Graphene/polyimide heat-conduction film and preparation method thereof

A technology of polyimide and graphene, applied in the field of graphene, can solve problems such as low thermal conductivity, difficult dispersion, and uncontrollable dispersion uniformity of polyamic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Such as figure 1 As shown, the embodiment of the present application provides a method for preparing a graphene / polyimide thermally conductive film, which includes the following steps:

[0037]Step 1, a) prepare the polyamic acid nanoemulsion taking water as medium:

[0038] The polyamic acid nanoemulsion can be directly used as a finished product, or can be self-made.

[0039] Emulsion refers to the dispersion system in which the dispersed phase is dispersed in the continuous phase composed of another phase (non-solvent) in the form of tiny droplets. According to the size of the dispersed phase, it can be divided into microemulsion and nanoemulsion.

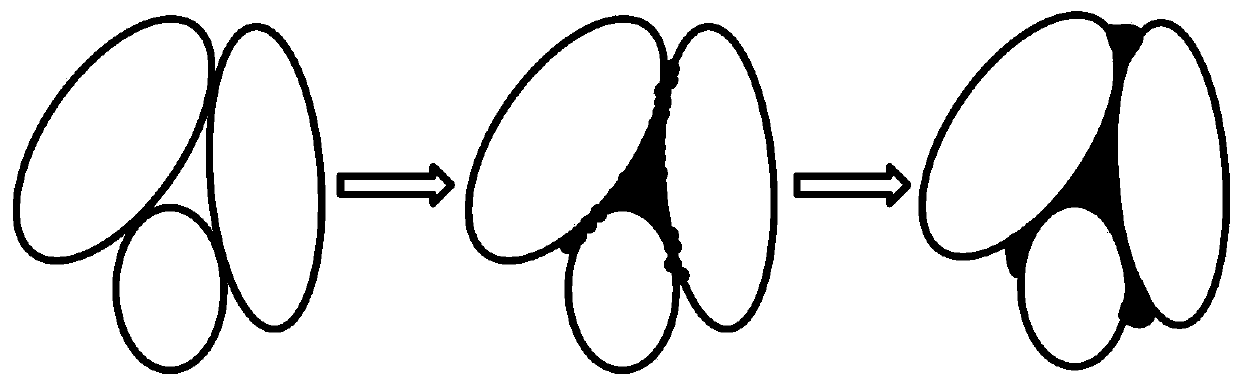

[0040] The preparation methods of nanoemulsions include: high-energy emulsification method and low-energy emulsification method. The high-energy emulsification method refers to the use of high-speed stirrers, high-pressure homogenizers, ultrasonic generators and other mechanical equipment to provide energy to nanonize t...

Embodiment 1

[0059] This embodiment provides a graphene / polyimide thermally conductive film, which is prepared according to the following preparation method:

[0060] Step 1, a) prepare the polyamic acid nanoemulsion taking water as medium:

[0061] Dissolve pyromellitic dianhydride in N,N-dimethylformamide to form pyromellitic dianhydride solution; dissolve diaminodiphenyl ether in N,N-dimethylformamide to form diaminodiphenyl ether Phenyl ether solution: adding the pyromellitic dianhydride solution into the diaminodiphenyl ether solution, stirring and mixing for 3 hours to obtain a polyamic acid solution with a concentration of 3 g / ml.

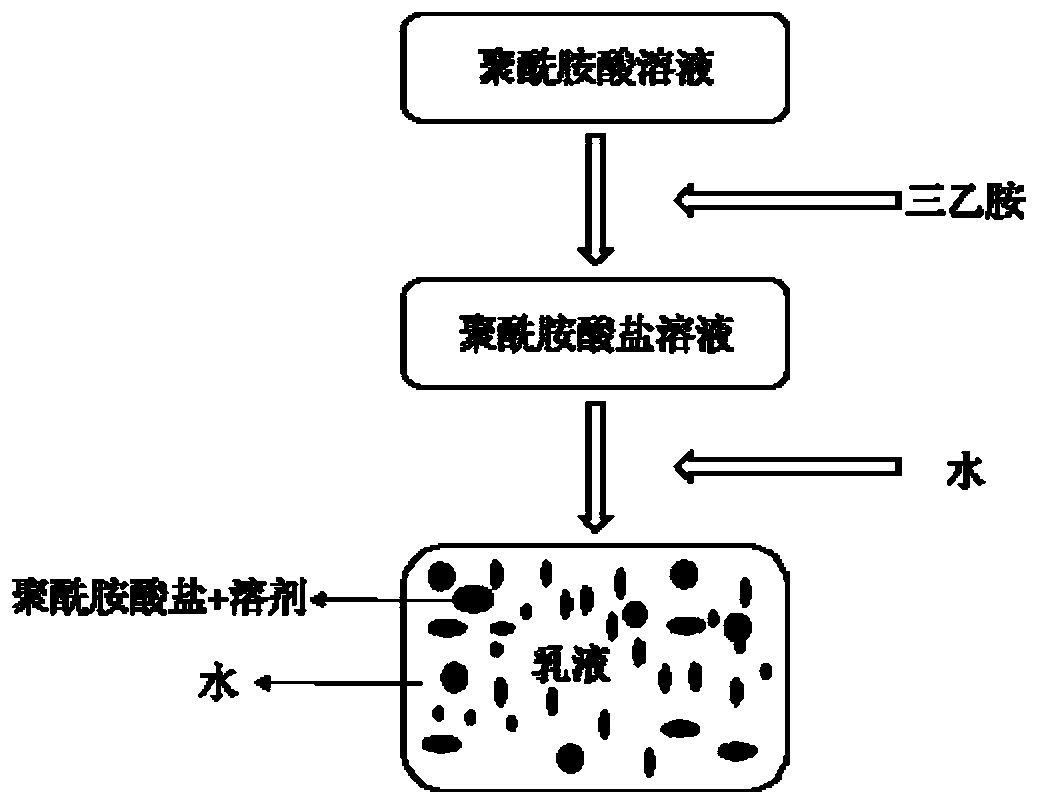

[0062] Mix and stir the polyamic acid solution and triethylamine, the amount of triethylamine added is 0.3wt%, to obtain a polyamic acid salt solution, continue to stir and add water, the amount of water added is polyamic acid solution: water = 1:10, The stirring speed is 300r / min, and the total stirring time is 2h to form a polyamic acid nanoemulsion w...

Embodiment 2

[0074] This embodiment provides a graphene / polyimide thermally conductive film, the preparation method of which is roughly the same as that of Embodiment 1, except that:

[0075] Step 2, adding the polyamic acid nanoemulsion to the graphene dispersion and stirring, the addition amount of the polyamic acid nanoemulsion is polyamic acid: graphene=10:100, and the stirring time is 4h, uniformly mixed to obtain graphene / poly Amic acid composite slurry.

[0076] After testing, the density of the obtained graphene / polyimide thermal conductive film is 1.92g / cm 3 ; Thickness is 48μm; In-plane thermal diffusivity is 603mm 2 / s, thermal conductivity 984W m -1 ·K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com