Organosilicon composite material and preparation method thereof

A composite material and silicone technology, which is applied in the field of high-performance silicone composite materials and its preparation, can solve the problems of increased low-temperature shrinkage of silicone rubber, cumbersome filler treatment process, and inability to meet special environmental requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

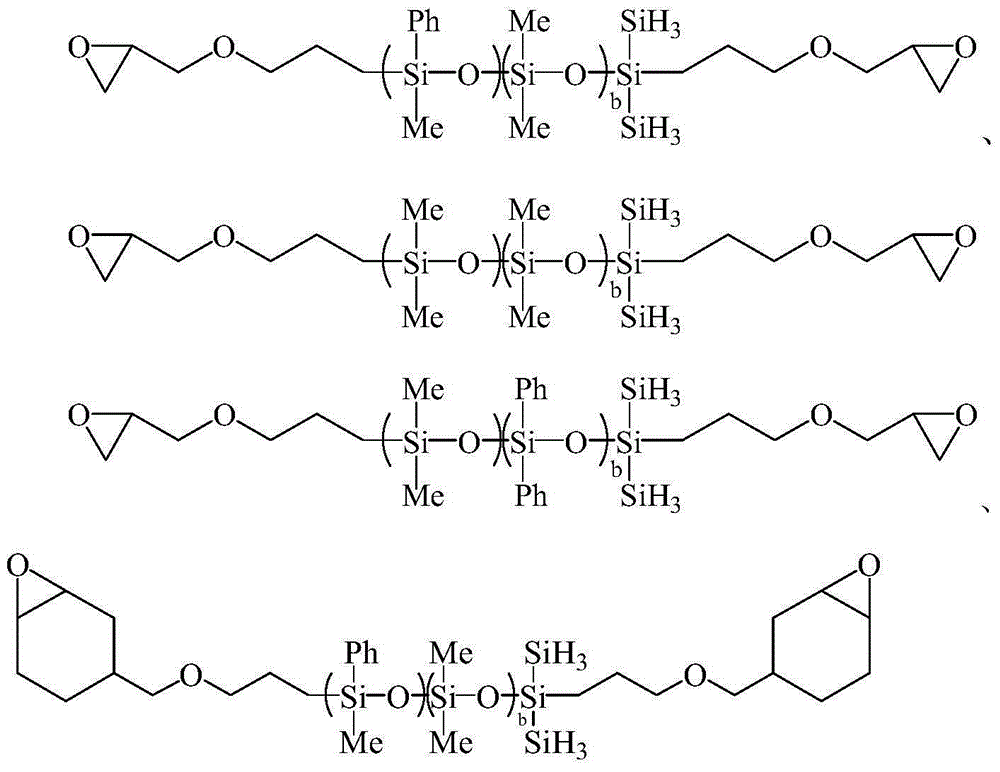

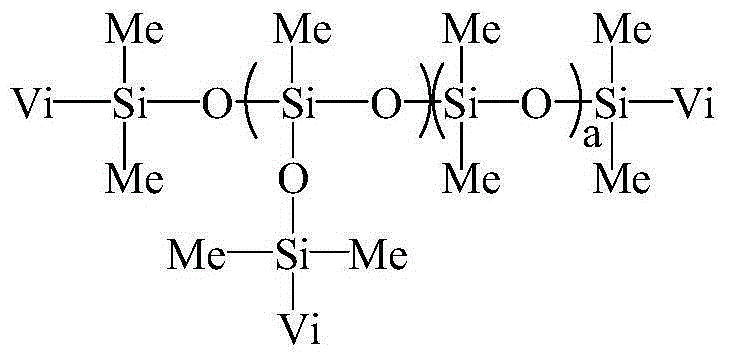

[0067] Add 30 parts of vinyl polysiloxane to the vacuum kneader: (a is 200, the viscosity is 0.47Pa.s,)

[0068]

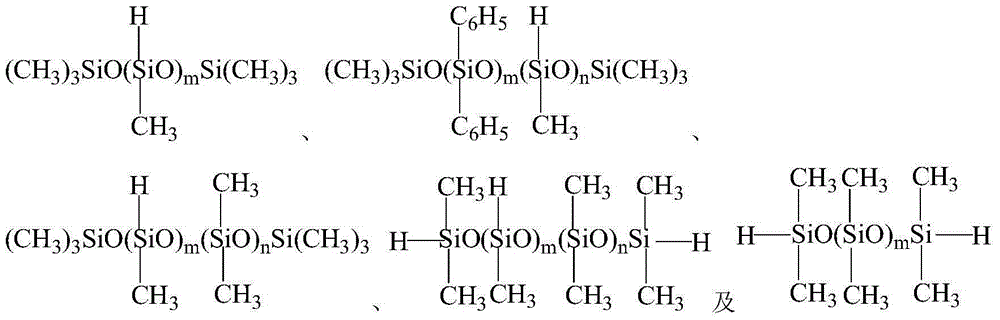

[0069] (The vinyl content is 0.535%), add 39μm spherical alumina (KH-560 treatment), stir for 45min, then add 4.7μm spherical alumina (KH-560 treatment), stir for 45min, and finally add 0.5μm spherical alumina (KH-560 treatment) -560 treatment), stirred for 45min, then added in turn the beryllium-containing silicon carbide fibers with an aspect ratio of 2 to 5 treated with KH-560, a total of 400 parts, kneaded at 120 ° C for 2 hours and cooled to room temperature, then transferred to a vacuum type Add 20 parts of vinyl polysiloxane and 2.6 parts to the high-speed disperser (where m=20, viscosity (25°C) is 15mPa.s, mass fraction of hydrogen is 1.48%), 2.5 parts of epoxy polysiloxane: 0.01 part of 3-methyl-3-penten-1-yne, stirred for 1 hour, vacuum degassed, and discharged.

[0070] Add 30 parts of olefin-based polysiloxane to the vacuum kneader, add 39 μm sph...

Embodiment 2

[0074] Add 30 parts of vinyl polysiloxane to the vacuum kneader: (a is 120, viscosity is 0.29Pa.s,) (the vinyl content is 0.87%)

[0075]

[0076] , add 45um spherical alumina (KH-560 treatment), stir for 45min, then add 5um spherical alumina (KH-560 treatment), stir for 45min, finally add 0.5um spherical alumina (KH-560 treatment), stir for 45min, then Add KH-560-treated four-needle zinc oxide whiskers, a total of 430 parts, knead at 120°C for 2 hours and cool down to room temperature, then transfer to a vacuum-type high-speed disperser and add 20 parts of vinyl polysiloxane, 5.5 share (where m=20, viscosity (25°C) is 15mPa.s, mass fraction of hydrogen is 1.48%), 2 parts of epoxy polysiloxane:

[0077]

[0078] , 0.01 part of 3-methyl-3-penten-1-yne, stirred for 60 minutes, vacuum defoamed, and discharged.

[0079] Add 30 parts of vinyl polysiloxane to the vacuum kneader, add 45um (KH-560 treatment) spherical alumina, stir for 45min, then add 5um (KH-560 treatment) s...

Embodiment 3

[0083] Add 30 parts of alkenyl-containing polysiloxane to the vacuum kneader: (a is 120, viscosity is 0.29Pa.s,) (the vinyl content is 0.87%)

[0084]

[0085] , add 45um (KH-560 treatment) spherical alumina, stir for 45min, then add 5um (KH-560 treatment) spherical alumina, stir for 45min, finally add 0.5um (KH-560 treatment) spherical alumina, stir for 45min, then Add KH-560 to treat beryllium-containing silicon carbide fibers with an aspect ratio of 2 to 5, a total of 380 parts, knead at 120°C for 2 hours and cool down to room temperature, transfer to a vacuum-type high-speed disperser and add 20 parts of olefin-based Polysiloxane, 5.5 parts (where m=20, viscosity (25°C) is 15mPa.s, mass fraction of hydrogen is 1.48%), 2.1 parts of epoxy polysiloxane:

[0086] 0.01 part of 3-methyl-3-penten-1-yne, stirred for 60 minutes, vacuum degassed, and discharged.

[0087] Add 30 parts of olefin-based polysiloxane to the vacuum kneader, add 5um (KH-560 treatment) spherical alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com