Preparation method of mica paper with high thermal conductivity

A technology of mica paper and high thermal conductivity, which is applied to paper, papermaking, paper machines, etc., can solve the problems of raising the overall price of mica paper-based composite materials with high thermal conductivity, shortening the service life of mica paper-based insulating materials, and reducing the electrical performance of mica paper. , to achieve the effect of improving the maintenance time interval and service life, shortening the warranty interval, and reducing the temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the embodiments, so that those of ordinary skill in the art can implement it after referring to this specification.

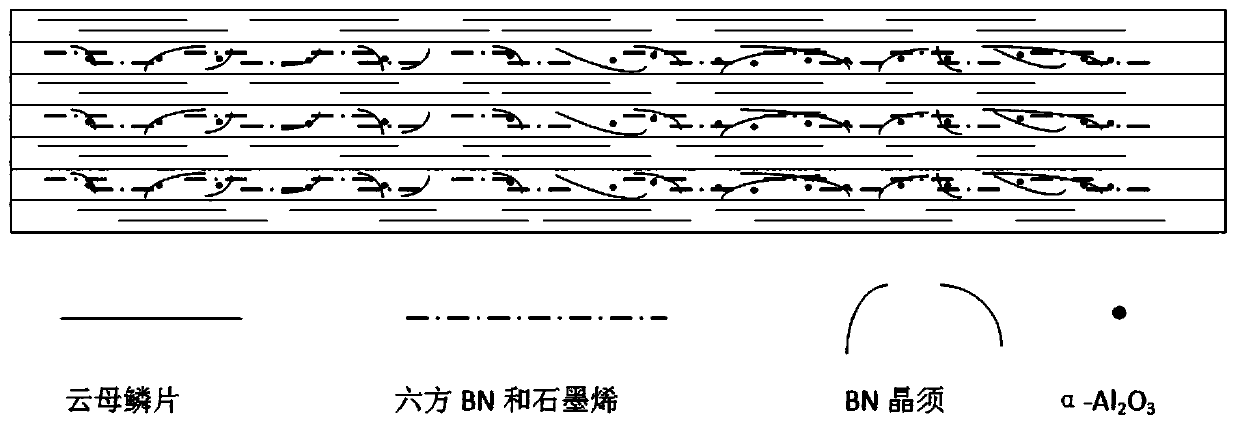

[0027] A method for preparing high thermal conductivity mica paper includes the following steps:

[0028] 1) Selection of mica raw materials: select the area to remove dead materials and bad materials ≤10cm 2 , Raw material of mica flakes with thickness ≤ 2cm;

[0029] 2) Preparation of mica slurry: the mica flake raw materials are uniformly delivered to the high-pressure hydraulic crusher through five belts for crushing, and the mica refined slurry is obtained after filtration, classification and dehydration;

[0030] 3) Preparation of highly conductive filler solution: Dilute the filler with a mixer, and stir the solution to keep its distribution uniform;

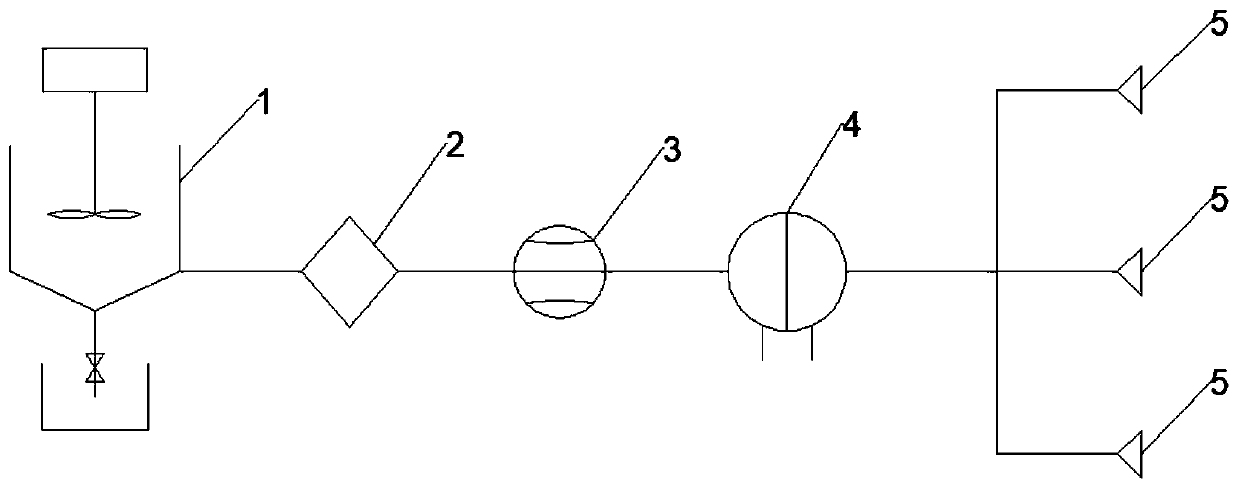

[0031] 4) Papermaking: paper making using a cylindrical mica paper machine, which is divided into five rounds of online pulping;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com