Recycling and reusing method of pulping deinking sludge

A technology for deinking sludge and pulping, which is applied in the field of papermaking, can solve the problems of deinking sludge being perishable and smelly, not easy to implement, and secondary pollution, so as to save the amount of waste paper raw materials, reduce the processing load, and reduce the amount of waste paper. The effect of improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

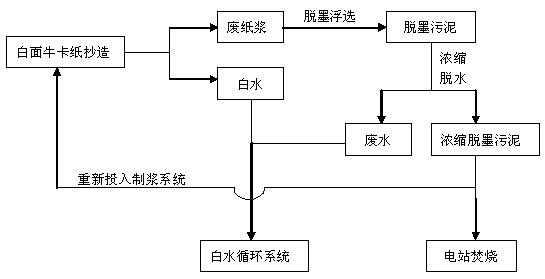

[0018] The present invention will be further explained below in conjunction with the drawings.

[0019] A method for recycling and reuse of pulping and deinking sludge, see figure 1 The process frame diagram shown includes the following units,

[0020] S1. Concentration treatment of deinked sludge: collect the deinked sludge after flotation into a sludge storage tank, and add a polymer flocculant to the sludge storage tank under agitation; after the sludge is aggregated into granular form, Transfer the sludge mixture to the sludge extrusion dewatering system to thicken and dehydrate the sludge;

[0021] S2. Utilization of thickened deinked sludge: re-enter the partially thickened deinked sludge into the pulping system of white flour cattle cardboard; send the remaining thickened deinked sludge directly to the power station for incineration, which can reduce transportation costs And coal cost;

[0022] S3. Wastewater treatment of deinking sludge concentration: the waste water generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com