Portable Exhaust Valve Heat Press

A technology of exhaust valve and hot press, which is applied to paper/cardboard containers, containers, bag making operations, etc. It can solve the problems of affecting the processing quality, inconvenient to carry, and restricting the processing efficiency, so as to improve the tightness and firmness of the connection Accuracy, improved stability and service life, ideal effect of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

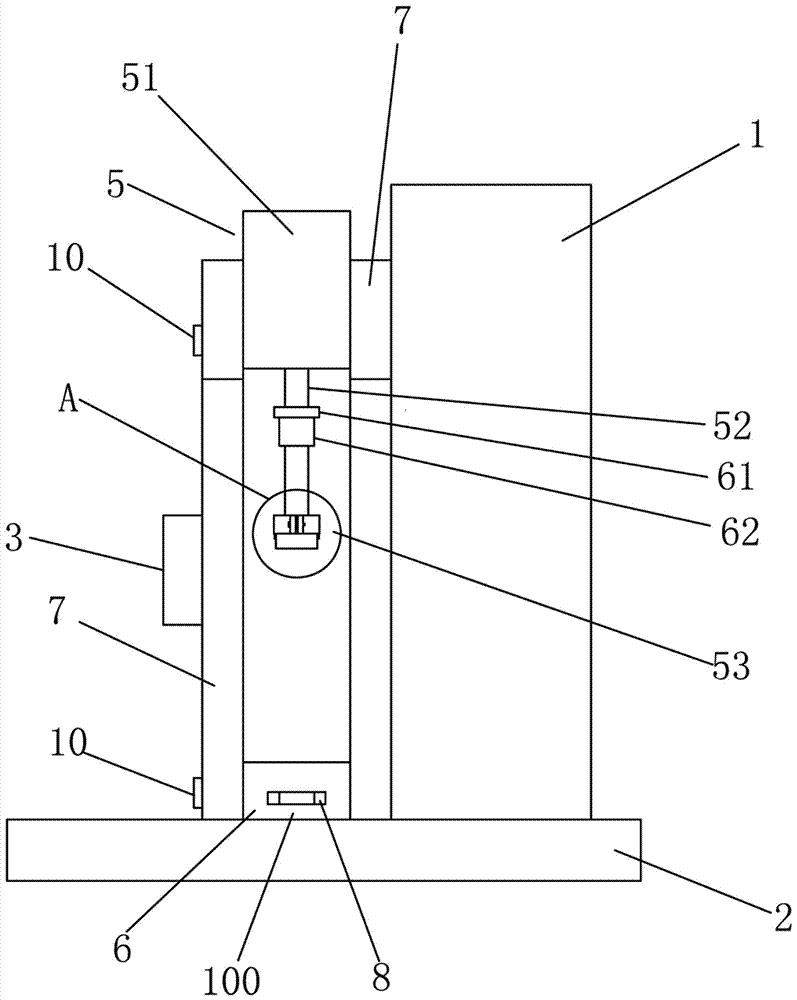

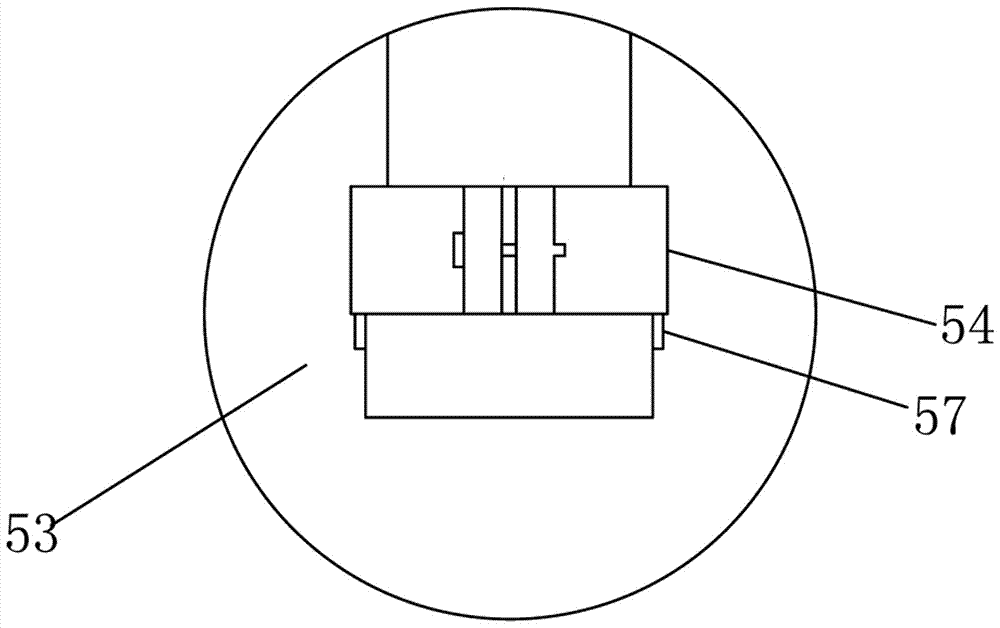

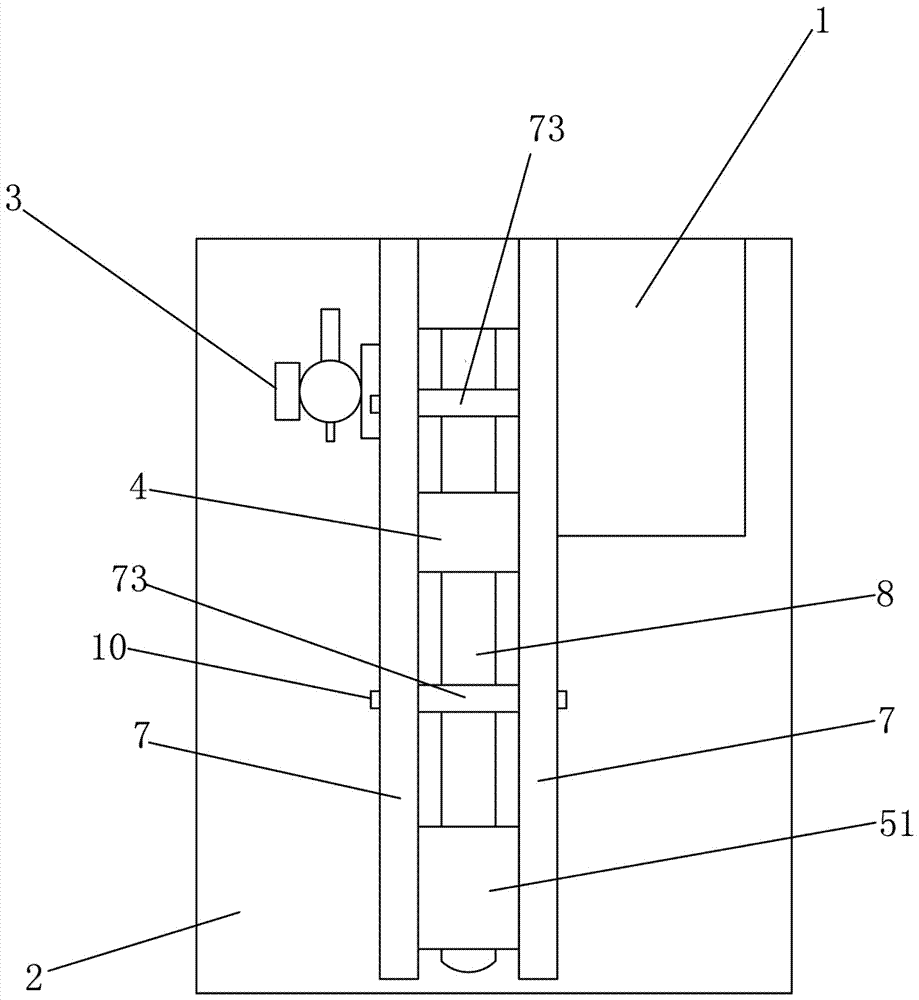

[0036] 实施例,结合 Figure 1 to Figure 13 所示,一种便携式排气阀热压机,包括控制箱1、底板2、隔热装置、气压调节装置3、电磁阀4、排气阀压制装置5和阀体安放臂8,底板2为透明的亚克力塑料板,底板2上设置有连接座6和左、右两块弯臂板7。

[0037] 所述连接座6为金属座,连接座6的底壁、两侧侧壁以及连接座6的前端分别开有固定孔9,连接座6的底壁设有便于阀体安放臂8基于模具头53的水平位置调节的四个调节螺钉200,方便使用者调节连接座6的位置,从而调节热压机更佳的热压效果。所述弯臂板7是近似半框状的亚克力塑料板,它包括横臂段71和竖臂段72,横臂段71和竖臂段72的连接处为圆弧过渡。

[0038] 所述连接座6安装在底板2上,弯臂板7的横臂段71与底座2平行,弯臂板7的竖臂段72下端通过螺钉10锁紧在连接座6侧壁的固定孔9 Inside. 所述左、右两块弯臂板7将相互平行固定在连接座6两侧壁上,而且左、右两个弯臂板7之间的横臂段71之间设有亚克力材质的套管73,螺钉10依次穿过左弯臂板7、套管73和右弯臂板7,加固左、右两个弯臂板7组合关系,保持弯臂板7的平衡。

[0039] 所述阀体安放臂8是金属板,阀体安放臂8一端构成具有三个面的连接罩11与连接座6前段通过螺钉10固定连接,阀体安放臂8另一端设有带保护胶圈56的阀体放置孔55并朝排气阀压制装置5的水平方向伸出并悬空,阀体安放臂8伸出部分与底座2之间留有间隙100,阀体安放臂8伸出部分能在间隙100范围内构成弹性活动区域。

[0040] The control box 1 is fixed on the bent arm plate 7 , and the control box 1 abuts against the outer side wall of the bent arm plate 7 . The air pressure regulating device 3 is fixed on another curved arm plate 7 , and the air pressure regulating device 3 abuts against the outer side wall of the curved arm plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com