Composite waterproof cable and preparation method thereof

A waterproof cable and cable technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of water and water vapor infiltrating into the conductor, and achieve excellent electrical and mechanical properties, high elongation of single wire, and ductility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present application also provides a method for preparing a composite waterproof cable. Since the process control conditions in the preparation process of the composite waterproof cable are prior art, details will not be repeated here. Wherein, the preparation method comprises the following steps:

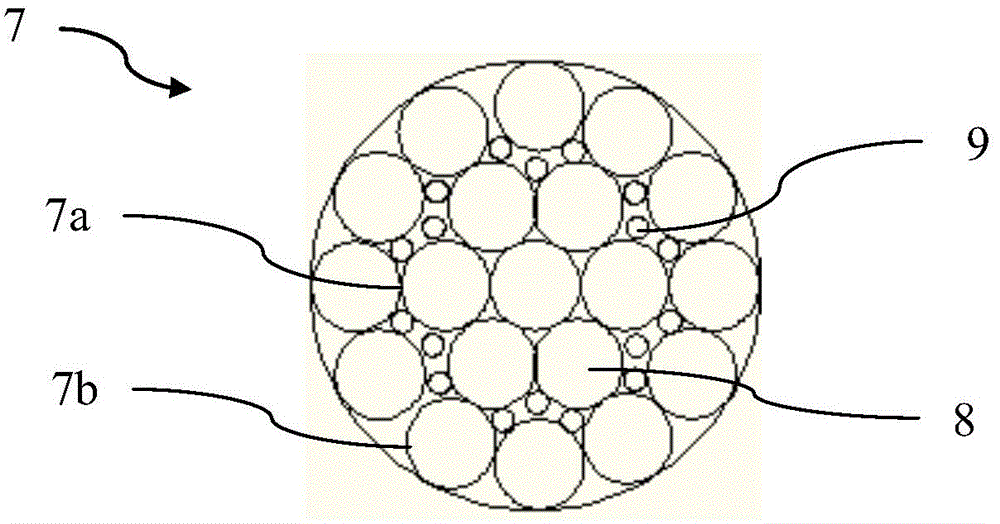

[0046] S1. Preparing the conductor group: After twisting the copper wire 8 and the water-blocking wire 9, the conductor group 7 is obtained.

[0047] Specifically, the preparation of the copper wire 8 includes three sub-steps: material selection, wire drawing and stranding. Material selection: Select the conductor material used according to the requirements of preparing different cables, such as choosing an electrical round copper rod as the conductor material; wire drawing: draw and anneal the conductor material to obtain annealed oxygen-free copper wire, the diameter of the annealed oxygen-free copper wire 0.15mm; Stranding: The annealed oxygen-free copper wire and wat...

Embodiment 1

[0052] S1. Preparing the conductor group: After twisting the copper wire 8 and the water-blocking wire 9, the conductor group 7 is obtained.

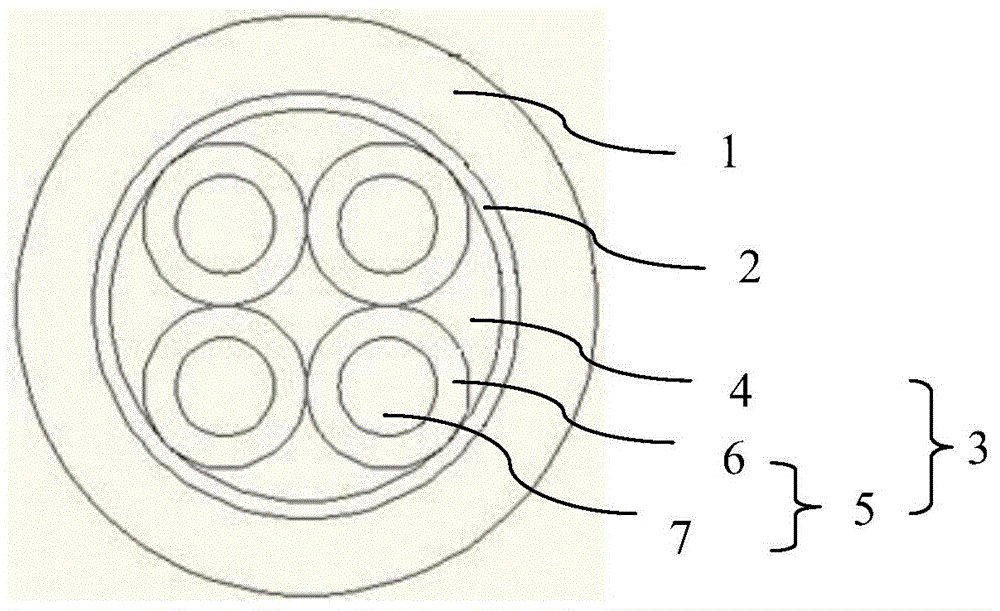

[0053] S2. Extruding the insulating layer: extruding the insulating layer 6 outside the conductor group 7 with an extrusion die to obtain the insulating core wire 5, and the insulating layer 6 is polyvinyl chloride insulating material.

[0054] S3. Wrapping isolation layer: Twisting a plurality of insulating core wires 5, and filling water-blocking ropes in the twisted gaps of the plurality of insulating core wires 5 to obtain the inner core 3 of the cable, and covering the isolation layer 2 evenly on the Outside the inner core 3 of the cable, the isolation layer 2 is formed by wrapping aluminum-plastic composite tape.

[0055] S4. Extruded sheath layer: the sheath layer 1 made of halogen-free low-smoke flame-retardant polyolefin composite material is evenly coated on the outside of the isolation layer 2 by extrusion.

[0056] Among th...

Embodiment 2

[0058] S1. Preparing the conductor group: After twisting the copper wire 8 and the water-blocking wire 9, the conductor group 7 is obtained.

[0059] S2. Extruding the insulating layer: extruding the insulating layer 6 outside the conductor group 7 with an extrusion die to obtain the insulating core wire 5, and the insulating layer 6 is polyvinyl chloride insulating material.

[0060] S3. Wrapping isolation layer: Twisting a plurality of insulating core wires 5, and filling water-blocking ropes in the twisted gaps of the plurality of insulating core wires 5 to obtain the inner core 3 of the cable, and covering the isolation layer 2 evenly on the Outside the inner core 3 of the cable, the isolation layer 2 is formed by wrapping aluminum-plastic composite tape.

[0061] S4. Extruded sheath layer: the sheath layer 1 made of halogen-free low-smoke flame-retardant polyolefin composite material is evenly coated on the outside of the isolation layer 2 by extrusion.

[0062] Among th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com