Steel structure fireproof anticorrosion function integrated coating and preparing method thereof

A steel structure and functional technology, applied in the field of coatings, can solve the problems of poor thermal barrier performance and anti-corrosion performance, failure to achieve complementary effects of modification, development obstacles, etc., to overcome poor barrier properties, good application prospects and practical significance, and increase traffic. The effect of link density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific examples.

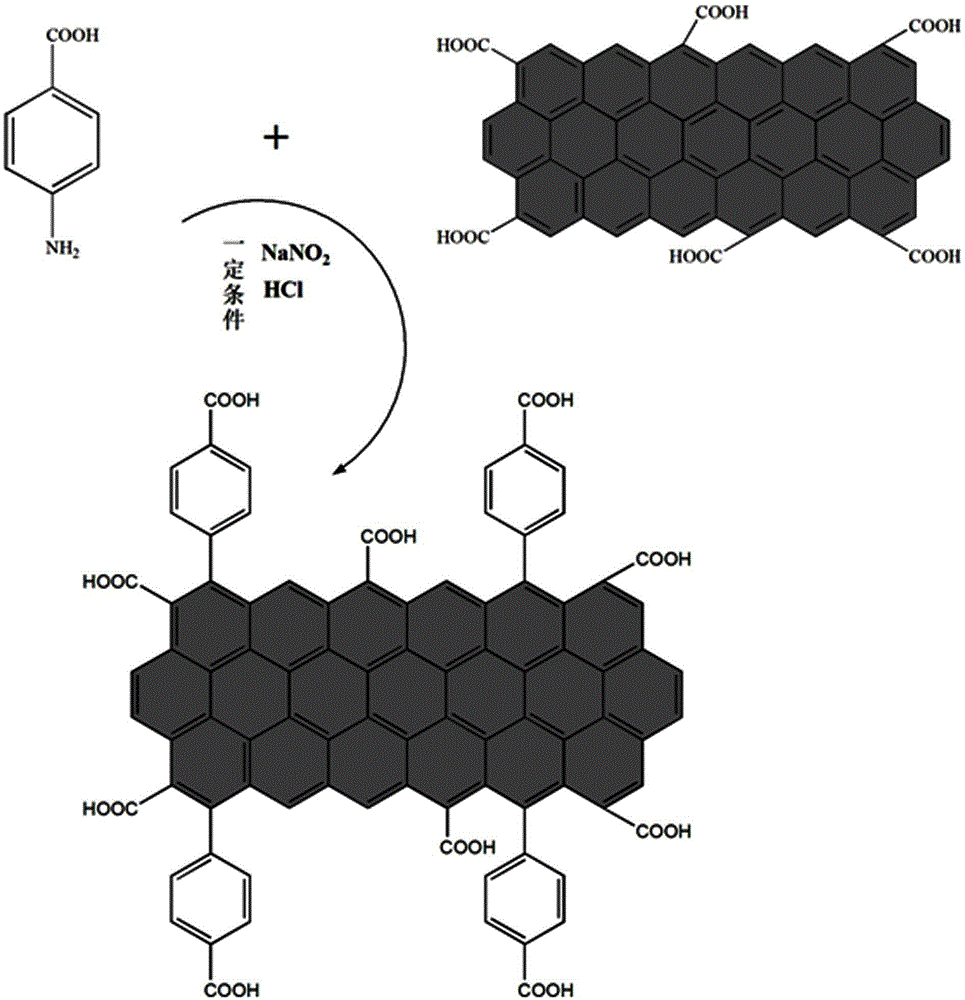

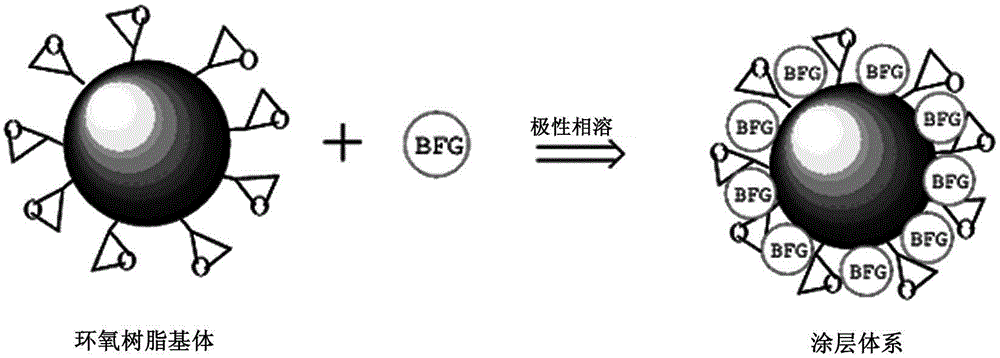

[0021] This embodiment provides a kind of steel structure fire prevention and anticorrosion functional integrated coating, is made by compounding of benzoic acid functionalized graphene, water-based epoxy resin, water-based curing agent and water; The benzoic acid functionalized graphene is mainly composed of graphene and Made from p-aminobenzoic acid; the water-based epoxy resin is E51 epoxy emulsion; the water-based curing agent is Aq419.

[0022] see figure 1 , figure 2 , this embodiment also provides a method for preparing a steel structure fireproof and anticorrosion functional integrated coating, including the following steps.

[0023] Step 1. Add 1.2g of graphite (flake graphite 325 mesh) and 2g of NaNO in an ice-water bath 3 ; Pour 50ml refrigerated (0°C) concentrated H 2 SO 4 And stir for 60min under the condition that the rotor speed is 350 rev / min; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com