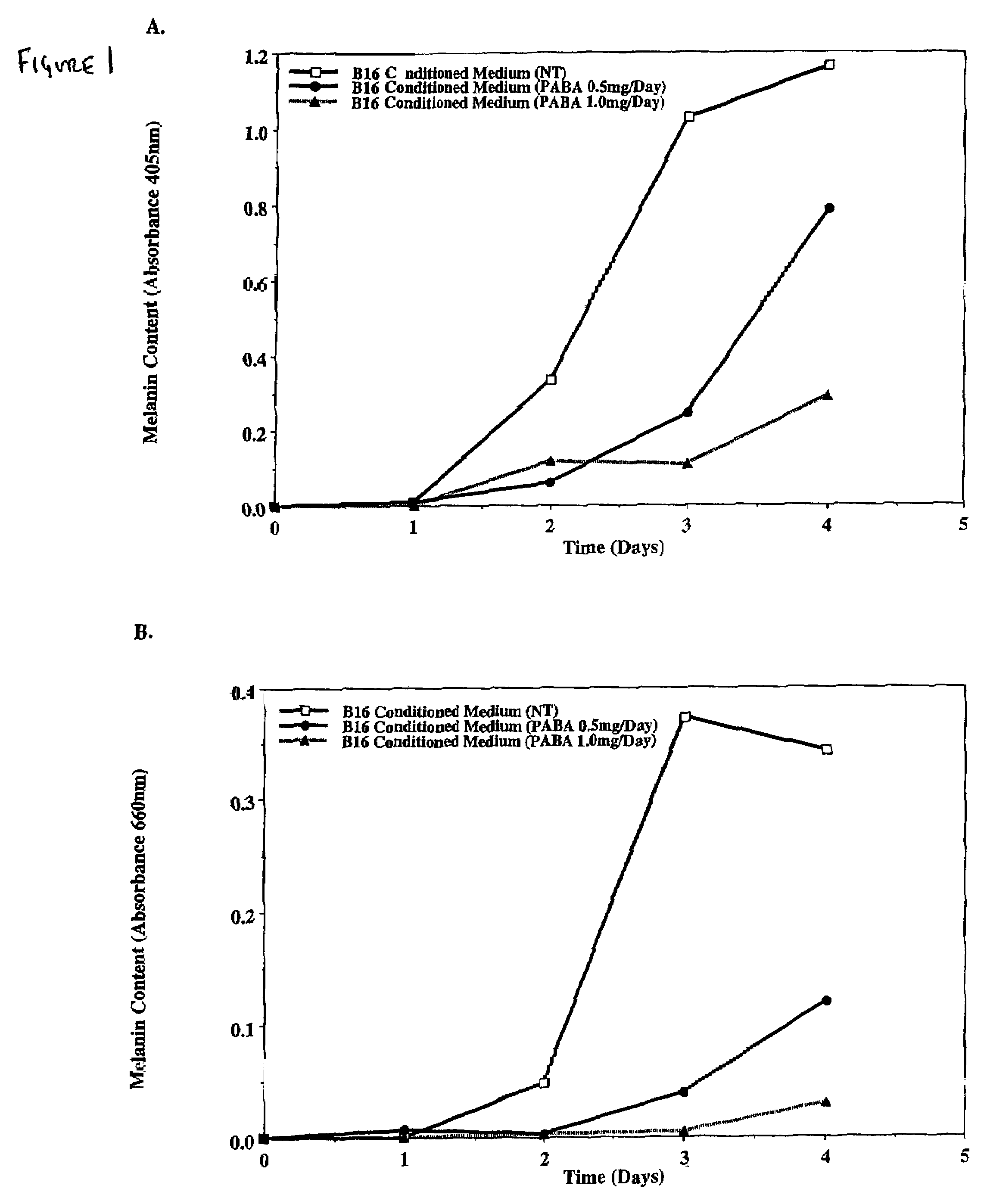

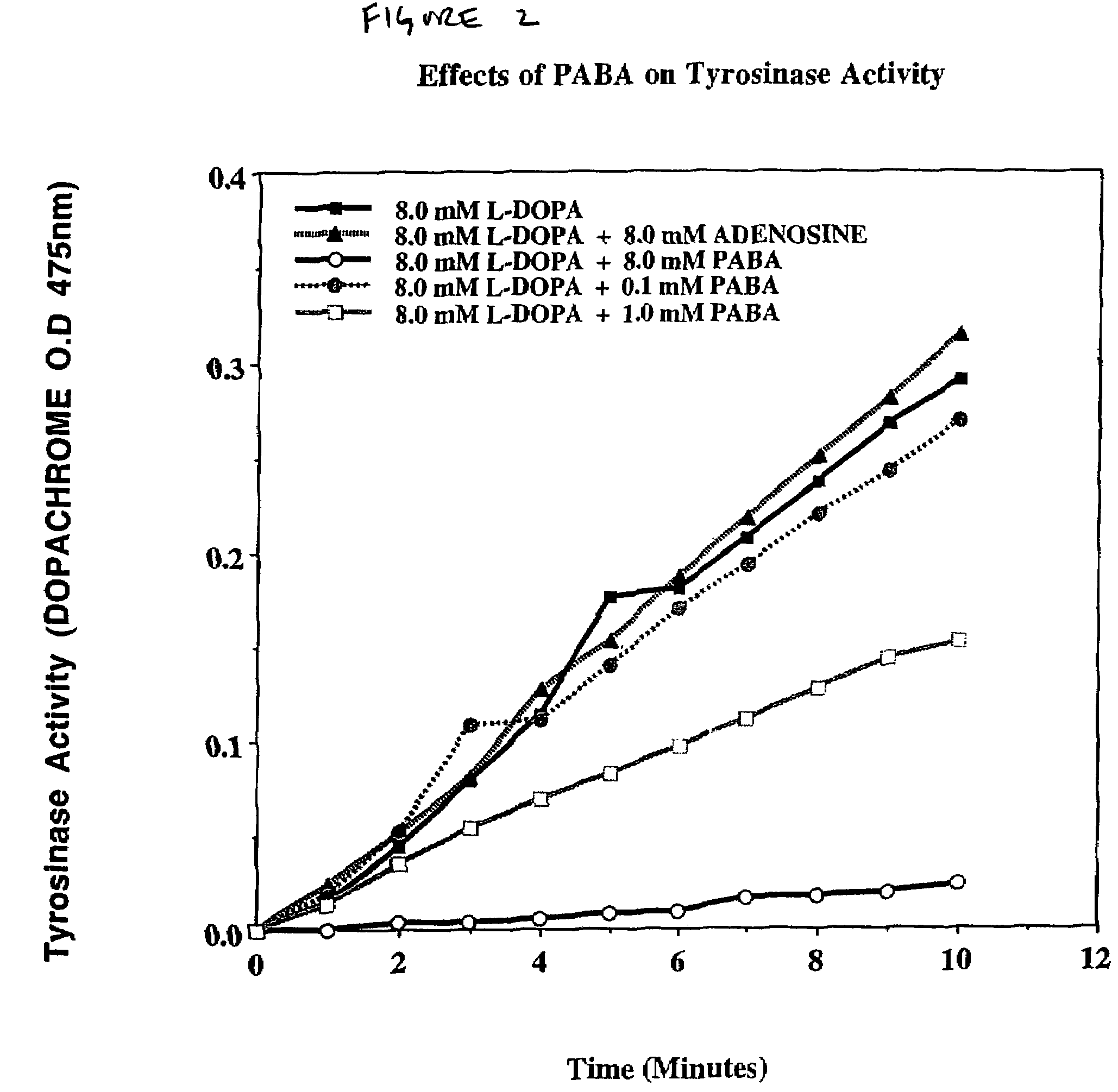

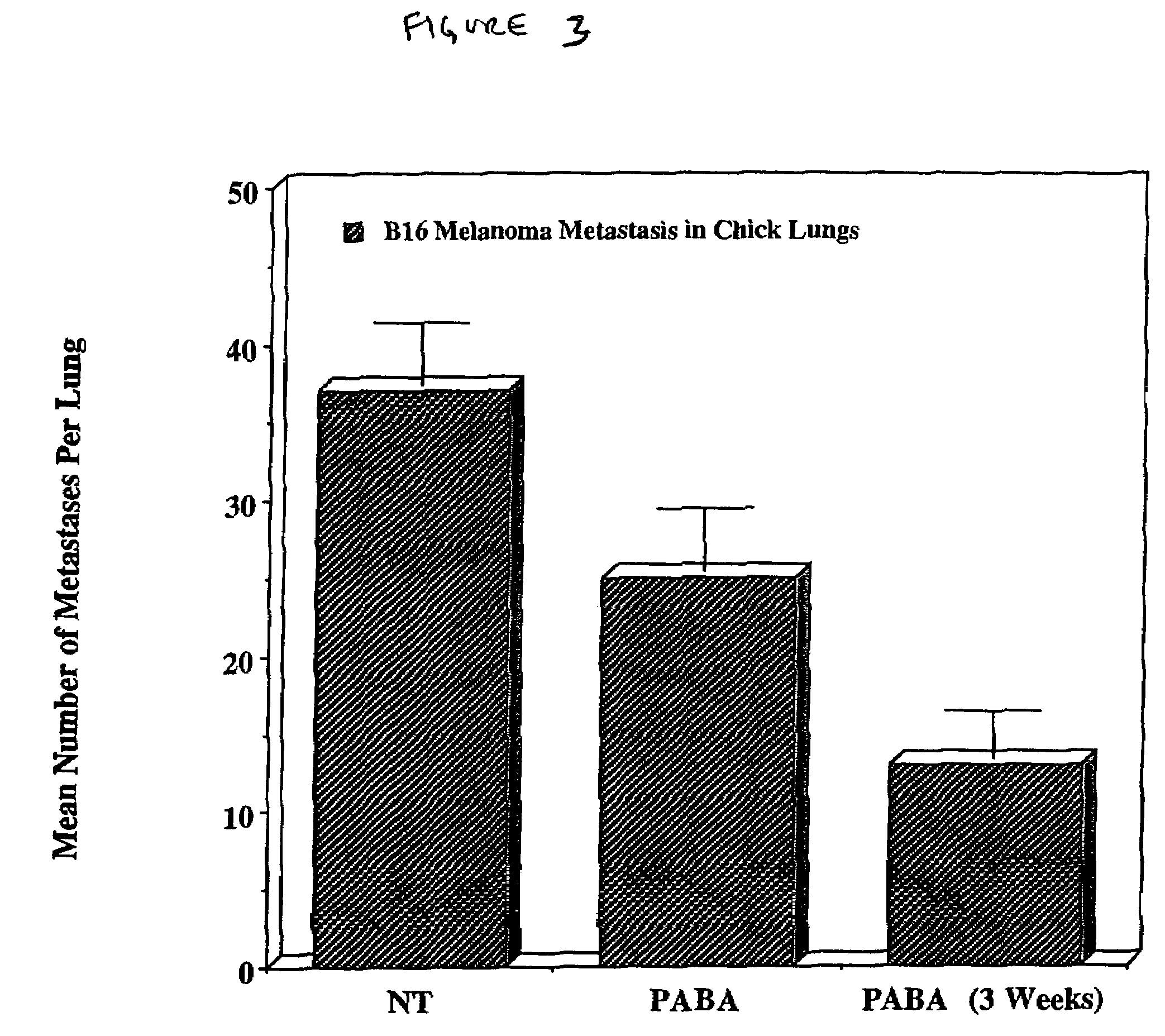

Inhibition of melanogenesis and melanoma metastasis with p-aminobenzoic acid (PABA)

InactiveUS7691905B2Reduce intrusionGrowth inhibitionBiocidePeptide/protein ingredientsMelanomaLymphatic Spread

The present invention relates to the inhibition of melanogenesis with para-aminobenzoic acid (PABA) and its use in treating melanotic cancer.

Owner:NEW YORK UNIV

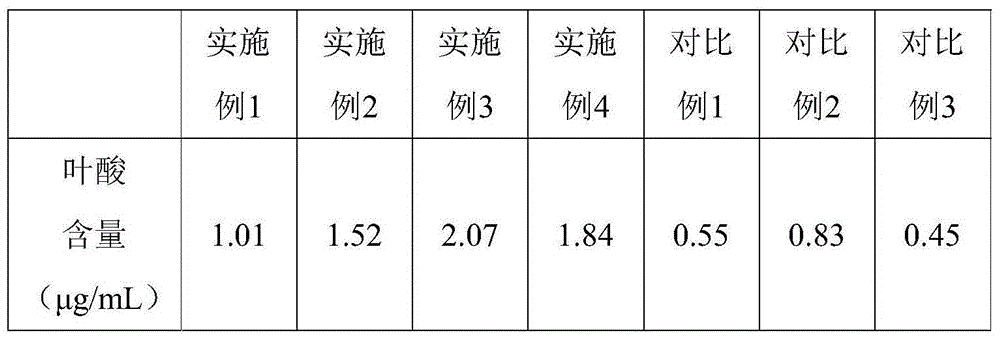

Lactobacillus culture medium, method for preparing folic acid and method for determining folic acid content

InactiveCN105063123AIncrease contentImprove securityComponent separationMicroorganism based processesSide effectP-Aminobenzoic acid

The invention provides a lactobacillus culture medium, a method for preparing folic acid and a method for determining folic acid content in a fermentation liquid. According to the embodiment of the invention, every 1 liter of lactobacillus culture medium comprises 10g of glutamic acid, 10g of beef extract, 5g of yeast extract, 20g of glucose, 2g of K2HPO4, 5g of CH3COONa, 1g of Tween-80, 2g of diamine citrate, 0.5g of MgSO4.7H2O, 0.3g of MnSO4.4H2O, 400g of p-aminobenzoic acid and 4g of glutamic acid. The lactobacillus culture medium at least has one of the following advantages: high content, high safety, favorable absorption effect, and no toxic or side effect.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

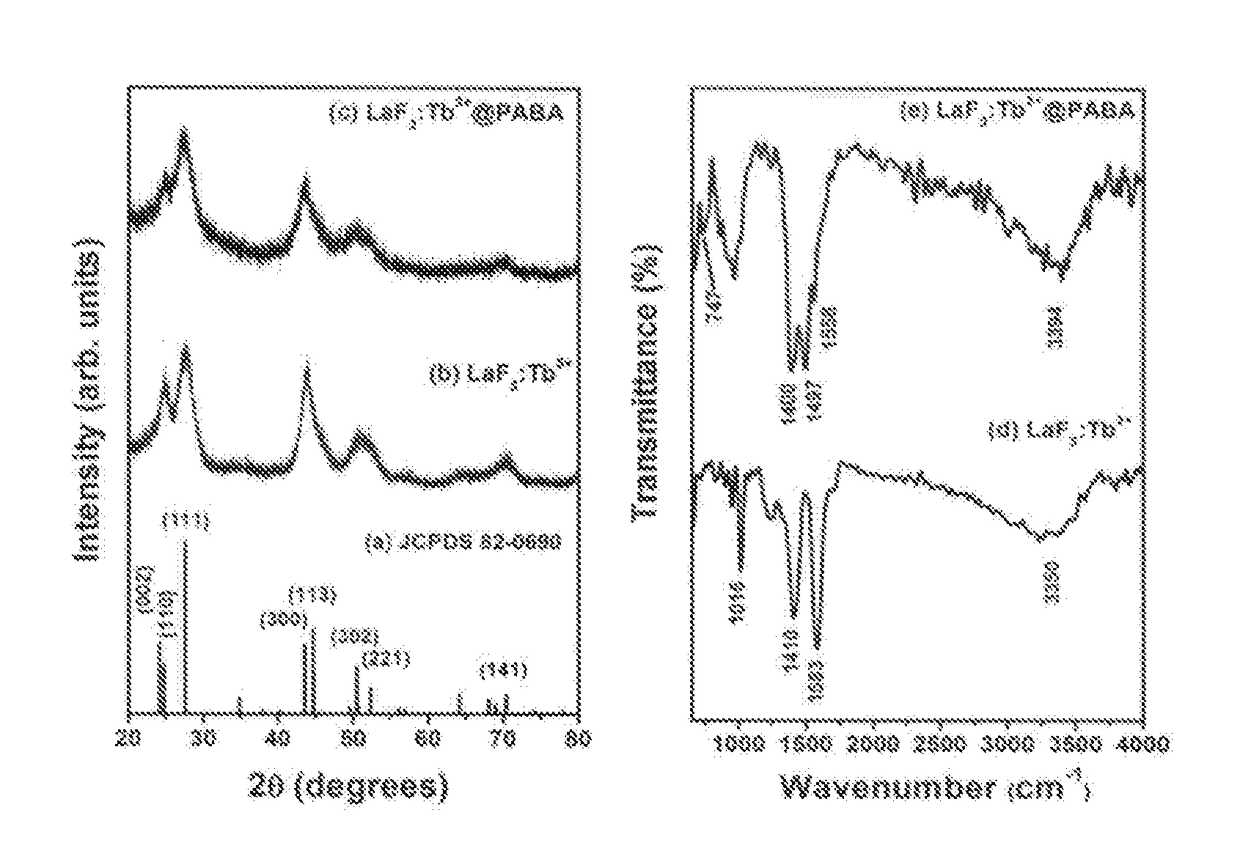

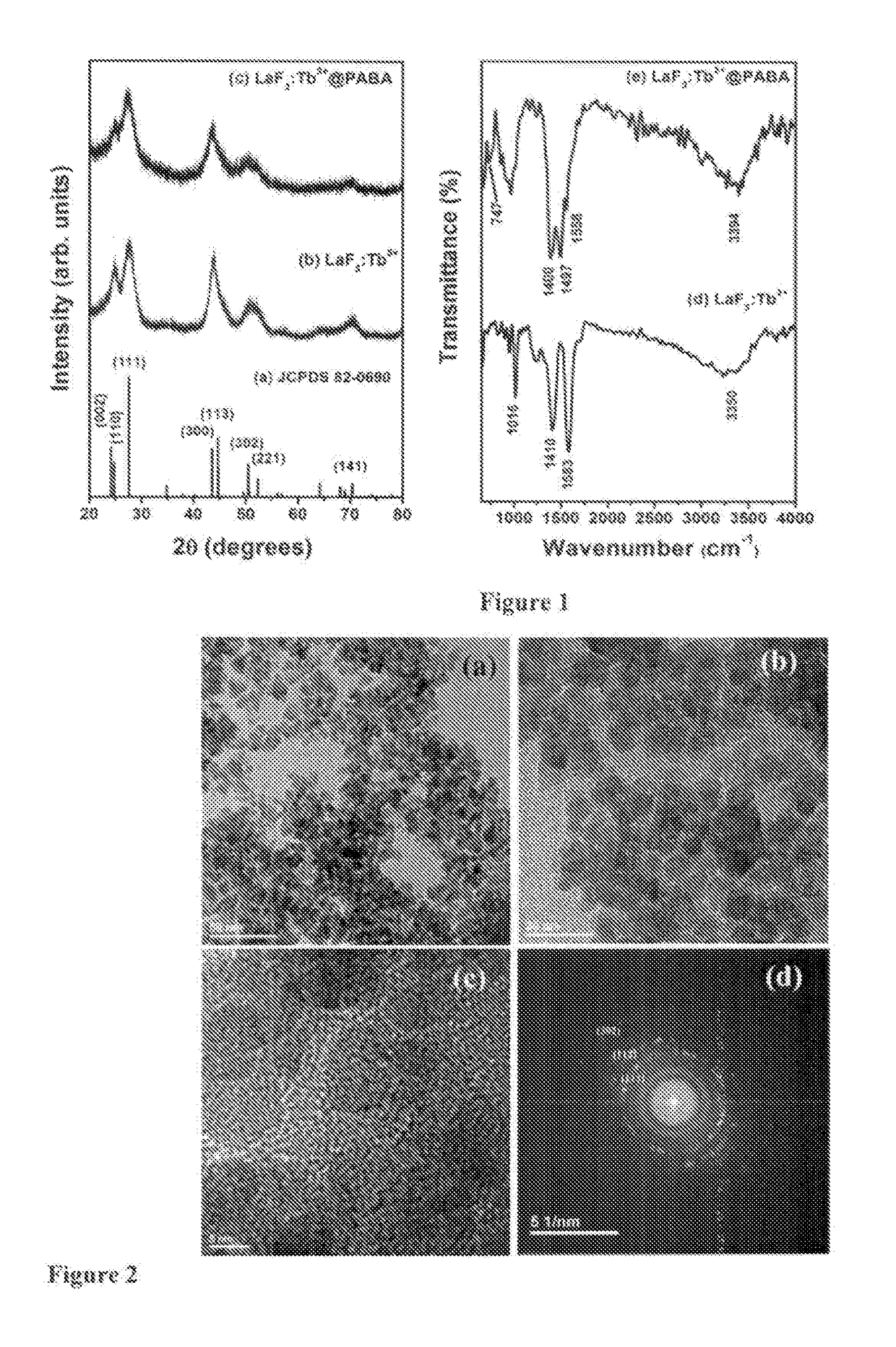

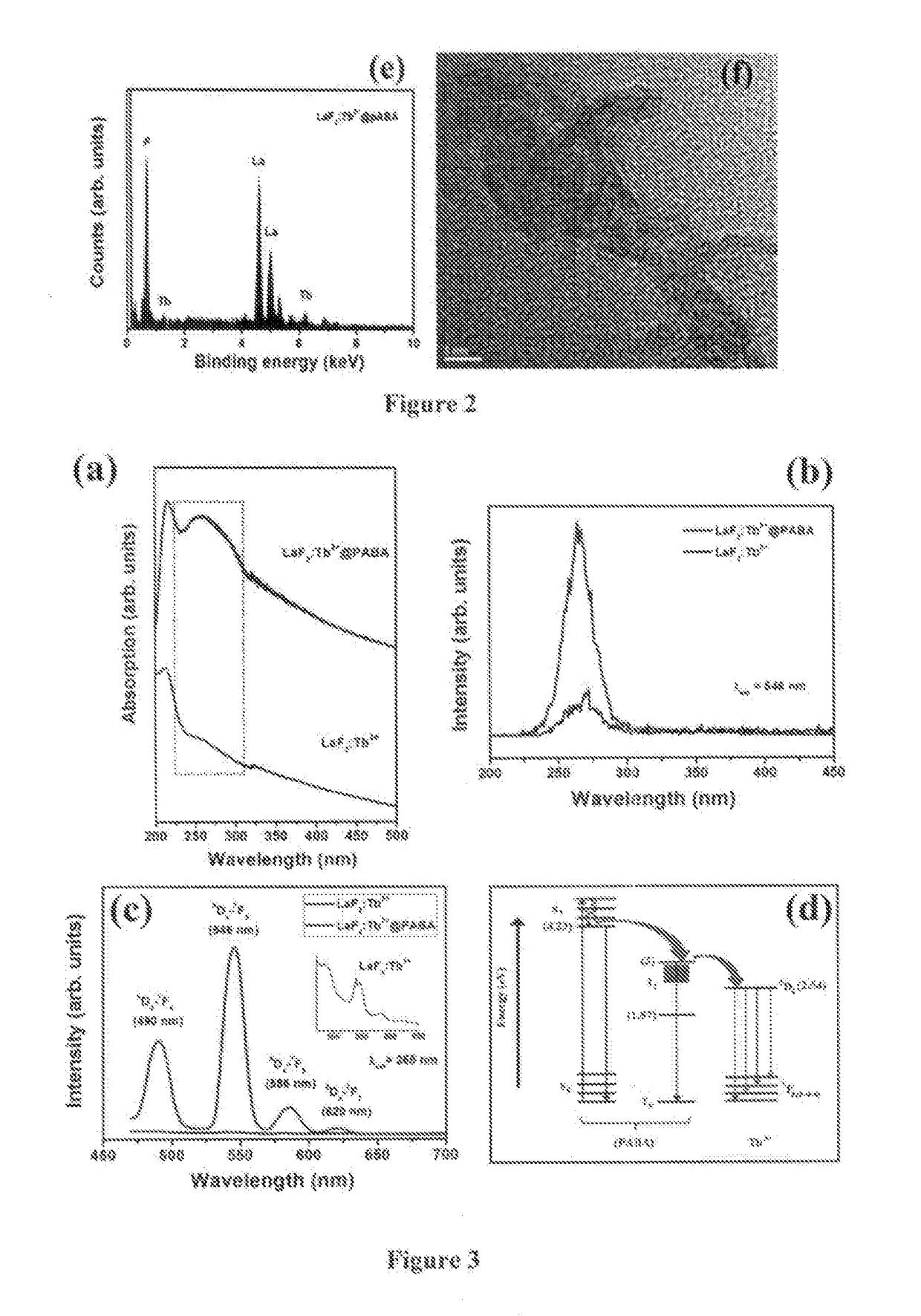

Para-aminobenzoic acid sensitized terbium doped laf3 nanoparticles for detection of explosive nitro compounds

ActiveUS20170225963A1Remarkable enhancement in luminescence intensityNanosensorsInvestigating pH valueNitro compoundBenzoic acid

The patent relates to para amino benzoic acid (pABA) sensitized terbium (Tb3+) doped spherical LaF3 nanoparticles used for detection of nitro group containing compounds using the terbium (Tb3+) doped spherical LaF3 nanoparticles sensitized by para amino benzoic acid (pABA).

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com