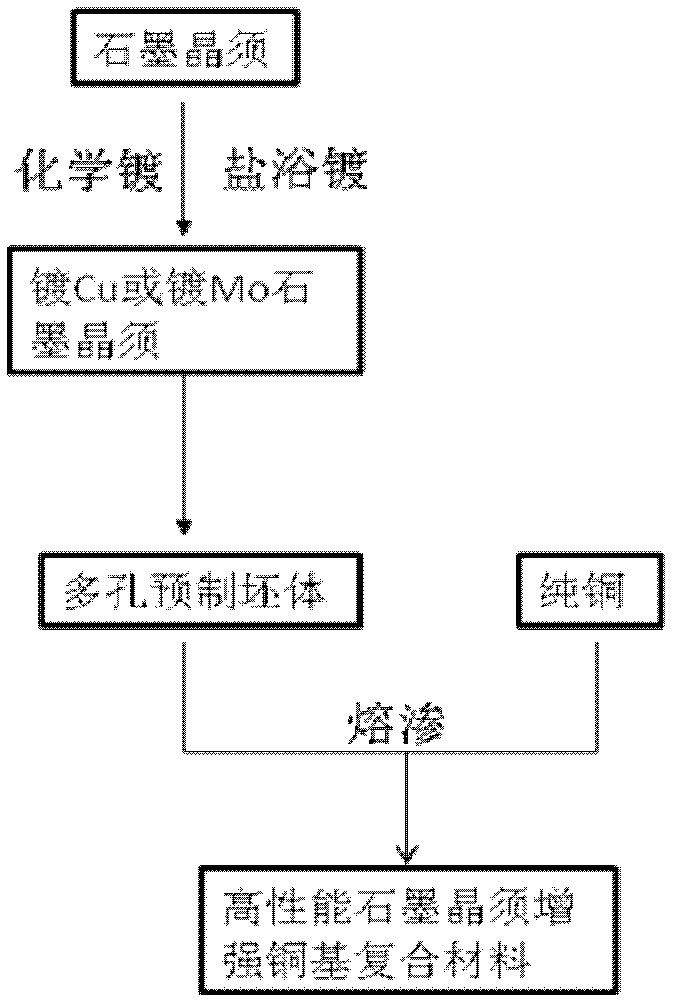

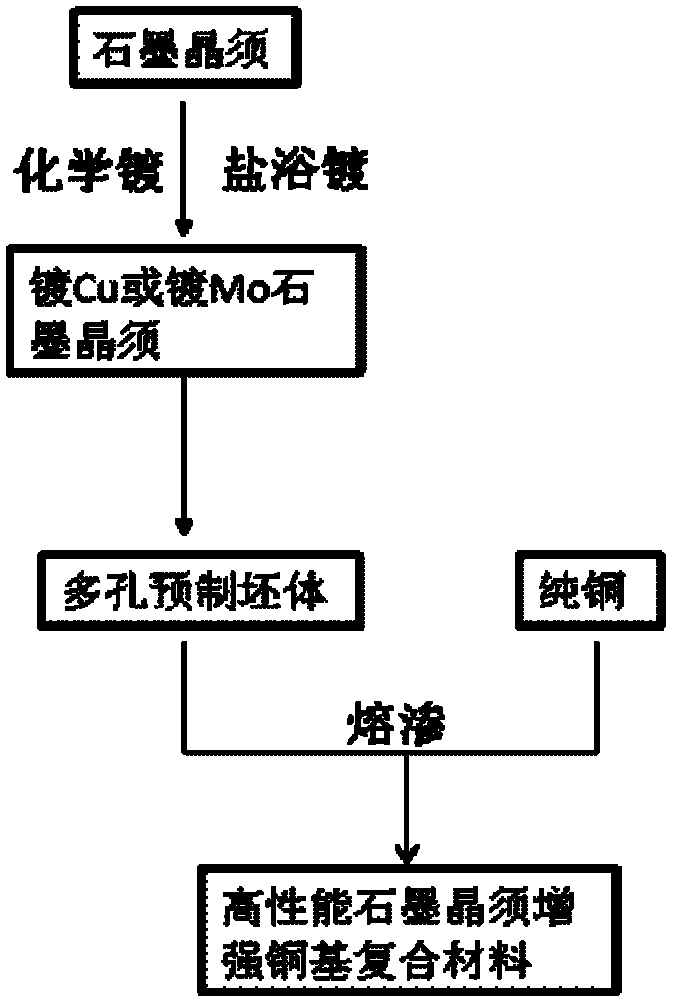

Preparation method of graphite whisker reinforced copper base composite material

A technology of copper-based composite materials and graphite whiskers, which is applied in the field of metal-based composite materials, can solve the problems of difficult infiltration of copper solution, achieve low production costs, improve interface conditions, and increase wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Electroless copper plating is used to plate a 1 μm copper layer on the surface of graphite whiskers: First, put graphite whiskers in 20% NaOH solution and boil for 15 minutes, then rinse with distilled water until neutral. Add 20% HNO 3 The solution was boiled for 15 minutes, rinsed with distilled water until neutral. Put the washed graphite whiskers into 20ml / LHCl+20g / LSnCl 2 Stir vigorously in the solution for 15 minutes until the solution is blue-gray, indicating that the reaction is complete. After washing with water, add 20ml / L HCl+0.5g / LPdCl to the graphite whisker 2 The solution was vigorously stirred for 15 minutes, and the reaction was complete when the solution turned light brown. Pour the sensitized and activated graphite whiskers into the copper plating solution. The formula of the solution is copper sulfate pentahydrate 15g / L, potassium sodium tartrate 14g / L, EDTA 19.5g / L, bipyridine 0.02g / L, Potassium ferrocyanide 0.01g / L. And add 10ml / L of formaldehyd...

Embodiment 2

[0023] A molybdenum layer with a thickness of 1 μm was plated on the surface of graphite whiskers by salt bath plating. Graphite whiskers and NaCl / KCl mixed salt with a certain amount of ammonium paramolybdate added were put into the ball mill and mixed for 30 minutes. The molar ratio of NaCl and KCl in the mixed salt was 1:1, and the mass fraction of ammonium paramolybdate in the mixed salt was 10%. After mixing evenly, put it into a tube furnace with a protective atmosphere and heat it to 1000°C, keep it warm for 120 minutes and then cool it with the furnace. The coated whiskers are washed with water and then sieved to remove excess impurities to obtain molybdenum-coated graphite whiskers. Using this process, a molybdenum layer with a thickness of 1 μm is evenly plated on the surface of the graphite whisker.

[0024] Preparation of porous preform: get a certain amount of molybdenum-coated graphite whiskers and binder paraffin into a beaker filled with n-heptane solution, t...

Embodiment 3

[0027] A molybdenum layer with a thickness of 0.5 μm was coated on the surface of graphite whiskers by salt bath plating. Graphite whiskers and NaCl / KCl mixed salt with a certain amount of ammonium paramolybdate added were put into the ball mill and mixed for 30 minutes. The molar ratio of NaCl and KCl in the mixed salt was 1:1, and the mass fraction of ammonium paramolybdate in the mixed salt was 10%. After mixing evenly, put it into a tube furnace with a protective atmosphere and heat it to 1000°C, keep it warm for 60 minutes and then cool it with the furnace. The coated whiskers are washed with water and then sieved to remove excess impurities to obtain molybdenum-coated graphite whiskers. Using this process, a molybdenum layer with a thickness of 0.5 μm is uniformly plated on the surface of the graphite whisker.

[0028] Preparation of porous preform: get a certain amount of molybdenum-coated graphite whiskers and paraffin wax binder and pour it into a beaker filled with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com