Conductive fluorinated silicone rubber foam composite material as well as preparation method and application thereof

A technology of composite materials and fluorosilicone rubber, which is applied in the direction of material analysis, analysis materials, instruments, etc. by electromagnetic means, can solve the problems of limited sensitivity, inability to expand foaming ratio, uneven dispersion, etc., and achieve a simple and easy preparation process The operation and preparation process are fast and environmentally friendly, and the effect of uniform cell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of conductive particle dispersion: 0.4 g of carbon-based conductive particles CB (ECP-600JD) was added to ethyl acetate solvent, and ultrasonically dispersed for 20 minutes to obtain a conductive particle dispersion.

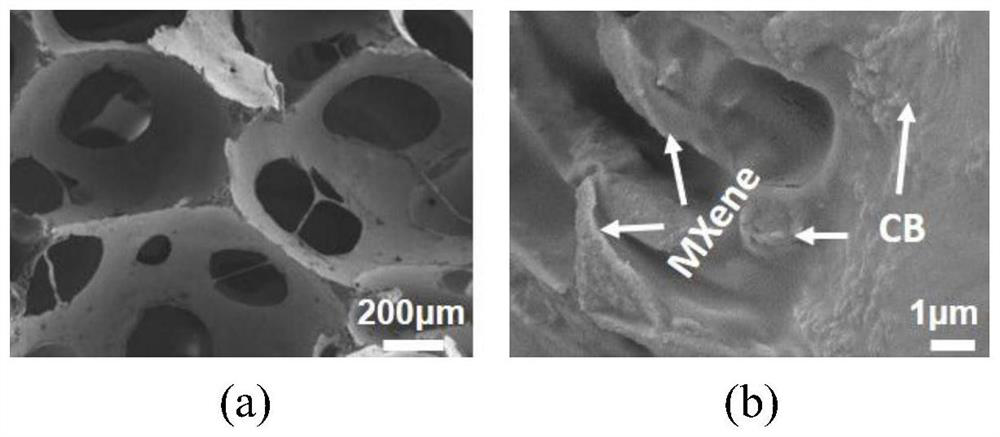

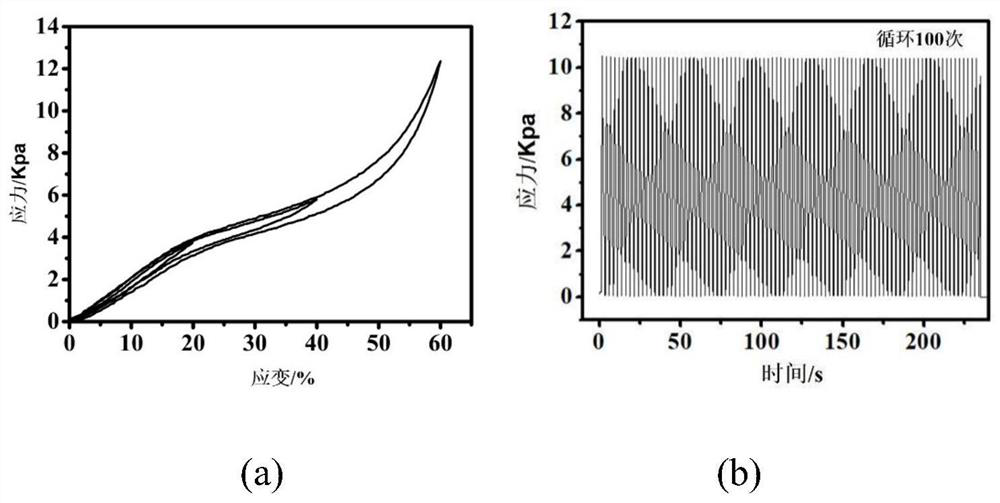

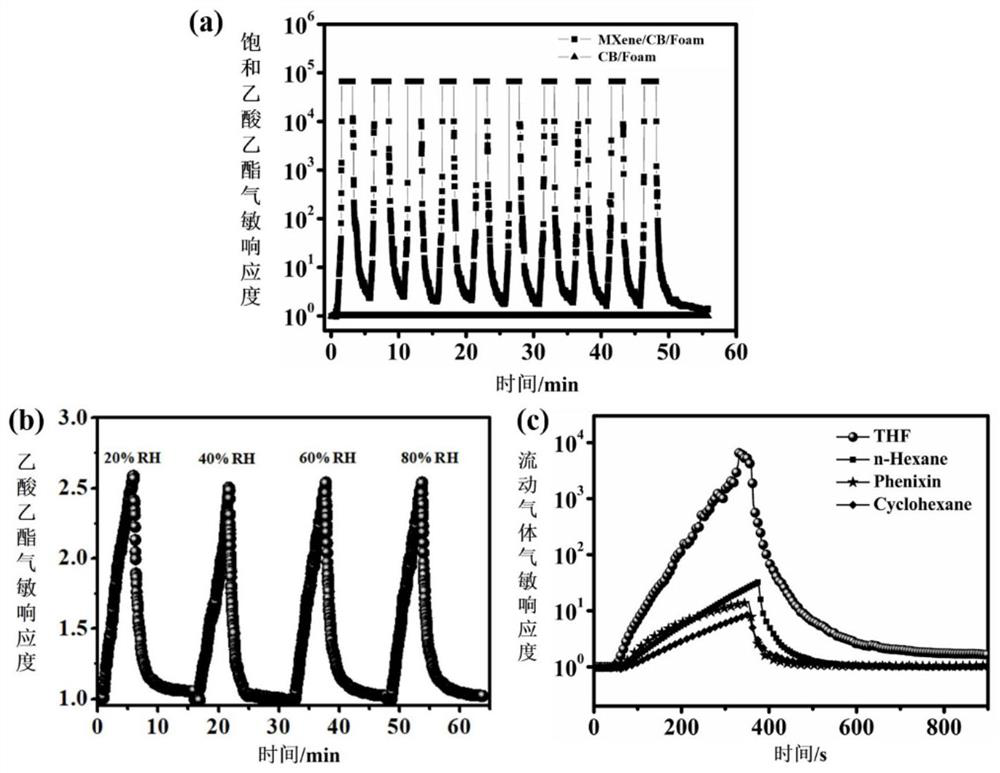

[0046] Preparation of perfluorosilicone rubber foam composites based on CB / MXene synergistic conductivity: take 12.0 g of perfluorosilicone oil with a viscosity of 20 Pa s and a vinyl content of 0.15 wt%, and a perfluoro silicone oil with a viscosity of 50 mPa s and a hydrogen content of 0.5 wt%. Add 8.0 g of hydrofluorosilicone oil into the ethyl acetate solvent, and add conductive particle dispersion to it, and mix well by mechanical stirring until the organic solvent is completely volatilized to obtain a CB (ECP-600JD) / perfluorosilicone mixture. Add 0.1 g of 1-ethynyl-1-(trimethylsilyloxy)cyclohexane and 0.8 g of MXene / glycerol solution to the CB(ECP-600JD) / perfluorosilicone mixture (MXene concentration is 450 mg / g ), and fully mix uniforml...

Embodiment 2

[0054] Preparation of conductive particle dispersion: 0.3 g of carbon-based conductive particles CB (EC-600JD) was added to ethyl acetate solvent, and ultrasonically dispersed for 15 minutes to obtain a conductive particle dispersion.

[0055] Preparation of conductive perfluorosilicone rubber foam composites based on CB / MXene synergy: Take 14.0 g of perfluorosilicone oil with a viscosity of 20 Pa s and a vinyl content of 0.15 wt%, and a perfluorosilicone oil with a viscosity of 50 mPa s and a hydrogen content of 0.5 wt%. Add 6.0 g of fluorosilicone oil to ethyl acetate solvent, and add conductive particle dispersion liquid to it, and mix well by mechanical stirring until the organic solvent is completely volatilized to obtain a CB (EC-600JD) / perfluorosilicone mixture. Add 0.1 g of 1-ethyn-1-(ethylsiloxy)cyclohexane and 0.6 g of MXene / ethylene glycol solution (MXene concentration is 250 mg / g) to the CB(EC-600JD) / perfluorosilicone mixture Component A was prepared after fully mi...

Embodiment 3

[0057] Preparation of conductive particle dispersion: 0.25 g of carbon-based conductive particles CB (EC-300J) was added to ethyl acetate solvent, and ultrasonically dispersed for 18 minutes to obtain a conductive particle dispersion.

[0058] Preparation of conductive perfluorosilicone rubber foam composites based on CB / MXene synergy: Take 15.0 g of perfluorosilicone oil with a viscosity of 20 Pa s and a vinyl content of 0.15 wt%, and a perfluorosilicone oil with a viscosity of 50 mPa s and a hydrogen content of 0.5 wt%. Add 5.0 g of fluorosilicone oil into the ethyl acetate solvent, and add the conductive particle dispersion to it, and mix well by mechanical stirring until the organic solvent is completely volatilized to obtain a CB (EC-300J) / perfluoroorganic silicon mixture. Add 0.1 g of 1-acetylene-1-(triethylsilyloxy)cyclohexane and 0.6 g of MXene / glycerol solution to the CB(EC-300J) / perfluorosilicone mixture (the concentration of MXene is 350 mg / g ), fully mixed uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com