Cable connector

A cable connector and connector technology, which is applied in the direction of connection, parts of the connection device, protective grounding/shielding device of the connection part, etc., can solve the problem of fragility, damage to the electrical performance of the connector, reliable connection of solder joints, high mold development costs, etc. Problems, to achieve a bright appearance, the effect of electrical performance is not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below by taking a cable connector with a Micro-HDMI connector at one end and an HDMI connector at the other end as an example with reference to the accompanying drawings.

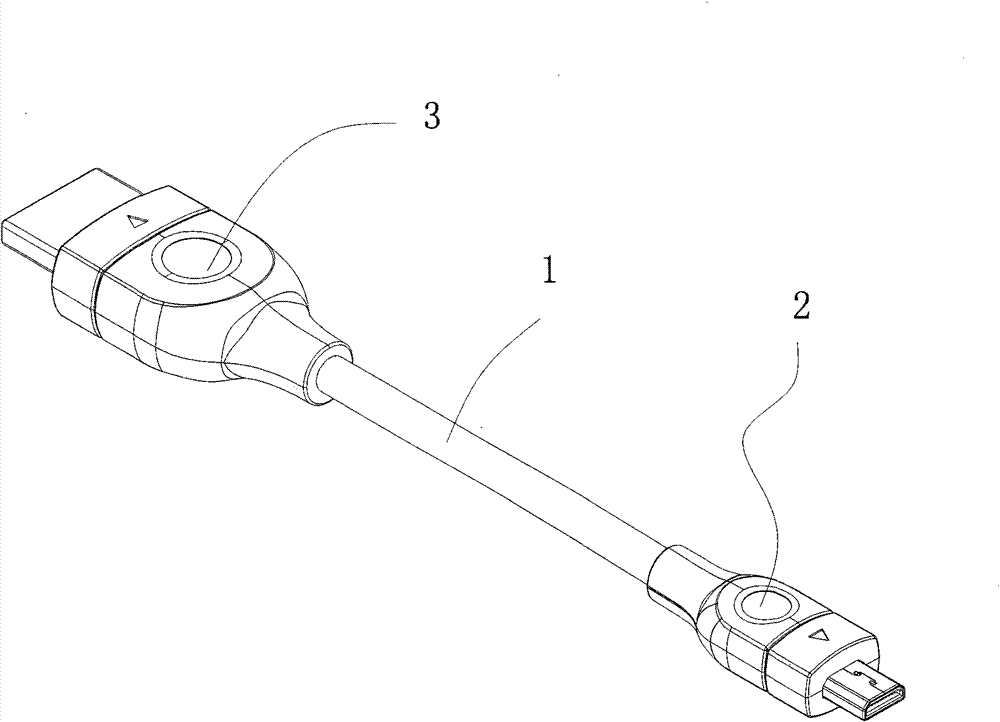

[0025] Such as figure 1 As shown, the cable connector of the embodiment of the present invention includes: a cable 1, a Micro-HDMI connector 2 connected to the first end of the cable 1, and a HDMI connector connected to the second end of the cable 1 Connector 3.

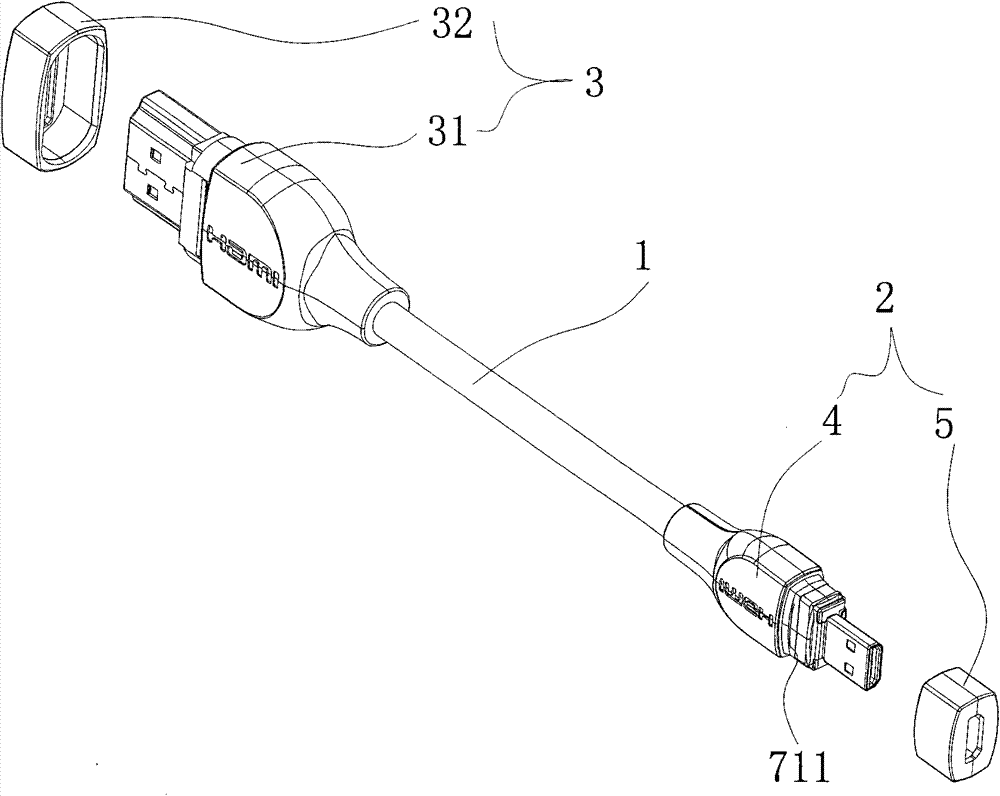

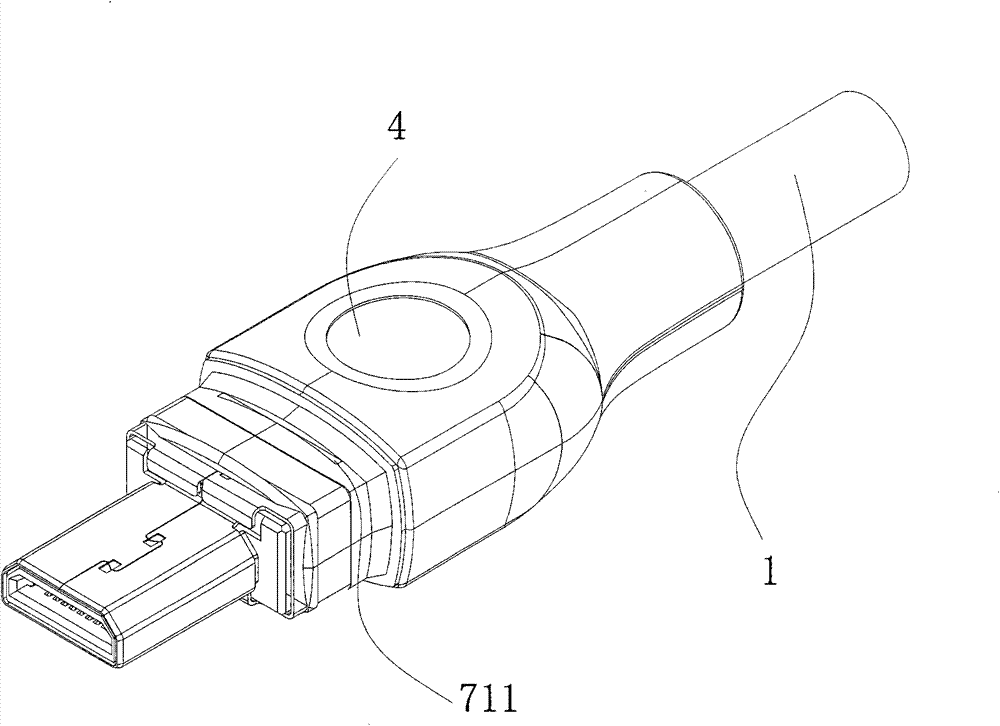

[0026] Such as figure 2 As shown, the Micro-HDMI connector 2 includes a main body 4 and a front cover 5 sleeved on the main body 4 ; the HDMI connector 3 includes a main body 31 and a front cover 32 sleeved on the main body 31 . Since the structures for fixing the front cover 5, 32 in the Micro-HDMI connector 2 and the HDMI connector 3 are very similar, only the first end of the cable 1, such as image 3 and Figure 4 The shown Micro-HDMI connector 2 is taken as an example, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com