Polymer-based composite thermally conductive material and its preparation method and application

A composite heat-conducting material and polymer technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of less attention to the thermal conductivity of the film's normal phase, sacrifice the mechanical properties of the film, and reduce flexibility, so as to improve the thermal conductivity of the normal phase Conductivity, low manufacturing cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

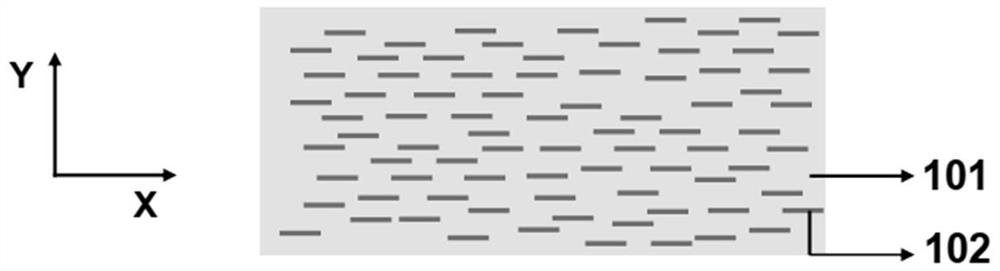

[0059] In one of the embodiments, the preparation method of the flake boron nitride comprises the following steps:

[0060] The spherical boron nitride 'is mixed with a surfactant and water, ball milled, filtered, and the boron nitride filter residue is collected, washed with water and ethanol, and collected to obtain a boron nitride slurry containing water and boron nitride. The boron nitride slurry is subjected to ultrasonic treatment to collect few-layer flake boron nitride.

[0061] In one of the embodiments, the particle size of the spherical boron nitride' is 200 mesh-500 mesh; and / or

[0062] The surfactant is at least one of dodecylsulfuric acid and its sodium salt, dodecylbenzenesulfonic acid and its sodium salt, and fatty alcohol ether sodium sulfate;

[0063] The mass ratio of the spherical boron nitride' to the surfactant is (60-100):1.

[0064] The rotating speed of ball milling is 200rpm-300rpm, and the time of ball milling is 20h-22h.

[0065] In one of the e...

Embodiment 1

[0082] This embodiment provides a polymer-based composite heat-conducting material and a preparation method thereof.

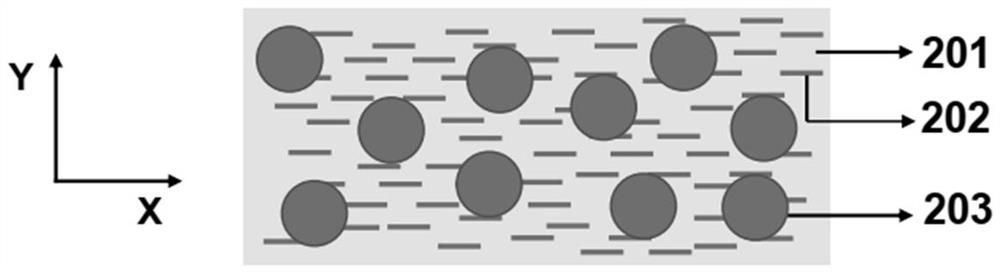

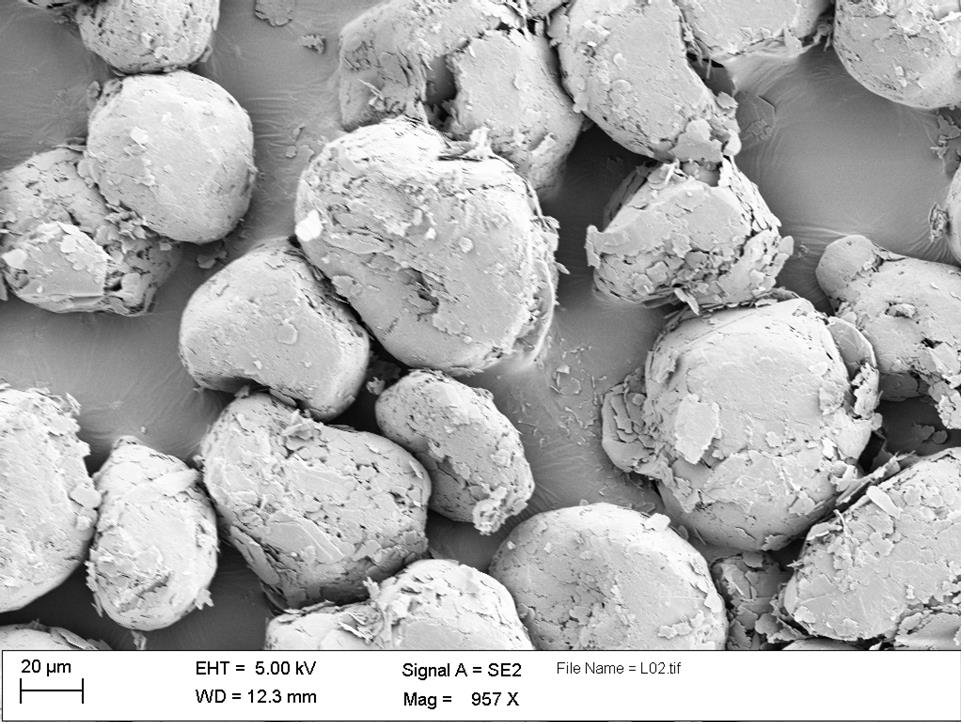

[0083] (1) The polymer-based composite heat-conducting material in this embodiment is composed of natural rubber and fillers. The total mass of fillers accounts for 40% of the mass percentage of natural rubber. The fillers are composed of flake boron nitride and spherical boron nitride according to Compounded with a mass ratio of 1:3;

[0084] Among them, the particle size of the spherical boron nitride is 50 μm-60 μm; the thickness of the flake boron nitride is 4 nm-10 nm, and the sheet diameter is 4 μm-5 μm.

[0085] (2) The preparation method of the polymer-based composite thermally conductive material in this example is as follows:

[0086] 1) Preparation of flake boron nitride

[0087] Mix 3g of 325-mesh spherical boron nitride with 0.05g of sodium dodecylbenzenesulfonate and 200 ml of water, place in a ball mill jar, the grinding speed is 300rpm, and t...

Embodiment 2

[0091] This embodiment provides a polymer-based composite heat-conducting material and a preparation method thereof.

[0092] (1) The polymer-based composite heat-conducting material in this embodiment is composed of natural rubber and fillers. The total mass of fillers accounts for 36% of the mass percentage of natural rubber. The fillers are composed of flake boron nitride and spherical boron nitride according to Compounded with a mass ratio of 1:3;

[0093] Among them, the particle size of the spherical boron nitride is 50 μm-60 μm; the thickness of the flake boron nitride is 4 nm-10 nm, and the sheet diameter is 4 μm-5 μm.

[0094] (2) The preparation method of the polymer-based composite thermally conductive material in this example is as follows:

[0095] 1) Preparation of flake boron nitride

[0096]Mix 3g of 325-mesh spherical boron nitride with 0.05g of sodium dodecylbenzenesulfonate and 200 ml of water, place in a ball mill jar, the grinding speed is 300rpm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com