Furnace cover of titanium and iron separation electric arc furnace

A technology for ferro-titanium separation and electric arc furnace, which is applied in the field of electric arc furnace, can solve problems such as difficult temperature reaching ferro-titanium separation temperature and reduction time, poor heat preservation performance, and prolonged smelting time, so as to shorten temperature and maintain reduction time, heat preservation Good effect, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

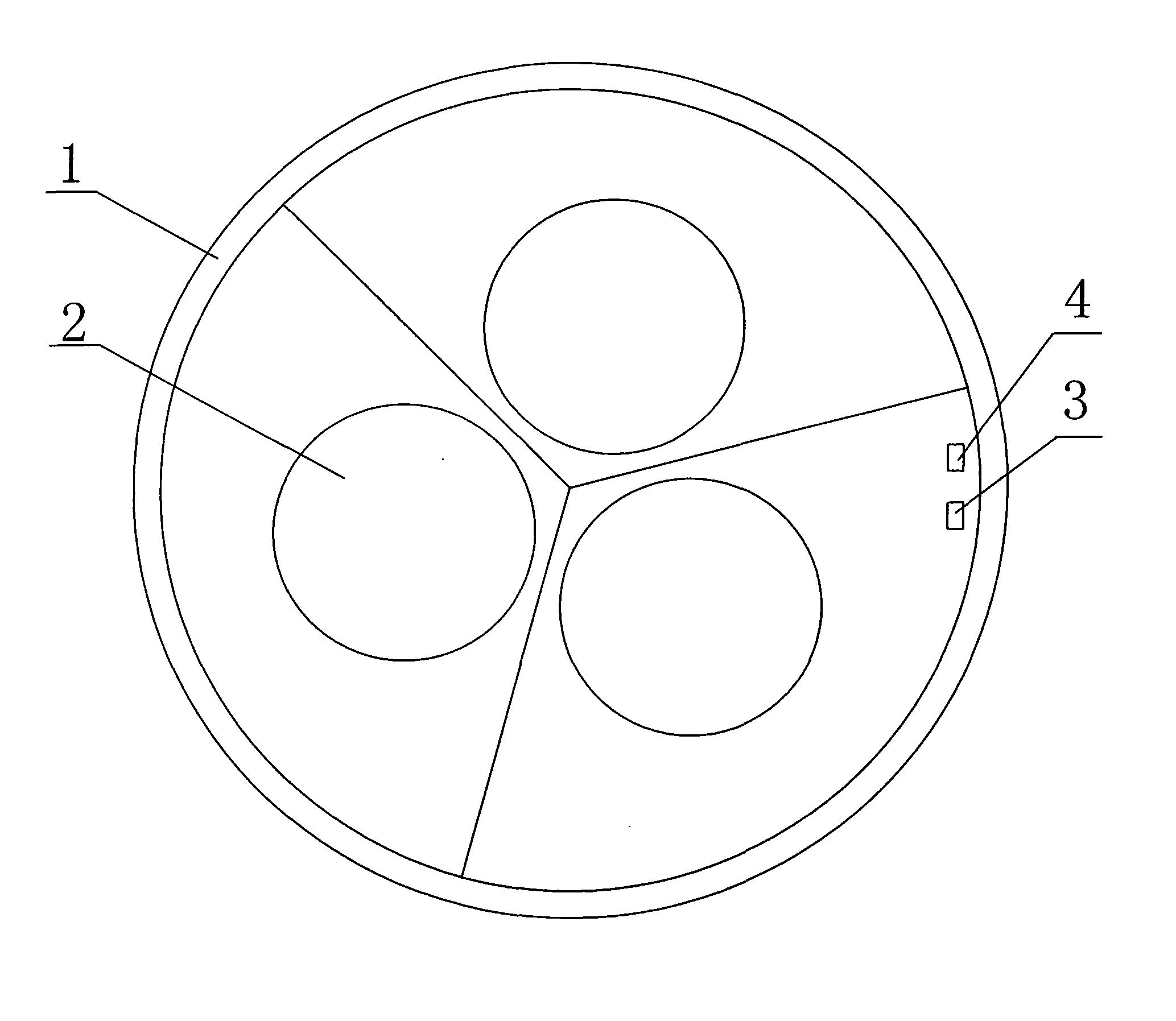

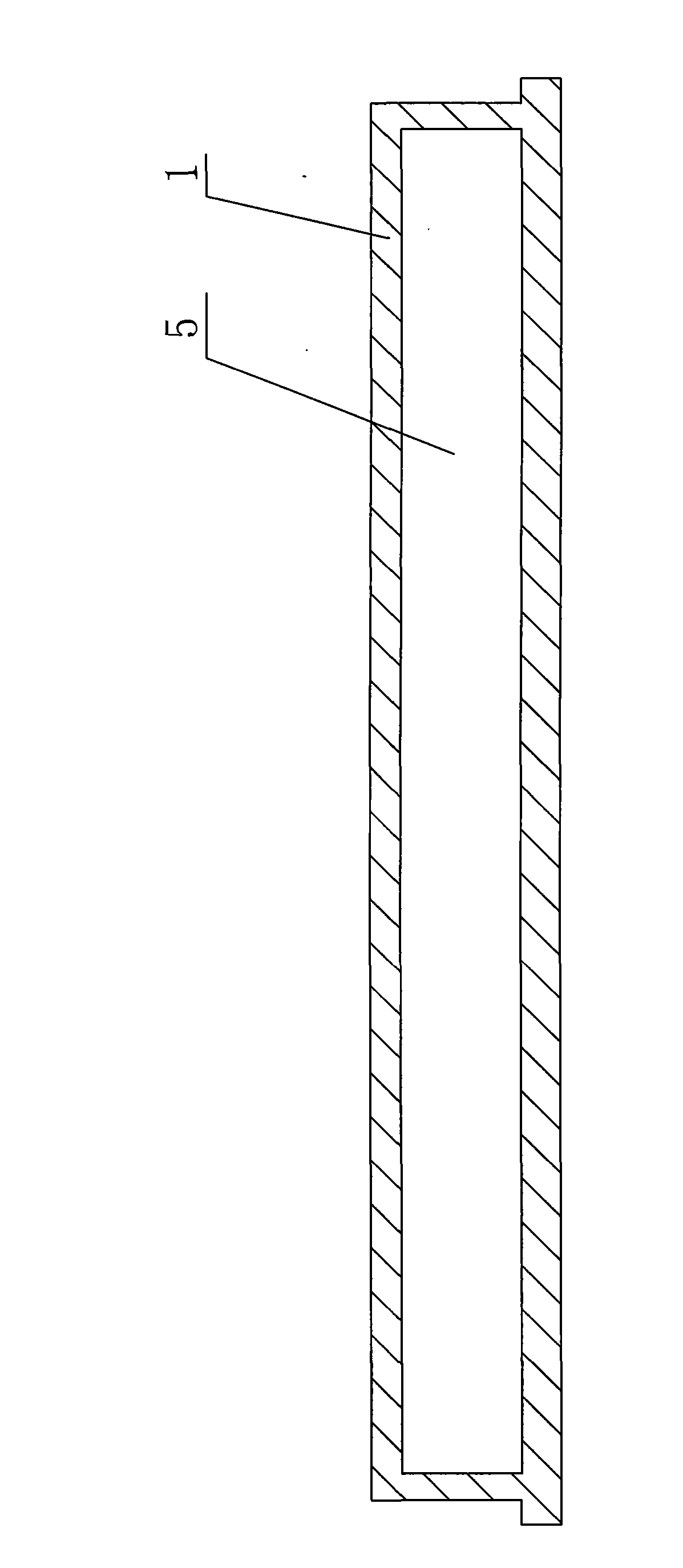

[0010] A titanium-iron separation electric arc furnace cover, including a circular cover 1, the middle of the circular cover 1 is evenly spaced with three circular holes 2 for electrode insertion, and the circular cover 1 is provided with a cavity flow channel 5 , The edge of the top surface of the circular cover 1 is provided with a water inlet 3 and a water outlet 4, and the water inlet 3 and the water outlet 4 communicate with the cavity flow channel 5 in the circular cover 1 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com