High-barrier PET material and preparation method thereof

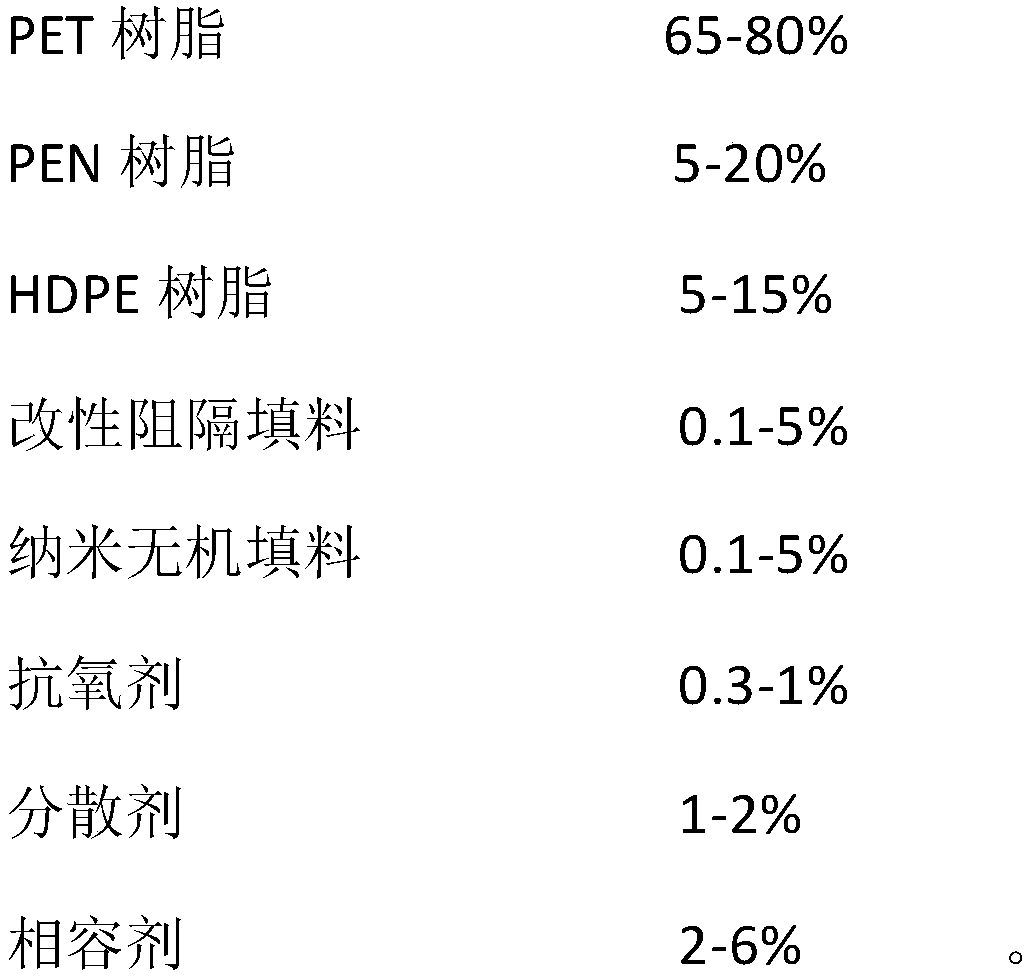

A high-barrier, nano-inorganic filler technology, applied in the field of polymer materials, can solve the problems of poor barrier properties of PET, achieve the effects of weakening loosening and plasticizing, improving water absorption, excellent barrier properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

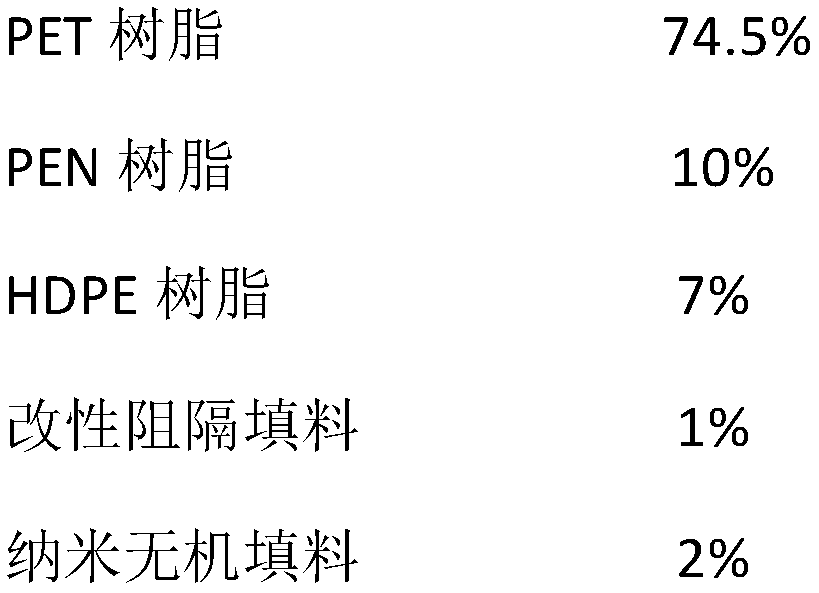

Embodiment 1

[0046] A high barrier PET material, including the following components: PET resin 74.5%, PEN resin 10%, HDPE resin 7%, modified halloysite 1%, nano silicon dioxide 1%, nano alumina 0.98%, nano nitrogen Titanium oxide 0.02%, antioxidant 0.5%, dispersant 1%, compatibilizer 4%.

[0047] The modified halloysite in this example is modified by aluminate coupling agent. The specific modification step is to stir the dried halloysite at 100°C and 500rpm for 5min; then slowly add aluminate Ester coupling agent (use diethyl ether diluent), maintain the temperature at 110°C, and continue to stir for 30 minutes.

[0048] The preparation method of the high-barrier PET material is to mix the antioxidant and the dispersant uniformly in proportion to obtain a mixed powder; the above-mentioned nano-silica with a particle size of 150nm, nano-alumina with a particle size of 150nm, and nano-nitrided 150nm Stir and mix the titanium and the above-mentioned modified halloysite evenly under the condi...

Embodiment 2

[0050] A high-barrier PET material, including the following components: PET resin 74.5%, PEN resin 10%, HDPE resin 7%, modified montmorillonite 1%, nano-silica 1%, nano-alumina 0.98%, nano-nitrogen Titanium oxide 0.02%, antioxidant 0.5%, dispersant 1%, compatibilizer 4%.

[0051] The modified montmorillonite in this example is obtained by modifying the montmorillonite through p-aminobenzoic acid hydrochloride. The specific steps are heating the dried montmorillonite to 60° C. and stirring at 500 rpm for 2 hours; Add p-aminobenzoic acid hydrochloride, maintain the temperature at 60°C and continue stirring for 16 hours; wash with water until the washing water does not contain chloride ions; then wash with absolute ethanol and dry.

[0052] The preparation method of the high-barrier PET material is to mix the antioxidant and the dispersant uniformly in proportion to obtain a mixed powder; the above-mentioned nano-silica with a particle size of 150nm, nano-alumina with a particle ...

Embodiment 3

[0054] A high barrier PET material, including the following components: PET resin 80%, PEN resin 7%, HDPE resin 5%, modified montmorillonite 2%, modified halloysite 2%, nano silicon dioxide 0.98%, Nano titanium nitride 0.02%, antioxidant 0.5%, dispersant 1%, compatibilizer 1.5%.

[0055] In this example, the modified halloysite is modified by an aluminate coupling agent, and the specific steps are the same as in Example 1.

[0056] The modified montmorillonite in this example is obtained by modifying the montmorillonite with p-aminobenzoic acid hydrochloride, and the specific steps are the same as in Example 2.

[0057] The preparation method of the high-barrier PET material is to mix the antioxidant and the dispersant uniformly in proportion to obtain a mixed powder; mix the above-mentioned nano-silicon dioxide with a particle size of 150nm, nano-titanium nitride with a particle size of 150nm and the above-mentioned modified Mongolian powder. The desoiling and modified halloys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com