Patents

Literature

58results about How to "Reduce the amount of filler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamide/oxidized graphite composite material with high conduction performance and preparation method thereof

InactiveCN101608061AImprove conductivityReduce the amount of fillerIn situ polymerizationConductive polymer

The invention discloses a polyamide / graphite composite material with high conduction performance and a preparation method thereof. The composite material consists of a polyamide substrate and nanometer graphite and is prepared through in-situ polymerization. The nanometer graphite has high diameter-to-thickness ratio; and an effective conduction network can be formed in a polymer by using little nanometer graphite. With the low content of a conduction filling of the nanometer graphite, a conduction polymer material keeps original good mechanical performance. The volume conductivity of the polyamide / graphite composite material with high conduction performance can reach 8*10S / cm; and compared with a conventional natural graphite and expanded graphite conductive composite material, the polyamide / graphite composite material has excellent properties of low filling amount and high conductivity.

Owner:TORAY IND INC

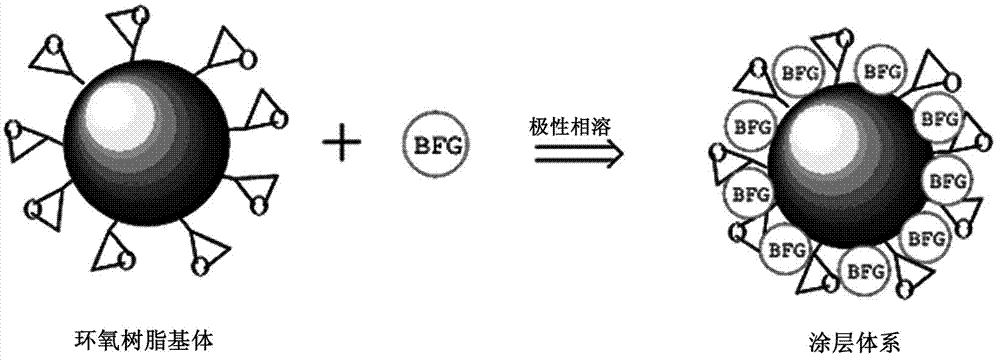

Preparation method of metal organic framework/ water-borne anti-corrosive coating

ActiveCN104861822ASolve the disadvantages of mechanical performance declineEliminate the disadvantages of the decline in anti-corrosion effectAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a preparation method of a metal organic framework / water-based anti-corrosive coating. The composite coating is formed by compounding a coordination compound of a metal organic framework (MOFs) and water-borne epoxy resin. As a novel organic hybrid material, the coordination compound of a metal organic framework (MOFs) has high void ratio and adjustability of hole dimension and shape; when the material gets the outside stimulation (such as pressure, light, chemical stimulation of a guest molecule), the framework shape can be changed. The preparation method introduces the metal organic framework material to an anti-corrosive coating system, thus the crosslinking density of the coating can be added, the corrosive particles can be absorbed; besides, the preparation method overcomes the shortcoming of poor barrier property and short anti-corrosive cycle which are generally existed in the water-borne anti-corrosive coating at present, and greatly improve the anti-corrosive performance of the anti-corrosive coating.

Owner:CHANGCHUN SHUNFENG XINCHENG BUILDING MATERIAL CO LTD

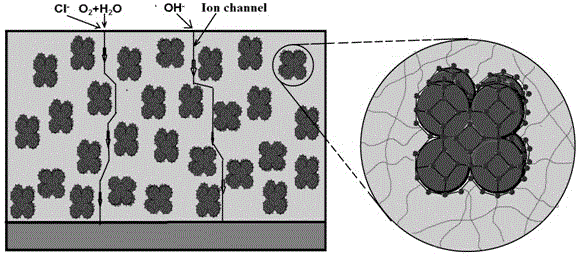

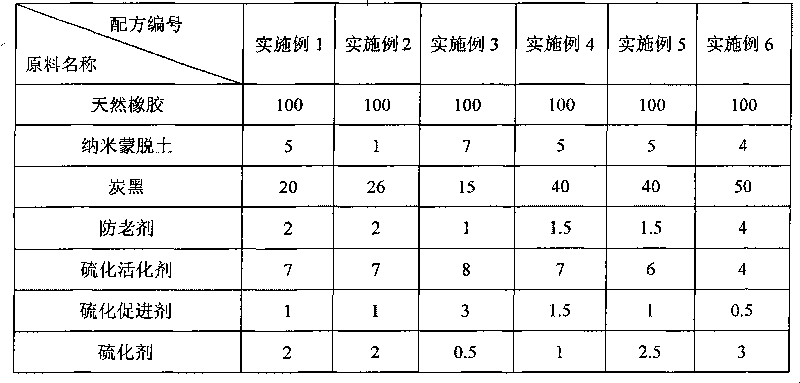

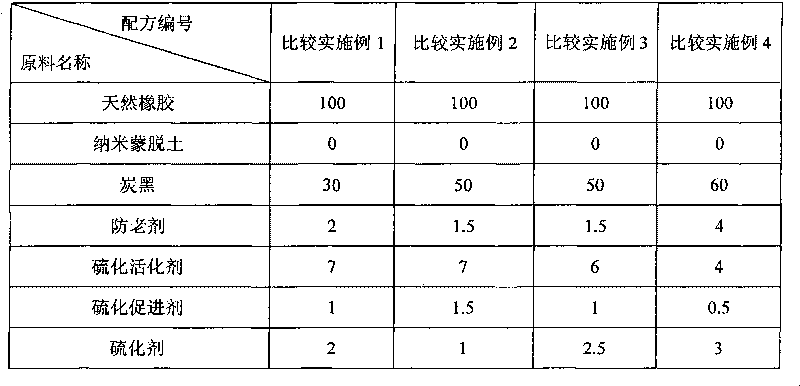

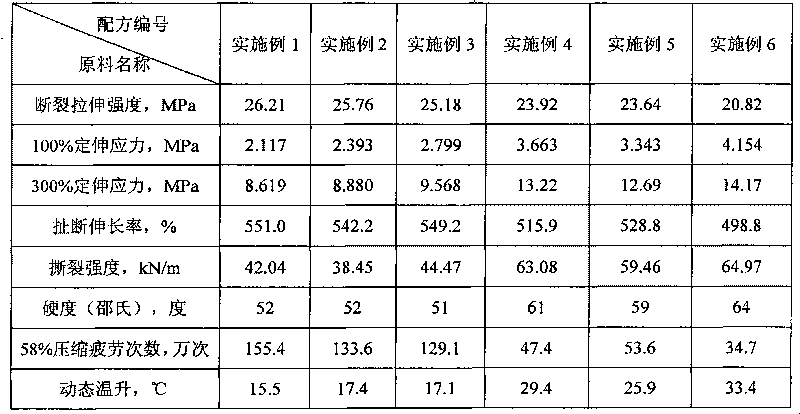

Fatigue-resisting natural rubber nano composite material and preparation method thereof

The invention discloses a fatigue-resisting natural rubber nano composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps of: carrying out mechanical intercalation on 100 parts of natural rubber and 1-7 parts of nano montmorillonoid, then adding 4-8 parts of vulcanizing activator, 1-4 parts of anti-aging agent, 15-50 parts of carbon black packing, 0.5-3 parts of vulcanizing accelerator and 0.5-3 parts of vulcanizing agent, then adding gelatine into a flat-plate vulcanizing machine, and carrying out mould pressing for 10-30 minutes with the temperature of 135-155 DEG C and the pressure of 10-15MPa to obtain the fatigue-resisting natural rubber nano composite material. The invention substitutes the traditional high-structure carbon black packing by adopting the organic nano montmorillonoid, reduces the thermogenesis of the material under the dynamic loading effect and the same hardness by adopting less packing usage amounts, effectively prevents internal cracks of the material from generating and expanding by utilizing the layered structure of the nano montmorillonoid, and obtains a series of natural rubber materials with excellent fatigue-resisting performance without sacrificing the tensile breaking strength and the breaking elongation ratio of the material at the same time.

Owner:SICHUAN UNIV

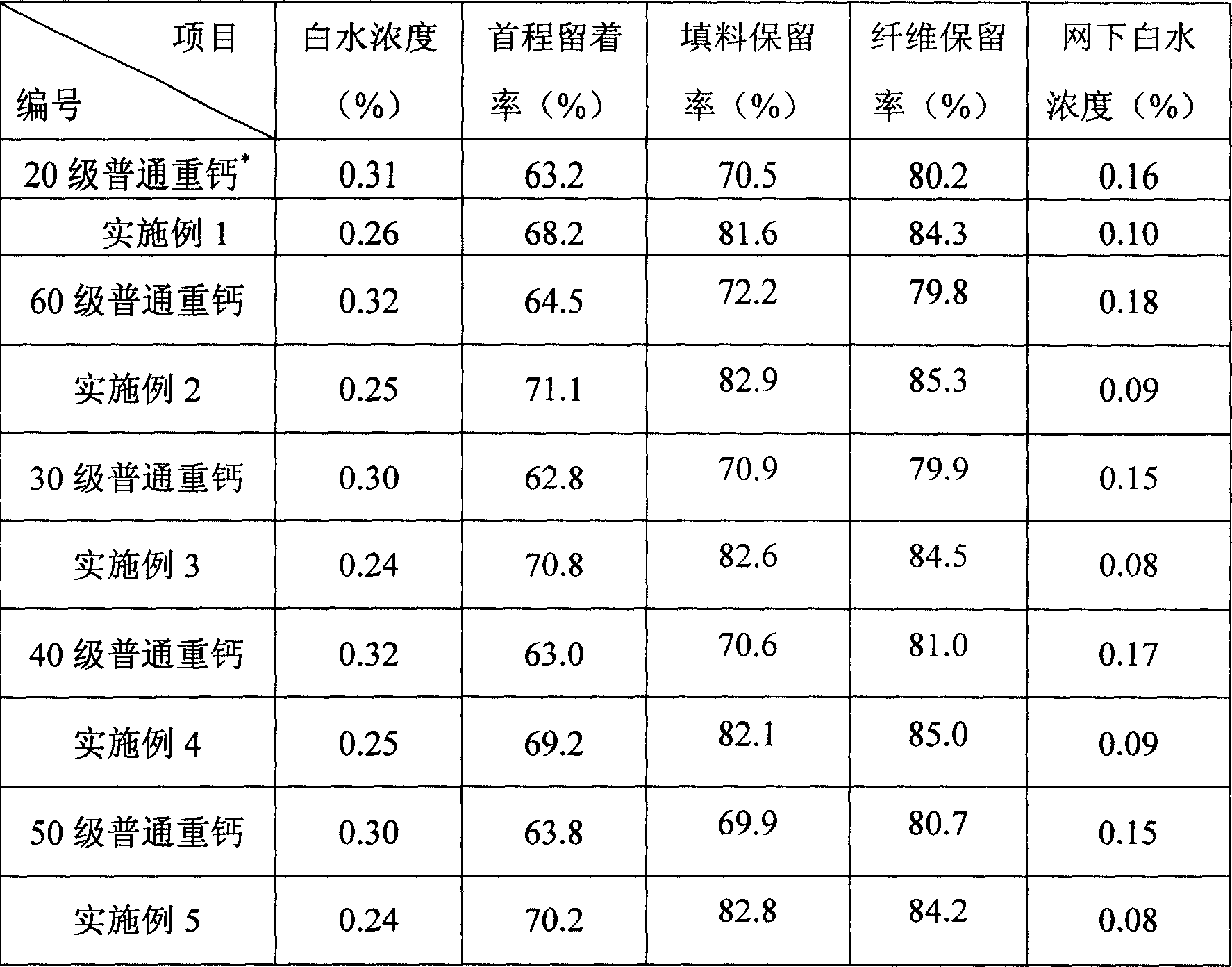

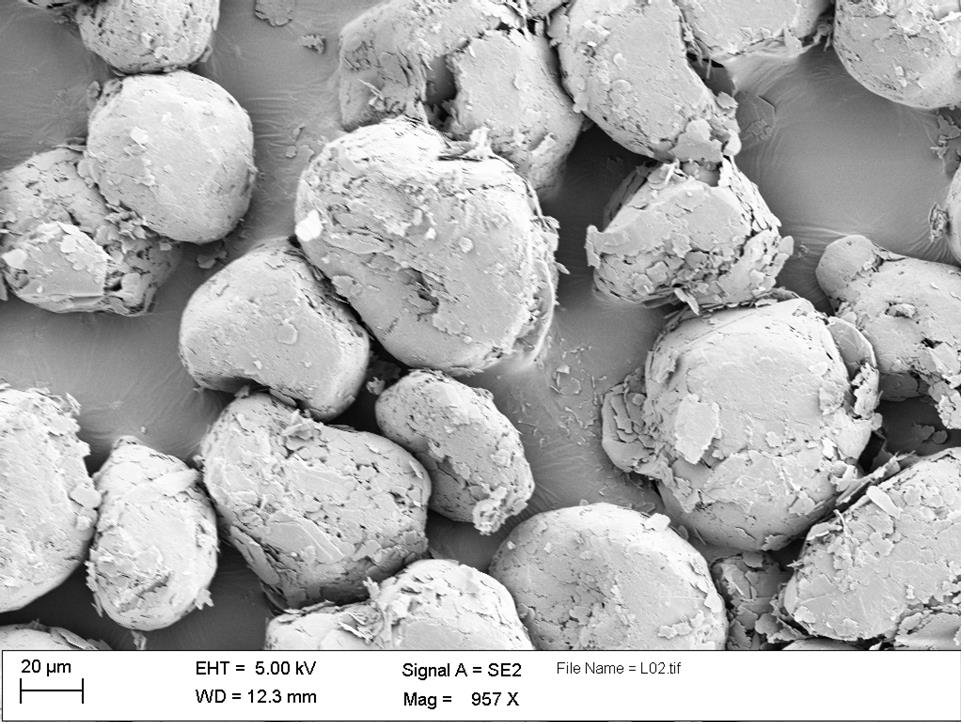

Preparation method of high retention heavy calcium carbonate

ActiveCN100999331AHigh retention rateReduce wearCalcium/strontium/barium carbonatesInorganic compound additionSodium polyacrylateChemistry

This invention discloses a preparation method that high remains water-ground limestone and its application. Add water-ground limestone in water, add sodium polyacrylate dispering agent in water, mix, get water-ground limestone mortar, grind, prepare water-ground limestone mortar, wherein content of less than 2mum is 20-60%; add cationic surfactant in mortar, mix 0.5-3.0 hours, add cationic surfactant in mortar, mix 0.5-3.0 hours, get high remaining water-ground limestone mortar. This high remaining water-ground limestone, which is used as paper fillers, can increase first - pass retention and total retention of bulking agent, and increase fiber retention. It profits to decrease water density, bulking agent dosage, wood pulp dosage, abrasion for papermachine forming fabric, and cost, and protect environment.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

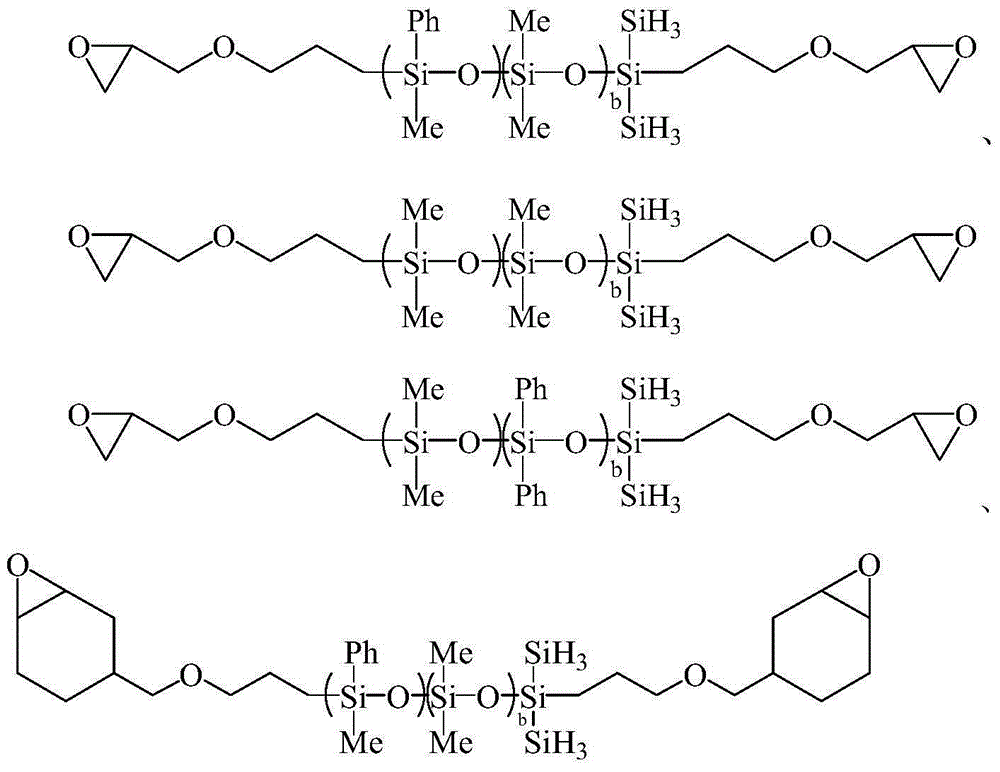

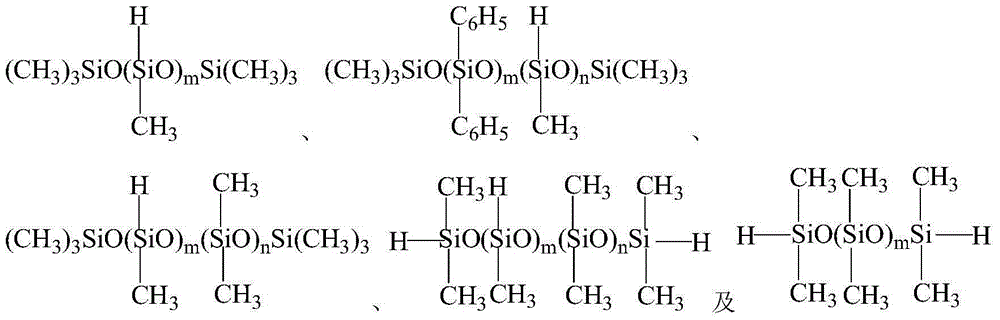

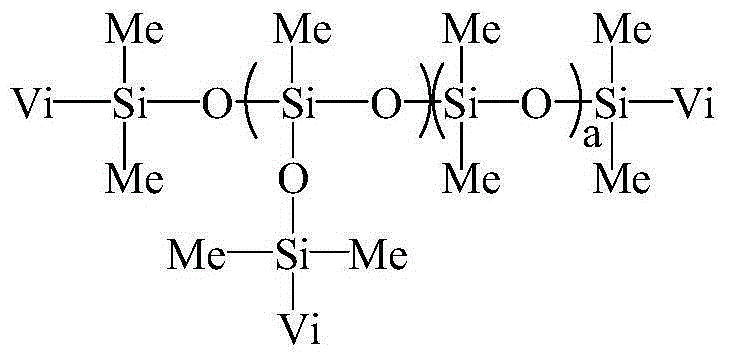

Organosilicon composite material and preparation method thereof

The invention discloses an organosilicon composite material and a preparation method thereof. The composite material is prepared from alkylene-containing polysiloxane, hydrogen-containing polysiloxane, epoxide group polysiloxane, a heat-conduction filling material, a hydrosilation catalyst, a reaction inhibitor and the like through mixing and curing. The prepared organosilicon composite material has the characteristics of low content of volatile compounds, resistance to high and low temperature, high heat conduction, light weight, high strength, good cementability, electrical insulating properties, etc., can meet development demands of functional assemblies for large power, microminiaturization, lightweight and high reliability, and is applicable as a badly-needed high-performance heat-conducting insulating material in military fields like aviation, spaceflight and weapons and in fields related to people's livelihood, e.g., an LED illumination system and an electronic circuit integration system.

Owner:HUNAN BOOM NEW MATERIALS

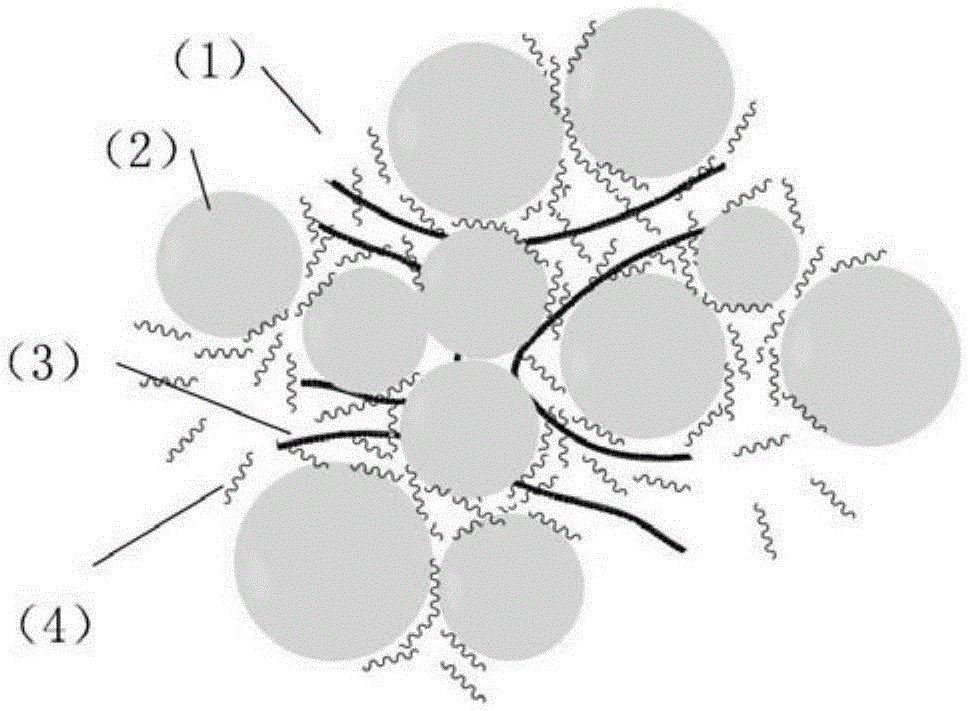

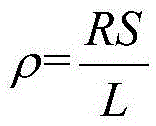

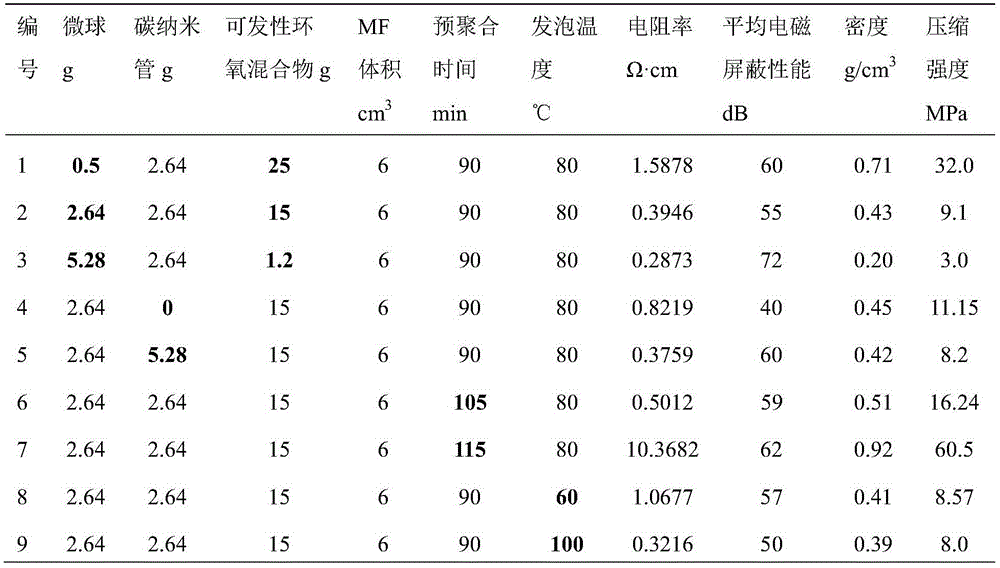

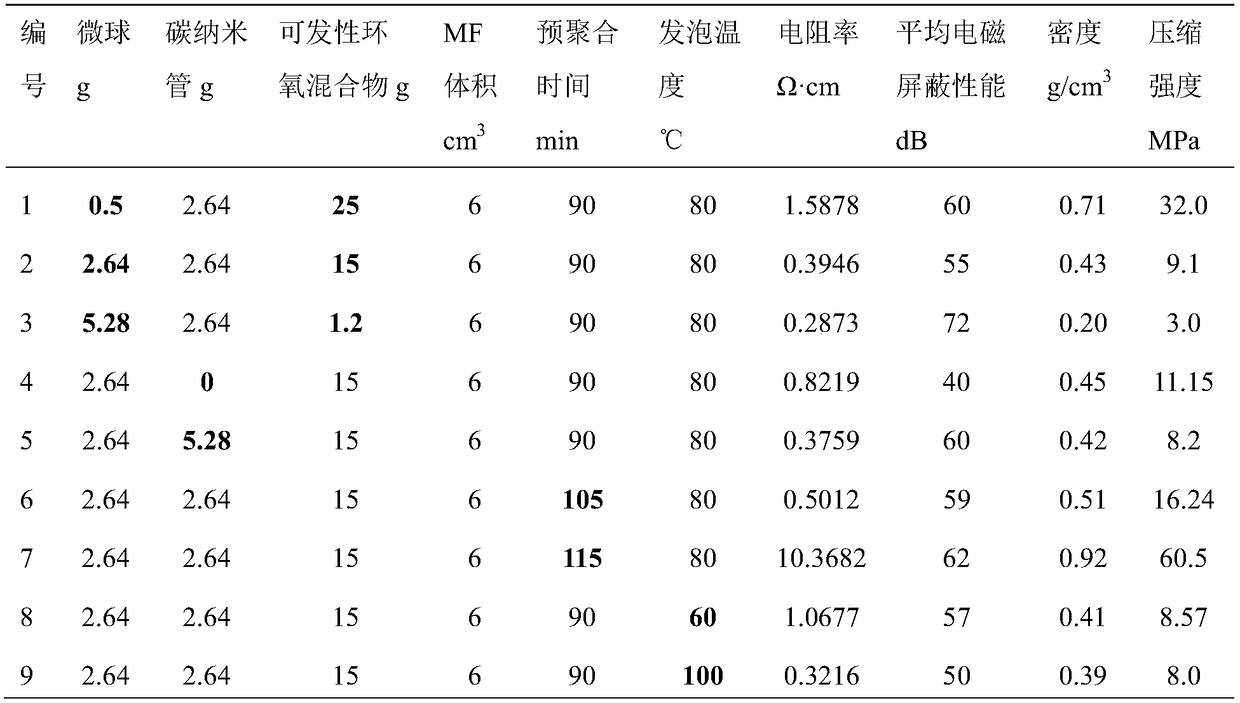

Light-weight epoxy resin composite material and preparation method thereof

The invention discloses a light-weight epoxy resin composite material, which is prepared from an expandable epoxy resin mixture and metallized foam, wherein the ratio of the weight of the expandable epoxy resin mixture to the volume of the metallized foam is greater than or equal to 0.2g / cm<3>. The light-weight epoxy resin composite material has various advantages of low density, high mechanical strength, low electrical resistivity, excellent electromagnetic shielding performance and the like, and is very suitable for being applied as a conducting material and / or an electromagnetic shielding material; in addition, a preparation method of the light-weight epoxy resin composite material is simple and convenient; the energy consumption is low; the production efficiency is high; good industrialization prospects are realized.

Owner:SICHUAN UNIV

Method for preparing flexible composite material with low filler content and high electrical conductivity on basis of swelling penetration method

Owner:HUBEI UNIV OF TECH

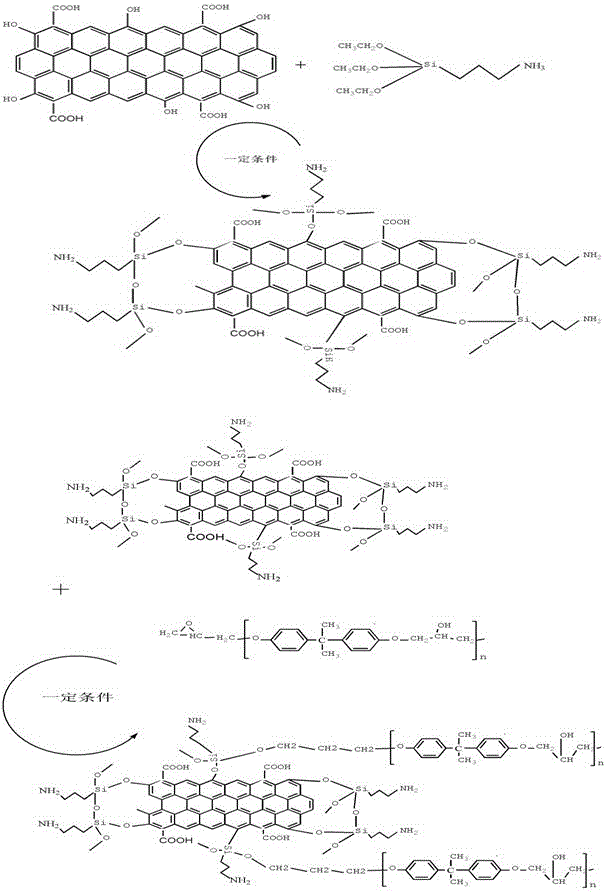

Preparation method of flame retardation graphene coating layer material

InactiveCN106497311AIncrease crosslink densityReduce energy consumptionFireproof paintsAnti-corrosive paintsEpoxyPorous carbon

The invention discloses a preparation method of a flame retardation graphene coating material, and relates to a preparation method of a coating. The method is characterized in that graphene oxide prepared through a Humeers hydrothermal technology is reduced by hydrazine hydrate, organosilane is used as a bridge to connect graphene with epoxy resin through chemical bonds, and a graphene and epoxy resin integrated coating material is synthesized through molecular design. The surface modifying organosilane avoids afresh stacking and aggregation of graphene flakes, so the heat stability and the tensile strength of the graphene and epoxy resin integrated coating material are substantially improved. The integrated functional material improves oxygen index of the tensile strength of the epoxy resin and reduces the heat release rate peak and the total heat release amount, because the integrated coating material can catalyze degradation of the epoxy resin to form a close and porous carbon layer covering the surface of polymer, prevent heat and mass exchange between a gas phase and a solid phase and delay further degradation of the internal material in order to reach the flame retardation purpose of the coating material.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

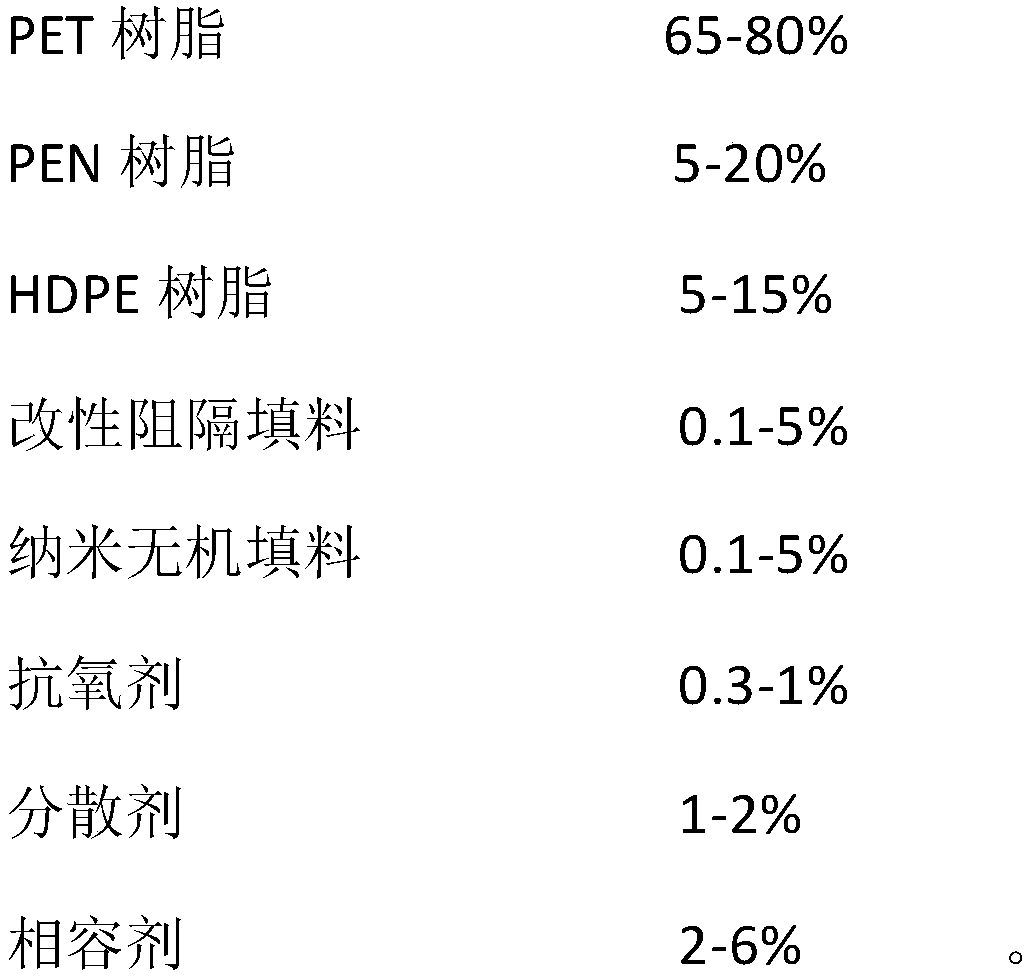

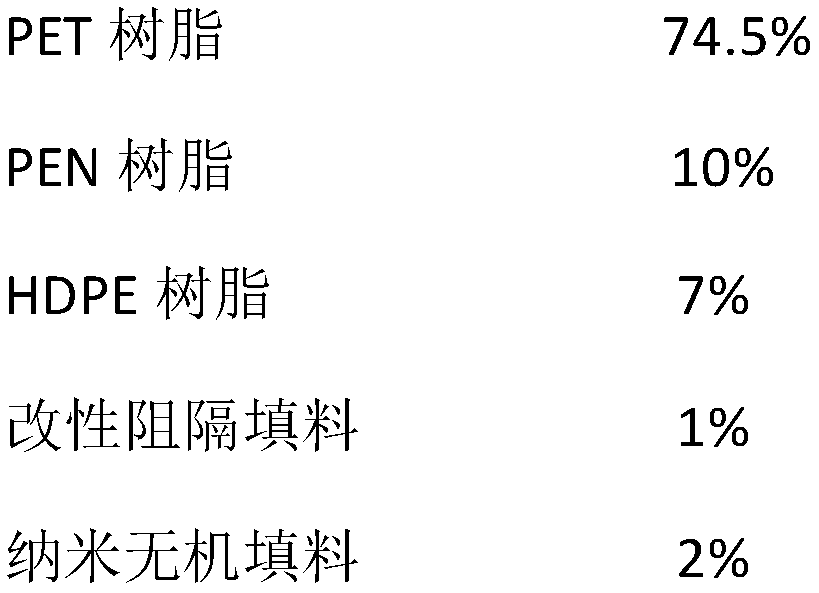

High-barrier PET material and preparation method thereof

InactiveCN109467895AOptimized transmission coefficientImprove barrier propertiesAntioxidantProduct gas

The invention relates to the technical field of polymer materials, in particular to a high-barrier PET material and a preparation method thereof. The high-barrier PET material is prepared from components in percentage by weight as follows: 65%-80% of PET resin, 5%-20% of PEN resin, 5%-15% of HDPE resin, 0.1%-5% of modified barrier filler, 0.1%-5% of nano inorganic filler, 0.3%-1% of an antioxidant, 1%-2% of a dispersant and 2%-6% of a compatilizer. The preparation method comprises the following steps: (1) raw material preparation; (2) mixing; (3) melt extrusion and granulation. The prepared high-barrier PET material gives consideration to balance of barrier property and mechanical property while having better oxygen blocking capacity and gas barrier property, the preparation process is simple and applicable to practical use, and large-scale production is easy.

Owner:CHANGZHOU RUIJIE NEW MATERIAL TECH CO LTD

Method for preparing sliding bearing of nano AI2O3/polyimide friction compound material

InactiveCN1701912AIncreased maximum ultimate loadRaise the failure temperatureOther manufacturing equipments/toolsNano al2o3Nitrogen gas

This invention relates to preparation method for nano Al2O3 / polyimide composite material sliding bearing. First sinter one layer bronze power as interlayer on steel plate surface; roll one polyimide layer included nano Al2O 3; by sintering on condition of nitrogen protection, mechanical working adornment and wrapped welding, obtain bearing; wherein, material composed weight per cent is: polyimide 70í½95úÑ, poly 2.5í½15úÑ, nano Al2O3 1.5í½10úÑ and lead power 1í½5úÑ. The product has well mechanical property and frictional behavior, and fit to oil-free lubrication situations of machine, foodstuff, aeronautics and astronautics.

Owner:SHANGHAI JIAO TONG UNIV

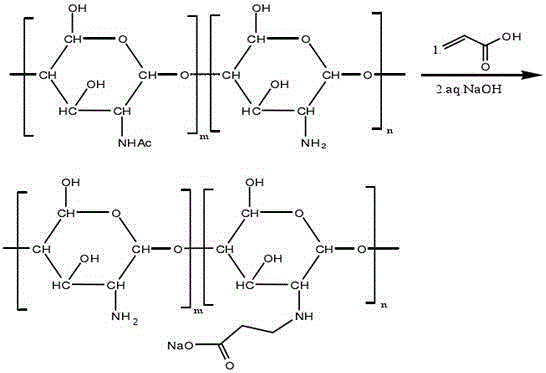

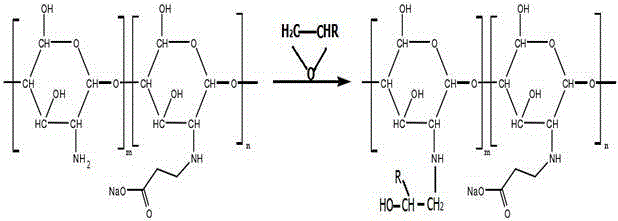

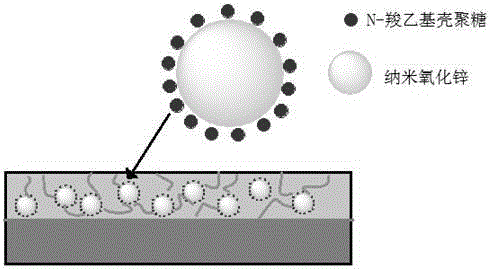

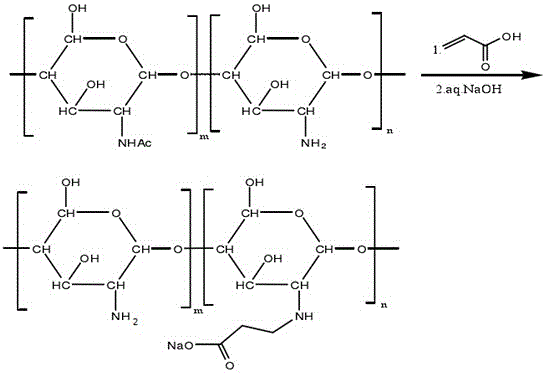

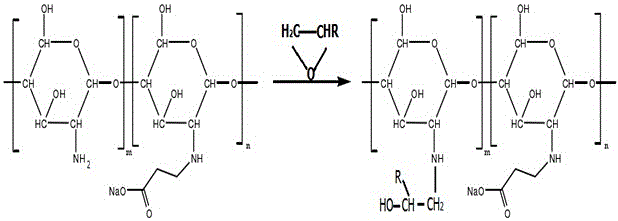

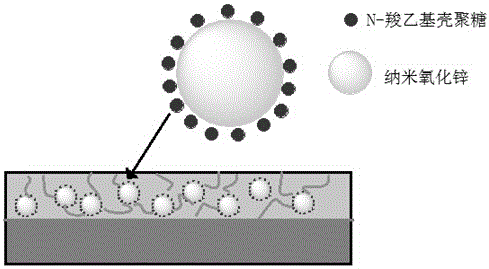

Preparation method for aqueous anticorrosion coating

ActiveCN105199541AReduce the amount of fillerGood weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFilling materials

A preparation method for an aqueous anticorrosion coating, relates to a preparation method for a coating, and concretely relates to a preparation method for a chitosan / nanometer zinc oxide composite material filled aqueous epoxy resin. The chitosan / nanometer zinc oxide composite material is prepared by performing blending modification on nanometer zinc oxide and chitosan. Nanometer zinc oxide possesses obvious anti-ageing performance and anti-ultraviolet characteristic, the agglomeration problem of nanometer zinc oxide is solved by preparing the composite material from nanometer zinc oxide and chitosan, and also the amino at the chitosan monomer molecule is capable of reacting with epoxy resin, and the filling material can be tightly combined with epoxy resin. The method helps to improve the outdoor weatherability of aqueous epoxy resin, the aqueous epoxy resin is safe, environment-friendly and non-toxic, electrochemical corrosion is alleviated, anticorrosion period is prolonged, the crosslinking density of the aqueous epoxy resin is enhanced, and the anticorrosion performance of the aqueous epoxy resin is effectively improved.

Owner:SHENYANG SHUNFENG IND GRP CO LTD

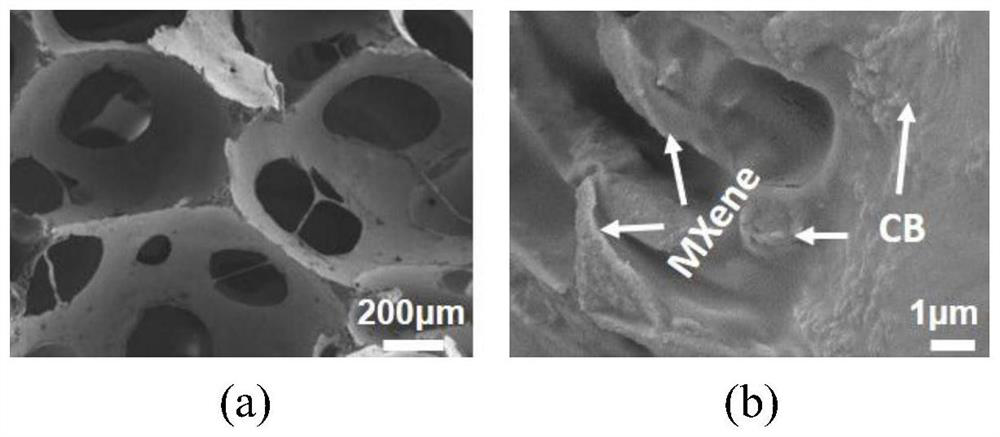

Conductive fluorinated silicone rubber foam composite material as well as preparation method and application thereof

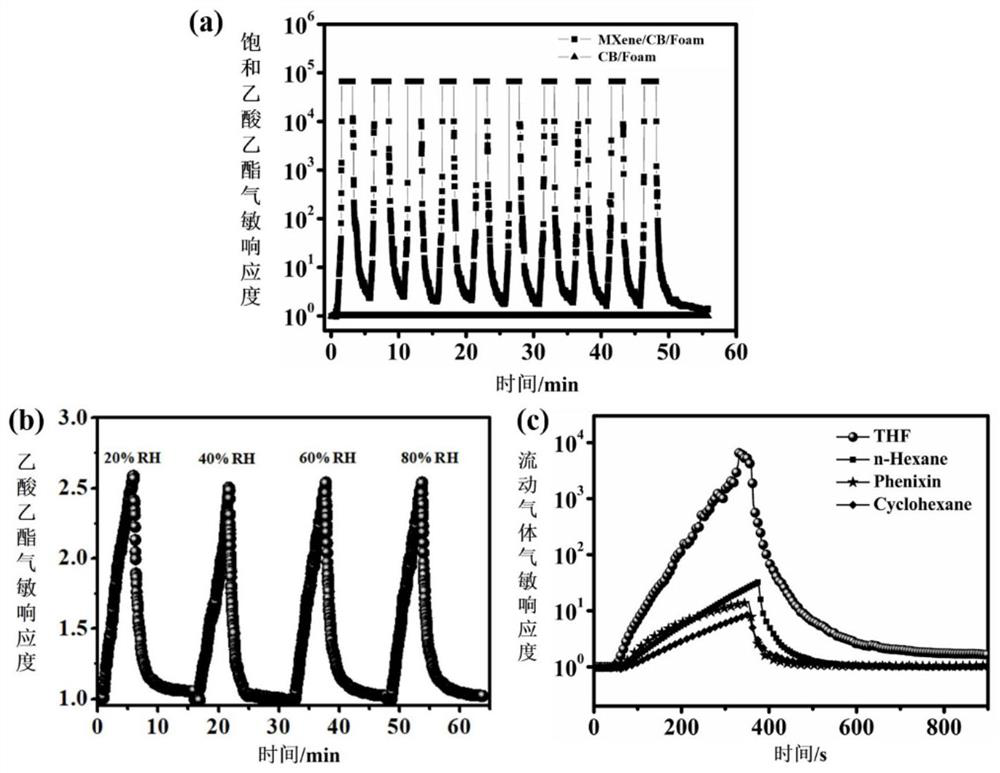

ActiveCN113150358AWell mixedEnvironmentally friendly manufacturing processMaterial analysis by electric/magnetic meansOrganic solventFoaming agent

The invention discloses a conductive fluorinated silicone rubber foam composite material, a preparation method thereof and application of the conductive fluorinated silicone rubber foam composite material in the field of gas-sensitive detection. The preparation method comprises the following steps: ultrasonically dispersing carbon conductive particles in an organic solvent which is volatile at normal temperature to obtain conductive particle dispersion liquid; stirring perfluorosilicone oil, hydrogen-containing fluorosilicone oil and conductive particle dispersion liquid in an organic solvent until the organic solvent is completely volatilized, then adding a foaming agent and an inhibitor, performing uniform mixing to obtain a component A, and uniformly mixing perfluorosilicone oil and a platinum catalyst to obtain a component B; mixing the component A and the component B, performing uniform stirring, reacting at room temperature for 5-30 minutes, and crosslinking and curing the obtained product at 50-125 DEG C for 10-60 minutes to obtain the conductive fluorinated silicone rubber foam composite material.

Owner:HANGZHOU NORMAL UNIVERSITY +1

Conductive polyester/graphite oxide composite material and preparation method thereof

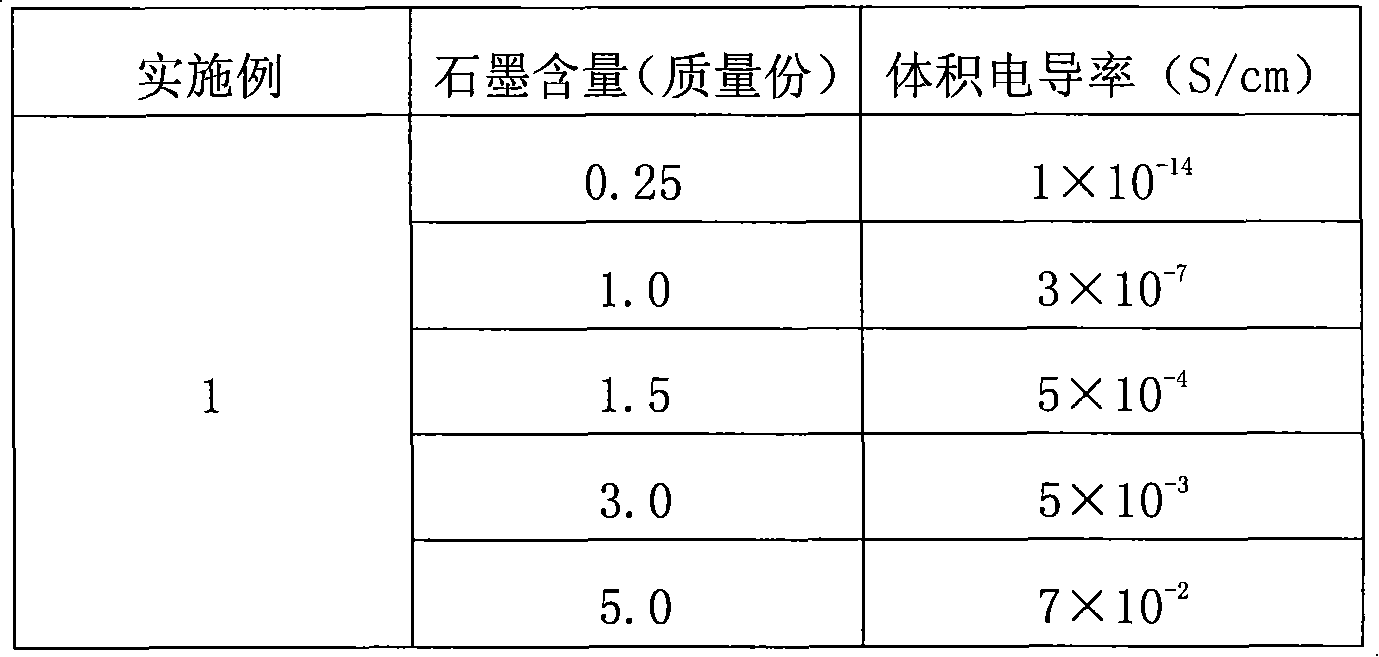

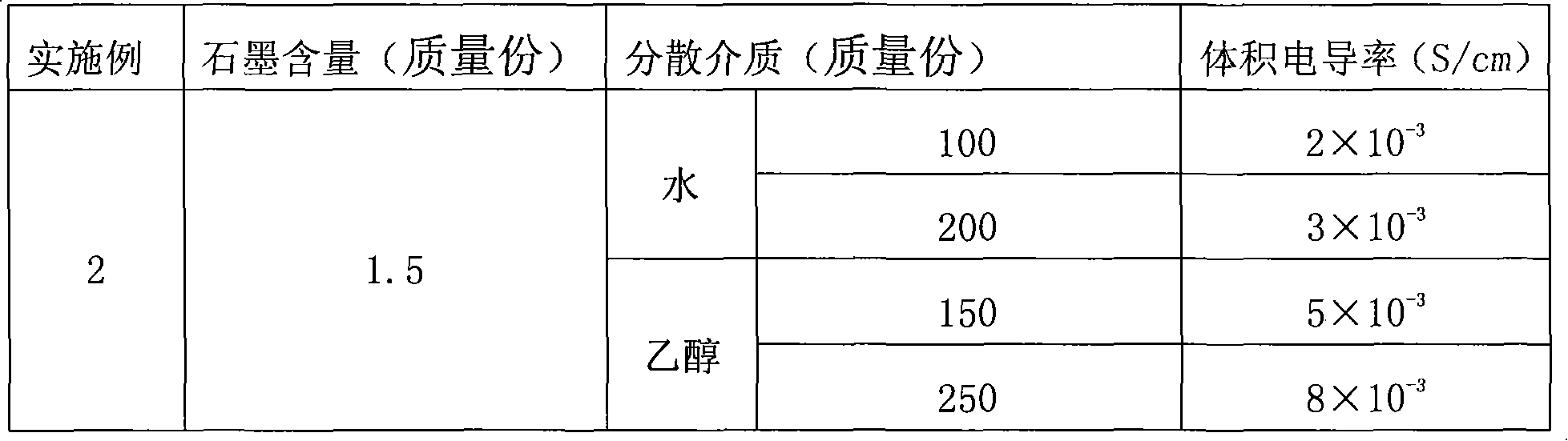

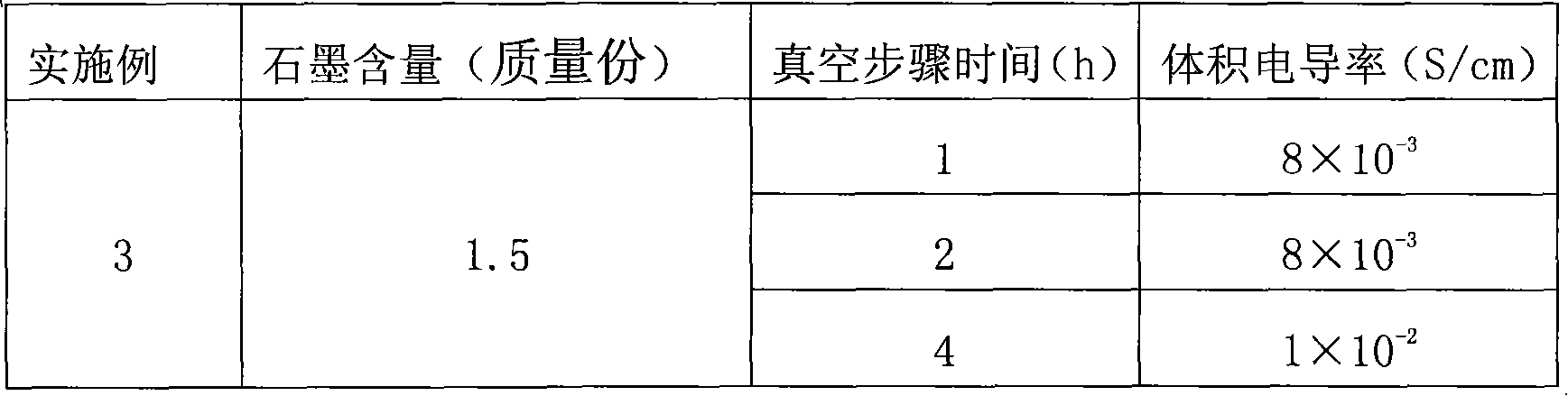

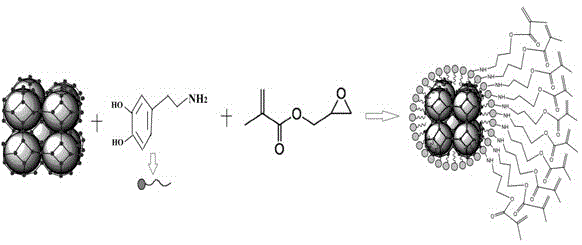

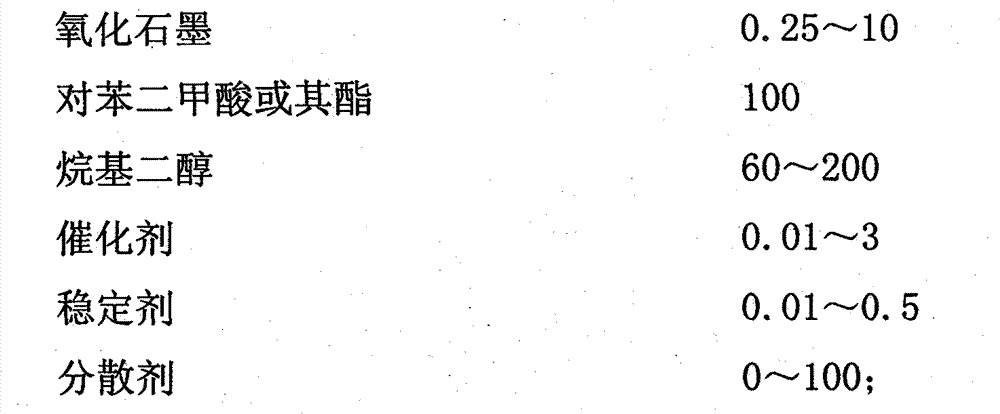

InactiveCN101875718BImprove conductivityReduce the amount of fillerIn situ polymerizationConductive polymer

The invention discloses a conductive polyester / graphite oxide composite material and a preparation method thereof. The composite material is prepared from the following raw materials in part by mass: 0.25 to 10 parts of graphite oxide, 100 parts of terephthalic acid or ester thereof, 60 to 200 parts of alkaline glycol, 0.01 to 3 parts of catalyst, 0.01 to 0.5 part of stabilizing agent and 0 to 100 parts of dispersant. The polyester / graphite oxide composite material of the invention is prepared by polymerizing a polyester substrate and a nano-graphite packing in situ, has the percolation threshold of 0.5 to 1.0 weight percent, can achieve the electric conductivity of 10 to 5 S / cm when graphite content is 3.5 weight percent, and compared with a conventional natural graphite conductive composite material and an expanded graphite conductive composite material, can achieve the high properties of low packing amount and high electric conductivity without adding an auxiliary substrate, and can be widely applied in the fields of conductive materials, antistatic materials, electromagnetic shielding materials, microwave absorption and the like.

Owner:TORAY IND INC

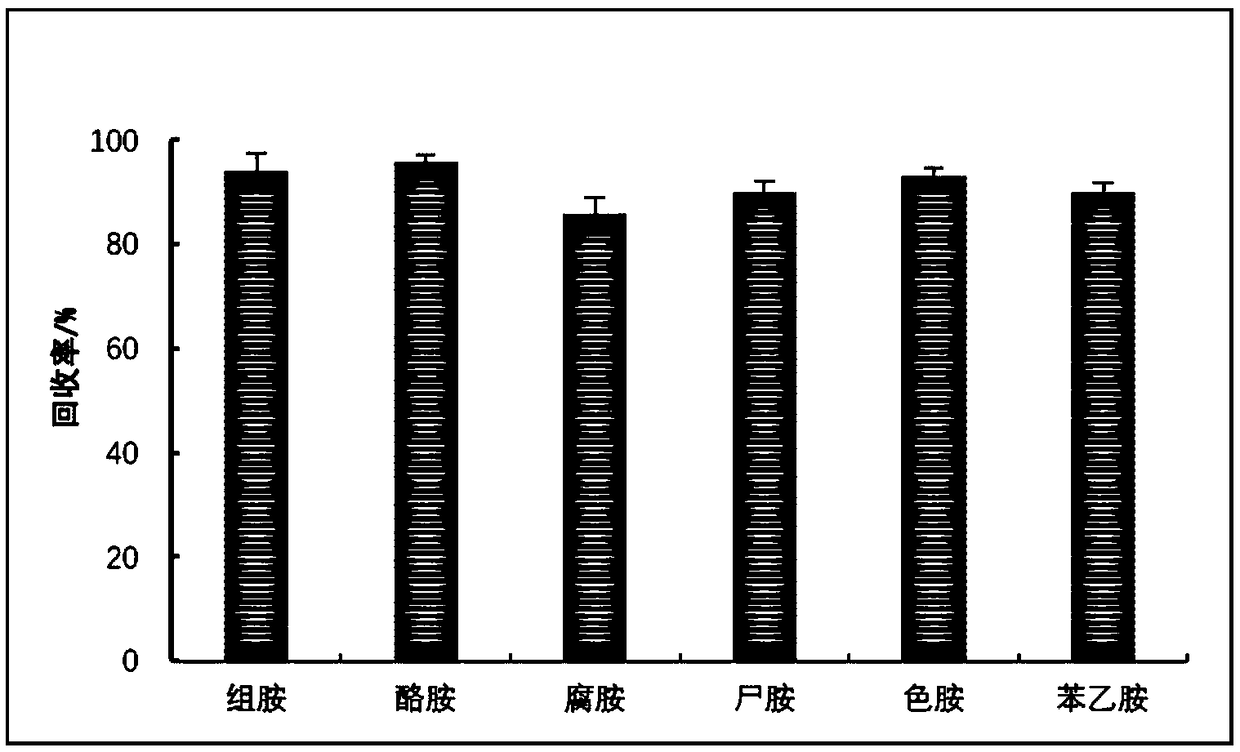

Preparation method and application of solid phase extraction column enriched with biogenic amines

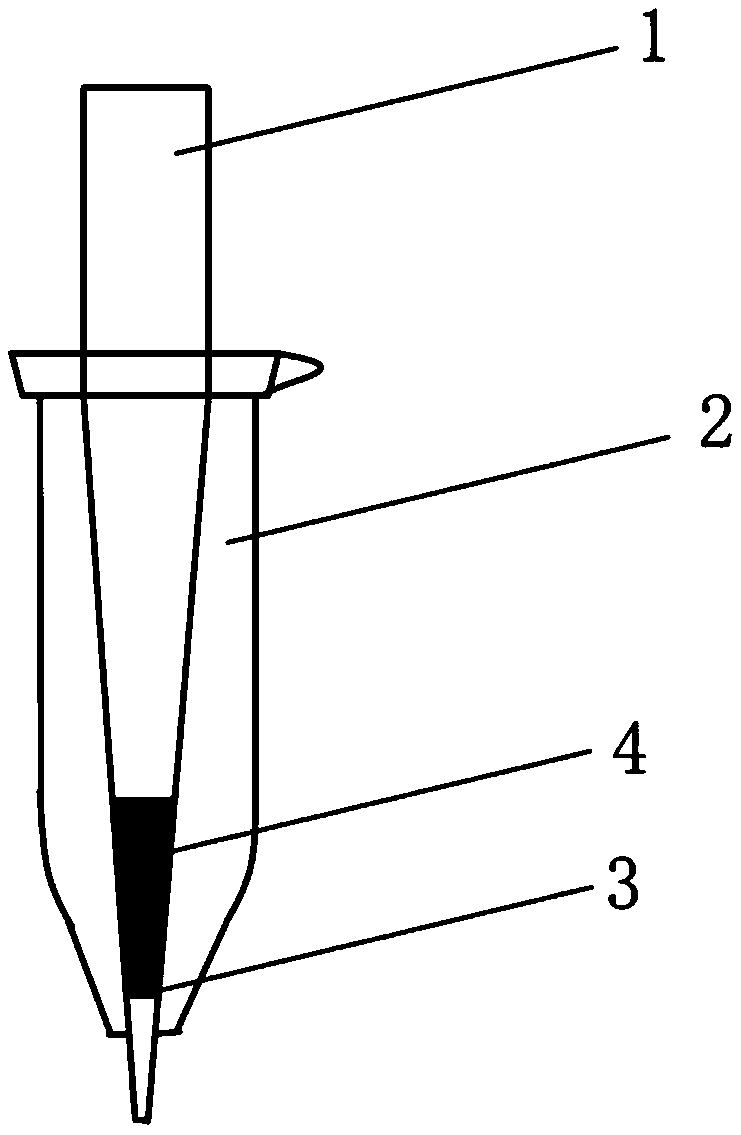

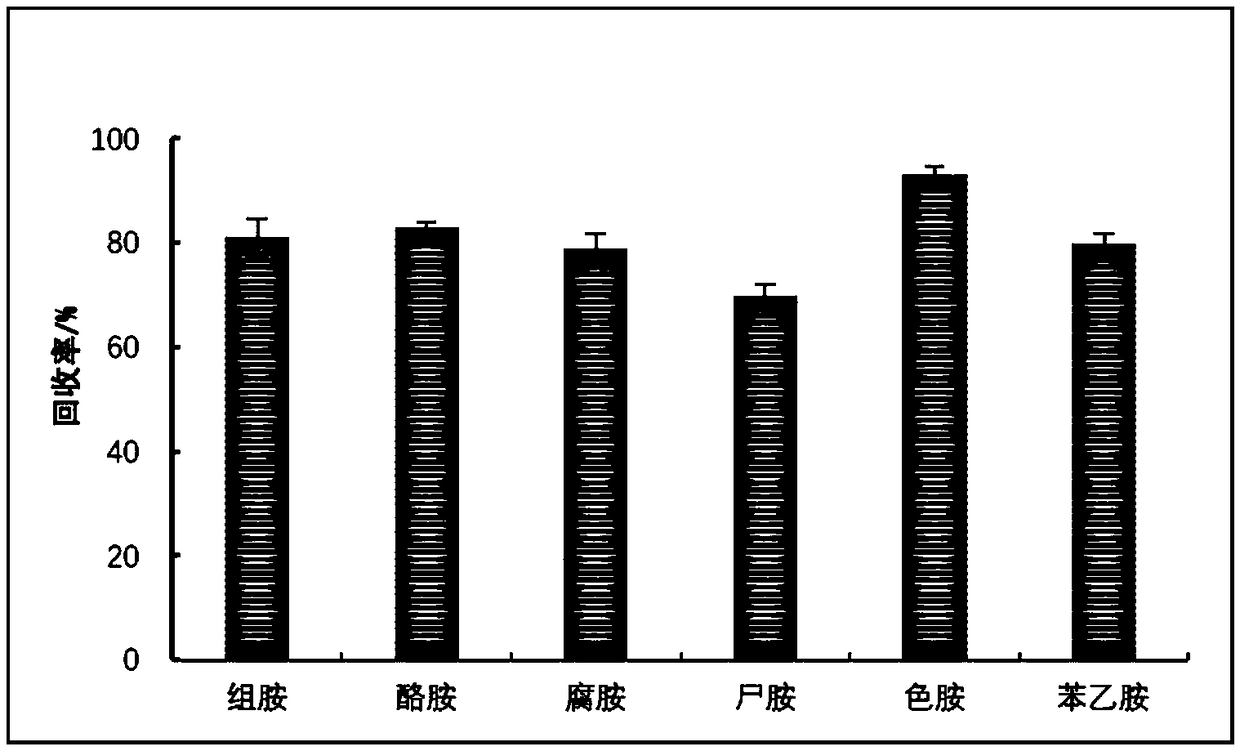

InactiveCN109061016ASimple stepsThe experimental process is shortComponent separationSolid sorbent liquid separationOrganic solventElution

The invention discloses a preparation method of a solid phase extraction column enriched with biogenic amines. The preparation method comprises the following steps that S1, a column pipe of the solidphase extraction column is a pipette superhead, and a lower sieve plate is placed at the bottom of the pipette superhead; S2, the middle portion and bottom of a centrifuge tube cover are drilled vertically, and the solid phase extraction column is fixed into a centrifugal tube after passing through the hole diameter of the centrifugal tube; and S3, the solid phase extraction column is obtained byplacing solid phase extraction packing into the column pipe. The invention further discloses an application method of the solid phase extraction column enriched with the biogenic amines. The application method comprises the steps of pretreatment of samples to be detected, activation of the solid phase extraction column, sample loading, leaching, elution and eluant concentration and drying. The solid phase extraction column prepared by the preparation method compares with a general solid phase extraction column, the amount of packing, the amount of sample treatment and the consumption of an organic solvent are reduced, the time of sample pretreatment is shortened, the cost is saved, and the detection of the biological amines is more convenient and efficient.

Owner:DALIAN POLYTECHNIC UNIVERSITY

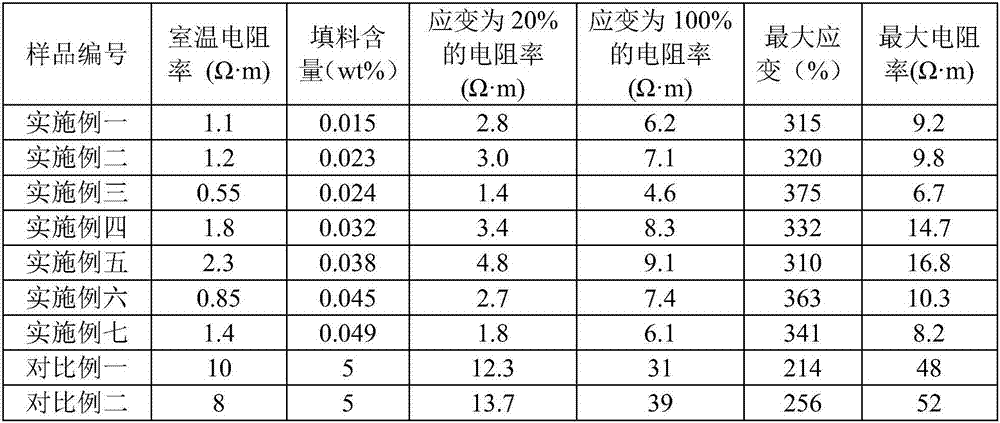

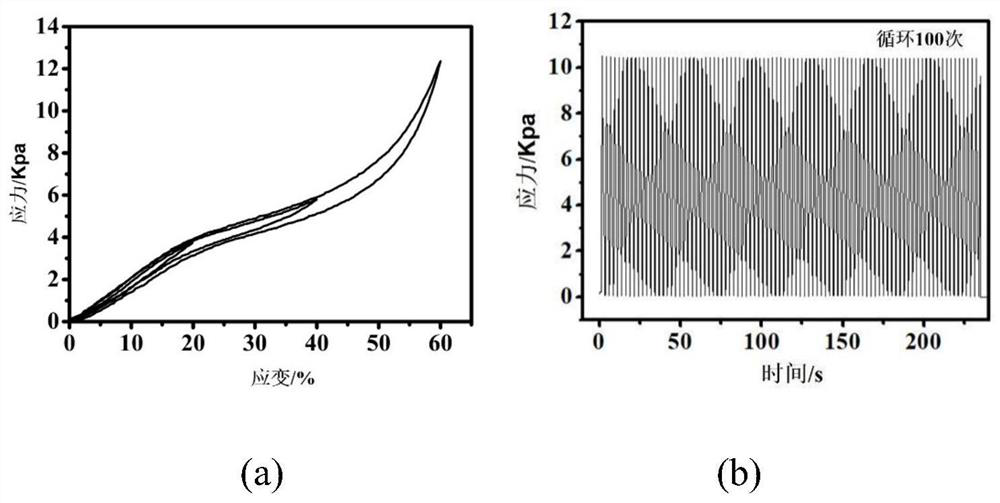

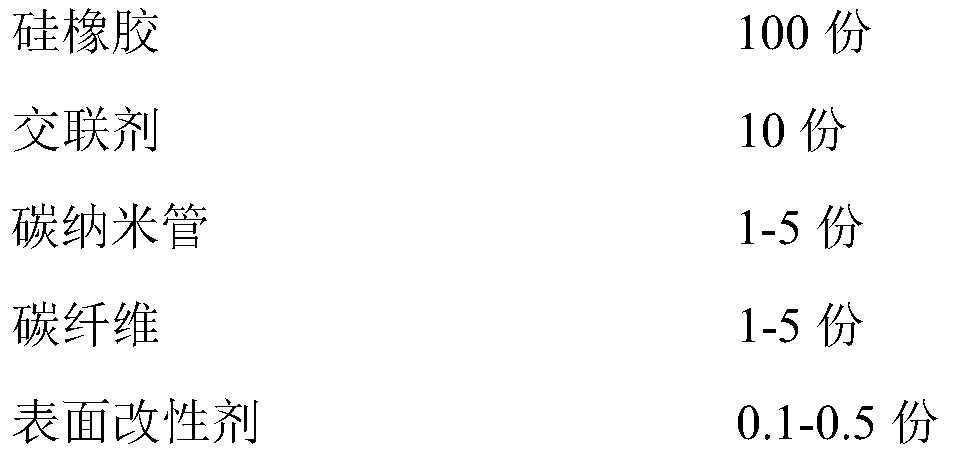

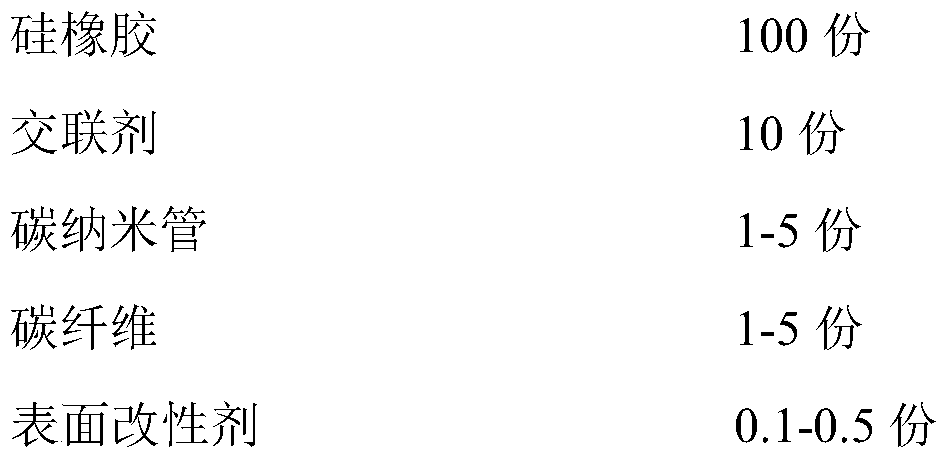

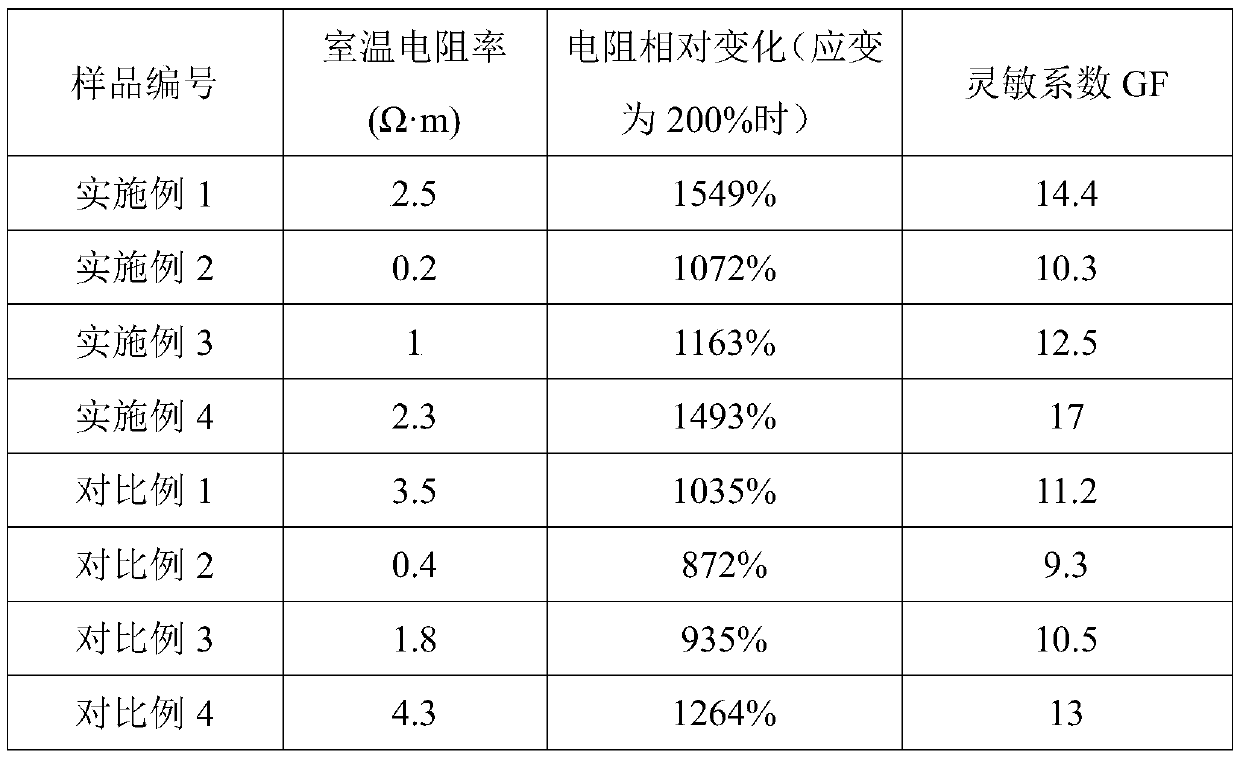

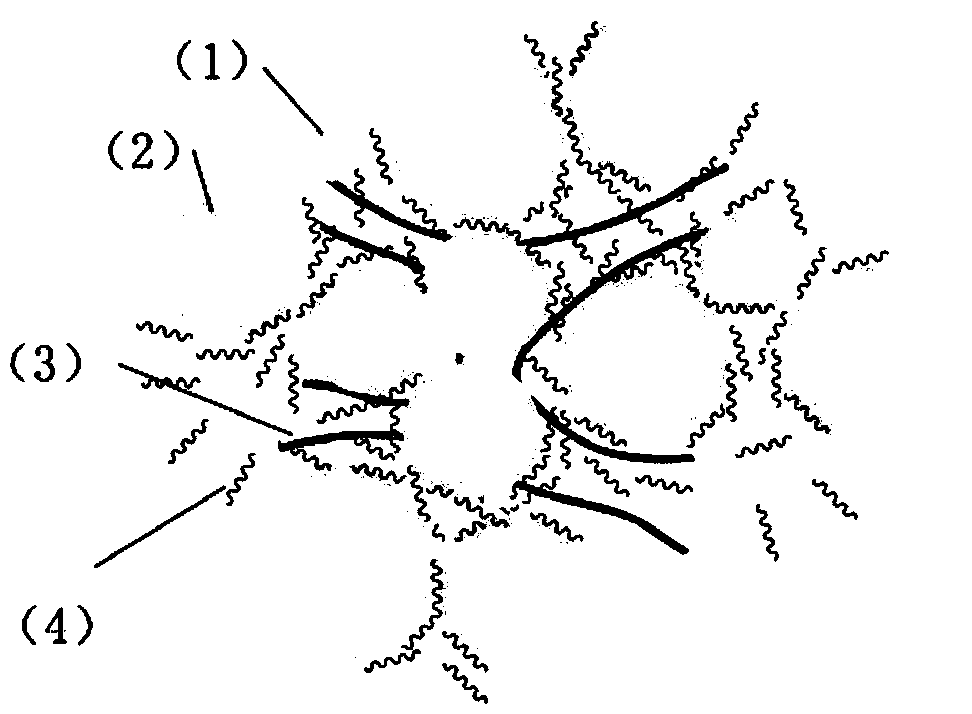

Hybrid filler/silicone rubber flexible force-sensitive conductive composite material prepared by cyclic stretching method and preparation method of material

The invention relates to a hybrid filler / silicone rubber flexible force-sensitive conductive composite material prepared by a cyclic stretching method and a preparation method of the material. The conductive composite material can be used in the fields of flexible force-sensitive sensing and the like. The method includes adding a carbon nano pipe, a cross-linking agent and carbon fiber into silicone rubber, performing ultrasonic action while stirring; then cross-linking at 100 DEG C for 0.5 hour to form a flexible silicone rubber conductor with hybrid fillers; cutting the sample into splines with length and width of 6cm and 2cm respectively, and then carrying out cyclic tensile relaxation treatment on a universal testing machine, wherein the specific parameters are as follows: strain rangeis 5-50%; and the frequency is 1-10Hz and the cycle number is 100-2000. According to the method, the synergistic effect of the hybrid fillers is utilized to reduce the dosage of the fillers, and thedistribution of carbon materials in the matrix can be adjusted by adopting a repeated stretching method, and thus the conductive network of the fillers can be improved, the orientation of the fillersis promoted to a certain extent, and the resistivity and sensitivity of the composite material are improved.

Owner:HUBEI UNIV OF TECH

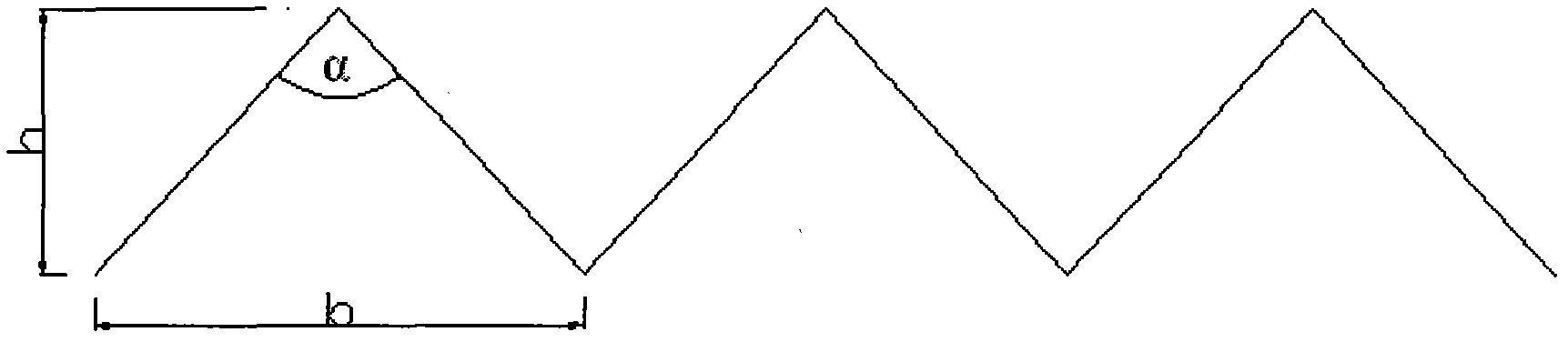

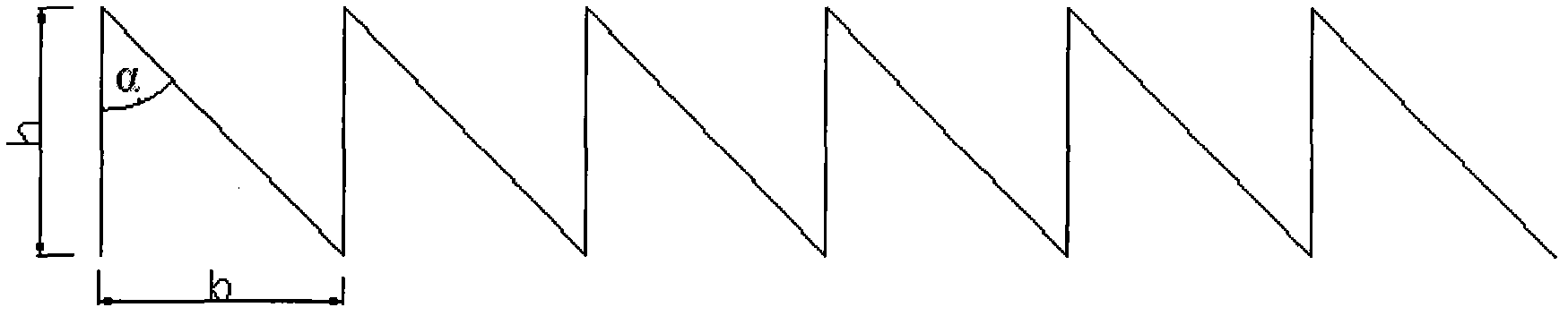

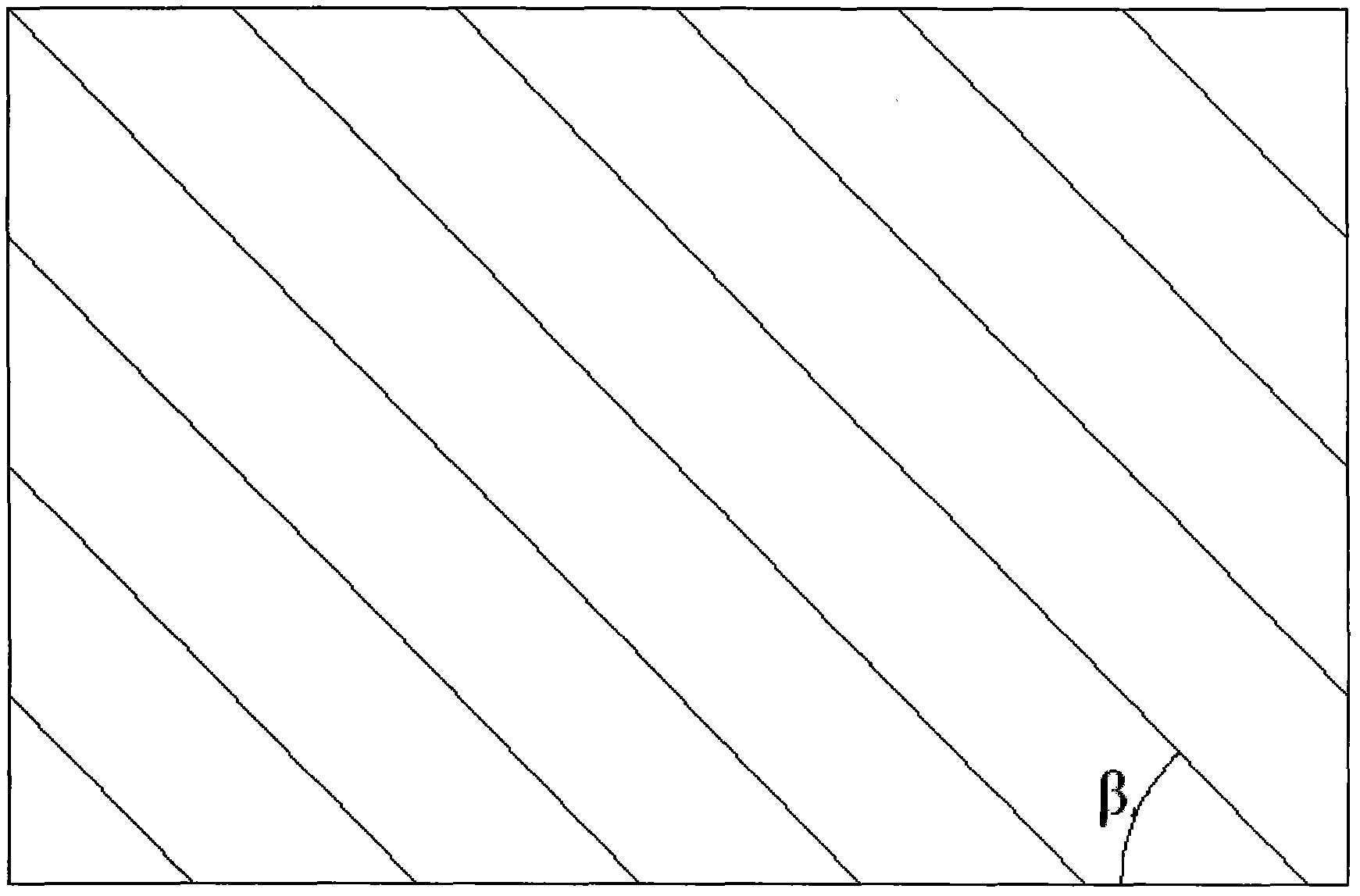

Serrate corrugated padding and use thereof

InactiveCN102008935BPromote wettingImprove effective utilizationChemical/physical/physico-chemical processesEngineeringMetal

The invention relates to serrate corrugated padding and use thereof, Zigzag-pak which is characterized in that: the metal platy material is rolled into to a serrate corrugated shape by a milling machine; one side of the saw-teeth is vertical to the extension direction of a padding sheet; the axis of the corrugation and the vertical direction form an angle; a corrugated plate is cut into rectangular padding sheets with different lengths and the same width; each two adjacent padding sheets are arranged in a staggered way; a plurality of padding sheets are bound to form a circular disk. The peak height (h) of the serrate corrugation is 1.5-8 mm; the serrate angle (alpha) is 15-75 DEG; and the corrugated inclination angle (beta) is 15-60 DEG. Compared with the prior art, the serrate corrugated padding is high in separation effect, low in cost and the like.

Owner:SHANGHAI RES INST OF CHEM IND

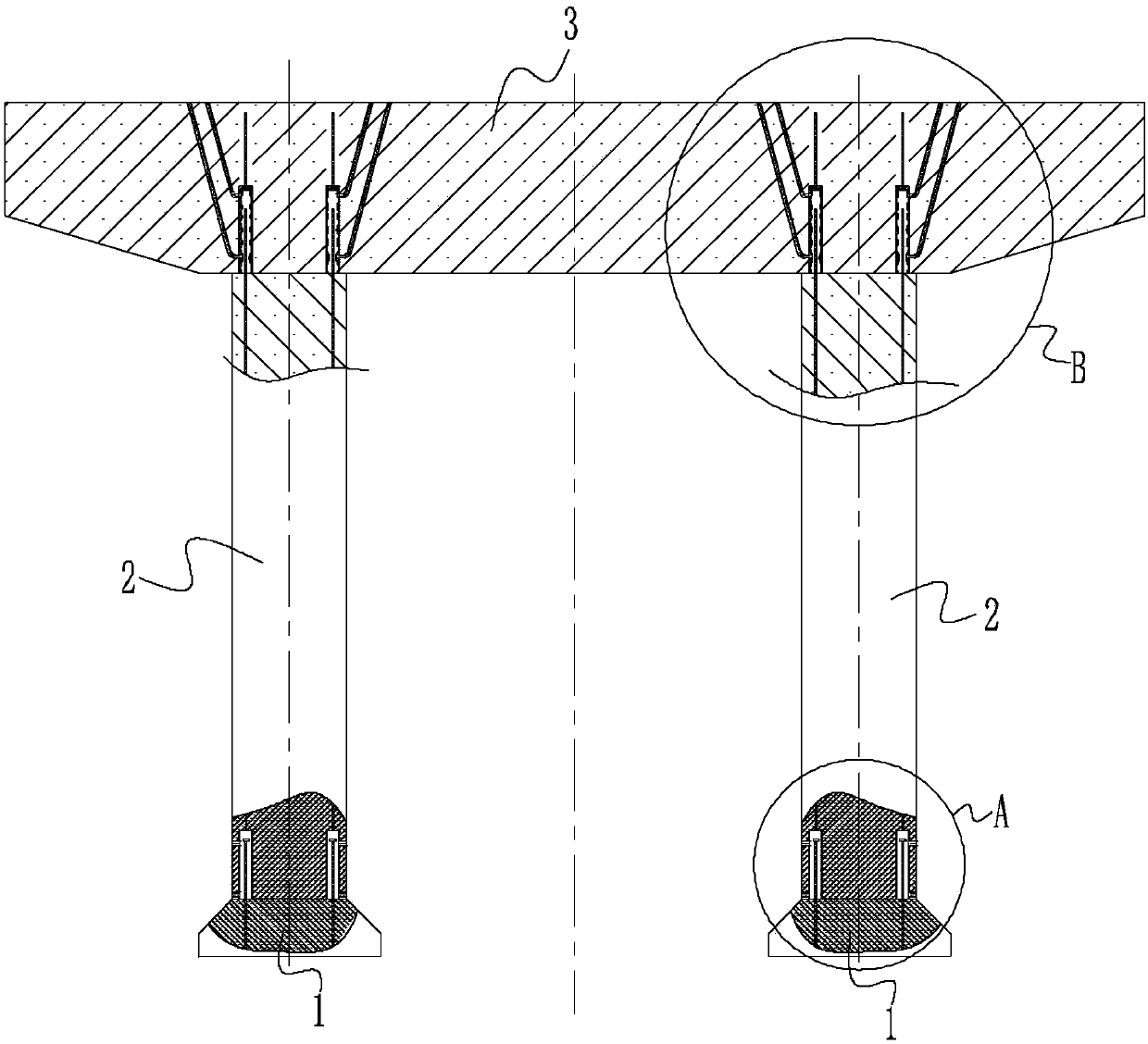

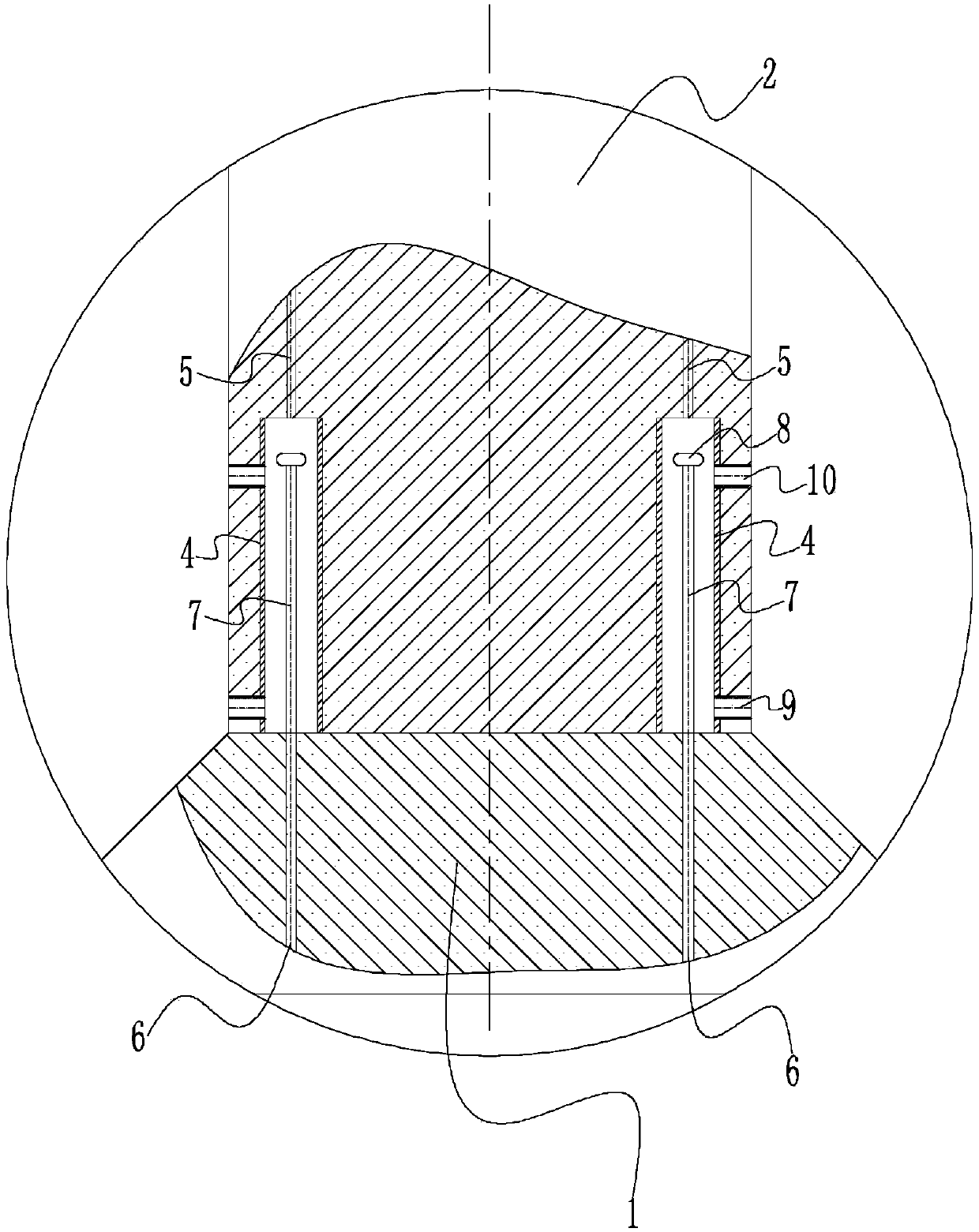

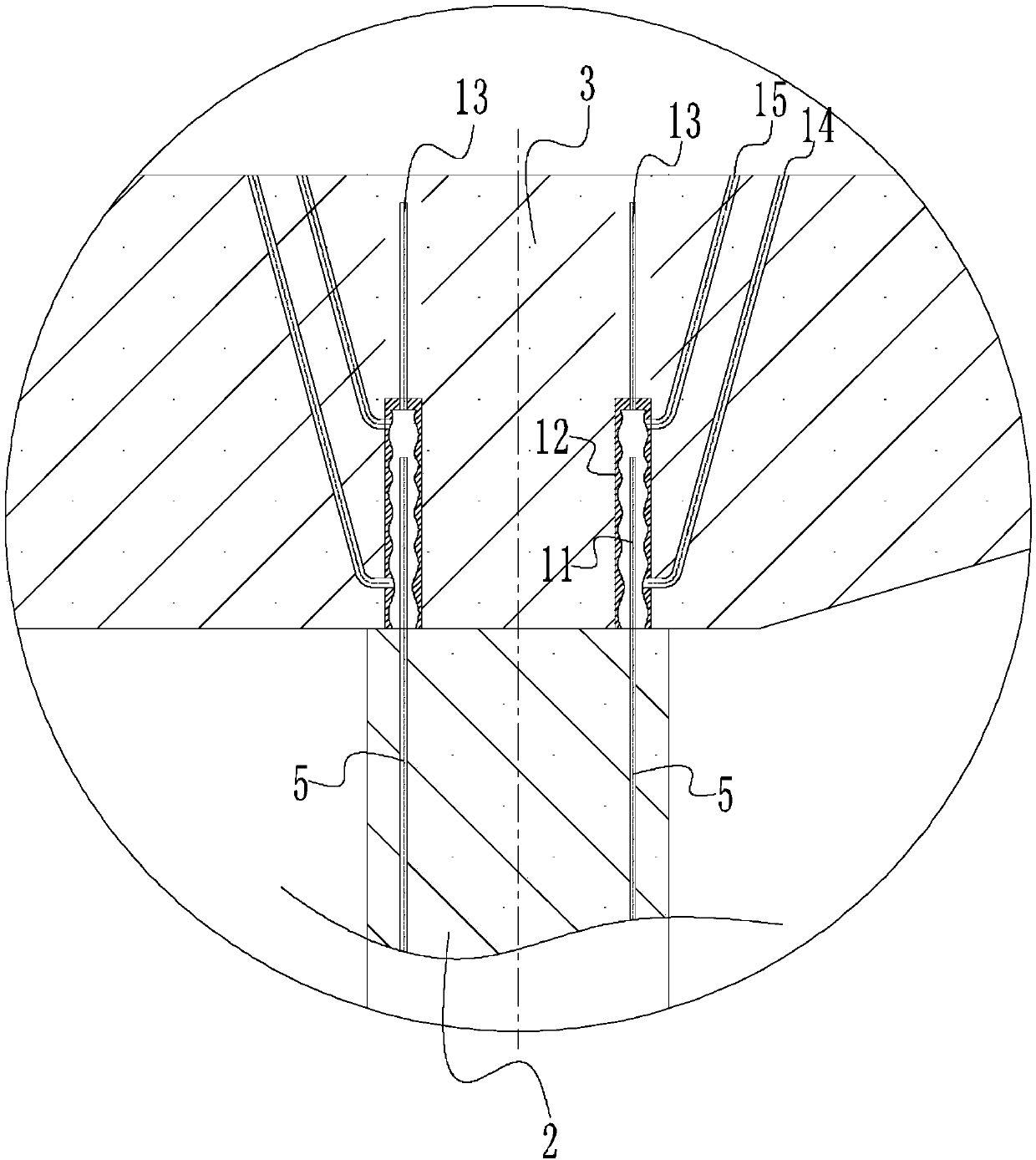

Combined box-type subgrade without bottom plate and subgrade construction method

InactiveCN110629617AReduce processingShorten construction timeRoadwaysLand resourcesPrecast concrete

The invention discloses a combined box-type subgrade without a bottom plate. The combined box-type subgrade comprises two bearing platforms, two lateral walls and a top plate, the top plate is a prefabricated concrete plate, and the lateral walls are prefabricated concrete walls; the two lateral walls are parallel to each other, the top plate is located on the bearing platforms, and the two vertical ends of both of the lateral walls are spliced with the two bearing platforms and the top plate correspondingly to form a hollow box body without the bottom plate. The invention further discloses asubgrade construction method. The subgrade construction method comprises the following steps: a foundation is treated, specifically, pipe piles or cast-in-situ bored piles are arranged in the foundation; the subgrade is laid, specifically, a first section of the subgrade is laid firstly, the concrete bearing platforms are poured on the foundation or the prefabricated bearing platforms are laid onthe foundation, the pile ends of the pipe piles or the pile ends of the cast-in-situ bored piles are anchored into the bottoms of the bearing platforms, then the lateral walls are connected with the bearing platforms, and then the top plate is fixed; and the subgrade laying step is repeated to lay other sections of the subgrade sequentially until laying is completed. According to the combined box-type subgrade without the bottom plate, land resources can be saved, the construction time of railway subgrade engineering can be shortened, and the construction cost of the railway subgrade engineering can be reduced.

Owner:周兆弟

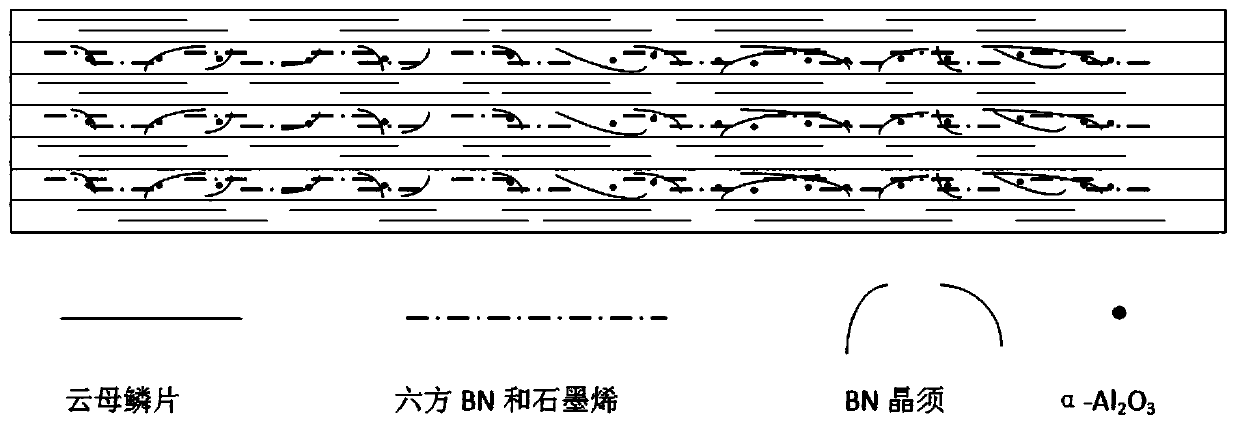

Preparation method of mica paper with high thermal conductivity

ActiveCN110258171AElectrical performance is not affectedImprove cooling effectPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperSlurryHigh pressure

The invention discloses a preparation method of a mica paper with high thermal conductivity. The preparation method comprises following steps: step one, picking mica: removing disqualified raw materials, and picking mica sheets with an area not greater than 10 cm2 and a thickness not greater than 2 cm; step two, preparing mica slurry: uniformly delivering mica sheets picked in the step one to a high pressure hydraulic grinding machine, grinding, filtering, grading, and dehydrating to obtain fine mica slurry; step three, preparing a highly conductive filler solution: adding water into a filler to dilute the filler and stirring the filler by a stirring machine; step four, papermaking: using a rotary screen mica papermaking machine to carry out papermaking, wherein rotary screen sizing is performed for five times, and each time, after rotary screen sizing, the highly conductive filler solution prepared in the step three is sprayed on the mica paper; and step five, dehydrating and drying: after spraying, carrying out dehydrating and drying to obtain the mica paper with high thermal conductivity. The prepared mica paper with high thermal conductivity has the advantages that the using amount of fillers is small, the fillers are uniformly distributed, the thermal conductive performance is strong, the mechanical properties are good, and the service life is long.

Owner:湖北平安电工材料有限公司 +1

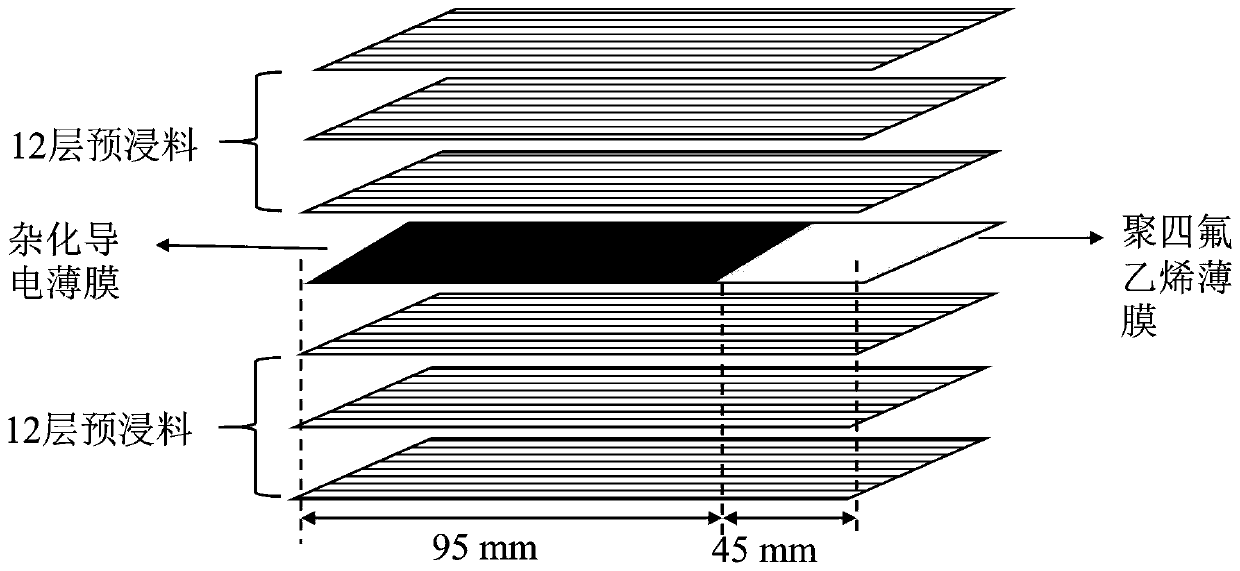

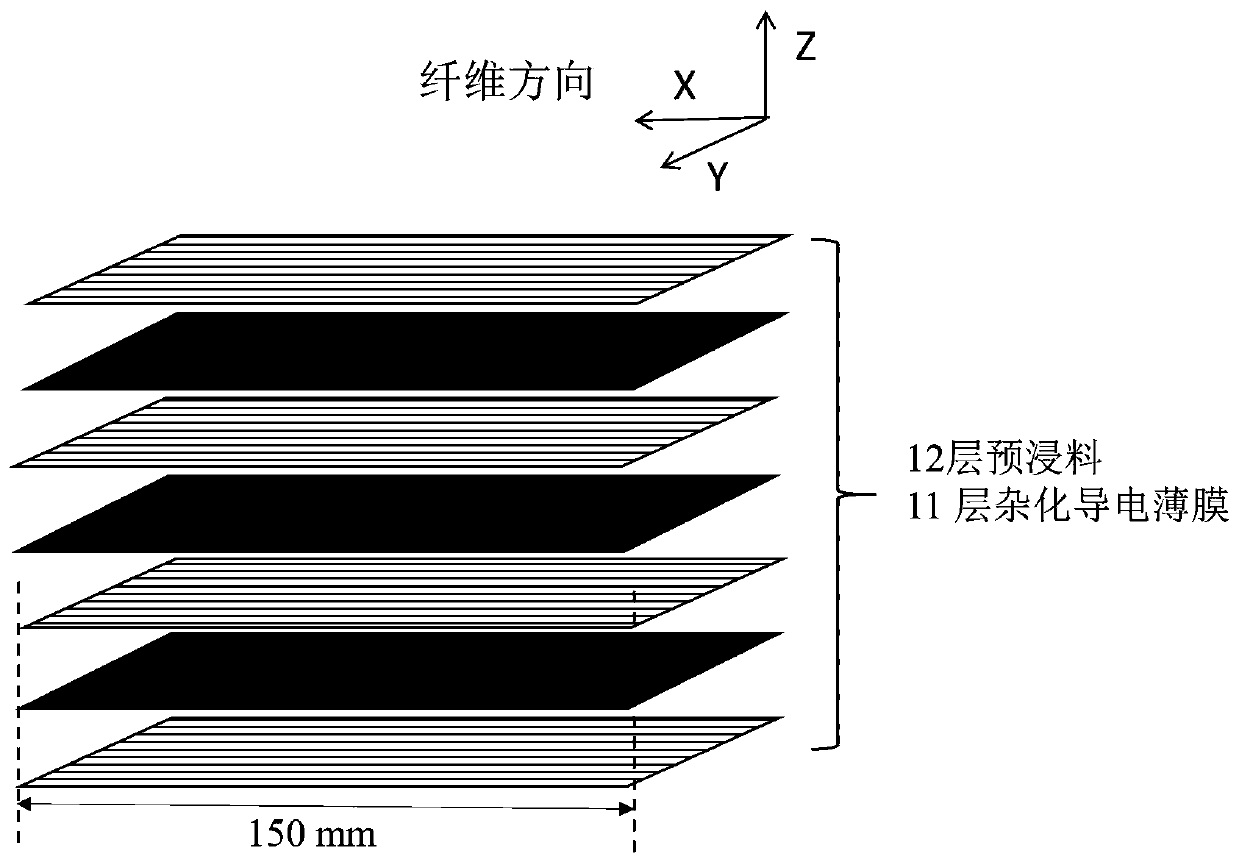

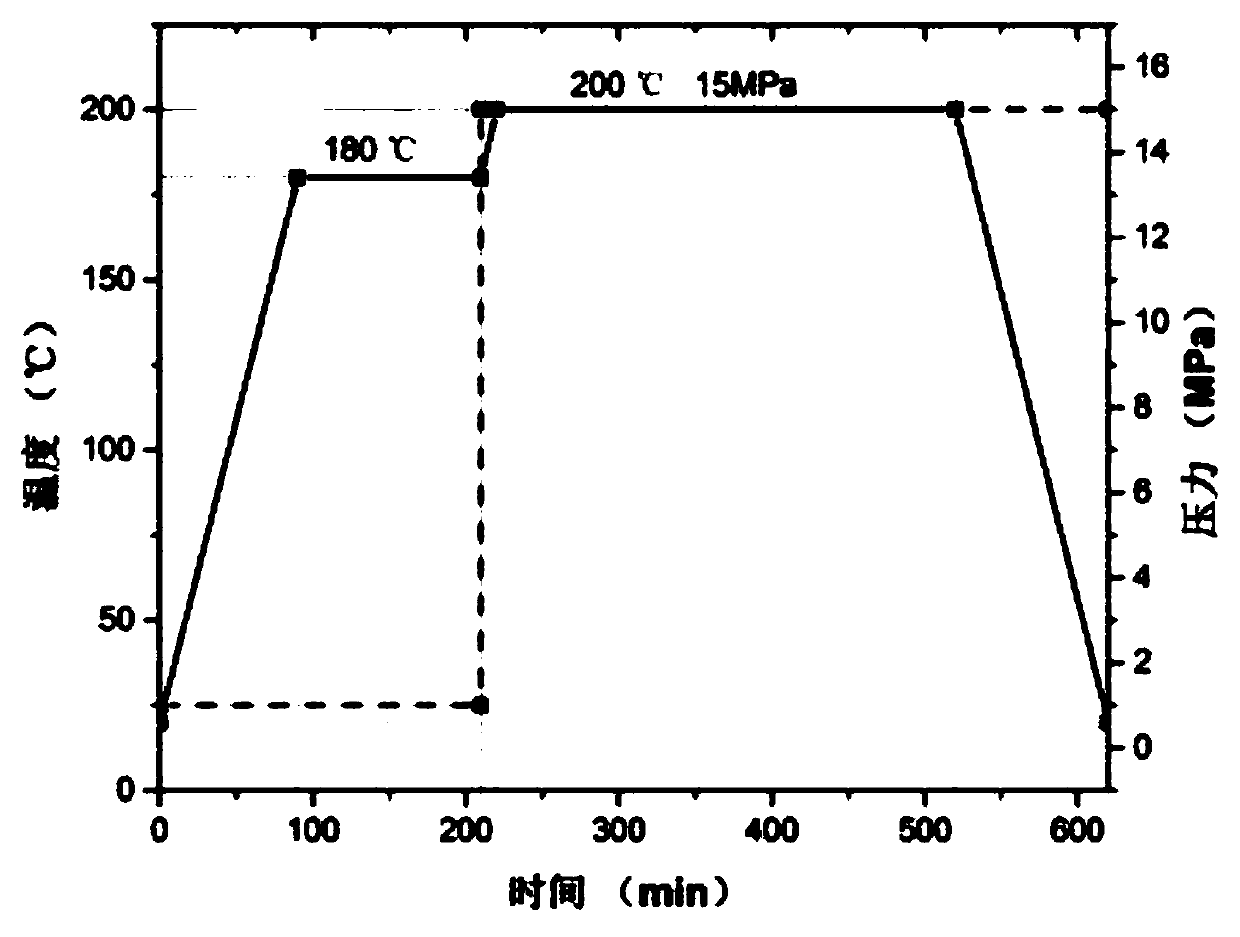

Hybridized film modified carbon fiber composite material and preparation method thereof

ActiveCN110181917AGood dispersionImprove conductivityLamination ancillary operationsSynthetic resin layered productsFiberModified carbon

The invention discloses a hybridized film modified carbon fiber composite material. The composite material is a composite material laminated board which is made by inserting a hybridized film into prepreg layers. The hybridized film is a composite packing hybridized polyether sulfone resin film consisting of carbon nanotubes and silver nanoparticles. A preparation method of the carbon fiber composite material comprises the following steps: S1, preparing CNT / AgNP composite packing, namely mixing a silver nitrate solution, carbon nanotubes and a sodium citrate solution, performing oil-bath heating and stirring till the solution is gray, and performing centrifugal separation so as to obtain the composite packing; S2, putting the composite packing and polyether sulfone resin powder into an organic solvent, and performing oil-bath heating and stirring so as to obtain a mixed material liquid; S3, pouring the mixed material liquid into a glass mold, and performing drying in a drying oven so as to obtain the hybridized film; and S4, inserting the hybridized film into the prepreg layers, and performing heating curing, so as to obtain the composite material laminated board. The electric conductivity, the impact damage resistance and the breaking toughness of the carbon fiber composite material disclosed by the invention are remarkably improved.

Owner:SOUTHWEST PETROLEUM UNIV

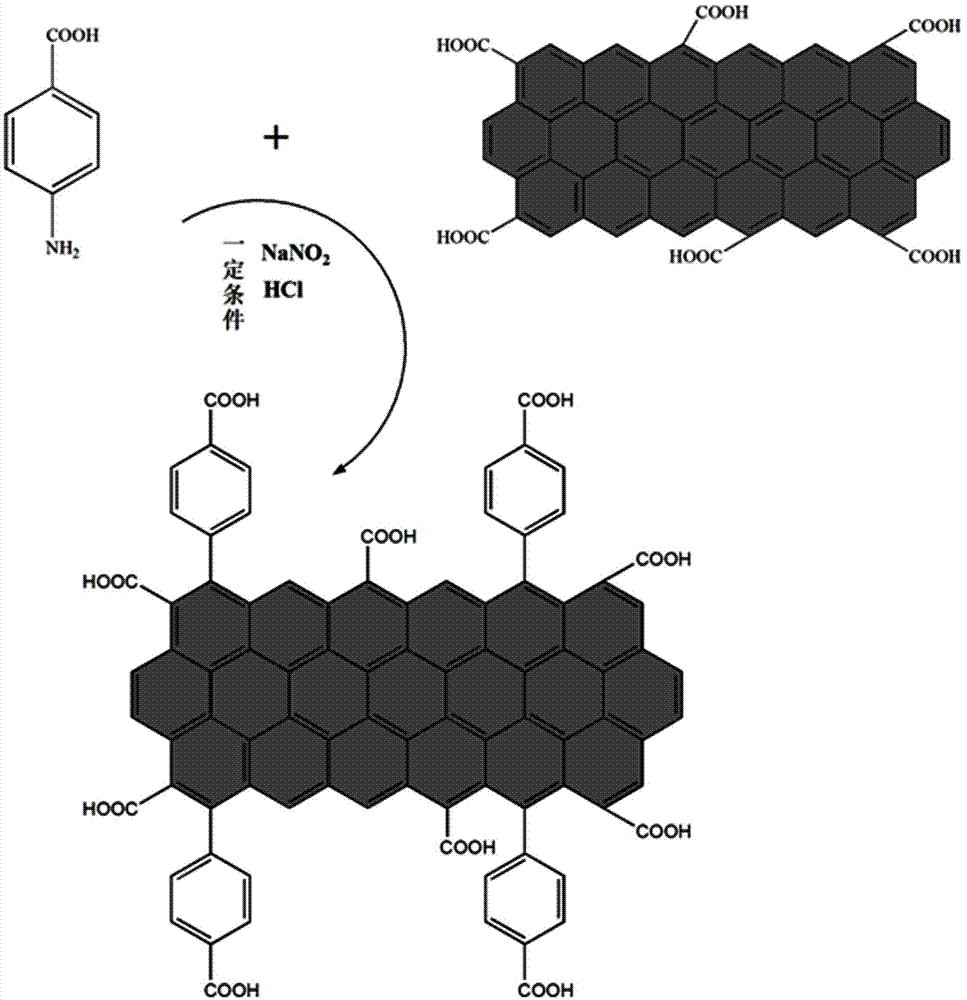

A fire-proof and anti-corrosion function integrated coating for steel structure and preparation method thereof

ActiveCN105385310BLarge specific surface areaImprove barrier propertiesFireproof paintsAnti-corrosive paintsBenzoic acidEnvironmental resistance

The invention provides steel structure fireproof anticorrosion function integrated coating and a preparing method thereof. The coating is prepared by compounding benzoic acid functionalized graphene, water-borne epoxy resin, a water-borne curing agent and water. The benzoic acid functionalized graphene is prepared from graphene and para aminobenzoic acid. The preparing method adopts a hydrothermal method to prepare the graphene and further functionalizes the graphene to generate the benzoic acid functionalized graphene as a nanofiller, and the benzoic acid functionalized graphene is compounded with the water-borne epoxy resin to form the steel structure fireproof anticorrosion function integrated coating, which has the characteristics of small filler use level, environment friendliness in a preparing process and low energy consumption. In the preparing method, the filler and the water-borne epoxy resin have better compatibility, and the crosslinking density of a coating is further increased, so that the thermal barrier property and corrosion resistance of the epoxy resin are furthest improved, more ideal flame-retardant and anticorrosion effects are achieved, the prevalent defects of poor barrier property and short anticorrosion period of the current water-borne anticorrosion coating are overcome, and better application prospect and practical significance are realized.

Owner:SHENYANG SHUNFENG IND GRP CO LTD

A kind of lightweight epoxy resin composite material and preparation method thereof

Owner:SICHUAN UNIV

Butylbenzene particle/graphene/aluminum composite and preparation method thereof

InactiveCN109912866AReduce the amount of fillerLow densityElectromagnetic shieldingElectro conductivity

The invention relates to a functional composite adopting a core-shell structure and a preparation method of the functional composite, in particular to a butylbenzene particle / graphene / aluminum composite with high electromagnetic shielding performance and a preparation method thereof. Composite particles of the composite take graphene-coated nanoscale butylbenzene particles as a core structure andan aluminum film layer as a core shell, wherein the content of the graphene-coated nanoscale butylbenzene particles is 90vol%-98vol%, the content of metal aluminum is 2vol%-10vol%, and the content ofgraphene in the composite particles is not lower than 0.05vol%. By preparation of the composite particles adopting the multilayer structure, the electrical conductivity and electromagnetic shielding performance of the composite can be significantly improved and the specific gravity of the material can be reduced under the condition of low-content aluminum metal and trace graphene, and the purposesof low specific gravity, high conductivity and high electromagnetic shielding performance are achieved.

Owner:唐山烯鹏石墨烯科技有限公司

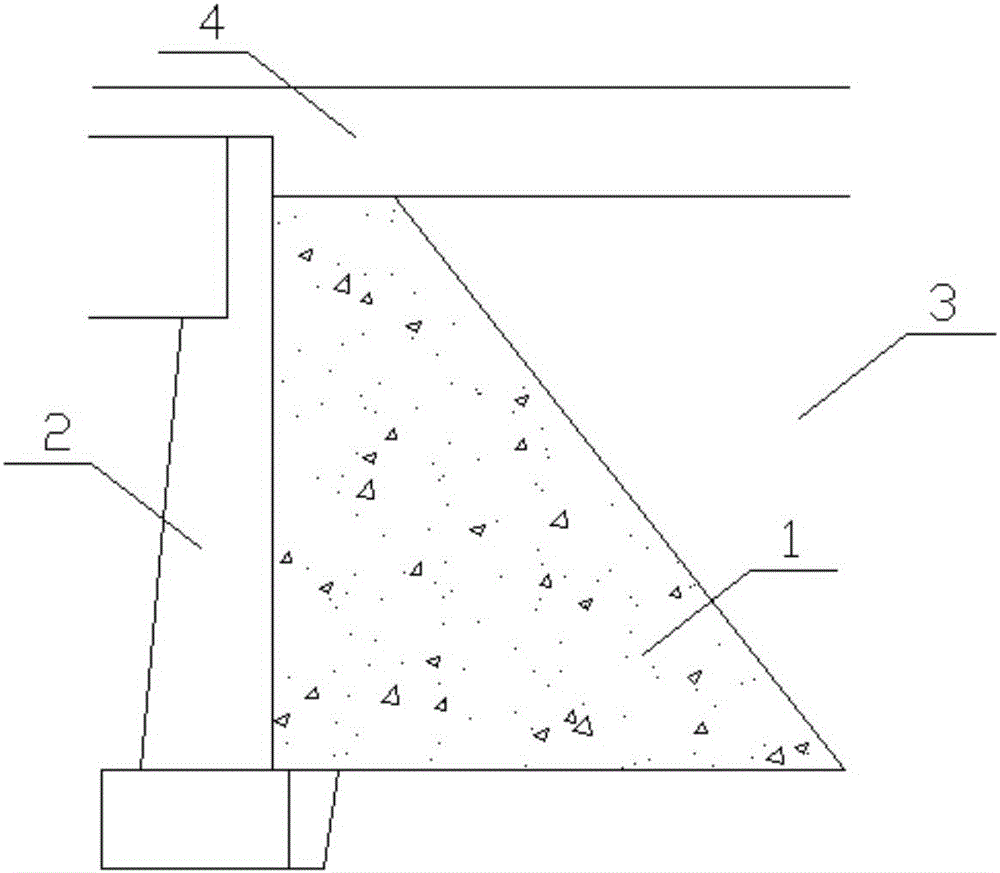

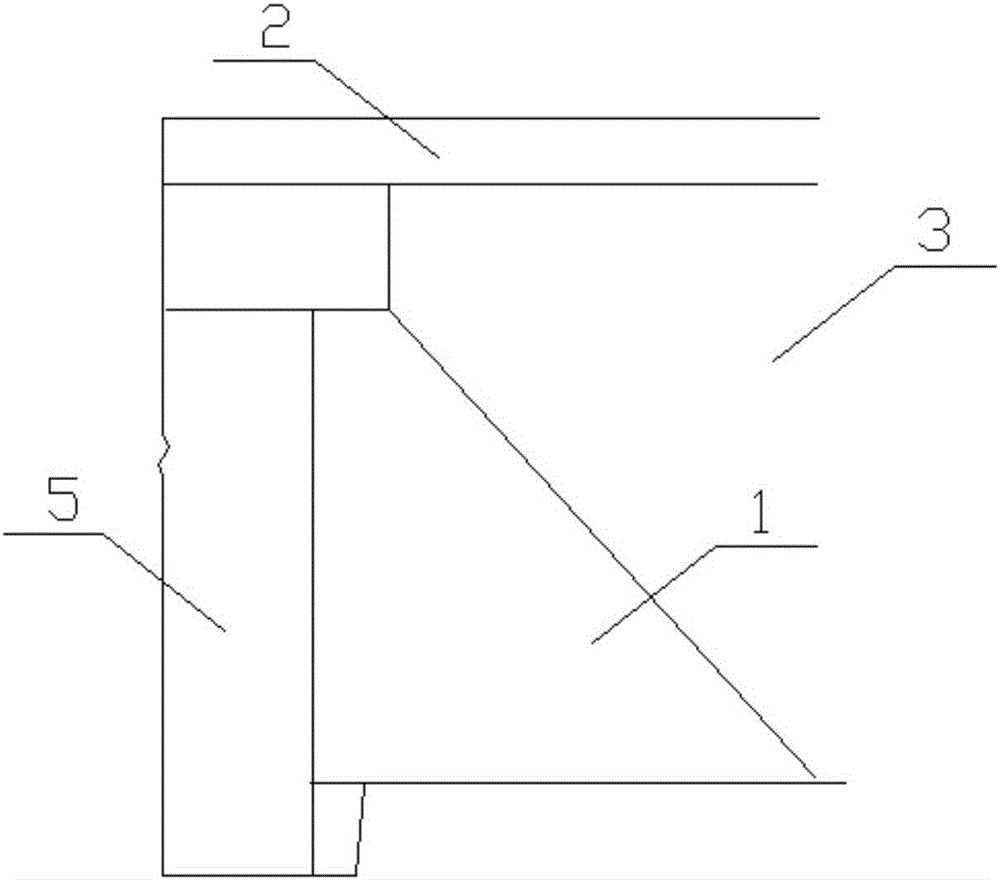

Bridge and culvert structure transition section anti-frost-heaving structure in cold region

The invention relates to a bridge and culvert structure transition section anti-frost-heaving structure in a cold region. The portion between the connecting portions of a side wall of a transverse building and a roadbed is filled with an anti-frost structural layer in a built manner. The longitudinal profile of the anti-frost structural layer is almost in a right trapezoid shape with the upper portion narrower than the lower portion. The longitudinal right-angle side of the trapezoid of the anti-frost structural layer faces the side wall of the transverse building. The longitudinal profile of the anti-frost structural layer is designed in the trapezoid with the upper portion narrower than the lower portion, the anti-frost-heaving effect can be guaranteed, meanwhile, materials are saved to the maximum extent, and the structure is low in construction cost, scientific and reasonable.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

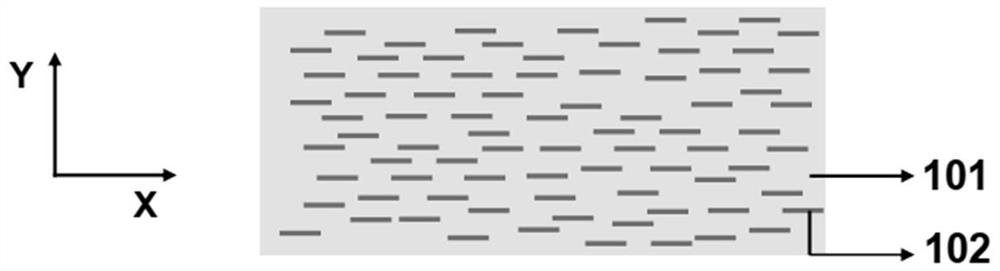

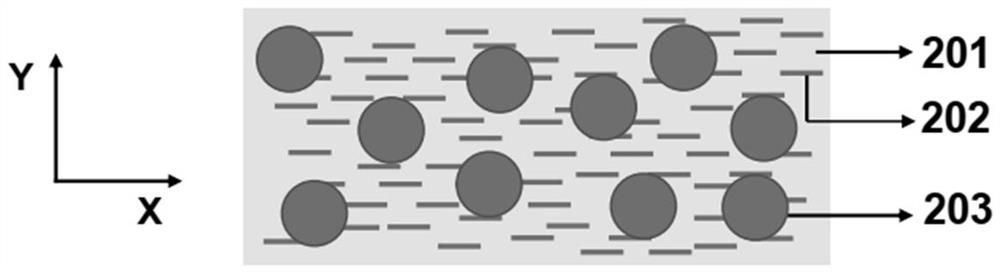

Polymer-based composite thermally conductive material and its preparation method and application

ActiveCN113912914BImprove in-plane thermal conductivityHigh densityHeat-exchange elementsPolymer scienceBoron nitride

The invention relates to a polymer-based composite heat-conducting material, a preparation method and application thereof. The polymer-based composite thermally conductive material includes a polymer matrix and a filler, the filler accounts for 32%-40% by mass of the polymer matrix, and the filler is flake boron nitride and spherical boron nitride according to the mass ratio 1: (2-4 ) mixture, the particle size of spherical boron nitride is 50μm-60μm, the thickness of flake boron nitride is 4nm-10nm, and the sheet diameter is 4μm-5μm. Flake boron nitride tends to build the basis of the heat conduction network in the horizontal direction and improve the in-plane thermal conductivity; spherical boron nitride is conducive to building a heat conduction network in the vertical direction, improving the normal phase thermal conductivity, and further increasing the thermal conductivity of the horizontal direction. Density, so that the polymer-based composite thermally conductive material has good thermal conductivity along the direction of the thermal interface and the direction perpendicular to the thermal interface, and at the same time, the mechanical properties of the polymer-based composite thermally conductive material are still good.

Owner:北京石墨烯技术研究院有限公司

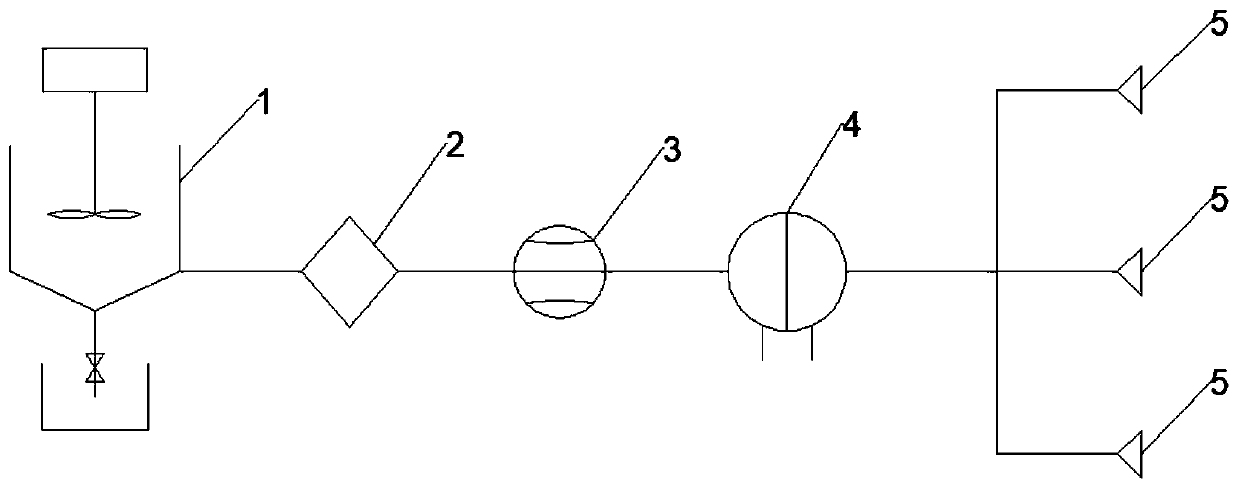

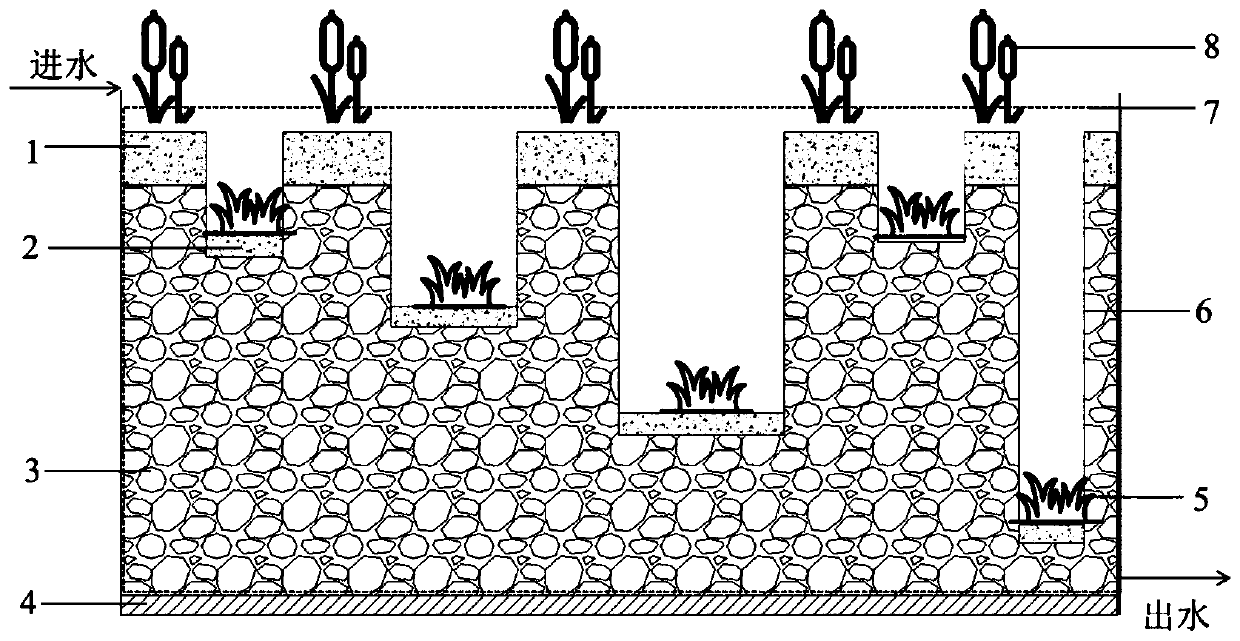

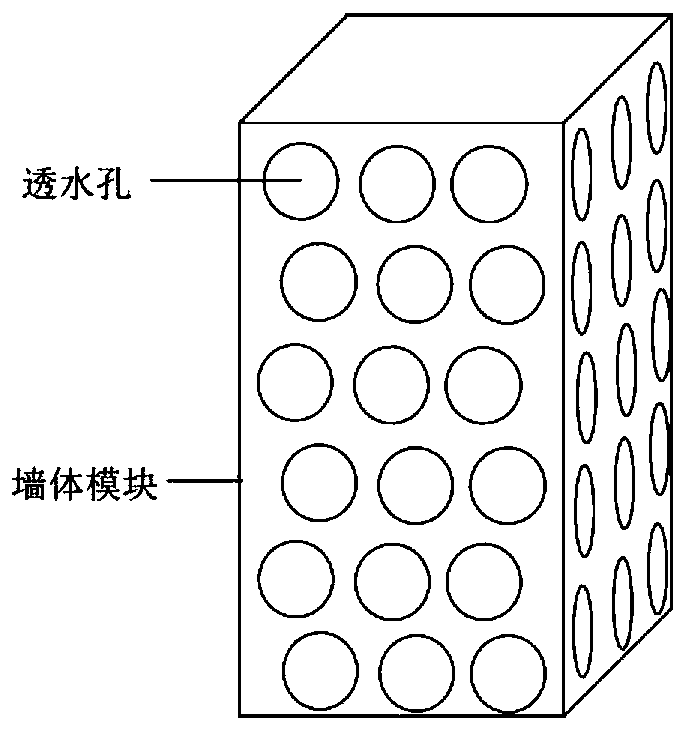

Construction method of local U-shaped underflow wetland for utilizing multi-phenological plants to enhance agricultural runoff denitrification

ActiveCN110316834AIncrease carbon to nitrogen ratioReduce the amount of fillerWater contaminantsBiological water/sewage treatmentConstructed wetlandEngineering

The invention discloses a construction method of a local U-shaped underflow wetland for utilizing multi-phenological plants to enhance agricultural runoff denitrification and belongs to the technicalfield of sewage treatment. The method aims to solve the problems in existing low-carbon-nitrogen-ratio agricultural runoff underflow wetland treatment technologies that the addition of carbon sourcesis difficult to control, the cost of carbon supply fillers is high, wetland treatment systems are complex and large in occupied area, and the denitrification effect is influenced by nonuniform distribution of carbon sources of wetland plants. According to the method, in the construction process of the underflow wetland, a plurality of U-shaped depressions different in size and depth are constructed in a mode of loading fillers or not loading the fillers. A plurality of phenological perishable submerged plants and floating plants are arranged in the depressions, and a plurality of phenologicalemergent aquatic plants are arranged on the surface of the wetland, so that the plants in the wetland have different phenological configuration characteristics in different levels, and the uniform distribution of plant carbon sources in the wetland is enhanced. The constructed wetland has the advantages of adjusting the carbon-nitrogen ratio of agricultural runoff, consuming few fillers and beinghigh in denitrification efficiency and resistant to hydraulic impact.

Owner:BEIJING FORESTRY UNIVERSITY

A kind of preparation method of water-based anticorrosion coating

ActiveCN105199541BReduce the amount of fillerGood weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyZno nanoparticles

Owner:SHENYANG SHUNFENG IND GRP CO LTD

A kind of high-voltage electric corrosion-resistant silicone rubber composition for composite insulators and its preparation method

ActiveCN104845378BHigh resistance to high voltage electric corrosionImprove cooling effectCross-linkComposite insulators

Owner:STATE GRID CORP OF CHINA +5

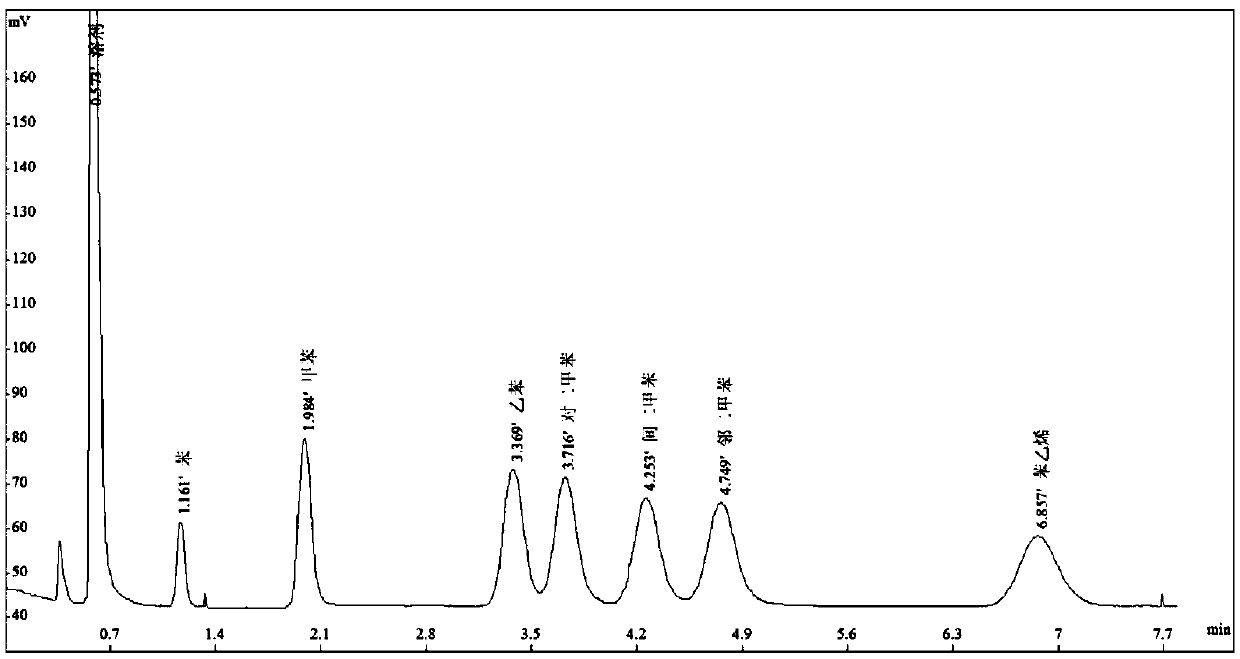

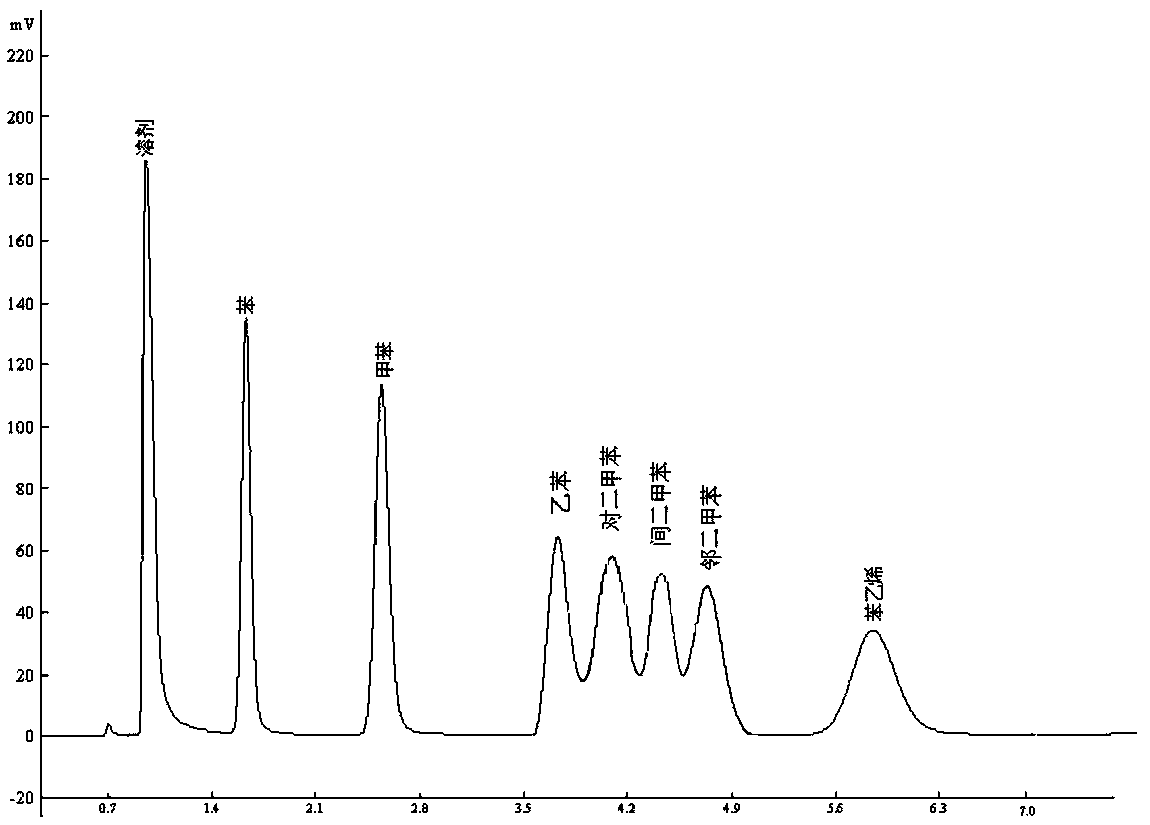

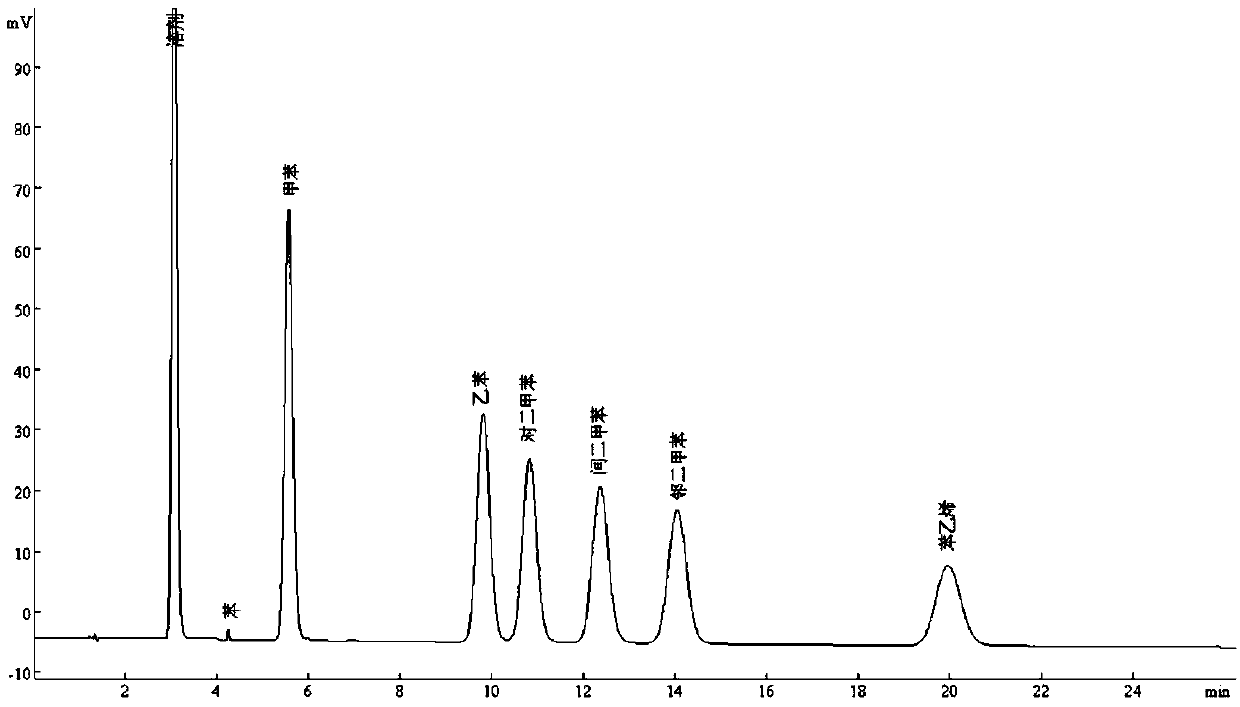

Gas chromatographic column used for analyzing benzene series

InactiveCN109580816AImprove selective separation performanceSmall sizeComponent separationVapor phase chromatographyChromatography column

The invention discloses a gas chromatographic column for analyzing benzene series. The gas chromatographic column comprises a chromatographic column tube, a supporter and a fixing liquid, wherein thelength of the chromatographic column tube is 1.5 m, the inner diameter of the chromatographic column tube is 3 mm, the supporter is Chromosorb WAW DMCS of 80-100 meshes, the fixing liquid comprises 3.7% of bentonite and 2.3% of dinonyl phthalate, and the chromatographic column tube is a stainless steel tube. Compared with the prior art, effective separation of the benzene series can be realized under a condition that the chromatographic column is shorter, and the gas chromatographic column is convenient, rapid and reliable.

Owner:LANZHOU ZKAT ANALYSIS TECH

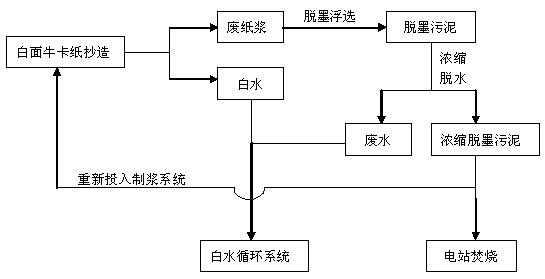

Recycling and reusing method of pulping deinking sludge

InactiveCN107619169ASave the amount of waste paper raw materialsReduce processing loadSludge treatment by de-watering/drying/thickeningWaste product additionPower stationDeinking

The invention discloses a recycling and reusing method of pulping deinking sludge. The recycling and reusing method includes three units which are concentration treatment of deinking sludge, use of deinking sludge after concentration, and waste water treatment of deinking sludge concentration. The concentration treatment of deinking sludge is carried out by collecting the deinking sludge after floating selection to a sludge storage tank, and adding macromolecular agglomeration in the sludge storage tank under a stirring state; after the sludge is agglomerated to be particle, conveying the sludge mixture to a sludge extruding dewatering system, concentrating and dewatering the sludge; the use of deinking sludge after concentration is carried out by re-feeding the deinking sludge after partially concentration to a pulping system of a white-faced craft paper; directly delivering the rest concentration deinking sludge to a power station to incinerate; the waste water treatment of deinkingsludge concentration is carried out by making waste water generated from the deinking sludge concentration enter a white water circulating system to purify; recycling the waste water. The recycling and reusing method of pulping deinking sludge can safely and effectively treat the deinking sludge, save waste paper raw material amount and filler dosage, reduce the sludge disposal load, and reduce the production cost.

Owner:JIANGSU LEE & MAN PAPER MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com