Preparation method for para aminobenzoic acid lossless modified carbon fiber enhanced paper base wet-type friction material

A technology of p-aminobenzoic acid and wet friction materials, which is applied in the treatment of carbon fiber, synthetic cellulose/non-cellulose material pulp/paper, and fiber raw materials. There are no problems such as practical application, to achieve the effect of improving the bonding effect, improving the friction and wear performance, and enhancing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

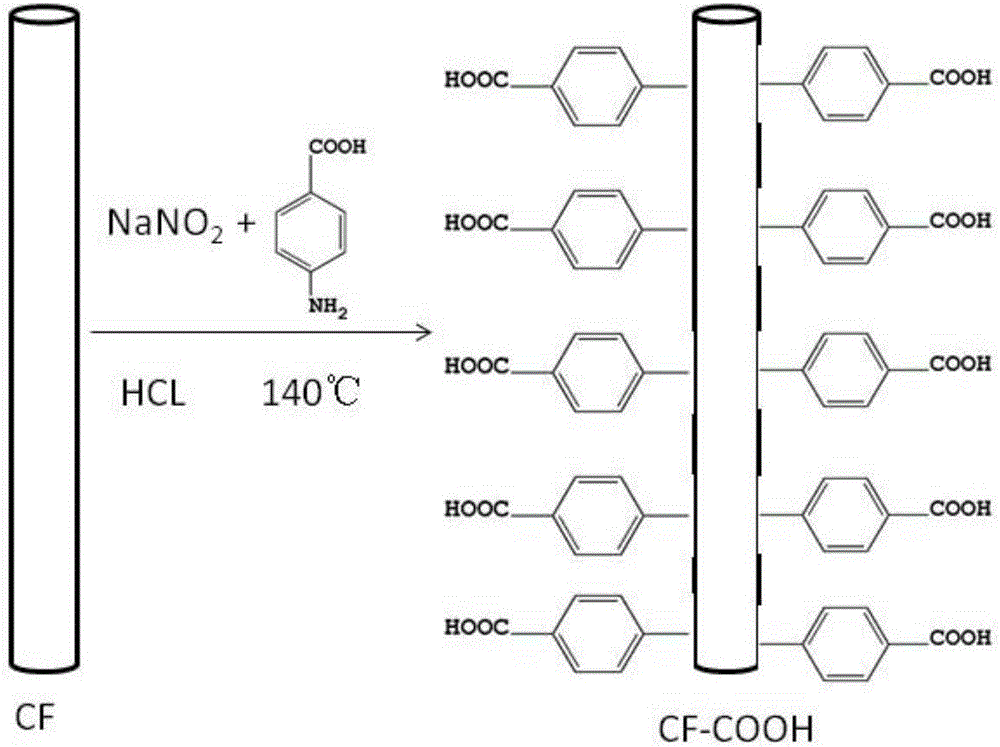

[0021] A method for preparing a nondestructively modified carbon fiber reinforced paper-based wet friction material with p-aminobenzoic acid, comprising the following steps:

[0022] Step 1: Soak the carbon fiber with acetone to remove the sizing agent and pollutants on the surface of the fiber. After repeated cleaning with deionized water, place it in an oven at 100°C and dry it for later use. The mass ratio of carbon fiber after drying: p-aminobenzoic acid is (1-5): (1-4) Mix carbon fiber and p-aminobenzoic acid, then add excess hydrochloric acid, heat to 60-100°C in an oil bath, then add sodium nitrite for diazotization reaction for 15-20min , wherein the molar ratio of p-aminobenzoic acid, hydrochloric acid and sodium nitrite is 2:4:1, after the reaction is completed, the carbon fiber sample is taken out, cleaned and dried to obtain the modified carbon fiber, and the carbon fiber is polyacrylonitrile carbon fiber or pitch-based carbon fiber;

[0023] Step 2: Use the wet p...

Embodiment 1

[0027] Step 1: Mix 0.5g of polyacrylonitrile-based carbon fiber with 0.4g of p-aminobenzoic acid and 0.213g of hydrochloric acid, add it into a three-necked flask, and react under the condition of an oil bath with magnetic stirring. When the reaction temperature reaches 60°C, add 0.124g Sodium nitrite was reacted for 15 minutes. After the reaction was completed, the carbon fiber was taken out and washed with deionized water and DMF repeatedly for 3 times, and then dried in an oven at 60°C to obtain the modified carbon fiber;

[0028] Step 2: Weigh 6.0 g of modified carbon fiber, 2.0 g of aramid fiber, 2.0 g of paper fiber, and 2.0 g of filler (including 1.5 g of kaolin and 0.5 g of diatomaceous earth) respectively. Then the fibers and fillers are mixed evenly by wet beating, and the friction material preform is obtained through a special suction filtration molding process, and the mass of the friction material preform after weighing and drying is recorded as W1;

[0029] Step ...

Embodiment 2

[0031] Step 1: Mix 0.4g of polyacrylonitrile-based carbon fiber with 0.3g of p-aminobenzoic acid and 0.160g of hydrochloric acid, add it into a three-necked flask, and react under the condition of an oil bath with magnetic stirring. When the reaction temperature reaches 100°C, add 0.09g Sodium nitrite was reacted for 10 minutes. After the reaction was completed, the carbon fiber was taken out and washed with deionized water and DMF repeatedly for 5 times, and then dried in an oven at 60°C to obtain the modified carbon fiber.

[0032] Step 2: Weigh 10.0 g of pretreated carbon fiber, 1.6 g of aramid fiber, 1.6 g of paper fiber, and 2.0 g of filler (including 0.8 g of quartz powder and 1.2 g of diatomaceous earth). Then, the reinforcing fiber and the filler are mixed evenly by wet beating, and then the friction material prefabricated body is obtained through a special suction filtration molding process. Weigh and dry the mass of the friction material prefabricated body and record i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com