A coal gangue-automatically modified zeolite composite filler artificial wetland system

A technology of constructed wetland system and composite filler, which is applied in the field of coal gangue-automatically modified zeolite composite filler constructed wetland system, can solve the problems of complex prefabricated modification process, wide application of constructed wetland, and reduction of wetland cross section, etc. Achieve the effects of reducing the risk of hydrogen ion leakage from coal gangue layer leaching, improving the removal effect and pollution holding capacity, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

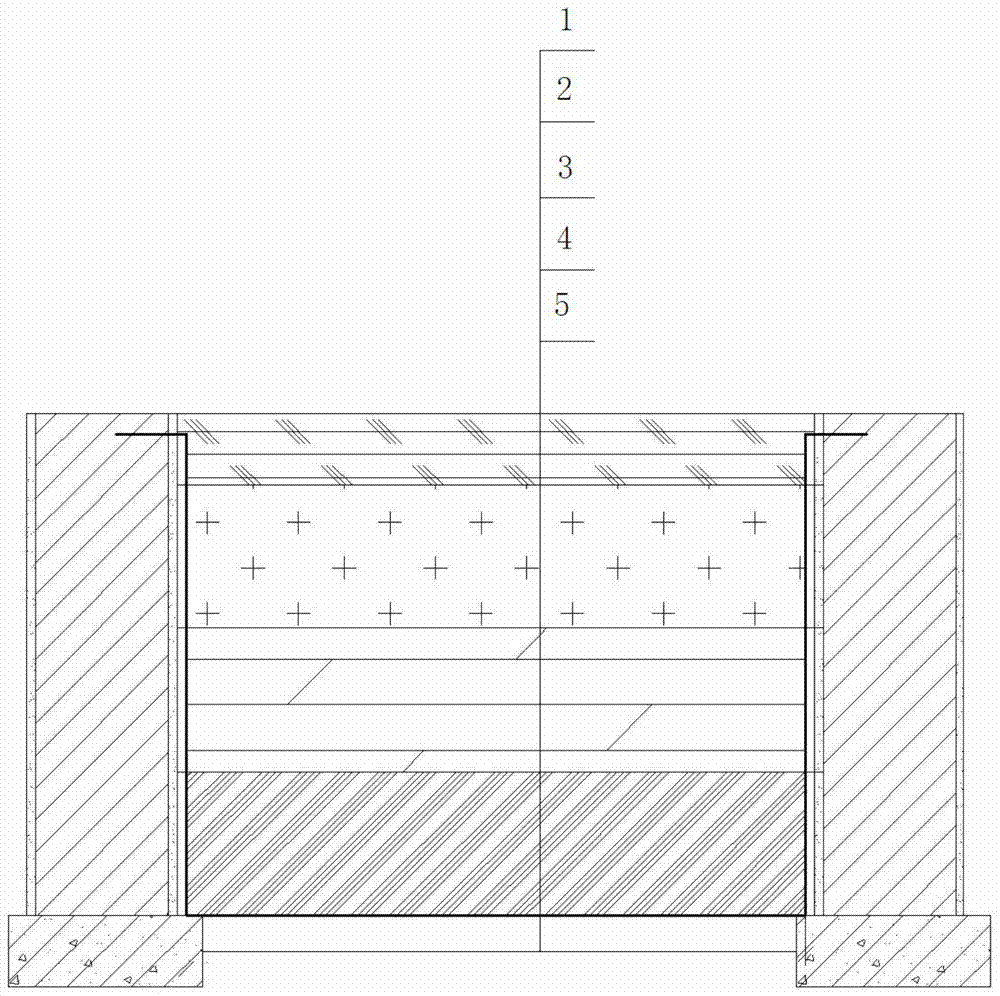

[0021] Example: such as figure 1 As shown, a coal gangue-automatically modified zeolite composite filler constructed wetland system of the present invention adopts a constructed wetland composite filler containing coal gangue, zeolite and gravel filler, the thickness of the filler layer is not less than 1.0m, and the filler is from top to bottom The order is planting soil 1, coal gangue 2, 3, gravel 4, and geomembrane 5.

[0022] The particle diameters of the fillers are coal gangue 8-20 mm, zeolite 5-10 mm, and gravel 10-25 mm.

[0023] The coal gangue 2, zeolite 3, and gravel 4 filter materials have an inhomogeneity coefficient K80 of 1.3-1.6.

[0024] The thickness of the planting soil 1 is 15cm, and the thickness of the gangue layer, zeolite layer, and gravel layer is different according to the concentration of influent suspended solids (SS), and the thickness and hydraulic load of the underflow wetland are determined, as follows:

[0025] When the influent concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com