Waterproof roll for tunnel roof and preparation method thereof

A technology for waterproofing membranes and tunnels, applied in tunnels, tunnel linings, chemical instruments and methods, etc., can solve the problems of non-environmental protection materials, inability to offset tunnel stress, and high difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

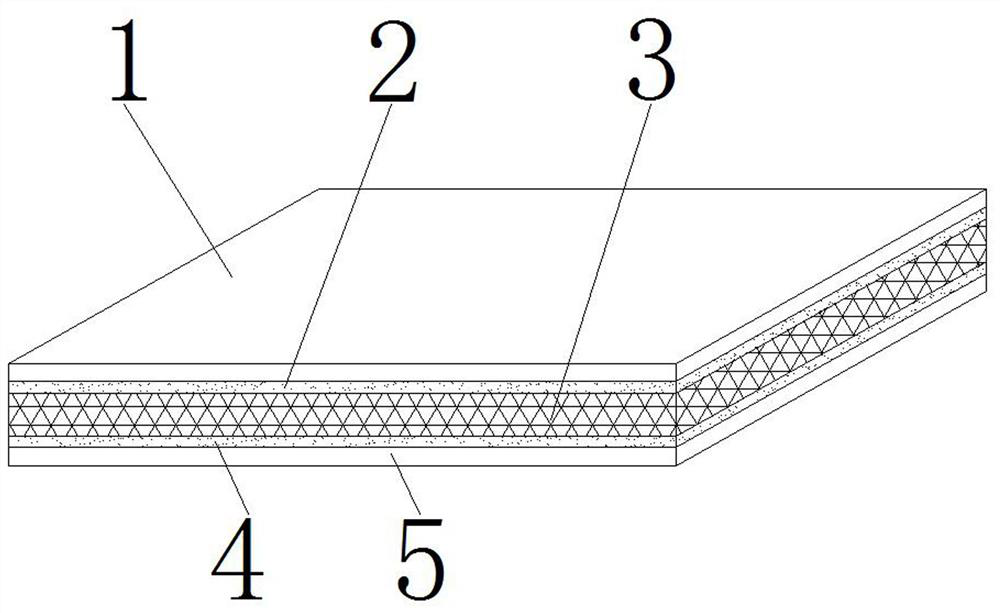

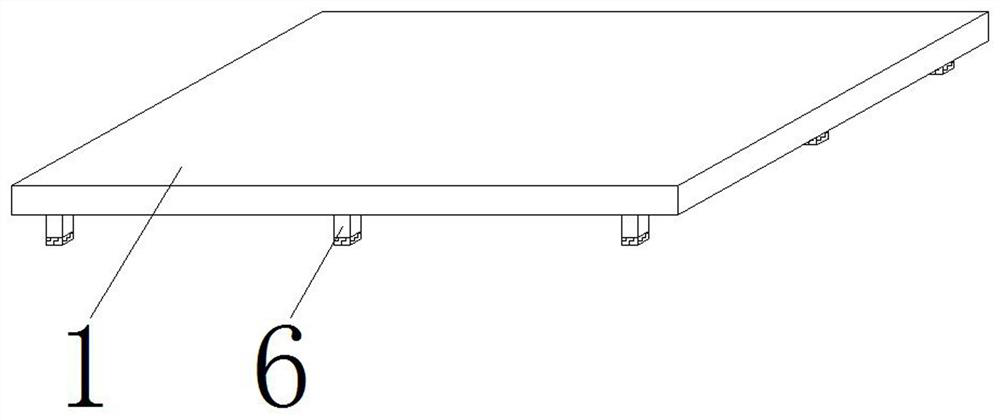

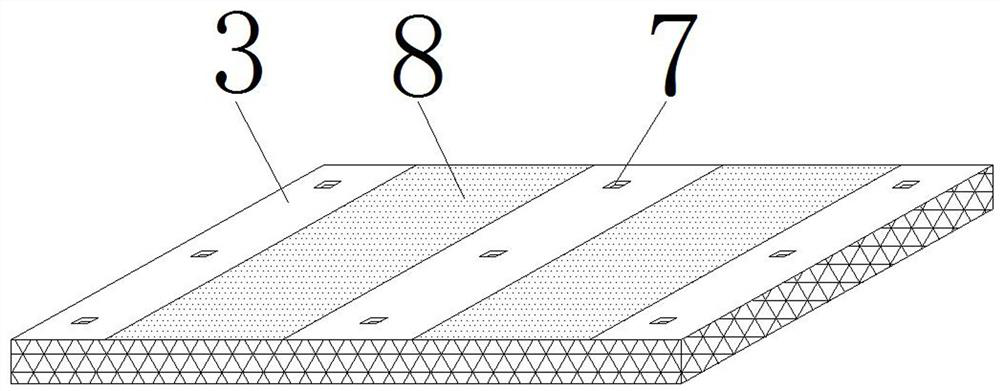

[0017] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a waterproof coiled material for the roof of a tunnel, which includes a first waterproof coiled material 1 and a second waterproof coiled material 5, the first waterproof coiled material 1 is made of the following raw materials in parts by weight: polybutylene ethyl styrene rubber 20- 35 parts, 12-18 parts of polyisoprene, 35-50 parts of tackifying resin, 25-45 parts of filler, 0.5-1 part of antioxidant, 2-5 parts of anti-aging agent, 5-10 parts of petroleum resin, The second waterproof coiled material 5 is made of the following raw materials in parts by weight: 45-65 parts of pine oil, 10-20 parts of light calcium carbonate, 3-5 parts of chlorinated paraffin, 1-3 parts of plasticizer, stable 1.5-2.5 parts of agent, 40-60 parts of butyl rubber.

[0018] A method for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com