Heat-conducting electromagnetic shielding material with orientation structure and preparation method thereof

A technology of electromagnetic shielding materials and thermally conductive fillers, which is applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, modification through conduction and heat transfer, etc., can solve problems affecting the service life of electronic equipment and human health, and improve electromagnetic shielding performance , conductivity and electromagnetic shielding performance are stable and reproducible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of filler / thermoplastic polymer material high thermal conductivity electromagnetic shielding composite material comprises the following steps:

[0040] (1) The preparation of a thermoplastic polymer material solution, comprising: dissolving polyurethane in an organic solvent, stirring evenly with a magnetic rotor, to obtain a polymer matrix solution;

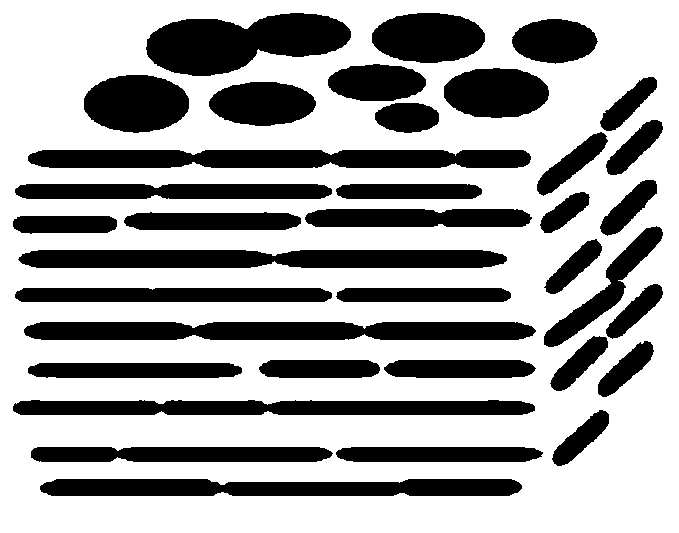

[0041](2) The preparation of the filler / thermoplastic polymer material composite material includes: mixing the polymer material matrix solution prepared in step (1) with the filler, stirring evenly, wrapping the PI film on a roller press and rolling it to form Film, the film is cut into small squares, put into a mold, stacked and hot-pressed to obtain a thermoplastic polymer material / filler composite material with a layered structure. Further, the composite material is cut to obtain a composite material with a vertically oriented structure.

[0042] In the technical solution of the present inventio...

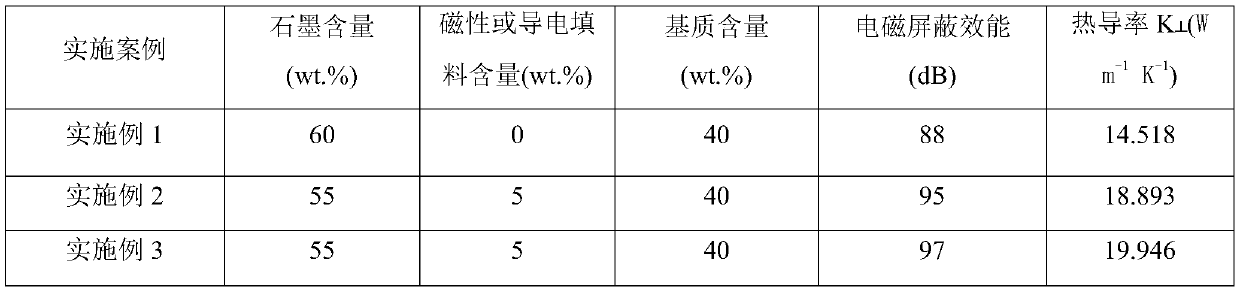

Embodiment 1

[0047] (1) The preparation of polyurethane / N,N-dimethylformamide solution, including: blending polyurethane and N,N-dimethylmethyl ester solution at a mass ratio of 3:7, stirring evenly with magnetic force, and obtaining 30wt% polyurethane / N,N-dimethylmethyl ester mixed solution.

[0048] (2) the preparation of graphite / polyurethane composite material, comprising: the 30wt.% polyurethane / N,N-dimethyl methyl ester mixed solution that makes in the step (1), add graphite mechanical stirring, with polyurethane dry weight, Dry mass of polyurethane: graphite=4:6, after mixing evenly, 60wt.% graphite / polyurethane slurry is obtained, wrapped with PI film on a roller press and rolled to form a wet film of 0.5mm, and put into a blast drying oven Dry in medium to get 60wt.% graphite / polyurethane film, cut the film into 4×4cm 2 The small square pieces are stacked in the mold and hot-pressed to form 4×4×3cm 3 of blocks.

[0049] The above block was cut along the vertical direction and t...

Embodiment 2

[0051] (1) The preparation of polyurethane / N,N-dimethylformamide solution, including: blending polyurethane and N,N-dimethylmethyl ester solution at a mass ratio of 3:7, stirring evenly with magnetic force, and obtaining 30wt.% polyurethane / N,N-dimethylmethyl ester mixed solution.

[0052] (2) The preparation of graphite / ferric oxide nanoparticles / polyurethane composite material comprises: the 30wt.% polyurethane / N,N-dimethyl methyl ester mixed solution that makes in the step (1), add graphite and four Ferric oxide nanoparticle mechanical stirring, in terms of polyurethane dry mass, is polyurethane dry mass: graphite: ferric oxide nanoparticle=4.5:5.5:0.5, after mixing uniformly, 55wt.% graphite / 5wt.% trioxide Iron nanoparticles / polyurethane slurry, wrapped with PA film and rolled on a roller press to form a 0.5mm film, put it into a blast drying oven and dry to obtain 55wt.% graphite / 5wt.% iron tetraoxide nano Particle / polyurethane membrane, cut the membrane into 4 x 4cm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com