Rigid oil guiding device capable of achieving reciprocate motion

An oil guide device and reciprocating movement technology, applied in fluid pressure actuating devices, mechanical equipment, etc., can solve problems such as hose drooping, inconvenient use, and affecting the normal operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

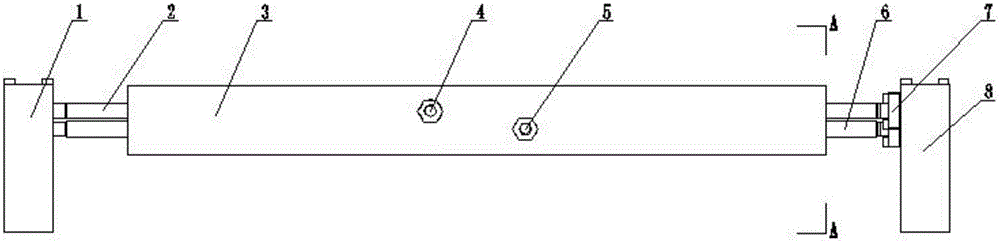

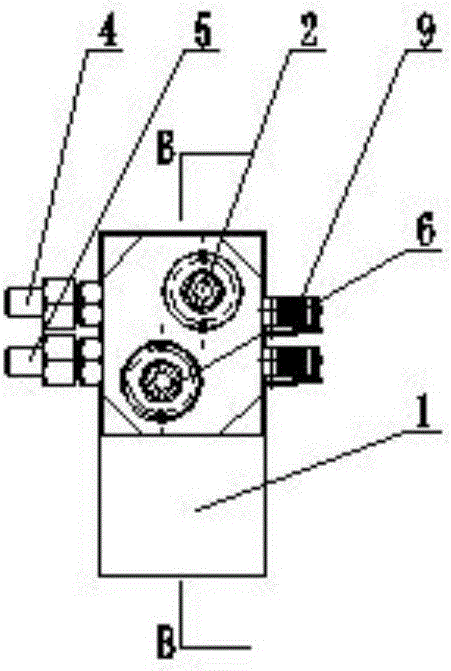

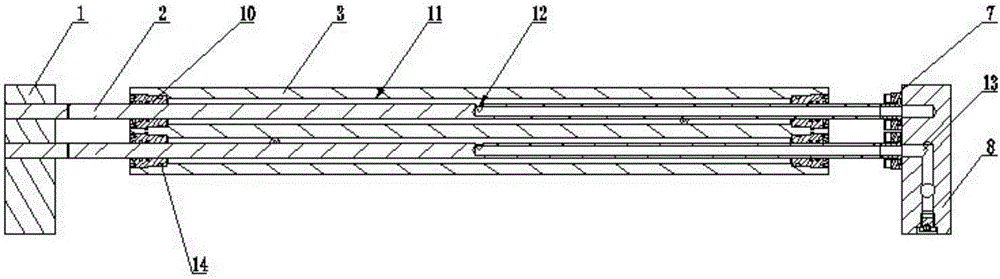

[0014] A rigid oil guiding device capable of reciprocating movement. The innovation of the present invention is that it includes two oil pipes arranged in parallel at intervals. One end of the two oil pipes is fixedly installed with a fixed bracket 1, and the other end of the two oil pipes An external oil guide bracket 8 is connected and installed through the joint 7, and an oil passage 13 is arranged inside the external oil guide bracket to communicate with the external hydraulic station. A movable box 3 is installed slidingly outside the two oil pipes, and the movable box is located outside the two oil pipes. A cavity 11 is respectively made in the space of the two oil pipes. One of the two oil pipes is the oil inlet pipe 2, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com