High-thermal-conductivity polypropylene/graphene composite material and preparation method thereof

A composite material and polypropylene technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor compatibility between fillers and matrix, imperfect thermal conduction paths, etc., and achieve ultra-high surface heat Conductivity, ease of mass production, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

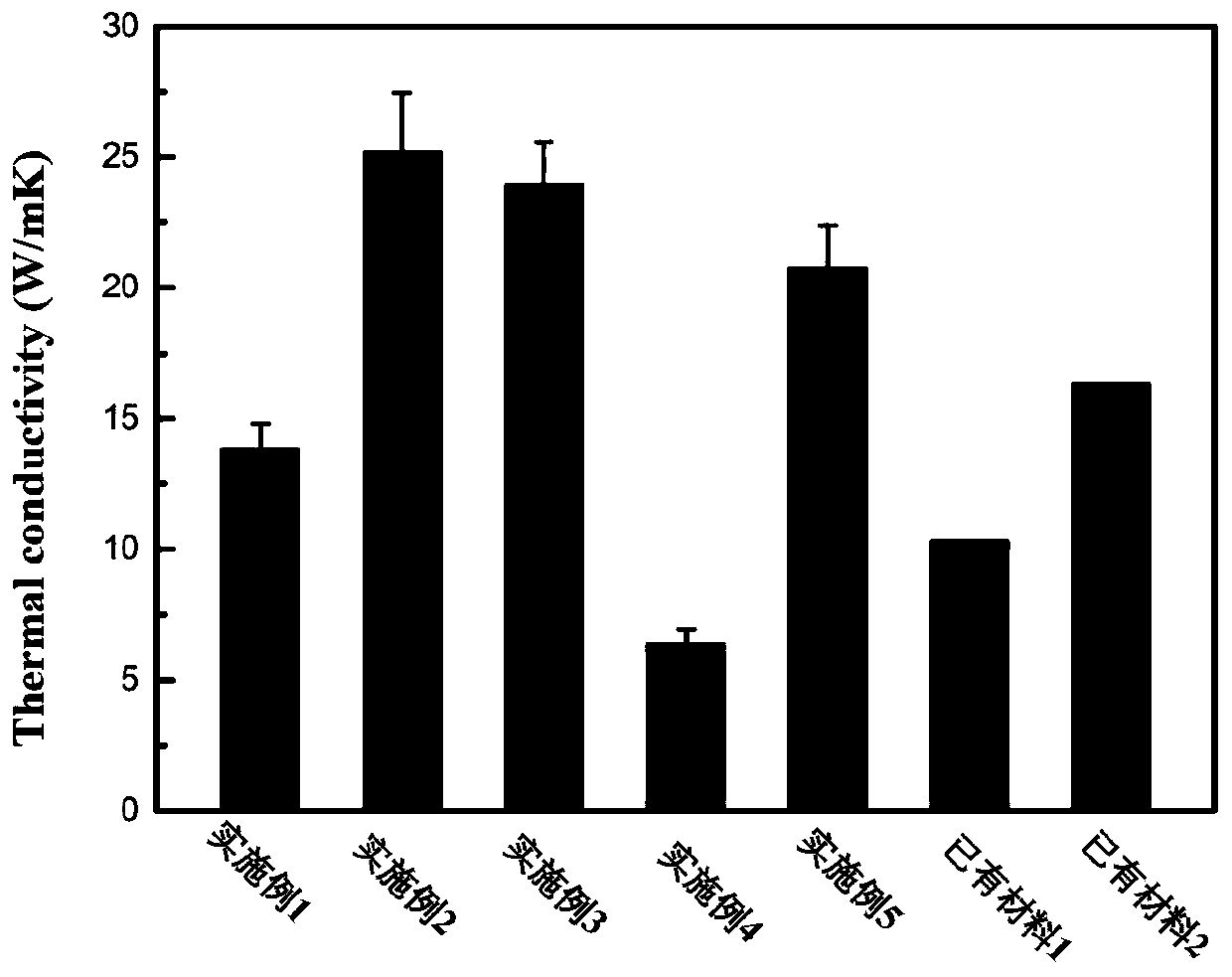

[0038] This embodiment is a high thermal conductivity polypropylene / graphene composite material, which is made of the following components in mass parts ratio: graphene oxide: polypropylene = 4:6.

[0039] A high thermal conductivity / polypropylene composite material and a preparation method thereof provided by an embodiment of the present invention comprise the following steps:

[0040] (1) Configure 10mmol / ml Tris buffer solution, adjust the pH to 8.5 with hydrochloric acid, add dopamine hydrochloride and graphene oxide, wherein the concentration of dopamine hydrochloride is 2mg / ml, stir at 60°C for 24h to obtain polydopamine Modified graphene oxide;

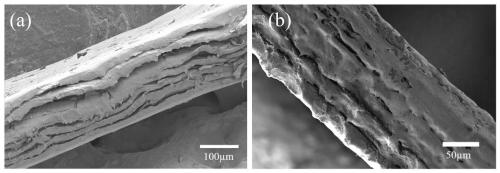

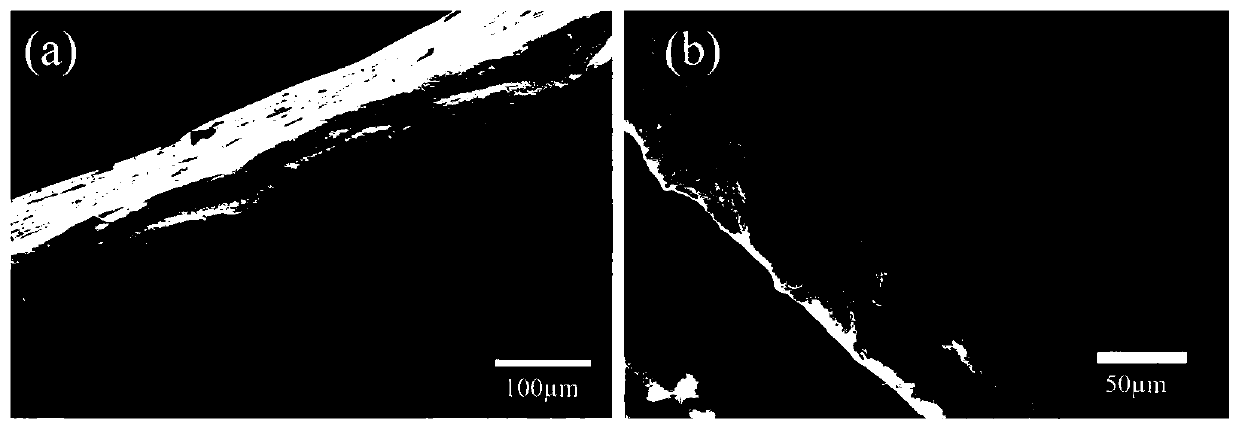

[0041] (2) Disperse the polypropylene powder in xylene, heat it under reflux to 130°C, until the polypropylene is completely dissolved, add the polydopamine-functionalized graphene oxide into the solution, wherein the polydopamine-functionalized graphite oxide and polypropylene The mass ratio of the mixture was 4:6, and the re...

Embodiment 2

[0044] The high thermal conductivity polypropylene / graphene composite material and preparation method thereof provided in this embodiment are basically the same as in Example 1, except that:

[0045] (1) Configure 10mmol / ml Tris buffer solution, adjust the pH to 8.5 with hydrochloric acid, add dopamine hydrochloride and graphene oxide, wherein the concentration of dopamine hydrochloride is 2mg / ml, stir at 60°C for 24h to obtain polydopamine modified graphene oxide.

[0046](2) Disperse the polypropylene powder in xylene, heat it under reflux to 130°C, until the polypropylene is completely dissolved, add the polydopamine-functionalized graphene oxide into the solution, wherein the polydopamine-functionalized graphite oxide and polypropylene The mass ratio of the mixture was 1:7, and the reflux stirring was continued at 130° C. for 4 hours to obtain a mixed dispersion. The resulting mixed dispersion was poured into a petri dish, and the solvent was dried in an oven at 150° C. t...

Embodiment 3

[0049] The high thermal conductivity polypropylene / graphene composite material provided by this embodiment and its preparation method are basically the same as those in Embodiment 1 and 2, except that:

[0050] (1) Configure 10mmol / ml Tris buffer solution, adjust the pH to 8.5 with hydrochloric acid, add dopamine hydrochloride and graphene oxide, wherein the concentration of dopamine hydrochloride is 2mg / ml, stir at 60°C for 24h to obtain polydopamine modified graphene oxide.

[0051] (2) Disperse the polypropylene powder in xylene, heat it under reflux to 130°C, until the polypropylene is completely dissolved, add the polydopamine-functionalized graphene oxide into the solution, wherein the polydopamine-functionalized graphite oxide and polypropylene The mass ratio of the mixture was 3:8, and the reflux stirring was continued at 130° C. for 4 hours to obtain a mixed dispersion. The resulting mixed dispersion was poured into a petri dish, and the solvent was dried in an oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com